3D printer time lapse camera

Best Time Lapse Cameras For 3D Printing – 3D Printerly

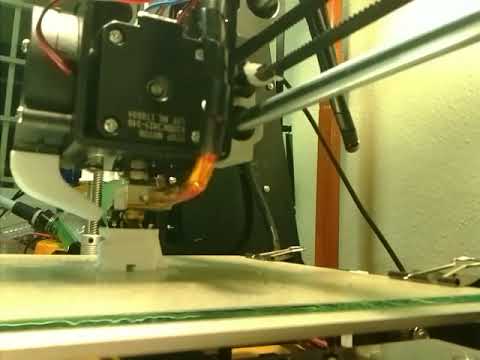

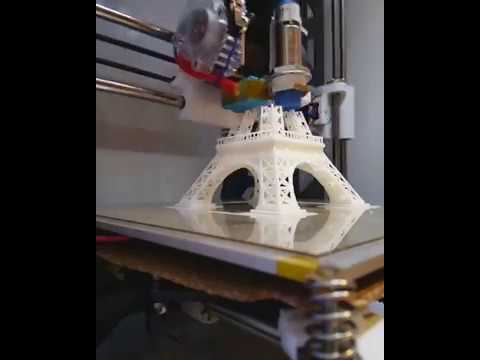

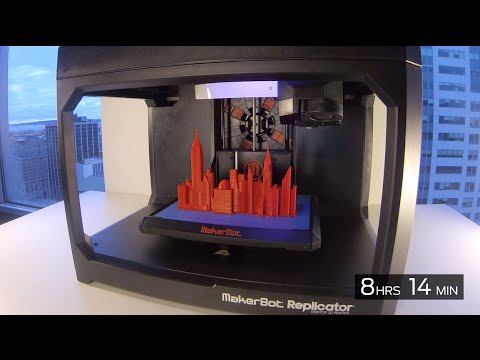

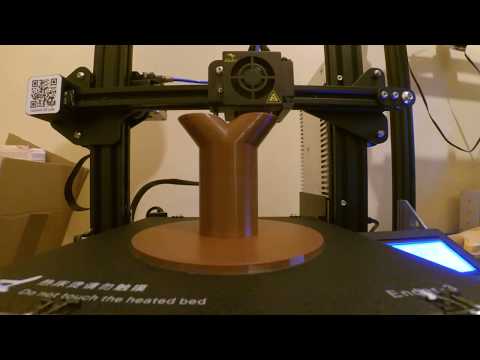

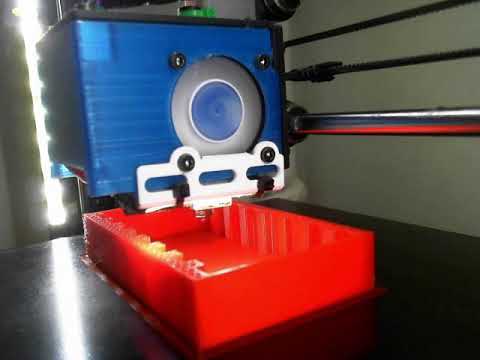

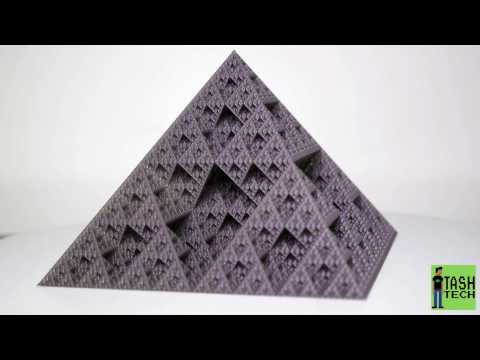

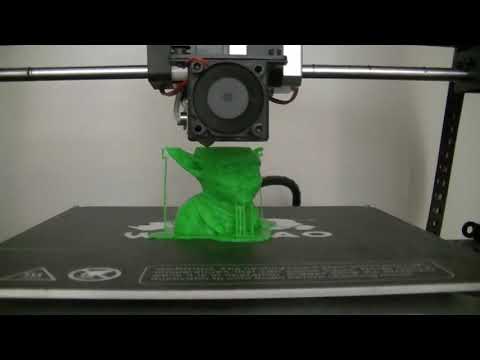

3D printing is a very interesting activity. Part of the appeal of 3D printing is slowly watching everything come together to form the final part. Luckily there are accessories that you can use to capture and record this process.

Time-lapse cameras are one of them.

Time-lapse photography is a technique where the camera takes many photos or still images over some time and splices them together to form a video. In 3D printing, you can use this to document the printing process and create fun short videos showing it.

The best part about time-lapse cameras is that they can be used for other things than time-lapse videos. You can use them to stream a live feed of your printer so you can monitor the print in real-time.

So, in this article, we’ll be talking about some of the best time-lapse cameras available on the market.

What to Look For When Buying A Time-Lapse Camera

Before we get to the reviews, let’s talk about some important things to look out for when getting a time-lapse camera. Don’t worry, these aren’t some complicated camera terms like ISO or shutter speed.

These are just some factors to use as a yardstick to judge each camera and decide which one is best for you. Let’s take a look at some of these factors.

StorageStorage simply refers to the amount of space on-board the camera that it can use for storing the videos. If the time-lapse camera you need is going to be connected to a PC or another device, you might not need onboard storage.

But to be on the safe side and have an additional backup in case the PC or the connection fails, it’s best to get a camera with onboard storage.

Connectivity

Connectivity refers to the way the camera connects and transmits the media it captures to the outside world. Standard cameras usually have options like USB, Wi-fi or Bluetooth for connecting to PCs.

If you want to monitor your prints remotely, it’s better to get a camera with wireless capabilities. Even better, you can buy some cheap hardware and set up a USB proxy like Octoprint.

USB proxies like this increase the functionality of both the camera and the printer.

Software

Software support is often overlooked when buying a camera for 3D printers. Some cameras on the market have software support in their firmware for creating time-lapse videos.

It’s best to go with these types of cameras to save time and money that would be otherwise spent on third-party software.

Camera Quality

The Quality of the camera determines how good the images or the time-lapse videos taken will turn out. The quality of the camera is often measured in MP for images and the number of pixels for video.

There is a whole lot of other things that go into image quality than these two, but they usually offer a good yardstick for making decisions.

Power

How the camera is powered is another factor to consider. Having a camera with a backup power supply can be useful in case of disruptions. These cost more, but if you feel it’s needed it’s a good investment.

Cost

Cost is usually the paramount factor in every buyer’s mind. When buying a camera like in everything, you have to make sure you get the best value for money.

This means weighing the features you need against the price you have to pay for them to achieve a middle ground.

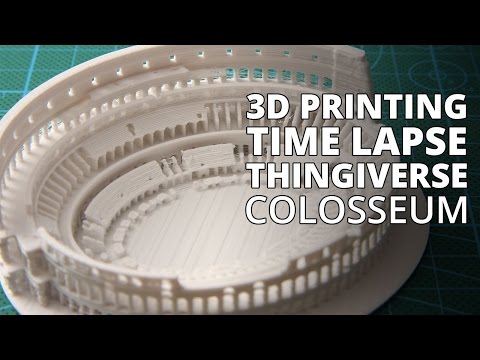

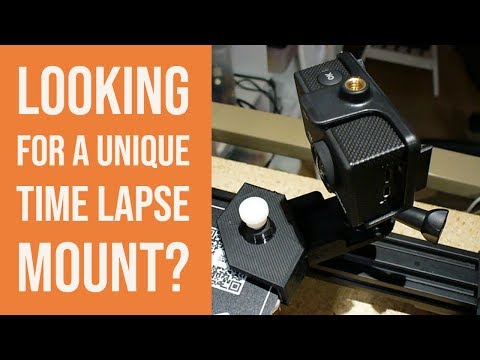

The video below shows how to create the best timelapses, then the rest of the article goes into the best timelapse cameras.

Raspberry Pi Camera Module V2-8 Megapixel 1080pPrice: $25 | Onboard Storage: N/A | Connectivity: Pi ribbon cable | Power: Battery N/A| Image Quality: 8MP | Video resolution: 1080p/30fps

The Raspberry Pi Camera (Amazon) is a wonderful low-cost method for creating time-lapse videos. It is capable of taking 1080p videos at 30 fps with its Sony sensor.

It is capable of taking 1080p videos at 30 fps with its Sony sensor.

It comes in a tidy little package weighing just over 3 grams and measuring 25mm x 23mm x 9mm.

The camera itself is an accessory that needs to be connected to a Raspberry Pi board to function. This Pi board can provide additional functionality like USB and Wi-fi connectivity for the camera.

User ExperienceCreating time-lapse videos with the Pi camera is easy. Usually, the Raspberry Pi board uses software called Octoprint to interface with the 3D printer and the computer. This software contains a plug-in called Octolapse.

This plugin creates time-lapse videos directly from the feed of the Pi camera.

One user commented how it works quite well as a 3D printer camera with an Octopi Server on a Raspberry Pi 3 B+.

Many people use it successfully for a timelapse of their 3D printers, but some have issues with picture quality when it comes to lighting.

There are some instances of bad video quality if there areissues like excessive pincushion distortion and bad lens focus. Pincushion distortion is a lens effect that causes images to get pinched in the middle.

Pincushion distortion is a lens effect that causes images to get pinched in the middle.

It isn’t going to give you the highest quality timelapses, but many users mention how it gets the job done for them, all at a very affordable price.

The autofocus doesn’t work very well in some cases, so you’d have to implement some good lighting and angles to get the best results.

The pincushion distortion can be corrected with the software but it may lead to loss of video quality. To put the lens in focus, you might also need to adjust it with a tweezer or a special tool. A better-focused lens often results in sharper images.

Pros- Great price

- Easy to setup

- Has excellent software support

- Can be used for remote monitoring

- Offers more functionality for the 3D printer

- Suffers from excessive pin cushion distortion

- Requires extra hardware in the form of a pi board

- Picture quality gotten can be blurry if the lens isn’t focused properly

Although the Pi camera is cheap and easy to use, it requires extra hardware which might be a bit technical to set up. Also, it doesn’t come with built-in memory for storing the videos captured, it is reliant on the on-board memory in the Pi and the computer.

Also, it doesn’t come with built-in memory for storing the videos captured, it is reliant on the on-board memory in the Pi and the computer.

Apart from the lens issues, it works as advertised, a low budget option for creating time-lapse videos with no frills. Looking over the issues, you’d be pressed to find this sort of camera quality for this price.

Get yourself the Raspberry Pi Camera – Module V2-8 Megapixel from Amazon today.

Logitech C920S HDPrice: From $90 | Onboard Storage: N/A | Connectivity:USB A cable | Power: Battery N/A| Image Quality: 15MP | Video resolution: 1080p/30fps

The Logitech C920S HD is a high-quality webcam geared towards business professionals looking for teleconferencing options. However, you can still use it to create time-lapse videos.

It’s high definition 1080p/30fps video recording and its wide-angle of view makes it perfect for recording and creating time-lapse videos for your print.

The camera measures 25.4mm x 30.48mm x 93mm and weighs around 165 grams. It comes with a plastic stand and a tripod mounting screw for use with different stands.

Unlike the Pi camera, it comes with autofocus and light correction for shooting videos in all conditions.

User ExperienceSetting up the Logitech C920S is very easy, it comes with a USB 2.0 cable that uses plug and play setup. The camera comes with the Logitech capture software. This software is very useful for modifying and correcting the camera settings to get the best videos.

However, users have reported software bugs that make it revert to default settings every restart.

For mounting it, you can either use the plastic clip to attach it to a flat vertical surface or use the included tripod screw with a tripod. The Logitech software doesn’t have a native time-lapse mode, so you’ll have to use a video editing software like Adobe pro.

The video quality gotten from this camera is top-notch according to users. As long as the surrounding area is well lit, this camera will produce great time-lapse videos that can easily be published.

As long as the surrounding area is well lit, this camera will produce great time-lapse videos that can easily be published.

- High video quality

- Wide-angle of view

- Easy plug and play setup

- Included mounting clip for easy mounting

- Limited connectivity (wired)

- A bit expensive

- Buggy software

The Logitech is a great camera, but it has to be said, it’s a bit of a one-trick pony. It does what it’s meant to do (record HD videos) well. Apart from that, it does not have any extra features like onboard storage, wireless connectivity, or remote monitoring.

Also, due to the pandemic, demand for this camera has skyrocketed so the price might be a bit higher than expected.

Get the Logitech HD Pro C920 1080p Webcam from Amazon today.

Microsoft Lifecam HD-3000Price: From $40 | On-board Storage: N/A | Connectivity:USB A cable | Power: Battery N/A| Image Quality: 4MP | Video resolution: 720p/30fps

The Lifecam HD Camera (Amazon) is a budget webcam from Microsoft. At its fairly competitive price, it’s suited for those looking for a time-lapse camera on a budget. It produces HD 720p video with its 4MP sensor.

At its fairly competitive price, it’s suited for those looking for a time-lapse camera on a budget. It produces HD 720p video with its 4MP sensor.

These videos are good, but they don’t match up as high as videos from a camera like the Logitech C920S.

The Lifecam HD weighs in at 90 grams, measuring 39mm x 44mm x 108mm. It has a plastic build and comes with a universal attachment base for mounting. It also comes with autofocus, color corrections, and a noise-canceling mic.

User ExperienceThe Lifecam HD has a USB 2.0 cord for a simple and fast plug and plays setup. It comes with the Microsoft LifeCam software for controlling it and modifying the settings.

This software has been known to have issues with some versions of windows but the issue seems to have been fixed in an update.

The camera comes with a universal attachment base for mounting. This base has no tripod attachment screw for alternative mounting. To capture time-lapse videos on this, you’ll have to use third-party software.

According to users, you can get pretty decent time-lapse videos from the camera. As long as the lighting conditions are all right, expect good performance for the money from this camera.

Pros- It is cheap

- Decent quality HD video

- Good software support from Microsoft

- Limited FOV

- No tripod mounting screw

- Lack of connectivity options

The Lifecam does what is expected of it as a budget camera. Expect clear videos, but at pedestrian quality. Bottom line, if you are on a budget and do not require anything special, this camera is for you.

Get the Microsoft Lifecam HD-3000 Camera from Amazon.

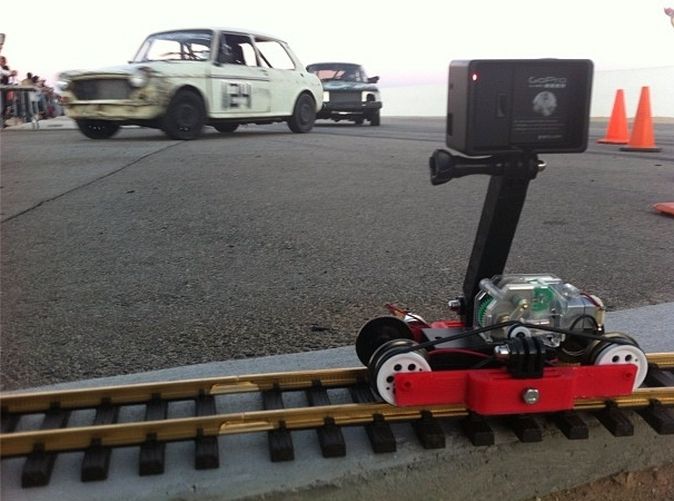

GoPro Hero7Price: From $250 | Onboard Storage:Expandable SD card slot | Connectivity:Wi-fi, Bluetooth, USB C | Power: 1220 mAH lithium battery| Image Quality: 12MP | Video resolution: 4K/60fps

The GoPro Hero 7 is a premium camera for those looking for the best video quality regardless of the price. At a $250 price tag, this camera does not disappoint. It shoots stunning 4K videos at 60fps with a wide-angle view.

At a $250 price tag, this camera does not disappoint. It shoots stunning 4K videos at 60fps with a wide-angle view.

It also employs its patented HyperSmooth video stabilization to produce smooth videos.

The GoPro Hero 7 comes in a compact package measuring 45mm x 62mm x 42mm, and weighing 118 grams. It has a very rugged waterproof and shockproof build and also comes with an LCD touch screen for easy operation.

User ExperienceSetting up the GoPro Hero 7 can be done with the aid of the LCD touch screen. With this touchscreen, you can link your camera to the GoPro app on your mobile device. With the app, you have control over a wide range of settings and functions.

The GoPro Hero 7 doesn’t come with any mounting options out of the box, but for $30 you can get this kit for your mounting needs.

On the firmware side, the GoPro hero 7 comes equipped with its native time-lapse mode called the TimeWarp. With this feature, you can produce and publish stunning time-lapse videos from a wide variety of conditions.

But, some users have complained about the battery life when recording at high resolutions.

The GoPro 7 also comes with several connectivity options like Wi-fi, USB C, and Bluetooth. With these features, you can create and live stream videos on the go. You can even control and monitor the camera remotely with the GoPro app.

Pros- High quality 4K video recording

- Multiple connectivity options for live streaming

- Expandable storage options

- Great image stabilization

- High price tag

- Poor battery life

The GoPro 7 is an expensive camera when compared to most on this list. But when you take into account its features, its quality shines through. If you are creative looking to record and publish high-quality videos then this is for you.

Get tthe GoPro Hero7 Camera from Amazon for some high quality timelapses.

Logitech BRIO Ultra HD WebcamPrice: From $200 | Onboard Storage: N/A | Connectivity:Wi-fi, Bluetooth, USB C | Power: Battery N/A| Image Quality: 12MP | Video resolution: 4K/60fps

The Logitech BRIO is one of the most advanced webcams on the market. This camera lives up to its $200 price tag by delivering crisp shots. It is capable of recording 4K UHD quality videos at 60fps.

This camera lives up to its $200 price tag by delivering crisp shots. It is capable of recording 4K UHD quality videos at 60fps.

The Logitech BRIO measures 27mm x 102mm x 26.5mm and weighs 85g. It comes with glass and plastic build housing a glass lens with a 90-degree FOV. It also comes with a plastic privacy shade and a plastic base for mounting.

User ExperienceThe Logitech BRIO comes with a wired detachable USB C to USB A connection for plug and plays setup. Like all Logitech cameras, you need the Logitech capture software to control and modify the camera’s settings.

The plastic mount available with the camera has a tripod compatible screw. You can either attach it to a vertical frame, use the stand or use the tripod.

The camera also comes with excellent software features like autofocus, color correction, and anti-glare for taking great shots.

The Logitech software does not have native time-lapse options, so you have to use third-party video software to create time-lapse videos. That being said, this camera creates high-quality HDR 4k videos.

That being said, this camera creates high-quality HDR 4k videos.

The Logitech BRIO is limited in the connectivity options it offers. It only has a USB C to USB 3.0 connection making it less ideal for live streaming and remote monitoring. It also does not come with any storage options onboard.

Pros- Excellent 4K video quality

- Wide-angle of view

- Easy to setup

- It works with Windows Hello

- Limited connectivity options

- No native time-lapse software

- It is fairly expensive

The Logitech BRIO produces excellent images and video, but it does not justify the premium price tag. If you’re looking for great video quality, you’ll be better off with a slightly more expensive camera like the GoPro Hero7. The GoPro 7 has additional features for the high price tag.

Go for the Logitech BRIO Camera from Amazon today.

Hopefully this article has narrowed down some great options for you to use to create awesome 3D printing timelapses!

Learn How to Make a 3D Print TimeLapse – Phone or Camera – 3D Printerly

Many people wonder how to create those awesome timelapse videos that they may have seen online, and it isn’t as hard as you think. If you want to learn how to make some cool 3D print timelapse, you are in the right place.

If you want to learn how to make some cool 3D print timelapse, you are in the right place.

Keep on reading through this article to learn how the experts make time lapses that you can be proud of.

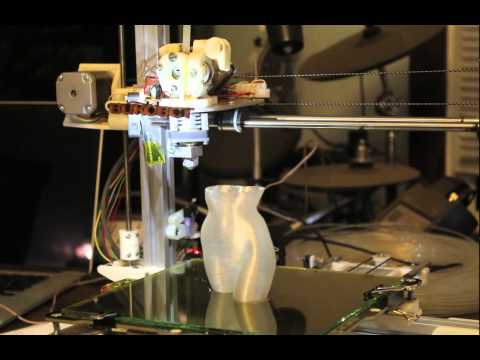

How to Make Smooth 3D Printing Time lapse with a Phone or Camera

To make a timelapse you’ll need a digital camera or phone, a printer, a remote shutter, a mount to hold the remote shutter, a trigger, and video editing software.

First, you will need to set up your printer, preferably in a dark area in your workstation. This is because it is more controlled and will prevent flickering.

Next, you need to print the mount that will hold your shutter in place if you’re using a digital camera or earphones if you’re using a smartphone for taking photos. You also need to print the trigger that will be placed on the print head.

Mount all the printed parts onto your printer. Position the remote shutter for the camera on the 3D printed mount. For the smartphone, position the earphones on its 3D printed headphone mount.

Mount the trigger in the right place on the print head so it can move and press the shutter or the button on the earphones each time it goes to the stop position.

Place the camera or smartphone, whichever is taking the timelapse, in a suitable position. There should be no obstructions so it can take the photos seamlessly.

On the printers LCD, determine where the exact position the print head should be in (the stop position) before any photo is taken. Calibrate the printer to a position where the trigger mounted on the extruder clicks the remote shutter or button on the headphones.

Inject the correct gcode into your slicing software to enable the print head to stop after every layer is completed in order for a photo to be taken. The gcode also specifies your 3D print timelapse interval.

The end result will be a compilation of photos that you can stitch together using a video editing software to turn your still photos to a timelapse video.

For a more detailed explanation you can check out this video.

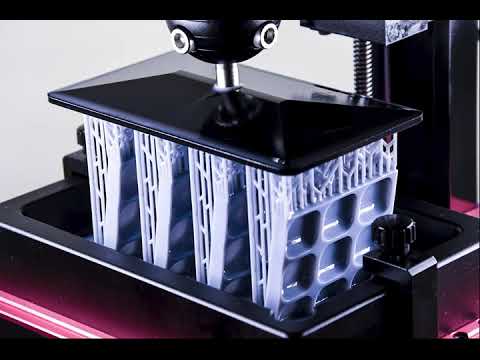

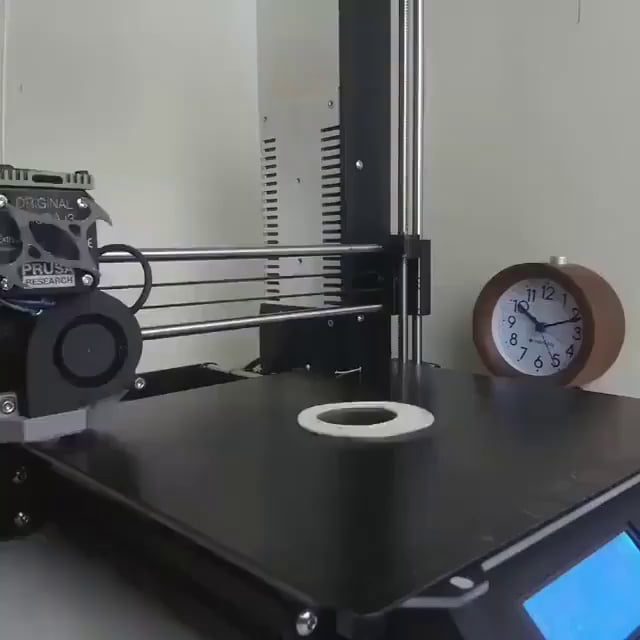

In this method, you get your 3D printer timelapse using a Raspberry Pi and the OctoPrint software.

OctoPrint is a remote control and monitoring software that you can install on Raspberry Pi. On the other hand, OctoLapse is a plugin that creates stabilized time lapses of your 3D printer in action.

First, download the latest OctoPi program and install it to your Raspberry Pi. Connect the Raspberry Pi to the 3D printer via USB and power it.

Install the OctoLapse plugin by clicking on the Octoprint settings icon, navigating to the plugin manager and installing it. You will need to restart the OctoPrint software before you can start using the Octolapse plugin.

Get a webcam e.g. a Raspberry Pi camera and hook the other side of its cable to the Raspberry Pi to get a working webcam stream.

3D print a camera stand, glue it to a sturdier pedestal and position the camera properly to get a good stream image. Also, adjust the focus of the camera.

You can adjust the OctoLapse 3D printing settings, to set your desired 3D print timelapse interval.

Upload the gcode locally to the OctoPrint software and hit print. You will notice that the OctoLapse 3D printing software will work fine. It will move the print head and bed to a fixed position after every layer for the camera to take a picture.

After the print is complete, the OctoLapse 3D printing software spats out a complete video file that you can download.

For a more detailed explanation of using OctoPrint to create 3D printing time lapses, have a look at this video.

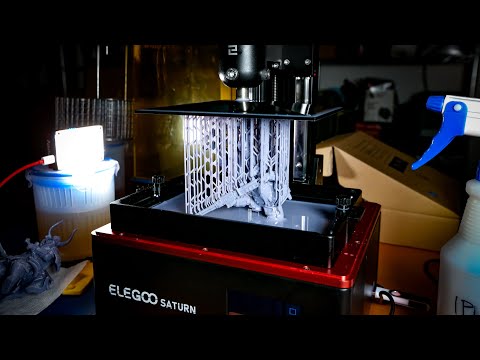

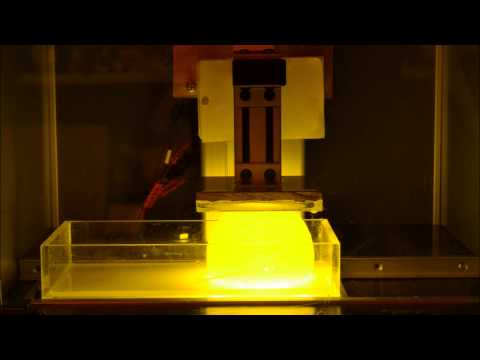

How to Use Resinlapse to Make Resin Time Lapses

Filament 3D printers get most of the attention with time lapses because they have had more time to be fine-tuned, though resin time lapses are starting to make their way into the field.

One of the simplest ways that you can capture a high quality resin 3D print timelapse is to use a product called Resin Lapse, made by Uncle Jessy, a well-known YouTuber.

You can find the Resin Lapse product on Uncle Jessy’s Resin Lapse Big Cartel page for just $20 at time of writing.

Along with the Resin Lapse, you’ll need your resin 3D printer of course, along with a camera that supports a TRS shutter release and a decent video editing software.

You’ll usually find that most Canon cameras have this needed shutter release.

To start off, you need to take the photosensitive end of the resin lapse and insert it into an opening on your resin 3D printer. This is to enable it to trigger the camera to take a photo each time a layer of your print is processed.

This is to enable it to trigger the camera to take a photo each time a layer of your print is processed.

Next, you insert the other end of the resin lapse cable into your camera. Place the camera in a stable position where it can capture the perfect view during the printing process.

After getting everything into place, start your resin 3D printer. Each time your printer finishes a single layer, the camera takes a picture. This process is perfectly synchronized.

You can then use a video editing software to stitch the images together to form a Resin lapse.

Example of video editing software that people use? Should be in the video guide I’m guessing.

To get a more detailed explanation of this process check out this video.

Best Camera for Time LapsesCanon EOS 77D

This camera is a beast when it comes to creating smooth time lapses.

The Canon EOS 77D has an optical viewfinder which enables you to view what you want to photograph exactly as the camera sees it in different lighting conditions. You can view your 3D prints with minimal lag and glare because this camera gets it in focus quickly.

When it comes to capturing images, the canon EOS 77D offers high speed continuous shooting. It can capture as much as 6 frames per second. It will not miss any moment in your 3D printing process.

It has HDR movie and timelapse movie modes. The latter takes photos for a long period of time and stitches it together to form a single high-speed video.

The former captures under-exposed and exposed images and blends them into a more detailed video. This feature will ensure that the timellapse on your 3D printer, whether it’s a Prusa or Ender 3D printer be excellent.

If you don’t have a workstation with optimal lighting conditions, then the anti-flicker shooting function will come in handy. It will enable you to take continuous shots without disparities in color or exposure since the camera compensates for flickering light.

For powering the camera, you have a DIGIC 7 image processor which will provide high quality and detailed results even in bad lighting conditions.

One satisfied customer from Amazon was impressed with how fast the camera captured images. She said that she was able to take 10-12 shots of her kids in a few seconds by just pressing the shutter quickly.

Another user ranked the Canon 77D over the Nikon especially when it comes to the autofocusing system. This enable to capture detailed images of his car without any flickering.

An Amazon user gave it a five-star feedback and said that it had a better sensor, resolution and CPU as compared to other cameras in the market. One person even won awards through using this camera, so that definitely counts for something!

You can get the Canon EOS 77D from Amazon today.

All about 3D printing. additive manufacturing. Basic concepts.

- 1 Technology

- 2 Terminology

- 3 Fundamentals

- 4 Printing Technologies

- 5 3D printers

- 6 Application

- 7 Domestic and hobby use

- 8 Clothing

- 9 3D bioprinting

- 10 3D printing of implants and medical devices

- 11 3D printing services

- 12 Research into new applications

- 13 Intellectual Property

- 14 Influence of 3D printing

- 15 Space research

- 16 Social change

- 17 Firearms

Technology

Charles Hull - the father of modern 3D printing

3D printing is based on the concept of building an object in successive layers that display the contours of the model. In fact, 3D printing is the complete opposite of traditional mechanical production and processing methods such as milling or cutting, where the appearance of the product is formed by removing excess material (so-called "subtractive manufacturing").

In fact, 3D printing is the complete opposite of traditional mechanical production and processing methods such as milling or cutting, where the appearance of the product is formed by removing excess material (so-called "subtractive manufacturing").

3D printers are computer-controlled machines that build parts in an additive way. Although 3D printing technology appeared in the 80s of the last century, 3D printers were widely used commercially only in the early 2010s. The first viable 3D printer was created by Charles Hull, one of the founders of 3D Systems Corporation. At the beginning of the 21st century, there was a significant increase in sales, which led to a sharp drop in the cost of devices. According to the consulting firm Wohlers Associates, the global market for 3D printers and related services reached $2.2 billion in 2012, growing by 29%.% compared to 2011.

3D printing technologies are used for prototyping and distributed manufacturing in architecture, construction, industrial design, automotive, aerospace, military-industrial, engineering and medical industries, bioengineering (to create artificial fabrics), fashion and footwear, jewelry, in education, geographic information systems, food industry and many other areas. According to research, open source home 3D printers will allow you to win back the capital costs of your own purchase through the economy of household production of items.

According to research, open source home 3D printers will allow you to win back the capital costs of your own purchase through the economy of household production of items.

Terminology

Additive manufacturing involves the construction of objects by adding the necessary material, and not by removing excess, as is the case with subtractive methods

The term "additive manufacturing" refers to the technology of creating objects by applying successive layers material. Models made using the additive method can be used at any stage of production - both for the production of prototypes (so-called rapid prototyping) and as finished products themselves (so-called rapid production).

In manufacturing, especially machining, the term "subtractive" implies more traditional methods and is a retronym coined in recent years to distinguish between traditional methods and new additive methods. Although traditional manufacturing has used essentially "additive" methods for centuries (such as riveting, welding, and screwing), they lack a 3D information technology component. Machining, on the other hand, (the production of parts of an exact shape), as a rule, is based on subtractive methods - filing, milling, drilling and grinding.

Although traditional manufacturing has used essentially "additive" methods for centuries (such as riveting, welding, and screwing), they lack a 3D information technology component. Machining, on the other hand, (the production of parts of an exact shape), as a rule, is based on subtractive methods - filing, milling, drilling and grinding.

The term "stereolithography" was defined by Charles Hull in a 1984 patent as "a system for generating three-dimensional objects by layering".

Fundamentals

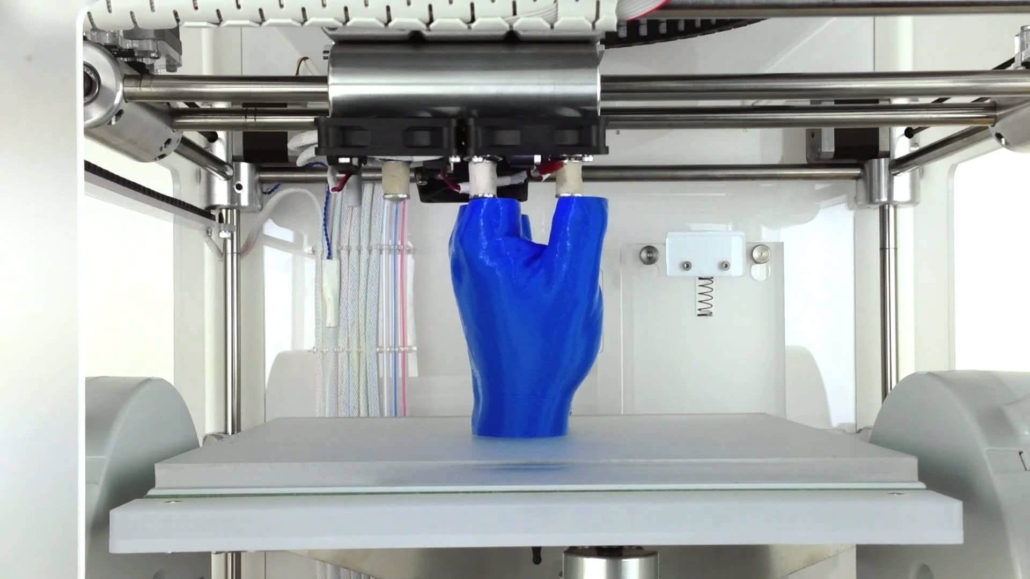

3D printed models

3D models are created by hand-held computer graphic design or 3D scanning. Hand modeling, or the preparation of geometric data for the creation of 3D computer graphics, is somewhat like sculpture. 3D scanning is the automatic collection and analysis of data from a real object, namely shape, color and other characteristics, with subsequent conversion into a digital three-dimensional model.

Both manual and automatic creation of 3D printed models can be difficult for the average user. In this regard, 3D printed marketplaces have become widespread in recent years. Some of the more popular examples include Shapeways, Thingiverse, and Threeding.

3D printing

The following digital models are used as drawings for 3D printed objects , powder, paper or sheet material, building a 3D model from a series of cross sections. These layers, corresponding to virtual cross-sections in the CAD model, are connected or fused together to create an object of a given shape. The main advantage of this method is the ability to create geometric shapes of almost unlimited complexity.

"Resolution" of the printer means the thickness of the applied layers (Z-axis) and the accuracy of positioning the print head in the horizontal plane (along the X and Y axes). Resolution is measured in DPI (dots per inch) or micrometers (the obsolete term is "micron"). Typical layer thicknesses are 100µm (250 DPI), although some devices like the Objet Connex and 3D Systems ProJet are capable of printing layers as thin as 16µm (1600 DPI). The resolution on the X and Y axes is similar to that of conventional 2D laser printers. A typical particle size is about 50-100µm (510 to 250 DPI) in diameter.

Typical layer thicknesses are 100µm (250 DPI), although some devices like the Objet Connex and 3D Systems ProJet are capable of printing layers as thin as 16µm (1600 DPI). The resolution on the X and Y axes is similar to that of conventional 2D laser printers. A typical particle size is about 50-100µm (510 to 250 DPI) in diameter.

One of the methods for obtaining a digital model is 3D scanning. Pictured here is a MakerBot Digitizer

3D Scanner Building a model using modern technology takes hours to days, depending on the method used and the size and complexity of the model. Industrial additive systems can typically reduce the time to a few hours, but it all depends on the type of plant, as well as the size and number of models produced at the same time.

Traditional manufacturing methods such as injection molding can be less expensive when producing large batches of polymer products, but additive manufacturing has advantages in small batch production, allowing for higher production rates and design flexibility, along with increased cost per unit produced. In addition, desktop 3D printers allow designers and developers to create concept models and prototypes without leaving the office.

In addition, desktop 3D printers allow designers and developers to create concept models and prototypes without leaving the office.

Machining

FDM Type 3D Printers

Although the resolution of the printers is adequate for most projects, printing slightly oversized objects and then subtractively machining them with high-precision tools allows you to create models of increased accuracy.

The LUMEX Avance-25 is an example of devices with a similar combined manufacturing and processing method. Some additive manufacturing methods allow for the use of multiple materials, as well as different colors, within a single production run. Many of the 3D printers use "supports" or "supports" during printing. Supports are needed to build model fragments that are not in contact with the underlying layers or the working platform. The supports themselves are not part of the given model, and upon completion of printing, they either break off (in the case of using the same material as for printing the model itself), or dissolve (usually in water or acetone - depending on the material used to create the supports). ).

).

Printing technologies

Since the late 1970s, several 3D printing methods have come into being. The first printers were large, expensive and very limited.

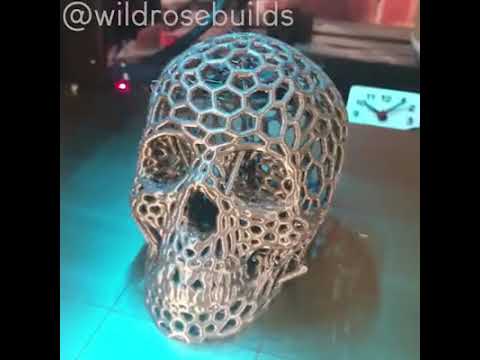

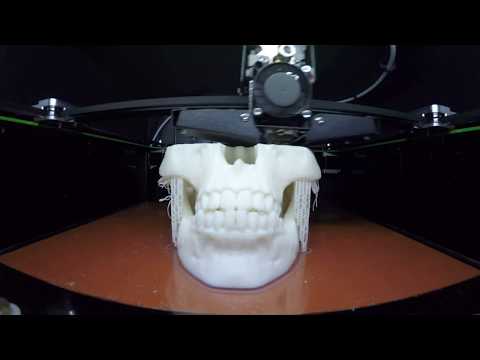

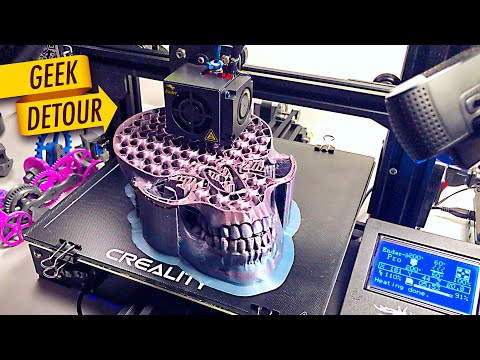

Complete skull with supports not yet removed

A wide variety of additive manufacturing methods are now available. The main differences are in the layering method and consumables used. Some methods rely on melting or softening materials to create layers: these include selective laser sintering (SLS), selective laser melting (SLM), direct metal laser sintering (DMLS), fusing deposition printing (FDM or FFF). Another trend has been the production of solid models by polymerization of liquid materials, known as stereolithography (SLA).

In the case of lamination of sheet materials (LOM), thin layers of material are cut to the required contour, and then joined into a single whole. Paper, polymers and metals can be used as LOM materials. Each of these methods has its own advantages and disadvantages, which is why some companies offer a choice of consumables for building a model - polymer or powder. LOM printers often use regular office paper to build durable prototypes. The key points when choosing the right device are the speed of printing, the price of a 3D printer, the cost of printed prototypes, as well as the cost and range of compatible consumables.

Each of these methods has its own advantages and disadvantages, which is why some companies offer a choice of consumables for building a model - polymer or powder. LOM printers often use regular office paper to build durable prototypes. The key points when choosing the right device are the speed of printing, the price of a 3D printer, the cost of printed prototypes, as well as the cost and range of compatible consumables.

Printers that produce full-fledged metal models are quite expensive, but it is possible to use less expensive devices for the production of molds and subsequent casting of metal parts.

The main methods of additive manufacturing are presented in the table:

| | ||

| Method | Technology | Materials used |

| Extrusion | Fused deposition modeling (FDM or FFF) | Thermoplastics (such as polylactide (PLA), acrylonitrile butadiene styrene (ABS), etc. ) ) |

| Wire | Manufacture of arbitrary shapes by electron beam fusing (EBFȝ) | Virtually all metal alloys |

| Powder | Direct Metal Laser Sintering (DMLS) | Virtually all metal alloys |

| Electron Beam Melting (EBM) | Titanium alloys | |

| Selective laser melting (SLM) | Titanium alloys, cobalt-chromium alloys, stainless steel, aluminum | |

| Selective heat sintering (SHS) | Powder thermoplastics | |

| Selective laser sintering (SLS) | Thermoplastics, metal powders, ceramic powders | |

| Inkjet | 3D Inkjet Printing (3DP) | Gypsum, plastics, metal powders, sand mixtures |

| Lamination | Lamination Object Manufacturing (LOM) | Paper, metal foil, plastic film |

| Polymerization | Stereolithography (SLA) | Photopolymers |

| Digital LED Projection (DLP) | Photopolymers |

Extrusion Printing

Fused Deposition Modeling (FDM/FFF) was developed by S. Scott Trump in the late 1980s and commercialized in the 1990s by Stratasys, a company of which Trump is credited as one of the founders. Due to the expiration of the patent, there is a large community of open source 3D printer developers as well as commercial organizations using the technology. As a consequence, the cost of devices has decreased by two orders of magnitude since the invention of the technology.

Scott Trump in the late 1980s and commercialized in the 1990s by Stratasys, a company of which Trump is credited as one of the founders. Due to the expiration of the patent, there is a large community of open source 3D printer developers as well as commercial organizations using the technology. As a consequence, the cost of devices has decreased by two orders of magnitude since the invention of the technology.

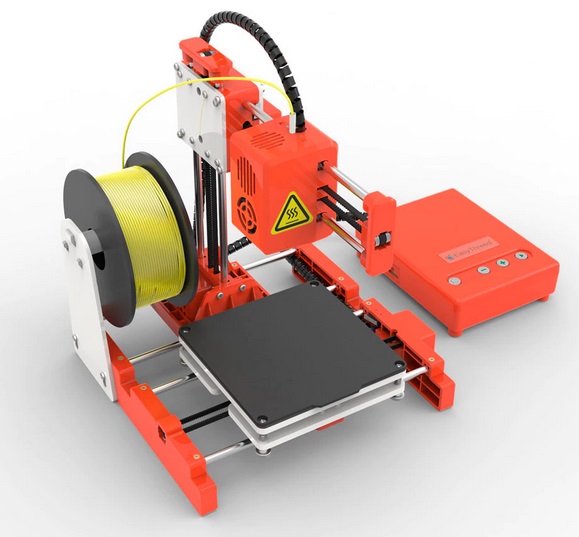

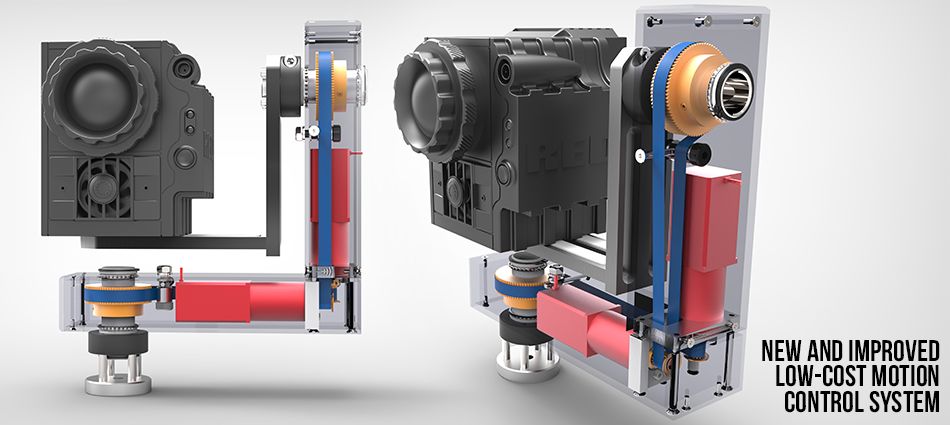

3D printers range from simple do-it-yourself printers to plastic...

Fusion printing process involves the creation of layers by extrusion of a fast-curing material in the form of microdrops or thin jets. Typically, consumable material (such as thermoplastic) comes in the form of spools from which the material is fed into a printhead called an "extruder". The extruder heats the material to its melting temperature, followed by extrusion of the molten mass through a nozzle. The extruder itself is driven by stepper motors or servomotors to position the printhead in three planes. The movement of the extruder is controlled by a manufacturing software (CAM) linked to a microcontroller.

The movement of the extruder is controlled by a manufacturing software (CAM) linked to a microcontroller.

A variety of polymers are used as consumables, including acrylonitrile butadiene styrene (ABS), polycarbonate (PC), polylactide (PLA), high pressure polyethylene (HDPE), polycarbonate-ABS blends, polyphenylene sulfone (PPSU), etc. Typically, polymer supplied in the form of a filler made of pure plastic. There are several projects in the 3D printing enthusiast community that aim to recycle used plastic into materials for 3D printing. The projects are based on the production of consumables using shredders and melters.

FDM/FFF technology has certain limitations on the complexity of the generated geometric shapes. For example, the creation of suspended structures (such as stalactites) is impossible by itself, due to the lack of necessary support. This limitation is compensated by the creation of temporary support structures that are removed after printing is completed.

Powder print

Selective sintering of powder materials is one of the additive manufacturing methods. Model layers are drawn (sintered) in a thin layer of powdered material, after which the work platform is lowered and a new layer of powder is applied. The process is repeated until a complete model is obtained. The unused material remains in the working chamber and serves to support the overhanging layers without requiring the creation of special supports.

The most common methods are based on laser sintering: selective laser sintering (SLS) for working with metals and polymers (e.g. polyamide (PA), glass fiber reinforced polyamide (PA-GF), glass fiber (GF), polyetheretherketone) (PEEK), polystyrene (PS), alumide, carbon fiber reinforced polyamide (Carbonmide), elastomers) and direct metal laser sintering (DMLS).

... to expensive industrial plants working with metals

Selective Laser Sintering (SLS) was developed and patented by Carl Deckard and Joseph Beeman of the University of Texas at Austin in the mid-1080s under the auspices of the Defense Advanced Research Projects Agency (DARPA). A similar method was patented by R. F. Householder in 1979, but has not been commercialized.

A similar method was patented by R. F. Householder in 1979, but has not been commercialized.

Selective laser melting (SLM) is characterized by the fact that it does not sinter, but actually melts the powder at the points of contact with a powerful laser beam, allowing you to create high-density materials that are similar in terms of mechanical characteristics to products made by traditional methods.

Electron Beam Melting (EBM) is a similar method for the additive manufacturing of metal parts (eg titanium alloys) but using electron beams instead of lasers. EBM is based on melting metal powders layer by layer in a vacuum chamber. In contrast to sintering at temperatures below melting thresholds, models made by electron beam melting are characterized by solidity with a corresponding high strength.

Finally, there is the 3D inkjet printing method. In this case, a binder is applied to thin layers of powder (gypsum or plastic) in accordance with the contours of successive layers of the digital model. The process is repeated until the finished model is obtained. The technology provides a wide range of applications, including the creation of color models, suspended structures, the use of elastomers. The design of models can be strengthened by subsequent impregnation with wax or polymers.

The process is repeated until the finished model is obtained. The technology provides a wide range of applications, including the creation of color models, suspended structures, the use of elastomers. The design of models can be strengthened by subsequent impregnation with wax or polymers.

Lamination

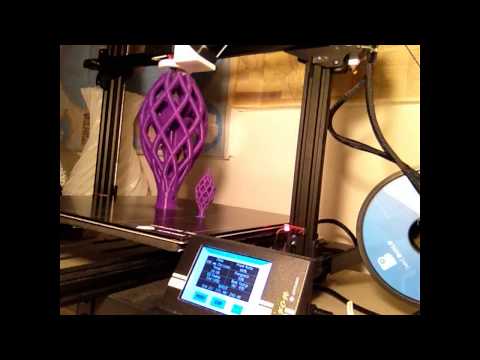

FDM 3D printers are the most popular among hobbyists and enthusiasts

Some printers use paper as a material for building models, thereby reducing the cost of printing. Such devices experienced the peak of popularity in the 1990s. The technology consists in cutting out the layers of the model from paper using a carbon dioxide laser with simultaneous lamination of the contours to form the finished product.

In 2005, Mcor Technologies Ltd developed a variant of the technology that uses plain office paper, a tungsten carbide blade instead of a laser, and selective adhesive application.

There are also device variants that laminate thin metal and plastic sheets.

Photopolymerization

3D printing allows you to create functional monolithic parts of complex geometric shapes, like this jet nozzle

Stereolithography technology was patented by Charles Hull in 1986. Photopolymerization is primarily used in stereolithography (SLA) to create solid objects from liquid materials. This method differs significantly from previous attempts, from the sculptural portraits of François Willem (1830-1905) to photopolymerization by the Matsubara method (1974).

The Digital Projection Method (DLP) uses liquid photopolymer resins that are cured by exposure to ultraviolet light emitted from digital projectors in a coated working chamber. After the material has hardened, the working platform is immersed to a depth equal to the thickness of one layer, and the liquid polymer is irradiated again. The procedure is repeated until the completion of the model building. An example of a rapid prototyping system using digital LED projectors is the EnvisionTEC Perfactory.

Inkjet printers (eg Objet PolyJet) spray thin layers (16-30µm) of photopolymer onto the build platform until a complete model is obtained. Each layer is irradiated with an ultraviolet beam until hardened. The result is a model ready for immediate use. The gel-like support material used to support the components of geometrically complex models is removed after the model has been handcrafted and washed. The technology allows the use of elastomers.

Ultra-precise detailing of models can be achieved using multiphoton polymerization. This method is reduced to drawing the contours of a three-dimensional object with a focused laser beam. Due to non-linear photoexcitation, the material solidifies only at the focusing points of the laser beam. This method makes it easy to achieve resolutions above 100 µm, as well as build complex structures with moving and interacting parts.

Another popular method is curing with LED projectors or "projection stereolithography".

Projection stereolithography

This method involves dividing a 3D digital model into horizontal layers, converting each layer into a 2D projection similar to photomasks. The 2D images are projected onto successive layers of photopolymer resin that harden according to the projected contours.

In some systems, the projectors are located at the bottom, helping to level the surface of the photopolymer material when the model moves vertically (in this case, the build platform with the applied layers moves up, rather than sinking into the material) and reduces the production cycle to minutes instead of hours.

The technology allows you to create models with layers of several materials with different curing rates.

Some commercial models, such as the Objet Connex, apply resin using small nozzles.

3D printers

Industrial plants

Industrial adoption of additive manufacturing is proceeding at a rapid pace. For example, US-Israeli joint venture Stratasys supplies $2,000 to $500,000 additive manufacturing machines, while General Electric uses high-end machines to produce gas turbine parts.

For example, US-Israeli joint venture Stratasys supplies $2,000 to $500,000 additive manufacturing machines, while General Electric uses high-end machines to produce gas turbine parts.

Home appliances

LOM takes papier-mâché to the next level The development of 3D printers for home use is being pursued by a growing number of companies and enthusiasts. Most of the work is done by amateurs for their own and public needs, with help from the academic community and hackers.

The oldest and longest running project in the desktop 3D printer category is RepRap. The RepRap project aims to create free and open source (FOSH) 3D printers provided under the GNU General Public License. RepRap devices are capable of printing custom-designed plastic components that can be used to build clones of the original device. Individual RepRap devices have been successfully applied to the production of printed circuit boards and metal parts.

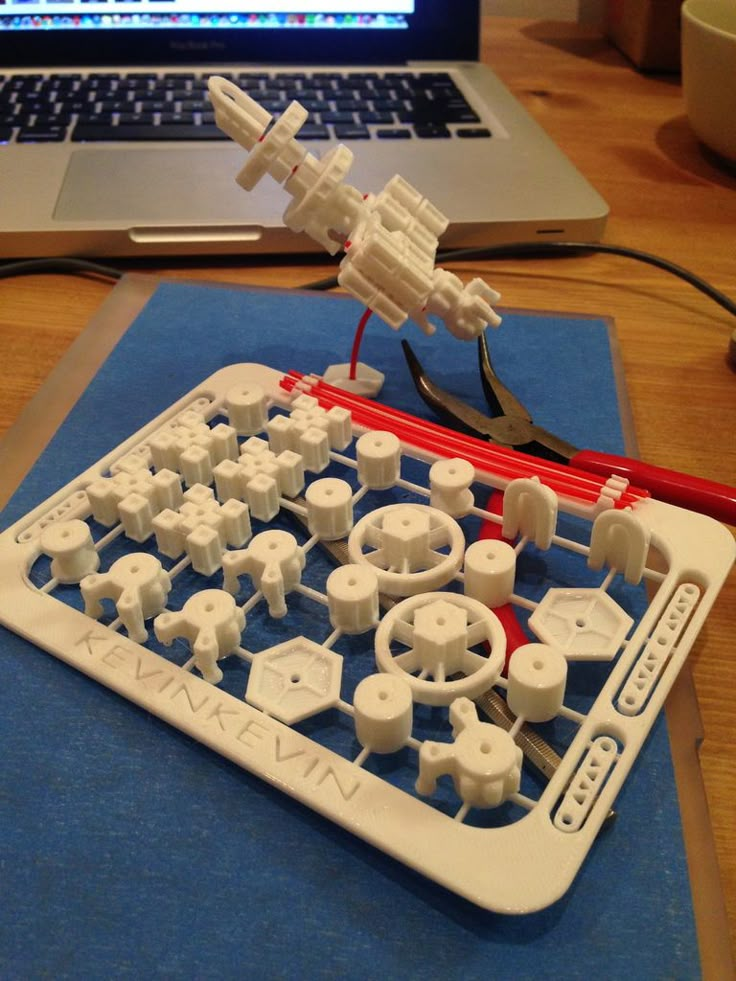

Due to the open access to drawings of RepRap printers, many of the projects adopt the technical solutions of analogues, thus creating a semblance of an ecosystem consisting mostly of freely modifiable devices. The wide availability of open source designs only encourages variations. On the other hand, there is a significant variation in the level of quality and complexity of both the designs themselves and the devices manufactured on their basis. The rapid development of open source 3D printers is leading to a rise in popularity and the emergence of public and commercial portals (such as Thingiverse or Cubify) offering a variety of printable 3D designs. In addition, the development of technology contributes to the sustainable development of local economies through the possibility of using locally available materials for the production of printers.

The wide availability of open source designs only encourages variations. On the other hand, there is a significant variation in the level of quality and complexity of both the designs themselves and the devices manufactured on their basis. The rapid development of open source 3D printers is leading to a rise in popularity and the emergence of public and commercial portals (such as Thingiverse or Cubify) offering a variety of printable 3D designs. In addition, the development of technology contributes to the sustainable development of local economies through the possibility of using locally available materials for the production of printers.

Stereolithographic 3D printers are often used in dental prosthetics

The cost of 3D printers has been declining at a significant rate since about 2010: devices that cost $20,000 at the time are now $1,000 or less. Many companies and individual developers are already offering budget RepRap kits under $500. The Fab@Home open source project has led to the development of general purpose printers capable of printing anything that can be squeezed through a nozzle, from chocolate to silicone putty and chemicals.

Printers based on this design have been available as kits since 2012 for around $2,000. Some 3D printers, including the mUVe 3D and Lumifold, are designed to be as affordable as possible from the start, with the Peachy Printer being priced around $100. .

Professional Kickstarter funded printers often perform well: Rapide 3D printers are quiet and fumes free at $1499. 3D Doodler's '3D Printing Pen' Raised $2.3M in Kickstarter donations, with a selling price of $99 for the device itself. True, it is difficult to call the 3D Doodler a full-fledged 3D printer.

3D Systems Cube is a popular consumer 3D printer

As prices drop, 3D printers are becoming more attractive for home production. In addition, home use of 3D printing technologies can reduce the environmental footprint of industry by reducing the volume of consumables and the energy and fuel costs of transporting materials and goods.

Parallel to the creation of home 3D-printing devices, the development of devices for processing household waste into printed materials, the so-called. Recyclebot. For example, the commercial model Filastrucer was designed to recycle plastic waste (shampoo bottles, milk containers) into inexpensive consumables for RepRap printers. Such methods of household disposal are not only practical, but also have a positive impact on the ecological situation.

Recyclebot. For example, the commercial model Filastrucer was designed to recycle plastic waste (shampoo bottles, milk containers) into inexpensive consumables for RepRap printers. Such methods of household disposal are not only practical, but also have a positive impact on the ecological situation.

The development and customization of RepRap 3D printers has created a new category of semi-professional printers for small businesses. Manufacturers such as Solidoodle, RoBo and RepRapPro offer kits for under $1,000. The accuracy of these devices is between industrial and consumer printers. Recently, high-performance printers using a delta-shaped coordinate system, or the so-called "delta robots", are gaining popularity. Some companies offer software to support printers made by other companies.

Application

The use of LED projectors helps reduce the cost of stereolithography printers. In the illustration DLP printer Nova

3D printing allows you to equalize the cost of producing one part and mass production, which poses a threat to large-scale economies. The impact of 3D printing may be similar to the introduction of manufacture. In the 1450s, no one could predict the consequences of the printing press, in the 1750s, no one took the steam engine seriously, and transistors 19The 50s seemed like a curious innovation. But the technology continues to evolve and is likely to have an impact on every scientific and industrial branch with which it comes into contact.

The impact of 3D printing may be similar to the introduction of manufacture. In the 1450s, no one could predict the consequences of the printing press, in the 1750s, no one took the steam engine seriously, and transistors 19The 50s seemed like a curious innovation. But the technology continues to evolve and is likely to have an impact on every scientific and industrial branch with which it comes into contact.

The earliest application of additive manufacturing can be considered rapid prototyping, aimed at reducing the development time of new parts and devices compared to earlier subtractive methods (too slow and expensive). The improvement of additive manufacturing technologies leads to their spread in various fields of science and industry. The production of parts previously only available through machining is now possible through additive methods, and at a better price.

Applications include breadboarding, prototyping, molding, architecture, education, mapping, healthcare, retail, etc.

Industrial applications:

Rapid prototyping: Industrial 3D printers have been used for rapid prototyping and research since the early 1980s . As a rule, these are quite large installations using powder metals, sand mixtures, plastics and paper. Such devices are often used by universities and commercial companies.

Advances in rapid prototyping have led to the creation of materials suitable for the production of final products, which in turn has contributed to the development of 3D production of finished products as an alternative to traditional methods. One of the advantages of fast production is the relatively low cost of manufacturing small batches.

Rapid production: Rapid production remains a fairly new method whose possibilities have not yet been fully explored. Nevertheless, many experts tend to consider rapid production a new level of technology. Some of the most promising areas for rapid prototyping to adapt to rapid manufacturing are selective laser sintering (SLS) and direct metal sintering (DMLS).

Bulk customization: Some companies offer services for customizing objects using simplified software and then creating unique custom 3D models. One of the most popular areas was the manufacture of cell phone cases. In particular, Nokia has made publicly available the designs of its phone cases for user customization and 3D printing.

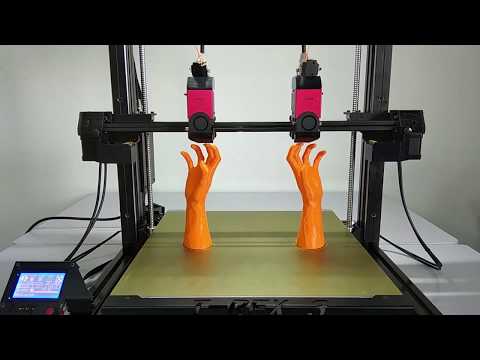

Mass production: The current low print speed of 3D printers limits their use in mass production. To combat this shortcoming, some FDM devices are equipped with multiple extruders, allowing you to print different colors, different polymers, and even create several models at the same time. In general, this approach increases productivity without requiring the use of multiple printers - a single microcontroller is enough to operate multiple printheads.

Devices with multiple extruders allow the creation of several identical objects from only one digital model, but at the same time allow the use of different materials and colors. The print speed increases in proportion to the number of print heads. In addition, certain energy savings are achieved through the use of a common working chamber, which often requires heating. Together, these two points reduce the cost of the process.

The print speed increases in proportion to the number of print heads. In addition, certain energy savings are achieved through the use of a common working chamber, which often requires heating. Together, these two points reduce the cost of the process.

Many printers are equipped with dual printheads, however this configuration is only used for printing single models in different colors and materials.

Consumer and hobby use

Today, consumer 3D printing mainly attracts the attention of enthusiasts and hobbyists, while practical use is rather limited. However, 3D printers have already been used to print working mechanical clocks, woodworking gears, jewelry, and more. Home 3D printing websites often offer designs for hooks, doorknobs, massage tools, and more.

3D printing is also being used in hobby veterinary medicine and zoology – in 2013, a 3D printed prosthesis allowed a duckling to stand up, and hermit crabs love stylish 3D printed shells. 3D printers are widely used for the domestic production of jewelry - necklaces, rings, handbags, etc.

3D printers are widely used for the domestic production of jewelry - necklaces, rings, handbags, etc.

The Fab@Home open project aims to develop general purpose home printers. The devices have been tested in research environments using the latest 3D printing technologies for the production of chemical compounds. The printer can print any material suitable for extrusion from a syringe in the form of a liquid or paste. The development is aimed at the possibility of home production of medicines and household chemicals in remote areas of residence.

Student project OpenReflex resulted in a design for an analog SLR camera suitable for 3D printing.

Clothing

3D printing is gaining ground in the fashion world as couturiers use printers to experiment with swimwear, shoes and dresses. Commercial applications include rapid prototyping and 3D printing of professional athletic shoes - the Vapor Laser Talon for soccer players and New Balance for track and field athletes.

3D bioprinting

EBM titanium medical implants

3D printing is currently being researched by biotech companies and academic institutions. The research is aimed at exploring the possibility of using inkjet/drip 3D printing in tissue engineering to create artificial organs. The technology is based on the application of layers of living cells on a gel substrate or sugar matrix, with a gradual layer-by-layer build-up to create three-dimensional structures, including vascular systems. The first 3D tissue printing production system based on NovoGen bioprinting technology was introduced in 2009year. A number of terms are used to describe this research area: organ printing, bioprinting, computer tissue engineering, etc.

One of the pioneers of 3D printing, research company Organovo, conducts laboratory research and develops the production of functional 3D human tissue samples for use in medical and therapeutic research. For bioprinting, the company uses a NovoGen MMX 3D printer. Organovo believes that bioprinting will speed up the testing of new medicines before clinical trials, saving time and money invested in drug development. In the long term, Organovo hopes to adapt bioprinting technology for graft and surgical applications.

For bioprinting, the company uses a NovoGen MMX 3D printer. Organovo believes that bioprinting will speed up the testing of new medicines before clinical trials, saving time and money invested in drug development. In the long term, Organovo hopes to adapt bioprinting technology for graft and surgical applications.

3D printing of implants and medical devices

3D printing is used to create implants and devices used in medicine. Successful surgeries include examples such as titanium pelvic and jaw implants and plastic tracheal splints. The most widespread use of 3D printing is expected in the production of hearing aids and dentistry. In March 2014, Swansea surgeons used 3D printing to reconstruct the face of a motorcyclist who was seriously injured in a road accident.

3D printing services

Some companies offer online 3D printing services available to individuals and industrial companies. The customer is required to upload a 3D design to the site, after which the model is printed using industrial installations. The finished product is either delivered to the customer or subject to pickup.

The customer is required to upload a 3D design to the site, after which the model is printed using industrial installations. The finished product is either delivered to the customer or subject to pickup.

Exploring new applications

3D printing makes it possible to create fully functional metal products, including weapons.

Future applications of 3D printing may include the creation of open source scientific equipment for use in open laboratories and other scientific applications - fossil reconstruction in paleontology, the creation of duplicates of priceless archaeological artifacts, the reconstruction of bones and body parts for forensic analysis, the reconstruction of heavily damaged evidence collected from crime scenes. The technology is also being considered for application in construction.

In 2005, academic journals began to publish materials on the possibility of using 3D printing technologies in art. In 2007, the Wall Street Journal and Time magazine included 3D design in their list of the 100 most significant achievements of the year. The Victoria and Albert Museum at the London Design Festival in 2011 presented an exhibition by Murray Moss entitled "Industrial Revolution 2.0: how the material world materializes again", dedicated to 3D printing technologies.

The Victoria and Albert Museum at the London Design Festival in 2011 presented an exhibition by Murray Moss entitled "Industrial Revolution 2.0: how the material world materializes again", dedicated to 3D printing technologies.

In 2012, a University of Glasgow pilot project showed that 3D printing could be used to produce chemical compounds, including hitherto unknown ones. The project printed chemical storage vessels into which “chemical ink” was injected using additive machines and then reacted. The viability of the technology was proven by the production of new compounds, but a specific practical application was not pursued during the experiment. Cornell Creative Machines has confirmed the feasibility of creating food products using hydrocolloid 3D printing. Professor Leroy Cronin of the University of Glasgow has suggested using "chemical ink" to print medicines.

The use of 3D scanning technology makes it possible to create replicas of real objects without the use of casting methods, which are costly, difficult to perform and can have a destructive effect in cases of precious and fragile objects of cultural heritage.

An additional example of 3D printing technologies being developed is the use of additive manufacturing in construction. This could make it possible to accelerate the pace of construction while reducing costs. In particular, the possibility of using technology to build space colonies is being considered. For example, the Sinterhab project aims to explore the possibility of additive manufacturing of lunar bases using lunar regolith as the main building material. Instead of using binding materials, the possibility of microwave sintering of regolith into solid building blocks is being considered.

Additive manufacturing allows you to create waveguides, sleeves and bends in terahertz devices. The high geometric complexity of such products could not be achieved by traditional production methods. A commercially available professional EDEN 260V setup was used to create structures with a resolution of 100 microns. The printed structures were galvanized with gold to create a terahertz plasmonic apparatus.

China has allocated nearly $500 million. for the development of 10 national institutes for the development of 3D printing technologies. In 2013, Chinese scientists began printing living cartilage, liver and kidney tissue using specialized 3D bioprinters. Researchers at Hangzhou Dianqi University have even developed their own 3D bioprinter for this challenging task, dubbed Regenovo. One of Regenovo's developers, Xu Mingeng, said it takes less than an hour for the printer to produce a small sample of liver tissue or a four to five inch sample of ear cartilage. Xu predicts the emergence of the first full-fledged printed artificial organs within the next 10-20 years. That same year, researchers at the Belgian Hasselt University successfully printed a new jaw for an 83-year-old woman. After the implant is implanted, the patient can chew, talk and breathe normally.

In Bahrain, sandstone-like 3D printing has created unique structures to support coral growth and restore damaged reefs. These structures have a more natural shape than previously used structures and do not have the acidity of concrete.

These structures have a more natural shape than previously used structures and do not have the acidity of concrete.

Intellectual property

Section of liver tissue printed by Organovo, which is working to improve 3D printing technology for the production of artificial organs

3D printing has been around for decades, and many aspects of the technology are subject to patents, copyrights, and trademark protection. However, from a legal point of view, it is not entirely clear how intellectual property protection laws will be applied in practice if 3D printers become widely used.

distribution and will be used in household production of goods for personal use, non-commercial use or for sale.

Any of the protective measures may negatively affect the distribution of designs used in 3D printing or the sale of printed products. The use of protected technologies may require the permission of the owner, which in turn will require the payment of royalties.

Patents cover certain processes, devices, and materials. The duration of patents varies from country to country.

Often, copyright extends to the expression of ideas in the form of material objects and lasts for the life of the author, plus 70 years. Thus, if someone creates a statue and obtains copyright, it will be illegal to distribute designs for printing of an identical or similar statue.

Influence of 3D printing

Additive manufacturing requires manufacturing companies to be flexible and constantly improve available technologies to stay competitive. Advocates of additive manufacturing predict that the opposition between 3D printing and globalization will escalate as home production displaces trade in goods between consumers and large manufacturers. In reality, the integration of additive technologies into commercial production serves as a complement to traditional subtractive methods, rather than a complete replacement for the latter.

Space exploration

In 2010, work began on the application of 3D printing in zero gravity and low gravity. The main goal is to create hand tools and more complex devices "as needed" instead of using valuable cargo volume and fuel to deliver finished products to orbit.

Even NASA is interested in 3D printing

At the same time, NASA is conducting joint tests with Made in Space to assess the potential of 3D printing to reduce the cost and increase the efficiency of space exploration. Nasa's additive-manufactured rocket parts were successfully tested in July 2013, with two fuel injectors performing on par with conventionally produced parts during operational tests subjecting the parts to temperatures of around 3,300°C and high pressure levels. It is noteworthy that NASA is preparing to launch a 3D printer into space: the agency is going to demonstrate the possibility of creating spare parts directly in orbit, instead of expensive transportation from the ground.

Social change

The topic of social and cultural change as a result of the introduction of commercially available additive technologies has been discussed by writers and sociologists since the 1950s. One of the most interesting assumptions was the possible blurring of boundaries between everyday life and workplaces as a result of the massive introduction of 3D printers into the home. It also points to the ease of transferring digital designs, which, in combination with local production, will help reduce the need for global transportation. Finally, copyright protection may change to reflect the ease of additive manufacturing of many products.

Firearms

In 2012, US company Defense Distributed released plans to create a "design of a functional plastic weapon that could be downloaded and played by anyone with access to a 3D printer." Defense Distributed has developed a 3D printed version of the receiver for the AR-15 rifle, capable of withstanding more than 650 shots, and a 30-round magazine for the M-16 rifle. The AR-15 has two receivers (lower and upper), but legal registration is tied to the lower receiver, which is stamped with a serial number. Shortly after Defense Distributed created the first working drawings for the production of plastic weapons in May 2013, the US State Department requested that the instructions be removed from the company's website.

The AR-15 has two receivers (lower and upper), but legal registration is tied to the lower receiver, which is stamped with a serial number. Shortly after Defense Distributed created the first working drawings for the production of plastic weapons in May 2013, the US State Department requested that the instructions be removed from the company's website.

The distribution of blueprints by Defense Distributed has fueled discussion about the possible impact of 3D printing and digital processing devices on the effectiveness of gun control. However, the fight against the proliferation of digital weapon models will inevitably face the same problems as attempts to prevent the trade in pirated content.

Go to the 3D Printing Encyclopedia Home Page

Printing 3D Objects in Photoshop

User Guide Cancel

Search

Last update Dec 13, 2021 08:23:10 PM GMT

- Photoshop User Guide

- Introduction to Photoshop

- Dream about it.

Do it.

Do it. - What's New in Photoshop

- Editing the first photo

- Create documents

- Photoshop | Frequently Asked Questions

- Photoshop system requirements

- Transferring presets, operations and settings

- Introduction to Photoshop

- Dream about it.

- Photoshop and other Adobe products and services

- Working with Illustrator artwork in Photoshop

- Working with Photoshop files in InDesign

- Substance 3D Materials for Photoshop

- Photoshop and Adobe Stock

- Working with the built-in Capture extension in Photoshop

- Creative Cloud Libraries

- Creative Cloud Libraries in Photoshop

- Working in Photoshop using the Touch Bar

- Net and guides

- Create transactions

- Cancellation and transaction history

- Photoshop on iPad

- Photoshop on iPad | General questions

- Introduction to the working environment

- System requirements | Photoshop on iPad

- Creating, opening and exporting documents

- Adding photos

- Working with layers

- Drawing and painting with brushes

- Selecting areas and adding masks

- Retouch compositions

- Working with adjustment layers

- Adjusting the key of a composition using the Curves layer

- Applying transform operations

- Trim and rotate compositions

- Rotate, pan, zoom and restore canvas

- Working with text layers

- Working with Photoshop and Lightroom

- Getting missing fonts in Photoshop on iPad

- Japanese text in Photoshop on iPad

- Application parameter management

- Touch shortcuts and gestures

- Key combinations

- Image resizing

- Live stream your creative process in Photoshop on iPad

- Repair imperfections with the Healing Brush

- Creating brushes in Capture and using them in Photoshop

- Working with Camera Raw files

- Creating and using smart objects

- Correcting the exposure of images with the Dodge and Burn tools

- Photoshop Web Application Beta

- Frequently Asked Questions | Photoshop Web App Beta

- General information about the operating environment

- System requirements | Photoshop Web Application Beta

- Keyboard shortcuts | Photoshop Web Application Beta

- Supported file formats | Photoshop Web App 9 Beta0004

- Opening and working with cloud documents

- Collaboration with stakeholders

- Limited cloud document editing capabilities

- Cloud Documents

- Photoshop Cloud Documents | Frequently Asked Questions

- Photoshop Cloud Documents | Workflow Questions

- Work with and manage cloud documents in Photoshop

- Cloud storage update for Photoshop

- Unable to create or save cloud document

- Troubleshooting Photoshop cloud documents

- Collection of cloud document synchronization logs

- Cloud document sharing and editing

- File sharing and commenting in the application

- Working environment

- Basic information about the working environment

- Learn faster with the What's New panel in Photoshop

- Create documents

- Working in Photoshop using the Touch Bar

- Tool gallery

- Performance settings

- Using tools

- Touch gestures

- Touch Gestures and Customizable Workspaces

- Overview versions of technology

- Metadata and comments

- Default key combinations

- Touch gestures and customizable workspaces

- Putting Photoshop images in other applications

- Installations

- Default key combinations

- Rulers

- Show or hide non-printing auxiliaries

- Specifying columns for the image

- Cancellation and transaction history

- Panels and menus

- File location

- Positioning of elements with referencing

- Positioning with the ruler tool

- Presets

- Customizing keyboard shortcuts

- Net and guides

- Web, screen and application content development

- Photoshop for design

- Artboards

- View on device

- Copy CSS from layers

- Dividing web pages into fragments

- HTML options for snippets

- Changing the arrangement of fragments

- Working with web graphics

- Create web photo galleries

- Understanding images and working with color

- Resizing images

- Working with raster and vector images

- Image size and resolution

- Importing images from cameras and scanners

- Creating, opening and importing images

- Image viewer

- "Invalid JPEG marker" error | Opening images

- Viewing multiple images

- Customize color palettes and color swatches

- HDR images

- Image color matching

- Converting between color modes

- Color modes

- Erase sub-images

- Blend Modes

- Choice of colors

- Making changes to indexed color tables

- Image information

- Distortion filters not available

- Color details

- Color and monochrome corrections using channels

- Selecting colors in the Color and Swatches panels

- Model

- Color mode (or picture mode)

- Shade

- Add color mode change to operation

- Add swatches from HTML CSS and SVG files

- Bit depth and settings

- Layers

- Understanding Layers

- Reversible editing

- Create and manage layers and groups

- Selecting, grouping and linking layers

- Putting images into frames

- Opacity and layering

- Layer masks

- Application of smart filters

- Layer compositions

- Move, arrange and lock layers

- Masking layers with vector masks

- Manage layers and groups

- Effects and Layer Styles

- Editing layer masks

- Retrieve resources

- Display layers with clipping masks

- Generation of graphic resources from layers

- Working with smart objects

- Blend Modes

- Combining several fragments into one image

- Combining images with Auto Layer

- Alignment and distribution of layers

- Copy CSS from layers

- Load selections based on layer boundaries or layer mask

- See-through to show the contents of other layers

- Layer

- Mixing

- Composite images

- Background

- Selections

- Select and Mask workspace

- Quick area selection

- Getting Started with Selections

- Selecting with the Marquee toolbox

- Selecting with the Lasso tools

- Color range selection in image

- Pixel highlight setting

- Convert between contours and selection boundaries

- Channel Basics

- Moving, copying and deleting selected pixels

- Creating a temporary quick mask

- Save selections and alpha channel masks

- Selecting focus areas in an image

- Duplication, splitting and merging of channels

- Channel calculation

- Allotment

- Bounding box

- Image corrections

- Perspective distortion

- Reducing blur due to camera movement

- Healing Brush Tool Examples

- Export color lookup tables

- Image sharpness and blur correction

- Understanding color grading

- Applying the Brightness/Contrast setting

- Shadow and Highlight Detail Correction

- Correction "Levels"

- Hue and saturation correction

- Juiciness correction

- Adjusting the color saturation in image areas

- Quick tone correction

- Applying special color effects to images

- Image enhancement with color balance correction

- HDR images

- View histograms and pixel values

- Image color matching

- Crop and straighten photographs

- Converting a color image to black and white

- Adjustment and fill layers

- Curves correction

- Blend Modes

- Target Imaging for Press

- Color and tone correction with Levels and Curves eyedroppers

- HDR Exposure and Toning Compensation

- Filter

- Blur

- Lighten or darken image areas

- Selective color correction

- Replacing object colors

- Adobe Camera Raw

- Camera Raw system requirements

- What's New in Camera Raw

- Introduction to Camera Raw

- Creation of panoramas

- Supported lenses

- Camera Raw Vignetting, Grain, and Haze Removal

- Default key combinations

- Automatic perspective correction in Camera Raw

- Reversible editing in Camera Raw

- Camera Raw Radial Filter Tool

- Manage Camera Raw settings

- Processing, saving and opening images in Camera Raw

- Image enhancements with Camera Raw's improved Spot Remover

- Rotating, cropping and modifying images

- Camera Raw color correction

- Function overview | Adobe Camera Raw | 2018 releases

- Overview of new features

- Processing versions in Camera Raw

- Making local adjustments in Camera Raw

- Fixing and restoring images

- Removing objects from photos using Content-Aware Fill

- Content-aware patching and relocation

- Photo retouching and correction

- Image Distortion and Noise Correction

- Basic troubleshooting steps to solve most problems

- Image transformation

- Object transformation

- Crop, rotate and canvas adjustment

- Crop and straighten photographs

- Creating and editing panoramic images

- Deformation of images, shapes and contours

- Perspective

- Using the Plastic filter

- Content-aware scale

- Transform images, shapes and paths

- Deformation

- Transformation

- Panorama

- Drawing and painting

- Drawing symmetrical ornaments

- Options for drawing a rectangle and changing the stroke

- Drawing details

- Drawing and editing shapes

- Paint tools

- Creating and modifying brushes

- Blend Modes

- Add color to contours

- Edit contours

- Painting with mix brush

- Brush Presets

- Gradients

- Gradient interpolation

- Fill and stroke selections, layers, and paths

- Drawing with the pen tool group

- Pattern making

- Creating a pattern with the Pattern Builder filter

- Circuit control

- Managing pattern libraries and presets

- Drawing with pen tablet

- Creating textured brushes

- Adding dynamic elements to brushes

- Gradient

- Draw stylized strokes with the Artistic Archive Brush

- Drawing with pattern

- Synchronizing presets across multiple devices

- Text

- Adding and editing text

- Universal text editor

- Working with OpenType SVG 9 Fonts0004

- Character formatting

- Paragraph formatting

- Creating text effects

- Text editing

- Leading and letter spacing

- Font for Arabic and Hebrew

- Fonts

- Troubleshooting fonts

- Asian text

- Creating text

- Text Engine error when using the Type tool in Photoshop | Windows 8

- Adding and editing text

- Video and animation

- Video editing in Photoshop

- Editing video and animation layers

- Introduction to video and animation

- Video and animation preview

- Drawing frames in video layers

- Import video files and image sequences

- Create frame animations

- Creative Cloud 3D Animation (Preview)