3D printed watch strap

3D Printed Apple Watch Bands Soon Available from 3D Systems and FreshFiber - 3DPrint.com

3D Systems (NYSE:DDD) has been known for their ability to stay ahead of their competition when it comes to 3D printing. It’s not just the 3D printing industry that they have been targeting as of late though. Their ‘first to market’ attitude can be seen today with Apple’s announcement of their much anticipated Apple Watch, as 3D Systems has been wasting no time in working with a company called FreshFiber in order to create uniquely designed 3D printed Apple Watch bands.

As most of the world knows, today was the much anticipated Apple event, in which the company officially unveiled the Apple Watch, a product that has been seemingly talked about for a couple years now. The watch, which includes many of the familiar features seen on the iPhone 6, will allow users to make phone calls, check into flights, see the latest happenings on their social networks, open doors and much more, from the convenience of their own wrists. These watches will have 18 hours of battery life, and their own special interface, which allows users to browse and download different apps built specifically for the watch itself.

Of course, one of the most interesting aspects of these watches, which will start at $349 and go up to over $10,000 for some models, are their ability to be customized, specifically the watches’ bands. There will be many bands to choose from at your local Apple store as well as online. However, it will be the third-party bands which could really make for some interesting looking and unique watches. After all no one will want a watch that looks identical to their friend’s. Today, 3D Systems and FreshFiber unveiled some prototype designs for their own 3D printed Apple Watch bands, which will be available sometime soon via the Cubify website.

Some of the 3D printed Apple Watch Bands – coming soon!

“We’re planning to do some interchangeable bands much like what we’ve done with the Nooka watches, Alyssa Hoyt, Director of Marketing for 3D Systems tells 3DPrint.

com. “There’s no direct tie with Apple — this is just something we’ve been concepting for the watch and may extend to other smart watches.”

The watch bands, will be 3D printed in Everlast (nylon) material using 3D Systems’ Selective Laser Sintering (SLS) machines, and they will be available exclusively on Cubify. As you can see in the photos provided, the watch bands certainly have a unique look to them.

Some more of the 3D printed Apple Watch Bands – coming soon!

We are told that these watch bands are still in the “concept phase” so we can expect the designers at FreshFiber to make some more adjustments after today’s official unveiling. As for pricing, there has been nothing set in stone as of yet, but Hoyt tells us that they will probably be priced somewhere between their Freshfiber phone cases and the Nooka watches — $40 – $99 depending on the chosen pattern and particular material used.

Undoubtedly 3D printing will play a major role in the future of the Apple watch.![]() We expect to see more companies bringing custom Apple Watch bands to market in the near future. For now though, it appears as though 3D Systems and FreshFiber are ahead of the curve. The Apple watch will be available for pre-order starting on April 10, with shipments beginning on April 24. It should be interesting to see if 3D Systems will have these available in time for shipments as well.

We expect to see more companies bringing custom Apple Watch bands to market in the near future. For now though, it appears as though 3D Systems and FreshFiber are ahead of the curve. The Apple watch will be available for pre-order starting on April 10, with shipments beginning on April 24. It should be interesting to see if 3D Systems will have these available in time for shipments as well.

What do you think about these 3D printed Apple Watch bands? Discuss in the FreshFiber Apple Watch Band forum thread on 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printed apple watch bands • 3d systems • apple event • apple watch • apple watch bands • apple watch event • apple watch release date • cubify • customize apple watch • ddd • freshfiber • tim cook

Please enable JavaScript to view the comments powered by Disqus.

Freshfiber presents 3D printed Apple Watch bands in three contemporary styles » 3D Printing Media Network

Stay up to date with everything that is happening in the wonderful world of AM via our LinkedIn community.

Like a phone case, which dresses up your smartphone and sets it apart from those around you who share the same hardware, a fun watch band for the Apple Watch lends a sense of personality and style to the increasingly popular wearable device. The latest Apple Watch bands to catch our eye are part of a 3D printed collection by Dutch designer Matthijs Kok and sold under the Freshfiber brand.

As a designer, Kok came onto our radar earlier this year thanks to his 3D printed Fold Case for the iPhone X. At the time, the up-and-coming designer promised more products were on the horizon and we are happy to say that he recently delivered on that promise.

The new Freshfiber Apple Watch band collection comprises of three 3D printed band designs—Pulse, Obsidian and Aurora—each inspired by a different natural element. The three Apple Watch band styles come in a variety of sizes and colours to best fit (and suit) the wearer. The innovative and visually striking watch bands are all made entirely out of 3D printed nylon and integrate a flexible coil structure that ensures flexibility, lightweight and, overall, comfort.

The three Apple Watch band styles come in a variety of sizes and colours to best fit (and suit) the wearer. The innovative and visually striking watch bands are all made entirely out of 3D printed nylon and integrate a flexible coil structure that ensures flexibility, lightweight and, overall, comfort.

Kok describes the structure of the 3D printed products on his website, saying: “A flat strip of material helix coiled into a flattened spiral forms the basis of Freshfiber’s new Apple Watch Band Collection. By taking the semi-rigid nylon material and wrapping it into a helical spring, the material is set into a versatile material with structural build, making it flexible yet sturdy with memory to return and retain its shape. The outside surface of the strip is decorated with delicate pattern designs, offering a variety of designs to complement your style. The nylon band wraps elegantly and comfortably around the wrist.”

The Apple Watch bands also integrate a 3D printed clasp mechanism which makes removing the watch easy for wearer and doesn’t compromise the product’s overall aesthetic. That is, the clasp is hidden underneath the subtle Freshfiber logo and utilizes a simple press-and-release technique to be unfastened.

That is, the clasp is hidden underneath the subtle Freshfiber logo and utilizes a simple press-and-release technique to be unfastened.

In terms of the three different watch band designs, the first model, Pulse, is based on a waveform structure that evokes “an undulating landscape of fluid lines.” The Obsidian watch band, as the name implies, is inspired by a type of igneous rock that is formed by the rapid cooling of viscous lava.

Obsidian Pulse Aurora“All all round landscape of interlinking fractiles tesselate to form a surface of obsidian facets,” Kok elaborates. “The landscape gradually evolves from delicate shards on the sides to larger facets in the center. This results in an intriguing gradient pattern, delivering a luxurious, sophisticated style to the Apple Watch.”

The last design, Aurora, was inspired by the curving and rhythmic lights of Aurora Borealis (aka the Northern Lights). The design juxtaposes the 3D printed nylon curves with negative space for a eye-catching, highly contemporary effect.

As mentioned, the 3D printed Apple Watch bands come in a range of sizes and colours, including black, grey, brown, blue and red (all matte). Available for purchase via Freshfiber’s online store, the watch band’s are retailing for €37.15 and are compatible with Apple Watch Series 1, 2, 3 and 4.

Related Articles

Back to top button

How to 3D print your own watch・Cults

3D printing technology has revolutionized the creation of many things, including watches. Yes, now you can design your own watch and 3D print it. Thanks to this, you can personalize the watch and decide how colorful, simple or complex it looks. You can now create your own clock at home.

Wristwatch is one of the oldest and most popular watches. This Garmin Instinct review post tells us that a wristwatch is not only a fashion statement, but also a very useful piece of your wardrobe. If you know how to design your own watch, you can easily match it to your outfit and lifestyle.

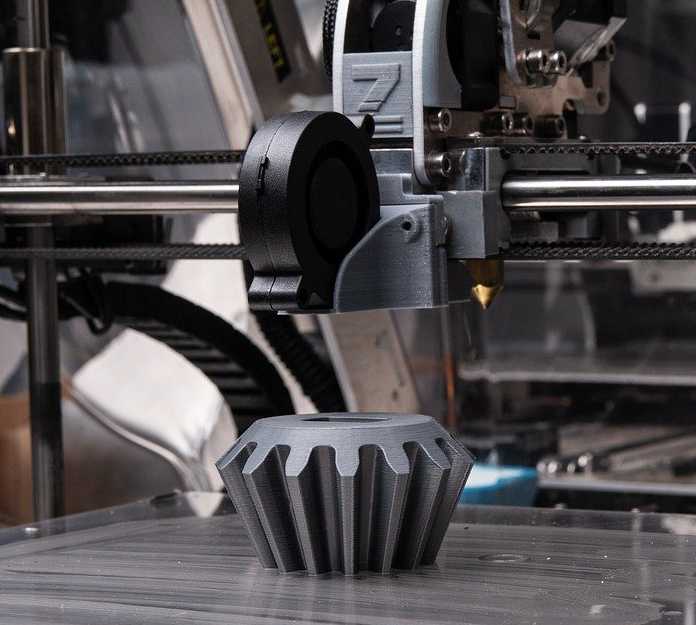

To create this watch, you will need some tools, including a 3D printer, a computer, a soldering iron, clockwork parts, and a small screwdriver.

Here's how to make your own watch with a 3D printer:

The first step is to design the basic look of the watch. This includes the type of dial, the material of the strap, the bottom of the case, and other small details. You can come up with the design yourself, download free files from the Internet, or outsource it to a professional design company. If you choose to work on the design yourself, you can proceed to the next step, which is choosing the type of 3D printing software you will use for the process.

CAD software allows you to design clocks simply by using CAD drawing tools and features including animated models. If you are new to clock design, you can learn how to design clocks with this software. The learning curve isn't too steep, but you'll have to spend time getting familiar with the various controls and features.

You can also download ready-to-print files from the Internet if you're not so picky about clock design.

Now that you have your design and a CAD drawing program, it's time to get your design onto paper. This step may seem tedious, but it will be worth it when you see the finished product. If you like to design your own, you might want to consider making your own printed clock.

The next step in creating a 3D printed clock is to print your design on a 3D printer. For best printing results, make sure you are using filament that comes with a high quality surface finish, and then set your printer settings to the highest resolution. Also, make sure the outer cases print with support. Printing the remaining parts without support is not difficult. If you're printing at 60mm/s, it should take 3.5 hours to print the parts.

Before assembling the watch, it is necessary to polish the printed parts. Start by removing any support materials you have used. If you don't have a grinder, you can do it by hand. If surface defects remain as a result of printing, you can use a specialized putty, let it dry, and then sand it again to smoothness.

If surface defects remain as a result of printing, you can use a specialized putty, let it dry, and then sand it again to smoothness.

If you want to coat the watch, apply one or two coats of primer and then sand the dry primed parts with 600+ grit sandpaper. With a slightly damp cloth, wipe the sanded parts and remove dust. Then you can apply two or three coats of paint. You can choose between standard spray paint or airbrush. Let the paint dry and apply a clear coat.

The last step in making your own 3D printed watch is assembling the watch. To do this, you will need some type of plastic tube, wire, or needle. Depending on the design of the watch, you will also need an adhesive that will allow you to keep the design intact and allow you to add details if you wish. Before assembling the clock, make sure that all the parts line up correctly and that the screws are as tight as possible.

Final Thoughts

Making your own watch has never been easier with this new technology. If you love customizing the look of your watch to suit your outfit and lifestyle, now you can do it with a design program and a 3D printer. If you're curious about what else you can do with a 3D printer, check out the numerous videos and tutorials online.

If you love customizing the look of your watch to suit your outfit and lifestyle, now you can do it with a design program and a 3D printer. If you're curious about what else you can do with a 3D printer, check out the numerous videos and tutorials online.

This page has been translated using machine translation. Suggest the best translation

Collection of printed straps for Apple Watch / 3d printing / 3Dmag.org

Recently, Freshfiber has merged the worlds of fashion and industrial design with beautiful, flexible, printed Apple Watch bands. The collection is an intriguing combination of three eye-catching products, offering many different shapes and shades that complement people's individual style. Made entirely of nylon, the watch bands have a nice fit and are light on the wrist.

By the way, if you are interested in watches and bracelets with the most accurate pedometer, then I recommend that you look at the full rating of 2021. From the article you will learn the detailed characteristics of each device, price, pros and cons, as well as general recommendations and specific tips.

From the article you will learn the detailed characteristics of each device, price, pros and cons, as well as general recommendations and specific tips.

With a complex interplay between form, space and practicality, bracelets are designed with sensitivity in mind. Each watch band comes in five sizes, compatible with 38/40/42/44mm Apple Watch of all 5 series, and has a printed clasp that makes it easy to change in just a few seconds. Combining form and function, the zipper is hidden and integrated with the Freshfiber logo. Both ends of the bracelet merge seamlessly with each other so that the lock does not disturb the decorative graphic element of the object. An innovative snap closure provides a snug, seamless fit around your wrist, and the straps themselves can be released with a simple press of the logo.

By taking a semi-rigid nylon material and wrapping it in a coil spring, the guys gave it flexibility while leaving it with the strength and memory to bounce back and keep its shape. The outer surface of the strip is decorated with a delicate pattern that will complement your style. The collection comes in three unisex designs and is available in a variety of colors.

The outer surface of the strip is decorated with a delicate pattern that will complement your style. The collection comes in three unisex designs and is available in a variety of colors.

1 design - Pulse.

Waveform The Pulse Watch Band consists of fifty-one differently shaped pieces that contract and expand in a vertical array. Their smooth movement creates an undulating landscape of flowing lines pulsing in gentle rhythm. Its geometry melds into an intriguing shape, creating a comfortable presence on the wrist.

2 design - Obsidian.

The name "Obsidian" comes from a type of volcanic rock that forms as a result of the rapid cooling of viscous lava. The circular landscape of interlocking pieces is tessellated, forming a surface of obsidian facets. The landscape gradually changes from thin fragments on the sides to larger facets in the center. The result is an intriguing gradient pattern that lends the Apple Watch a luxurious, sophisticated style.

3 design - Aurora.