3D printing food nasa

3D Printing: Food in Space

Text Size

3D Printing: Food in Space

[image-62]

[image-78]

[image-94]

NASA and a Texas company are exploring the possibility of using a "3D printer" on deep space missions in a way where the "D" would stand for dining.

NASA has awarded a Small Business Innovation Research (SBIR) Phase I contract to Systems and Materials Research Consultancy of Austin, Texas to study the feasibility of using additive manufacturing, better known as 3D printing, for making food in space. Systems and Materials Research Consultancy will conduct a study for the development of a 3D printed food system for long duration space missions. Phase I SBIR proposals are very early stage concepts that may or may not mature into actual systems. This food printing technology may result in a phase II study, which still will be several years from being tested on an actual space flight.

As NASA ventures farther into space, whether redirecting an asteroid or sending astronauts to Mars, the agency will need to make improvements in life support systems, including how to feed the crew during those long deep space missions. NASA's Advanced Food Technology program is interested in developing methods that will provide food to meet safety, acceptability, variety, and nutritional stability requirements for long exploration missions, while using the least amount of spacecraft resources and crew time. The current food system wouldn't meet the nutritional needs and five-year shelf life required for a mission to Mars or other long duration missions. Because refrigeration and freezing require significant spacecraft resources, current NASA provisions consist solely of individually prepackaged shelf stable foods, processed with technologies that degrade the micronutrients in the foods.

Additionally, the current space food is selected before astronauts ever leave the ground and crew members don't have the ability to personalize recipes or really prepare foods themselves. Over long duration missions, a variety of acceptable food is critical to ensure crew members continue to eat adequate amounts of food, and consequently, get the nutrients they need to maintain their health and performance.

NASA is funding this phase I six-month $125,000 study on 3D printing of foods to determine the capability of this technology to enable nutrient stability and provide a variety of foods from shelf stable ingredients, while minimizing crew time and waste. NASA selected this proposal because the research team, subcontractors and consultants included premier food rheology and flavor expertise that would be required for a novel product development system. The work plan for this feasibility study also was well laid out and the technology offers the potential to meet some of the food requirements using basic food components for long duration missions.

NASA recognizes in-space and additive manufacturing offers the potential for new mission opportunities, whether "printing" food, tools or entire spacecraft. Additive manufacturing offers opportunities to get the best fit, form and delivery systems of materials for deep space travel. This's why NASA is a leading partner in the president's National Network for Manufacturing Innovation and the Advanced Manufacturing Initiative.

3D printing is just one of the many transformation technologies that NASA is investing in to create the new knowledge and capabilities needed to enable future space missions while benefiting life here on Earth.

Systems and Materials Research Consultancy proposal abstract is available online at http://sbir.gsfc.nasa.gov/SBIR/abstracts/12/sbir/phase1/SBIR-12-1-h22.04-9357.html?solicitationId=SBIR_12_P1

› Back To Top

Image Token:

[image-47]

Space food product development.

Image Token:

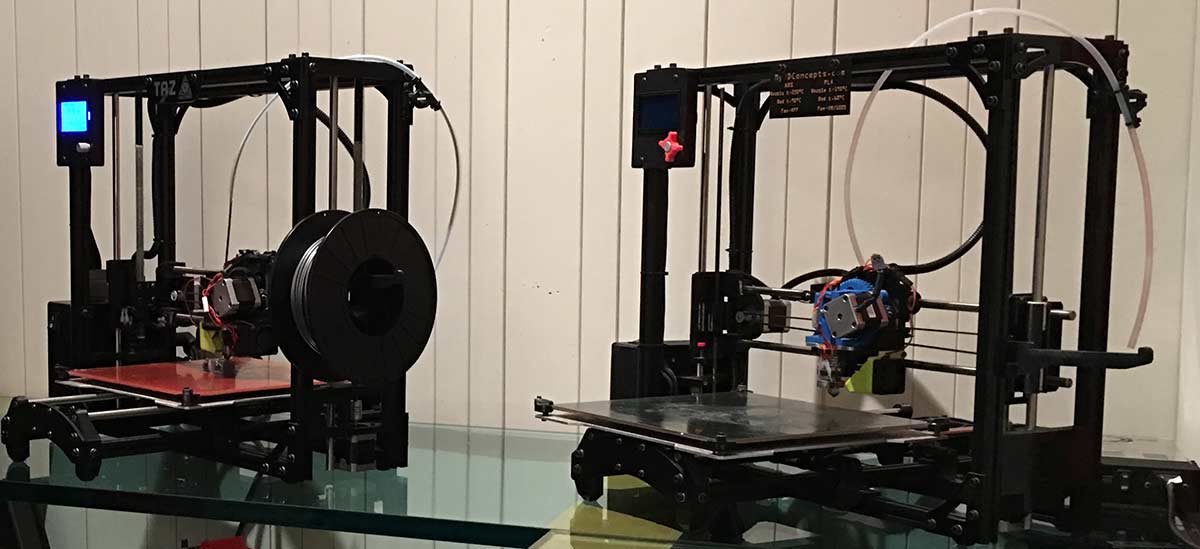

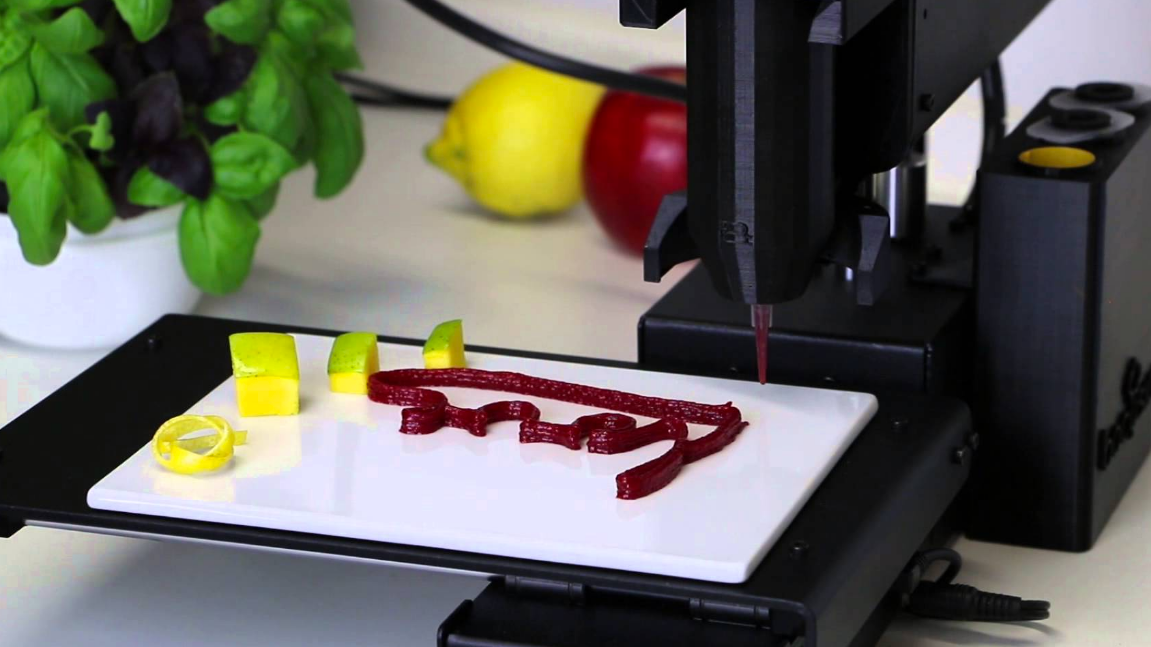

[image-62]

Food tasting session in the Habitability and Environmental Factors Office at NASA's Johnson Space Center.

Image Token:

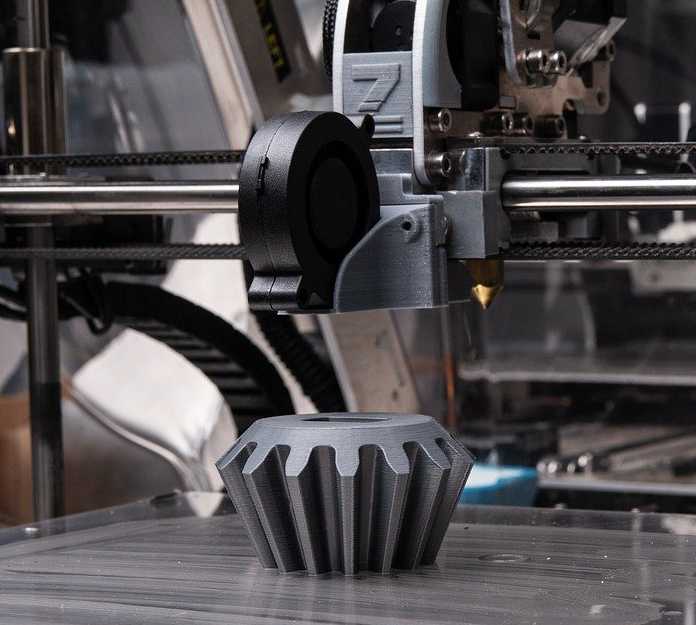

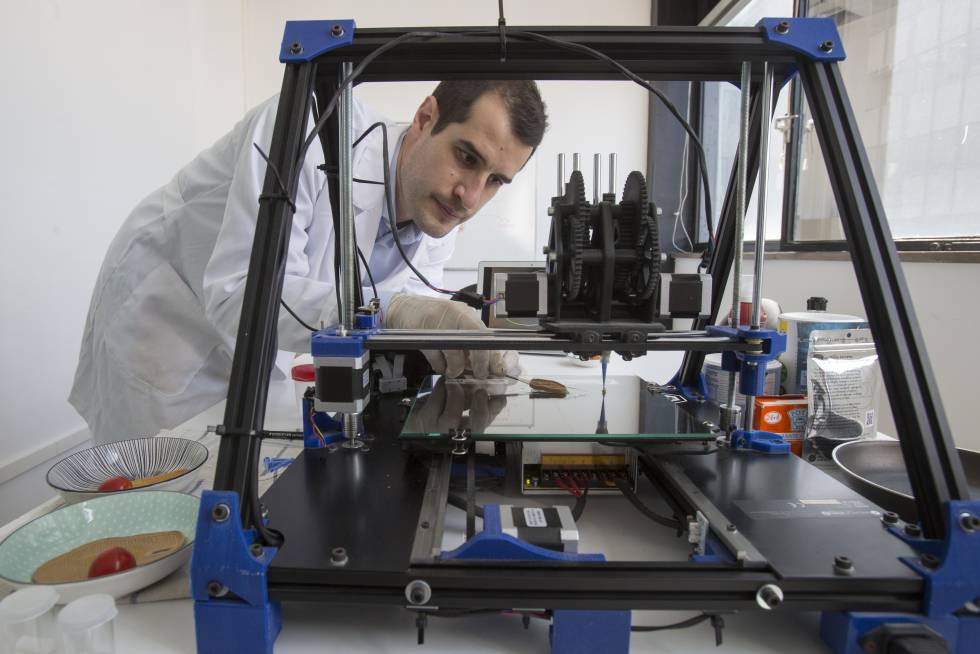

[image-78]

Expedition 26 and STS-133 crew members share a meal in the Unity node of the International Space Station.

Image Token:

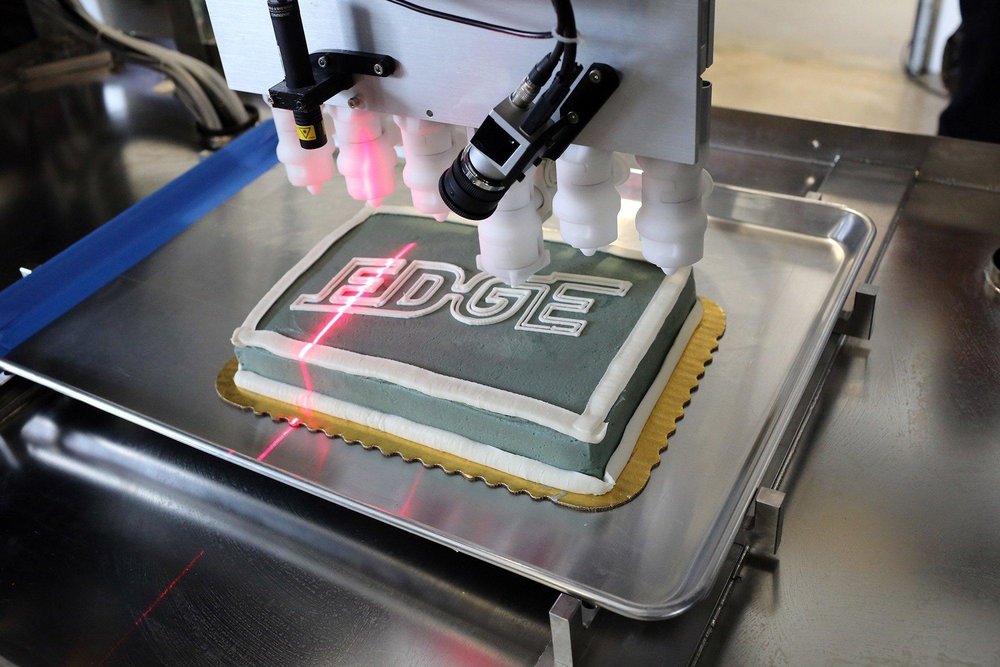

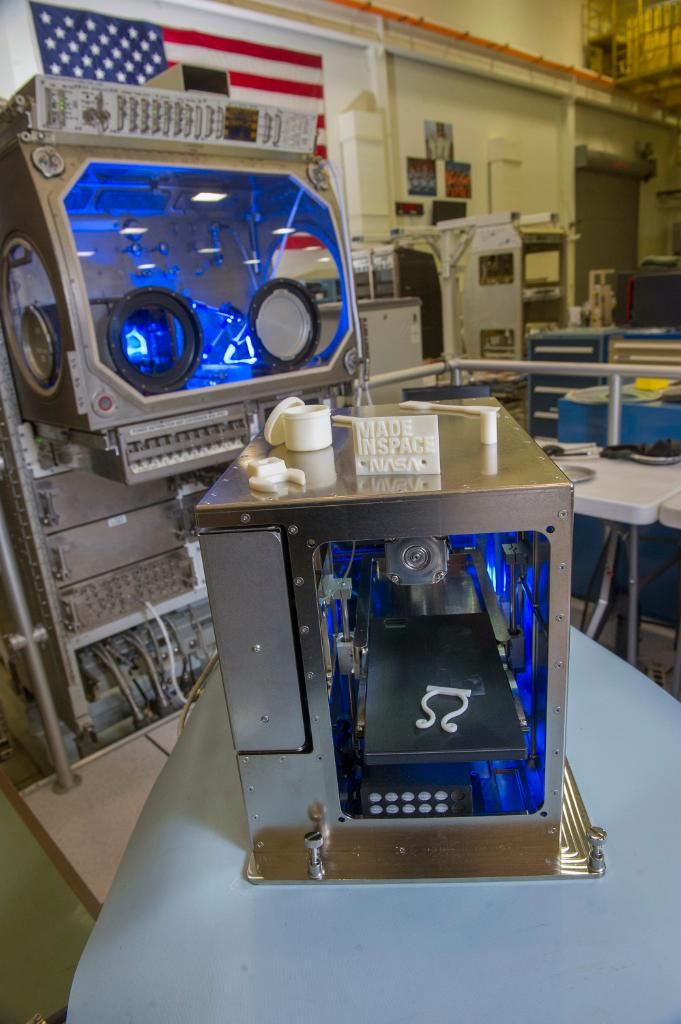

[image-94]

Arrival of fresh food and supplies delivered on the International Space Station.

Image Token:

[image-110]

Deep-Space Food Science Research Improves 3D-Printing Capabilities

NASA Technology

Crew health is critical to any successful mission, and maintaining astronauts’ nutrition gets harder the farther they get from Earth and any chance of a resupply mission. A crewed mission to Mars, for example, will have to pack food for up to five years in space. The food must stay as fresh as possible, provide precise amounts of needed nutrients, create as little trash as possible, and be appetizing enough for the crew to keep eating it.

A crewed mission to Mars, for example, will have to pack food for up to five years in space. The food must stay as fresh as possible, provide precise amounts of needed nutrients, create as little trash as possible, and be appetizing enough for the crew to keep eating it.

NASA currently supplies the International Space Station (ISS) with individually wrapped, shelf-stable dishes, many of which simply require heating in the ISS food warmer. Space station astronauts can also choose from a variety of single-serving, freeze-dried side dishes and beverage packets that require hot or cold water be added. But these options are designed to last only six months in space, where food refrigeration would be an inefficient use of precious resources. The meals take up storage space before they’re eaten, and their packaging then becomes waste.

In its continuing search for new ways to provide nutrients and variety to astronauts on long-duration missions, NASA in 2013 awarded a Small Business Innovation Research (SBIR) contract to an Austin, Texas-based company with a novel idea. Systems and Materials Research Corporation (SMRC) proposed building food from scratch with a 3D printer that could deliver starch, protein, and fat, creating properly textured edible structures that would be supplemented with micronutrients, flavor, and aroma delivered by inkjet technology.

Systems and Materials Research Corporation (SMRC) proposed building food from scratch with a 3D printer that could deliver starch, protein, and fat, creating properly textured edible structures that would be supplemented with micronutrients, flavor, and aroma delivered by inkjet technology.

Unflavored macronutrients like protein and starch would be stored as dry powders and fed directly to the 3D printer, where oil or water would be mixed in at the printhead. The micronutrients and flavors, stored in packets as liquids or pastes, would then be delivered by inkjet.

These nutrients, even in powder form, break down over time, so NASA’s food scientists needed a way to deliver precise amounts of nutrients, accounting for the inevitable degradation. Adding too much could result in nutrient toxicity, while too little could mean deficiency.

Technology Transfer

Anjan Contractor, then a senior engineer at SMRC, was behind the company’s proposal. The intent was to eventually provide astronauts with precise, personalized, 3D-printed nutrition in microgravity, where crew time is limited and cooking is not an option. The connection was natural for Contractor, whose educational background is in mechanical engineering, with a focus on additive manufacturing, robotics, automation, and some software development.

The connection was natural for Contractor, whose educational background is in mechanical engineering, with a focus on additive manufacturing, robotics, automation, and some software development.

As with most Phase I SBIR projects, the SMRC proposal was just an idea in its very early, conceptual stages. With the NASA funds, Contractor and his colleagues successfully developed a system capable of printing some basic foods from powdered nutrients, oil, and other liquids.

When Phase II SBIR funds to improve the nutritional components didn’t immediately follow, Contractor started to think about other applications for 3D food printing. It seemed unlikely that earthbound consumers would be interested in foods derived from powders, so he turned his attention to fresh ingredients instead. He began working on a 3D printer that could put together customized pizzas, with traditional (or even gluten-free cauliflower) dough, sauce, cheese, and toppings, one at a time. Pizza was a natural fit for 3D printing, which builds things layer by layer.

“It was basically the work I did for the NASA deep-space missions that led to this idea,” Contractor says. “Out of that knowledge and technology, I made my first prototype at home.”

In 2016, he founded his own company, BeeHex, with the initial strategy of traveling around with the prototype doing tech demos—and selling the results to people for lunch. After one such event—a football game at his alma mater, Ohio State University—local media picked up the story, including a front-page story the next day in The Columbus Dispatch titled “3D Printer Promises to Change Way Food Is Made.”

That story drew BeeHex’s first seed funding—nearly $1 million from the owner of a restaurant chain who saw endless applications for the technology, from breakfast bars to confections and baked goods, in addition to pizza.

Benefits

“Since then, we’ve come a long way,” Contractor says. He moved BeeHex to Columbus, Ohio, and began working on a production-level prototype of his machine that could be customized for different tasks.

For one thing, he adapted it to decorate cookies and cakes. While BeeHex isn’t the first to use 3D printing technology to make food and decorate cakes and confections, Contractor says his approach was informed by his work for NASA, through SMRC.

The BeeHex printer, dubbed Chef 3D, can create protrusions and texture—the ribbon on the edge of a cake, a flower, or seasonally themed cookies, for example—designs that traditionally require skilled cake decorators.

BeeHex is trying a variety of business models. One route is a stand-alone machine that bakers can use to design on-demand confections. The company deploys the machine at minimal cost to bakers and charges only for the duration of use.

“We will have one in a popular cookie shop in Columbus,” Contractor says. “Any customer can go, select a shape, print their cookie, and right there get a fresh customized cookie on the spot.”

BeeHex has other 3D-printed food technology in the pipeline as well. For example, Contractor is working on a recovery bar machine that can personalize a breakfast or late lunch nutrition bar depending on a person’s individual needs, such as genetics, metabolism, and blood markers.

“We are trying to connect it to physiological data like heart rate, calories burned, hydration levels,” says Contractor, who is in talks with Columbus-area gyms about hosting such a device. “Right after a workout, people can get a personalized bar that covers 30 percent of daily recommended nutrition values.”

The breakfast bar got a boost from research BeeHex is working on with the U.S. Army. “With that project, we collect the personal profile of soldiers—genetics, lactose intolerance or a gene presence that may trigger it, diabetes, physical activity over the last seven days,” Contractor says. “Then we make the recovery bar.”

Even with so much potential on Earth—BeeHex has two patents pending for its Chef 3D device—Contractor believes the truly revolutionary 3D-printing developments will occur back in space, where human tissue may one day be printed in layers without concern that the bottom layers will get squashed by the top ones.

“I’m very confident that this is going to happen sooner or later,” Contractor says. “Tissues and organs needed for drug discoveries or human parts can be grown in space. It could be 30 or 60 or 100 years, but it’s very likely this will happen. The foundation is in the 3D printing—the same thing we’re doing.”

“Tissues and organs needed for drug discoveries or human parts can be grown in space. It could be 30 or 60 or 100 years, but it’s very likely this will happen. The foundation is in the 3D printing—the same thing we’re doing.”

NASA Funds 3D Food Printer ?

- Food

- Technologies

- Cosmos

- CANCEL

NASA's ANJAN Contractor engineer (Anjan Contractor) print" food, reports Quartz.

The printer will prepare food from ingredients stored in powder form in replaceable cartridges. By mixing the components in different proportions and adding water or oil, you can get different dishes. The shelf life of a refilled cartridge is up to thirty years.

The shelf life of a refilled cartridge is up to thirty years.

The company's grant application states its intention to use "advanced inkjet printing technologies" to create a "complete power system for long-range missions beyond Earth orbit." The device will mix nutrients such as starch, protein and fats, form a three-dimensional structure of the product and add flavors to the dishes. According to NASA experts, the use of the printer will help in solving the nutritional problems of astronauts during multi-month space flights, for example, to Mars.

“Ingredients stored as powders will be contained in dry, sterile containers and fed directly to the printer. In the print head, these elements will be combined with water or oil in predetermined ratios to minimize waste and product spoilage,” the application says. The ability to quickly prepare different dishes will make it possible to diversify the menu of astronauts, taking into account their diet, preferences and dietary restrictions due to illness.

The first product that NASA's funded printer can "print" is pizza. This dish was chosen for its simplicity of structure and ingredients, making it easy to create in layers.

The printer will use open source software. This will allow enthusiasts to improve the device, as well as to exchange recipes for "printed" dishes.

Cornell University 3D printer prints all sorts of food:

Anjan Contractor of Texas-based Systems and Materials Research Corporation received a NASA grant to build a prototype "3D food printer" for printing chocolate. The hardware of the device is based on the RepRap 3D printer, the schemes of which are distributed under the "free" GNU license.

Other researchers have suggested using 3D printing technology for cooking. So, the developers of the Fab@Home 3D printer believe that hydrogels with flavoring additives can be used as “consumables” for “printing” food.

Sources:

http://lenta.ru/news/2013/05/21/nasa/

http://www. gazeta.ru/science/2013/05/22_a_5332517.shtml 3d printing, nasa, food, perspective, technology

gazeta.ru/science/2013/05/22_a_5332517.shtml 3d printing, nasa, food, perspective, technology

Subscribe

-

Potential and kinetic energy of asteroids - a new source of energy for spacecraft air storage

Martian base using new technology. Part 3

Original taken from alboros in Stages of building a Martian base using new technology. Part 3 The triad of colonies of Phobos, Deimos and the Moon ...

-

Dancer Bus, Lithuania

Original taken from subbotazh in Dancer Bus, Lithuania A modified trolleybus that was created by the Klaipeda company Vėjo projektai,… /igrick/pic/000r1edq

-

Potential and kinetic energy of asteroids - a new source of energy for spacecraft air storage

Original taken from alboros в Potential and kinetic energy of asteroids – a new source of energy for spacecraft-accumulators of air Brief…

-

Stages of building a Martian base using new technology.

Part 3

Part 3 Original taken from alboros in Stages of building a Martian base using new technology. Part 3 The triad of colonies of Phobos, Deimos and the Moon…

-

Dancer Bus, Lithuania

Original taken from subbotazh in Dancer Bus, Lithuania Modified trolleybus, which was created by the Klaipeda company Vėjo projektai,…

NASA will fund a 3D food printer!

Archive

Follow author

Follow

Don't want

"I, like many economists, believe that it is not possible to feed 12 billion people today," says Anjan Contractor, senior mechanical engineer at Systems and Materials Research Corporation (SMRC) in Austin, Texas. "Thus, we must change our perception of what we see and used to call food." The contractor's company, Systems & Materials Research Corporation (SMRC), recently received $125,000 NASA grant - NASA Small Business Innovation Research (SBIR) program - to further develop a full-featured 3D printer to print nutritious food products for astronauts on long-duration space missions.

Over the years, SMRC has been involved in a wide range of projects to develop innovative photo and 3D printing technologies, food 3D printing is one of their cutting-edge developments. The company recently demonstrated its achievements in this industry on a laboratory scale. Anjan, a licensed professional engineer and Six-Sigma Green Belt with 13 years of experience in research, prototyping and design, sees the future of 3D printers and people creating culinary delights from common powdered ingredients in every kitchen. Soon, he believes, everyone will be eating "foods with individualized nutritional composition, and the process of preparing them will require only the use of a printer with the right cartridge of powder and oil, which will be available at the nearest grocery store." If the cartridge runs out, it will need to be returned to the store. Since the cartridges will only contain powder, any ingredients containing the correct organic molecules can be included in its composition.

Over the years, SMRC has been involved in a wide range of projects to develop innovative photo and 3D printing technologies, food 3D printing is one of their cutting-edge developments. The company recently demonstrated its achievements in this industry on a laboratory scale. Anjan, a licensed professional engineer and Six-Sigma Green Belt with 13 years of experience in research, prototyping and design, sees the future of 3D printers and people creating culinary delights from common powdered ingredients in every kitchen. Soon, he believes, everyone will be eating "foods with individualized nutritional composition, and the process of preparing them will require only the use of a printer with the right cartridge of powder and oil, which will be available at the nearest grocery store." If the cartridge runs out, it will need to be returned to the store. Since the cartridges will only contain powder, any ingredients containing the correct organic molecules can be included in its composition. This system will bring an end to food waste, as the powder in Anjan's device will have the ability to retain its beneficial properties for 30 years. NASA Grant was awarded to a Contractor to develop a food printing system for astronauts on long-duration space missions such as Mars. "Long-distance space missions require products with a shelf life of more than 15 years," says Anjan. "Our job is to create carbohydrates, proteins, micro and macro elements in the form of a powder. We extract moisture from products, after which their shelf life reaches 30 years." And yet, which dish is best for 3D printing? - Pizza! "Because each layer of the product can be printed separately, therefore the print head can work with one ingredient at a time." Work on the pizza printer is scheduled to begin within the next two weeks. The basis of the pizza printer was a device for printing chocolate, the project of which from the developer RepRap Mendel is in the public domain.

This system will bring an end to food waste, as the powder in Anjan's device will have the ability to retain its beneficial properties for 30 years. NASA Grant was awarded to a Contractor to develop a food printing system for astronauts on long-duration space missions such as Mars. "Long-distance space missions require products with a shelf life of more than 15 years," says Anjan. "Our job is to create carbohydrates, proteins, micro and macro elements in the form of a powder. We extract moisture from products, after which their shelf life reaches 30 years." And yet, which dish is best for 3D printing? - Pizza! "Because each layer of the product can be printed separately, therefore the print head can work with one ingredient at a time." Work on the pizza printer is scheduled to begin within the next two weeks. The basis of the pizza printer was a device for printing chocolate, the project of which from the developer RepRap Mendel is in the public domain. The main principle of its work is the printing of dough, which at the same time is baked on a heated plate at the bottom of the printer. Then a "tomato layer" is printed, "which is also initially in the cartridge as a powder and then mixed with water and oil," says Anjan. Finally, the last “protein layer” is applied, the basis of which can be proteins of both animal and dairy or vegetable origin. The contractor also plans to make the design of his device public so that anyone can borrow his recipes, or find their own creative use for the device. The ultimate goal of the project is to turn the system for printing products into a device that anyone can license and use as the basis of a new business. Undoubtedly 3D printed food is a very interesting idea. If the project is successful, then such 3D printers will not only provide food for astronauts during long missions, but will also become an indispensable item in the kitchen. Developing, technology can take root both in space and on earth, where people will need food.

The main principle of its work is the printing of dough, which at the same time is baked on a heated plate at the bottom of the printer. Then a "tomato layer" is printed, "which is also initially in the cartridge as a powder and then mixed with water and oil," says Anjan. Finally, the last “protein layer” is applied, the basis of which can be proteins of both animal and dairy or vegetable origin. The contractor also plans to make the design of his device public so that anyone can borrow his recipes, or find their own creative use for the device. The ultimate goal of the project is to turn the system for printing products into a device that anyone can license and use as the basis of a new business. Undoubtedly 3D printed food is a very interesting idea. If the project is successful, then such 3D printers will not only provide food for astronauts during long missions, but will also become an indispensable item in the kitchen. Developing, technology can take root both in space and on earth, where people will need food.

-