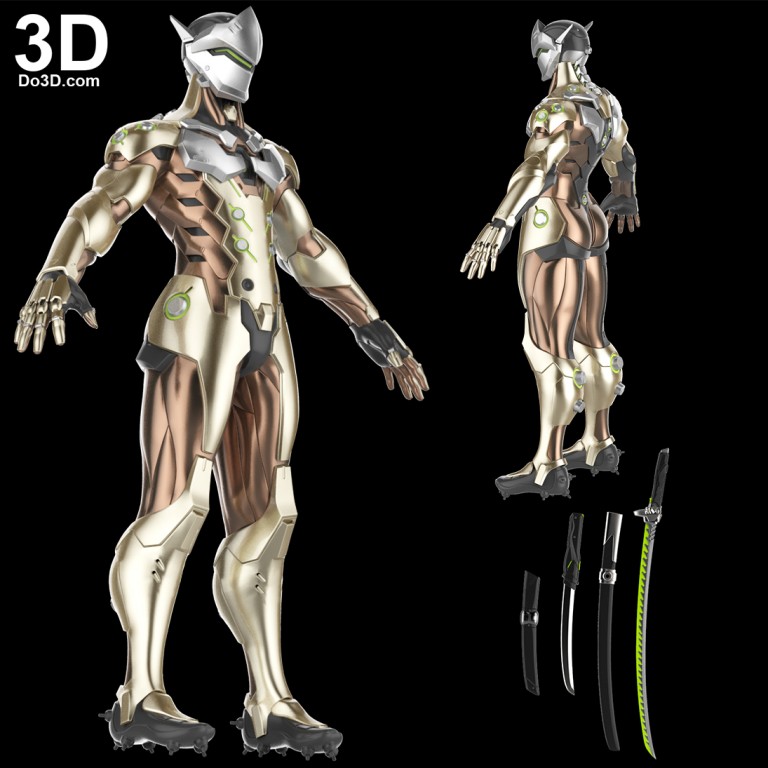

Wearable 3d printed armor

3d Printed Armor - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

Armor best 3D printer files・Cults

Skip to contentDarth Maul character Skull from star wars ready to print

€20. 12

Road Pig Kit for action figures

€15

saint seiya fenix ikki

€12.83

saint seiya poseidon

€12.19

Schürzen Brackets for StuG III/IV and Pz IV

Free

Tank And Artillery Cannons

€3.02

Justice Banner

€3.90

Watcher of Justice Nude and Normal Set x8

€19.90

Watcher of Justice Nude Set x4

€11.90

Watcher of Justice Set x4

€11.90

Bust Oracle Topless - Wings and No wings

€4.50

Bust Oracle - Wings and No wings

€4.50

Bust Oracle Topless and Normal - Wings and No wings

€6.90

Watcher of Justice D Nude and Normal

€6.90

Watcher of Justice D Nude

€3. 90

90

Watcher of Justice D

€3.90

Watcher of Justice C Nude and Normal

€6.90

Watcher of Justice C Nude

€3.90

Watcher of Justice C

€3.90

Watcher of Justice B Nude and Normal

€6.90

Watcher of Justice B Nude

€3.90

Watcher of Justice B

€3.90

Watcher of Justice A Nude and Normal

€6.90

Watcher of Justice A Nude

€3.90

Watcher of Justice A

€3.90

Real Hippogriff Set x3

€9.90

Real Hippogriff C

€3.90

Real Hippogriff B

€3.90

Real Hippogriff A

€3.90

Keeper of Justice Nude and Normal Set x8

€19. 90

90

Keeper of Justice Nude Set x4

€11.90

Keeper of Justice Set x4

€11.90

Keeper of Justice D Nude and Normal

€6.90

Keeper of Justice D Nude

€3.90

Keeper of Justice D

€3.90

Keeper of Justice C Nude and Normal

€6.90

Keeper of Justice C Nude

€3.90

Keeper of Justice C

€3.90

Keeper of Justice B Nude and Normal

€6.90

Keeper of Justice B Nude

€3.90

Keeper of Justice B

€3.90

Keeper of Justice A Nude and Normal

€6.90

Keeper of Justice A Nude

€3.90

Keeper of Justice A

€3.90

Judgment Oracles Nude and Normal Set x6

€19. 90

90

Judgment Oracles Nude Set x3

€11.90

Judgment Oracles Set x3

€11.90

Judgment Oracles C Nude and Normal

€7.90

90,000 3D printed armor, the incredible possibilities of 3D technology!Incredible 3D printed armor

Remember Melissa Angie? The same artist who creates amazing 3D printed masks, jewelry and who wowed us some time ago with incredible 3D printed armor. It seems that the excitement of society over her latest creation inspired Melissa to continue working in the same direction. Just a week ago, the artist presented the world with amazing women's armor called Sovereign Armor. Most of their elements were printed on a 3D printer. Incredible 3D-printed armor impresses with beauty and elegance.

By the way, the opinion of the general public had a significant impact on the design of the armor: despite the many positive reviews, there were many people who expressed doubts about the practicality and design of the armor. Based on these judgments, the artist decided to somewhat revise the manufacturing process. Therefore, in the next project, she took into account the actual structure of the armor, without compromising their elegant appearance.

Based on these judgments, the artist decided to somewhat revise the manufacturing process. Therefore, in the next project, she took into account the actual structure of the armor, without compromising their elegant appearance.

Melissa Angie spent over 500 hours creating Sovereign Armor, researching the structure of medieval armor, experimenting with materials and transferring the learned knowledge to a 3D armor model. The artist was assisted with 3D printing by Shapeways and completed the final finishing herself. Finished 3D printed armor has 91 separate part and equipped with LEDs for more impressiveness.

How the 3D printed armor was made

Melissa took inspiration from 15th century German gothic armor to create the armor, in particular its design features that sometimes resemble waves or ripples on water. The LEDs built into the armor give the impression that the person wearing it glows brightly, radiating "aetheric energy".

More impressive than the 3D printed armor itself, only the work done by the artist can be considered. According to Melissa herself, it was an extremely long and difficult process that paid off completely. Since the designer designed the suit for herself, there was no need to use a 3D scanner - the artist took all the measurements by hand to then use them when creating a 3D model of the armor.

According to Melissa herself, it was an extremely long and difficult process that paid off completely. Since the designer designed the suit for herself, there was no need to use a 3D scanner - the artist took all the measurements by hand to then use them when creating a 3D model of the armor.

The hardest part of the process was modeling the base armor, which is all articulated. So, 3D printed armor includes articulated gauntlets, a helmet and several moving parts below the belt. After completing the design of the base, the artist began to develop the intricate patterns that adorn the armor, as well as thin and embossed structural elements.

The next step was to check the finished 3D model for suitability for 3D printing. Immediately upon completion of this process, Melissa sent the files to the Shapeways organization, where each armor component was 3D printed from Elasto plastic. This was followed by the most time-consuming part of the work: the final processing of parts and the selection of optimal color solutions for painting the armor.

3D-printed armor in stages

First, all armor components were connected to each other and fixed with a special matte varnish, which helped to strengthen the material and fill the porous areas of the product. The 3D printed armor was then meticulously sanded using sandpaper and a special Dremel multi-tool.

When painting, the details of the items were first covered with several layers of basic black paint, then using an airbrush, the artist applied patterns with a combination of bronze, silver and turquoise paints. Melissa painted all the golden elements with a brush by hand, which took a total of about 40 hours.

The last step was to fit the LEDs into the structure and add some protruding parts. Once this process was completed, the designer fully assembled all the elements of the armor. The hinged parts were connected with fabric strips, and the fixed parts with glue, after which the 3D printed armor was fully wearable.

The finished result simply cannot leave the observer indifferent, because it demonstrates not only amazing design work, but also the incredible possibilities of innovative 3D technologies, thanks to which the most daring ideas can be brought to life.

https://skfb.ly/MI6s

Back home

World's first 3D printed training shoe comes out from under armor

We saw 3D printed shoes back in 2012. Adidas has innovated with ocean waste and some even fit your foot. Now Under Armor has created the world's first commercially available 3D printer. training shoes.

Under Armor teamed up with Autodesk to create this innovative shoe to make the shoe lightweight and supportive. The result is UA Architek, an athletic shoe that promises to be comfortable, durable and supportive.

In order for the new shoe to fit the bill, Under Armor had to use a new midsole structure. The final design uses a trellis structure, an idea they got from a computer program rather than a sports expert. During the design stages, the company consulted algorithmic systems to create structures based on desired criteria, a process known as generative design. When it came time to assemble the shoes, the task proved too difficult for existing production methods. Included is Autodesk with its Autodesk software within used to create a new stable heel.

Included is Autodesk with its Autodesk software within used to create a new stable heel.

“Traditional manufacturing processes, such as injection molding, are usually not suitable for the complex structures that result from generative design,” said Mark Davies, Senior Design Director. “3D printing does give a lot of flexibility in the production of mesh shoes – in this case, it provides more stability and cushioning than traditional models.”

But 3D printing isn't just limited to the midsole. These elements are also found in the heel and upper of the shoe, where the "Clutchfit Auxetic" design is designed to adapt to the wearer's shape and movements for a more precise fit. These new features are in addition to Under Armor's signature "Charged Foam" cushioning for comfort and responsiveness, and a thin rubber outsole for traction. The combination of all these elements results in the perfect Under Armor trainer.

Under Armor isn't the only company to incorporate 3D printing technology into their shoes.