Pc abs 3d printing

3DXMAX PC-ABS | High Performance 3D Filament

$42.00 – $168.00

4 interest-free payments with Learn More

3DXMAX® PC-ABS offers many of the advantages of PC including strength and durability, but is easier to print and offers a lower-gloss surface finish that hides layer lines and gives a professional look and feel every print.

[yith_wcwl_add_to_wishlist]

SKU: Select options above Brand: 3DXMAX® Categories: PC-ABS, PC-ABS Family

- Description

- Reviews

- Questions & Support

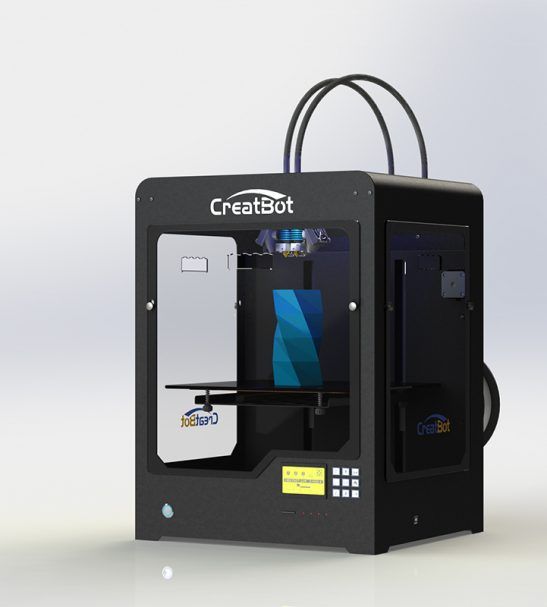

3DXMAX® PC-ABS (polycarbonate + acrylonitrile butadiene styrene) is a premium high-heat 3D printing filament. PC-ABS alloys the mechanical properties & high-heat resistance of PC with the printability of ABS and allows for the printing of functional prototypes and production parts with very fine detail and excellent surface quality. 3DXMAX® Low-Gloss PC-ABS is suitable for use in both consumer-grade and industrial FDM/FFF printers that have a heated print bed. Made by 3DXTECH® in the USA.

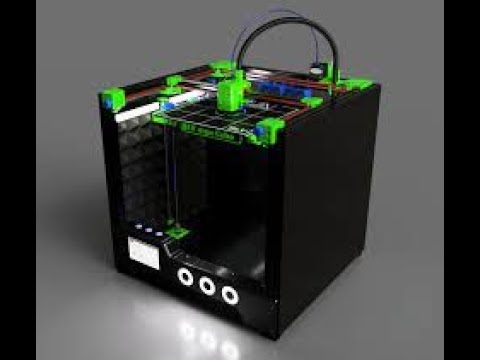

Gearbox HT2™ 3D Printer:

Print industrial-grade parts using our PC-ABS and more with the new Gearbox™ HT2 High-Temp 3D Printer.

Extruder Temp

270-290°C

Bed Temp

110-120°C

Heated Chamber

Recommended

Nozzle Specs

No special concerns

Bed Adhesion

Magigoo Bed Prep

Layer Height

No special concerns

Drying Specs

110°C for 4 hours

Supports

Works best with

X1 USM Water Soluble Support

Benefits of 3DXMAX® PC-ABS:

- Sturdy parts with durable qualities from PC and printability from ABS

- Easier to print than Polycarb, yet tougher than ABS

- Improved thermal properties, ductility, and impact resistance

- Amorphous structure giving it lower, near isotropic shrinkage

- Beautiful low-gloss surface finish helps hide layer lines and makes highly technical-looking printed parts

Filament Specifications:

1. 75mm and 2.85mm +/- 0.05mm in diameter

75mm and 2.85mm +/- 0.05mm in diameter

Recommended Print Settings:

- Extruder: 270-290°C

- Bed Temp: 110-120°C

- Bed Prep: Magigoo Bed Prep Adhesive or 3DXTECH Polyimide Tape gives us the best results

- Heated Chamber: Recommended, a chamber helps reduce warping and improves layer adhesion

- Supports: Water soluble AquaTek X1 USM works ideal for complex parts.

- Drying Instructions: 110°C for 4 hours.

Questions?

Send us a message and we'll reach out as soon as we can!

Please enable JavaScript in your browser to complete this form.Name *

Business / Organization

Email *

Phone

What can we help you with? *

Newsletter Signup

- Sign me up for the 3DXTECH newsletter

3D Printing with PC-ABS: Tips and Tricks

Tis the season to be jolly, join the Wolfpack in a fun 25 Days of Materials 3D printing countdown to Christmas and learn about 25 different materials and their unique properties! The objects to be 3D printed are part of the Advent Calendar/Christmas Tree designed by pleppik. Everyday we will be unveiling a new part of the Advent Calendar and talking about a different special 3D printing material.

Everyday we will be unveiling a new part of the Advent Calendar and talking about a different special 3D printing material.

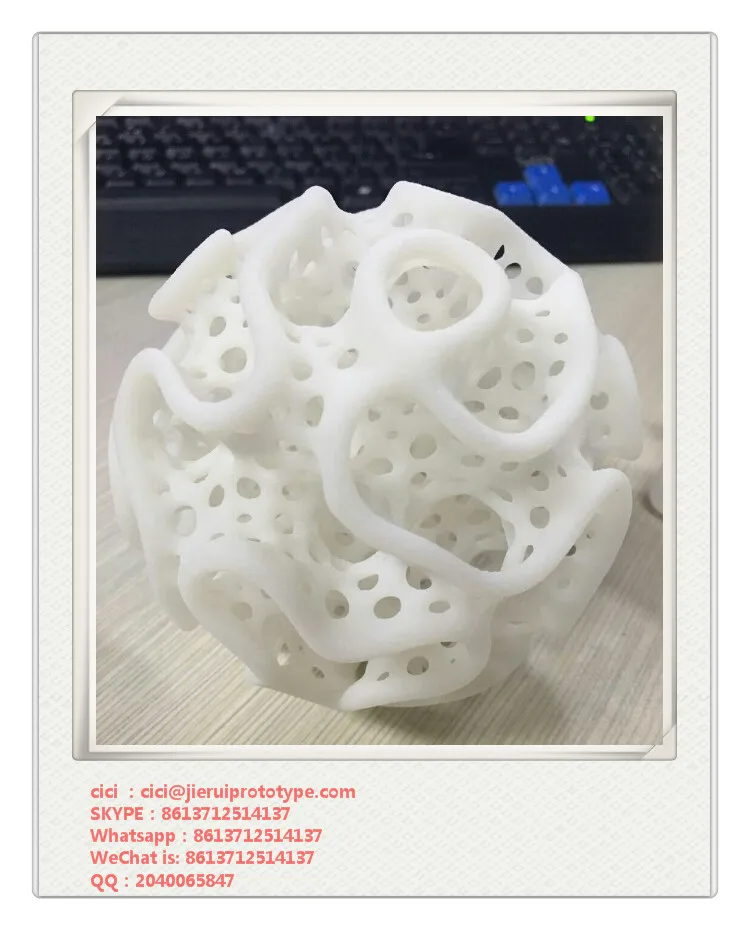

Following the Wolfpack’s 25 Days of Materials 3D printing countdown is an ”X-Wing” 3D Printed with PC-ABS. Our Polycarbonate-ABS (PC-ABS) is an incredibly tough material designed for strong, resilient parts. This unique material provides vast improvements (over standard ABS) in heat deflection, impact resistance, rigidity, and surface finish. PC-ABS is a blend of Polycarbonate and ABS plastic which combines the strength of PC with the flexibility of ABS.

Some interesting facts about PC-ABS:

- PC-ABS acts like ABS while being 3D printed. Just like many engineering thermoplastics, it will shrink when it cools down.

- Our PC-ABS filament is moisture sensitive and should be kept bagged with desiccant.

- 3D printed parts in PC-ABS are tough and durable. Parts are built tough and can be used as usable parts and functional end-use products.

- PC-ABS is widely used in automotive, electronics and telecommunications applications.

3D Printing with PC-ABS: Tips and Tricks

- Because this this filament is hygroscopic, pre-drying the filament in an oven at 85-95°C for an hour may be required for good printing.

- One of the limiting factors for the professional consumers using 3D printers is the problem with bed adhesion. Wolfbite MEGA can be applied directly to the 3D printer bed. It perfectly bonds to PC-ABS and Polycarbonate parts. After the part is complete and cool it removes easily. One coat of Wolfbite MEGA is good for up to 10 prints, without having to re-apply.

- PC-ABS prints best with the bed set at 140°C.

- Make sure to set your hot end temperature to 270° C when 3D printing with PC-ABS.

What is made with

PC-ABS?- Laptop computer cases.

- Keyboards, monitors, printer enclosures.

- Non-professional safety helmets.

- Small tractor hoods.

- Automotive instrument panel retainers.

- Portable appliances, flashlights, phones.

- Wheel covers.

Are you ready to start 3D Printing with PC-ABS? Great! You can buy some PC-ABS filament here https://airwolf3d.com/shop/pc-abs-professional-filament-2-85mm-2-2lb-186/.

More Materials To Follow!

Below is a chart to list a few of the 3D printing filaments that we will be discussing over the next 25 Days of Materials.

25 Days of Materials.

Day 1: Nylon.

Day 2: HIPS.

Day 3: Stainless Steel PLA.

Did you like this article about 3D Printing with PC-ABS and are you interested in learning more about 3D printing materials? Then sign up for our newsletter to receive your daily dose of 3D printing material knowledge – happening only in this month!

Subscribe to our

Mailing List. This entry was posted in 3D Printing Tips & Tricks, Blog, Materials and Filaments and tagged 25 Days of Materials, Wolfbite MEGA. 90,000 ABS plastic 3D printing on order at Sprint 3D!

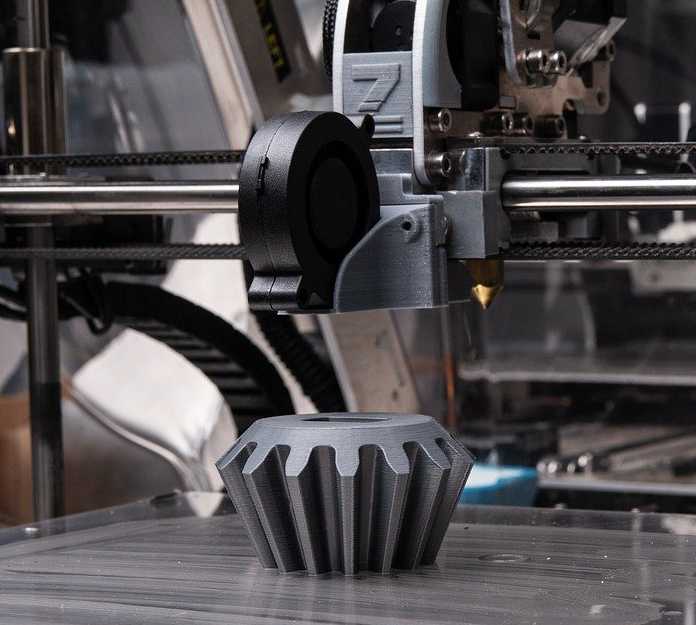

This entry was posted in 3D Printing Tips & Tricks, Blog, Materials and Filaments and tagged 25 Days of Materials, Wolfbite MEGA. 90,000 ABS plastic 3D printing on order at Sprint 3D! custom ABS plastic 3D printing is a service that allows you to create high-quality and durable prototypes and master models using FDM technology. Products from ABS, in comparison with other types of plastics, have better performance in operation. Separately, it is necessary to highlight the high physical resistance to mechanical damage and maximum protection from environmental influences. The surface of the product, after 3D printing, is smooth and shiny.

Maximum quality.

With a large industrial workshop of FDM printers, we can fulfill any order in the shortest possible time, printing batches (from one piece) of both small-sized and large-sized products.

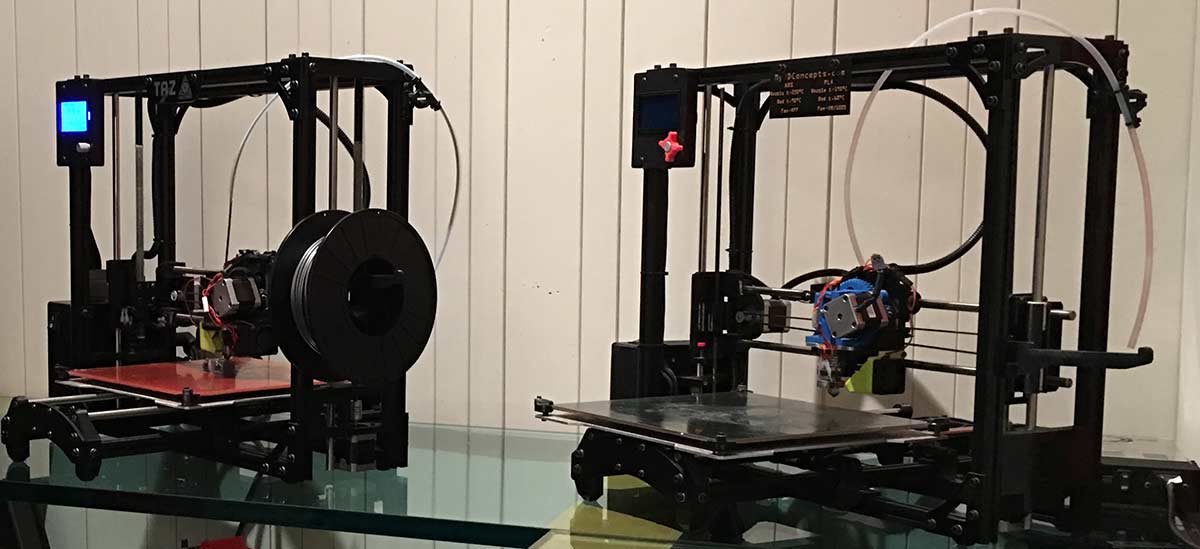

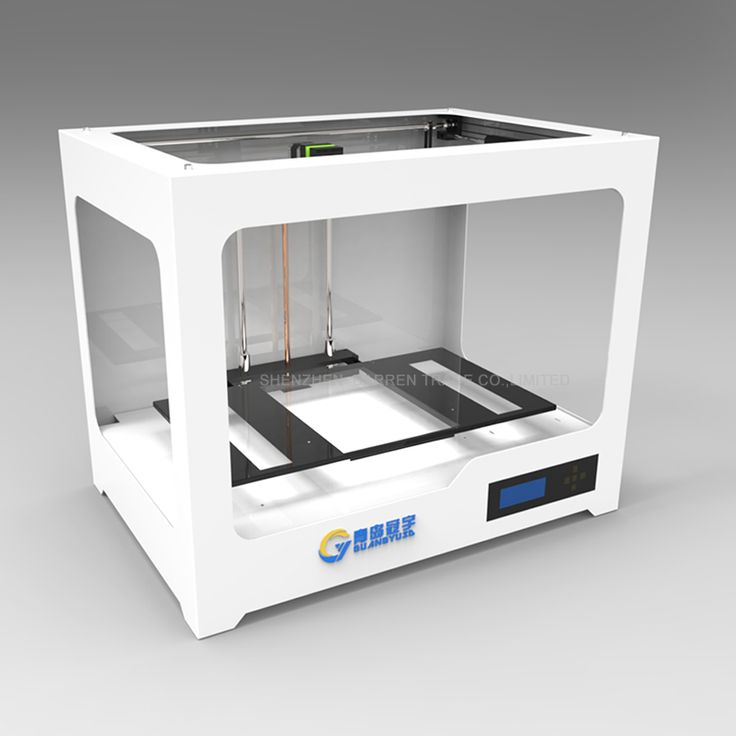

Sprint 3D has at its disposal modern 3D printers of both foreign and domestic assembly. Printing with ABS plastic takes place on equipment:

Printing with ABS plastic takes place on equipment:

Satellite, Zortrax, Hori Fobos.

3D printed ABS plastic B SPRINT 3D

3D-printing on its own industrial 3D printers

The largest working area is 500x500x800 mm

Work with high-quality plastic rods

Color of the material for a choice

Delivery throughout Russia and CIS countries

22 If the product does not meet the technical specifications, we return the money

Dimensional printing

When printing, we use only high-quality consumables (ABS plastic spools) of different colors that meet all quality standards for this type of production.

Separately, it is worth noting our staff of qualified 3D printers who have been working in the field of additive technologies for many years and fulfill orders of varying complexity.

We are fully confident in our abilities and guarantee our customers the best quality products in the shortest possible time.

ABS Applications

3D printed ABS plastic products are very popular in the fields of mechanical engineering, auto manufacturing, etc. Through the creation of working prototypes, customers can start production of final products faster while reducing initial costs manufacturing.

Our company prints boxes, cases and panels for various industrial units, electronic devices and equipment, automotive parts and much more.

Additional services

Creation of a 3D model.

If you do not have a ready 3D model, we provide 3D modeling and 3D scanning services.

Post-processing.

We use ABS plastic in different colors, however, despite the color of the final printed prototype, they will lend themselves well to coloring. If necessary, Sprint 3D offers customers the services of a professional artist to paint products.

FDM (FFF) printing is a layer-by-layer printing technology in which layers of minimal thickness can be present on final ABS products. To create a smooth surface, we use two types of services: grinding and acetone bath. The latter, in turn, makes the product as smooth as possible.

To create a smooth surface, we use two types of services: grinding and acetone bath. The latter, in turn, makes the product as smooth as possible.

Specifications

Material properties

| Tensile strength | 35 - 50 MPa |

| Terminity for bend | 52 - 95 MPa |

| The softening temperature | 90 - 120 ° C |

| Melting temperature | 240 ° C | 1.02 - 1,1,1,02 g/cm3 |

| Surface type | Matte |

Parameters 3D print

| layer thickness (surface surface) | 90 - 300 μm |

3D printing of a product with ABS plastic;

3D printing of a product with ABS plastic;