Xyzprinting nobel 1.0 sla 3d printer

XYZprinting Nobel 1.0 3D Printer review: Highly detailed prints at a high cost

The Nobel 1.0 is unlike any 3D printer I've worked with before. It's the first stereolithography 3D printer with a price low enough for general consumers, costing $1,500. (Pricing for the UK and Australia will be announced at a later date, but that converts to around £965 or AU$2,065.) Though that's hardly cheap, it's by far the least expensive SL 3D printer on the market; others can cost twice the price or even much more.

And if the price of the printer hasn't put you off yet, keep in mind that the consumables for this type of printer, namely the liquid resin, are not cheap either. The resin for the Nobel 1.0 costs $120 for 1kg (2 pounds).

In return, the Nobel 1.0 can print in extremely high detail and can print objects with overhang features that are difficult for fused-filament fabrication (FFF) printers -- which the rest of the 3D printers I've reviewed are -- to print. The Nobel 1. 0 is also compact and relatively quiet during operation.

The new SL technology doesn't make the Nobel 1.0 print quickly. In fact, most of the time it takes longer to print an object of the same physical size than do FFF printers. This is because, as an SL printer, the Nobel 1.0 always prints solid forms while FFF printers can hollow out the thick parts. And that means the printer will use up materials much faster, increasing the total cost over time.

All things considered, I really like Nobel 1.0 for the way it prints -- which is as fascinating as pulling a solid object out of a liquid container -- and its print quality. However, considering its slow print speed, and most importantly its total cost of ownership, I feel that the printer is only suitable for 3D printing enthusiasts, and not for general use. For other options that are not as cool, but are faster and more affordable, check out our recent 3D printer roundup.

The Nobel 1.0 3D printer is quite compact and comes with a light-blocking hood. Josh Miller/CNET

Josh Miller/CNETCompact design

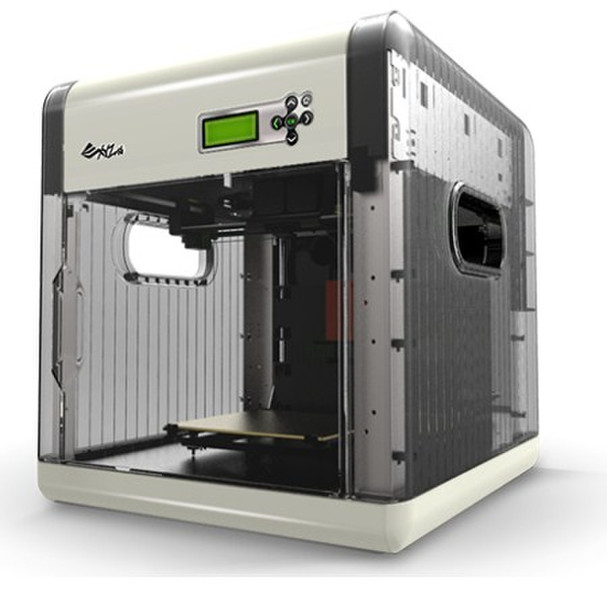

The Nobel 1.0 is compact, just about the size of a large home coffee maker. The company gives its dimensions as 11 by 13.2 by 23.2 inches (280 by 337 by 590 mm), and when I measured it myself I got similar figures.

On top the printer has a large black plastic hood that protects the print platform and the resin tank from the outside world. The printer needs to be covered up during operation (it won't work without the hood on), mostly to keep other light sources and dust from interfering with its laser beam. But when it's not running, you can remove this cover to add more resin, remove the printed object and clean up.

The printer comes already assembled. All you have to do is remove its packaging and install the included 500ml resin bottle as well as the resin build tank. It took me just a few minutes to do this thanks to the clear instructions included. During a print job, a pump will automatically fill the build tank with resin from the bottle.

The print platform is directly on top of the build tank and is attached to an arm designed to move it up and down. The build tank is made of glass and underneath it there's an ultraviolet laser beam that does the work of turning liquid resin solid. (More on how the printer works below). The print platform determines the size of objects the Nobel 1.0 can produce, which is objects of up to 5 by 5 by 7.9 inches (127 by 127 by 200 mm). This is quite large considering how compact the printer is.

Similarly to other XYZprinting 3D printers, such as the da Vinci Jr, the Nobel 1.0 has 2.6-inch LCD screen and six navigation buttons on the front. You can use these buttons to manage the printer, including replacing resin, viewing the printer's status and initiating a print job. The printer connects to a computer via a USB 2.0 port on the back. It doesn't feature an SD card but it does support printing from a thumbdrive, via another USB port also on its back.

Unlike FFF printers, the Nobel 1. 0 has a simple initial calibration to ensure the build platform and the bottom of the resin build tank are leveled. All I had to do was follow the instruction on the printer's screen to move the platform all the way down until it pressed against the bottom of the tank. After that the printer was ready to work, and it did, without any hiccups or the need for further calibration.

0 has a simple initial calibration to ensure the build platform and the bottom of the resin build tank are leveled. All I had to do was follow the instruction on the printer's screen to move the platform all the way down until it pressed against the bottom of the tank. After that the printer was ready to work, and it did, without any hiccups or the need for further calibration.

XYZprinting Nobel 1.0 Specs

| Technique: | SLA (Stereolithography Apparatus) |

|---|---|

| Printer dimensions: | 11x13x23.8 inches (280x345x594 mm) |

| Weight: | 21.2 pounds (9.6kg) |

| Display: | 2.6-inch touchscreen |

| Light source: | UV Laser λ 405nm (100mW) |

| Connectivity: | USB wire |

| Build size: | 5 by 5 by 7.9 inches (128x128x200 mm) |

| Power requirements: | 100-240V 50/60Hz 60W |

| Layer thickness: | X/Y axis resolution: 0. 3mm (300 Microns)/ Z axis: 0.025mm (25 Microns) 3mm (300 Microns)/ Z axis: 0.025mm (25 Microns) |

| Print material: | Photopolymer resin |

| Resin supply: | Auto-refilling |

| Resin bottle capacity: | 500ml |

| Software: | XYZWareNobel |

| Operating system: | Windows XP (.Net 4.0 required), Windows 7+ (for PC), Mac OS X 10.8 (for Mac) |

| File types: | STL, XYZ format, GCODE |

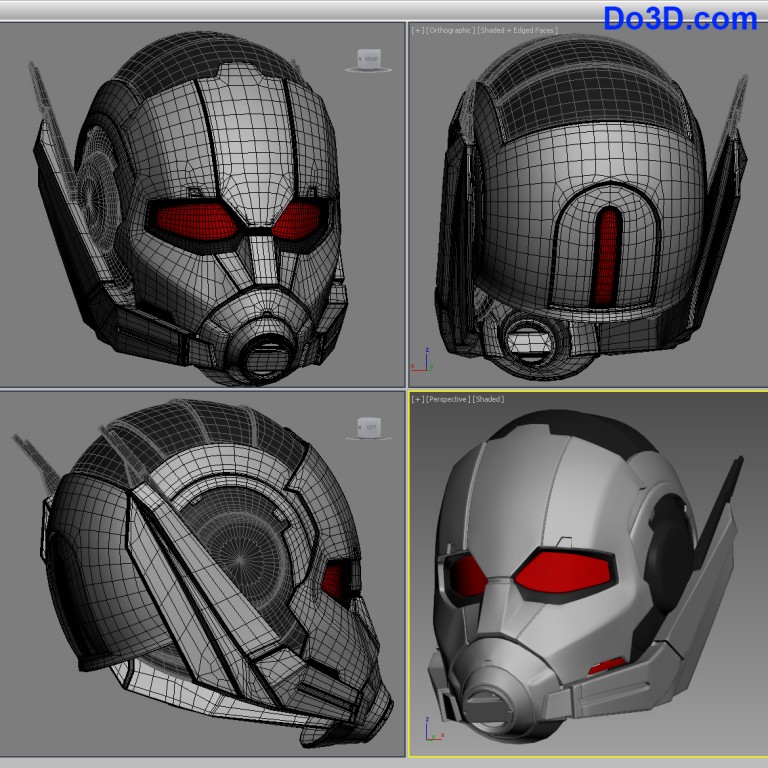

Stereolithography 3D printing technology

The Nobel 1.0 uses stereolithography (SL) 3D printing technology, also known as stereolithography apparatus (SLA). In a nutshell, this technology works in the opposite direction from fused filament fabrication (FFF).

With FFF, the printer builds an object layer by layer from the bottom up on the print platform, similarly to icing a cake or using calking. With SLA, however, the printer's print platform dips itself into a container full of nothing but liquid resin and slowly pulls up a solid 3D object, upside down. Imagine you put your fingers into a cup of cocoa and slowly pull out a candy bar that has never been there before. It's kind of magical like that.

Imagine you put your fingers into a cup of cocoa and slowly pull out a candy bar that has never been there before. It's kind of magical like that.

Technically, however, there's no magic. In the case of the Nobel 1.0, the print process is like this. First the print platform lowers itself into the resin glass tank, then an ultraviolet laser light, reflected from an actuated-mirror device underneath the tank, shines on the resin underneath the build platform. (For this reason, SLA is sometimes called the laser 3D-printing technology.) Exposed to the laser light, the resin cures, solidifies and sticks to the platform. As more resin is exposed to the laser light, the pattern is created and joins the layer above. As more and more layers are being created, the build platform slowly -- very slowly -- moves upward and finally pulls the entire object out of the tank when the print process is finished.

Enlarge Image

The object the Nobel 1. 0 printed (left) is clearly more detailed than the one printed by an FFF printer. Josh Miller/CNET

0 printed (left) is clearly more detailed than the one printed by an FFF printer. Josh Miller/CNETAnother big difference between FFF and SLA 3D printing is that while FFF produces a lot of heat during a print (which is required to melt the plastic filament), SLA remains cool the whole time. Instead you have to deal with the liquid sticky resin, which can be messy. Also, while with FFF the 3D object is ready to be used right after the print, an SLA 3D object needs to be washed with strong solvent (over 75 percent alcohol) afterwords; otherwise, it will remain wet (and sticky) for weeks. This is the case with the Nobel 1.0.

XYZprinting says the resin used by the Nobel 1.0 is made mainly of acrylic monomer. It has a strong candylike smell and is not harmful to humans or the environment, though certain people might be allergic to it.

With large self-explanatory icons, the XYZWareNobel software is easy to use. Screenshot by Dong Ngo/CNETFamiliar software

The XYZWareNobel software comes with the Nobel 1. 0, and you can also download it (registration required). The software for the most part is the same as the XYZWare software used with XYZprinting's FFF printers. The only difference is that the software for the Nobel 1.0 doesn't include customizations that the printer doesn't support, such as the filling level. And thanks to SLA, the Nobel 1.0 can easily print objects with overhanging features, such as a robot with extended arms, without needing to make supports for the arms.

0, and you can also download it (registration required). The software for the most part is the same as the XYZWare software used with XYZprinting's FFF printers. The only difference is that the software for the Nobel 1.0 doesn't include customizations that the printer doesn't support, such as the filling level. And thanks to SLA, the Nobel 1.0 can easily print objects with overhanging features, such as a robot with extended arms, without needing to make supports for the arms.

The software is easy to use: its interface consists of large and self-explanatory buttons allowing you to import and manipulate the 3D object files, and print directly to the printer. Once the print command is invoked, depending on the size and complexity of the 3D model, the software takes from a few seconds to a few minutes to transfer the data to the printer. After that, the printer can print on its own, without having to be connected to the computer. Alternatively, you can also load 3D model files onto a USB thumbdrive, connect that drive to the printer's USB port and use the LCD screen to print directly from there.

Note that the printer in most cases prints the object upside down, since effectively it pulls the object up from the tank of liquid resin as mentioned above. In the software, however, you should still work with the object in the normal orientation. If you manually flip the object, the print might fail because the printer will print the top part first, which might not have enough surface to stick to the print-platform firmly enough to hold the rest of the object.

The Nobel 1.0 supports standard and popular 3D model files. There's a huge collection of free 3D object models at Thingiverse that you can use, or you can make your own using software, such as SketchUp or Autodesk 123D. XYZprinting also has a large collection of 3D model files to choose from at no cost.

Performance

Despite using laser to print, the Nobel 1.0's print speed is definitely not that of a regular laser printer. In my testing, it was slower than FFF printers most of the time. For example, for a small round object that an FFF printer takes about an hour to build, the Nobel took almost 2 hours. This difference varied, however, depending on the objects. When I printed something thin, such as an iPhone case, the Nobel 1.0 was about as fast as the Da Vinci Jr. But when I printed an object with thicker parts, such as a little puppy, the Nobel 1.0 took much longer.

This difference varied, however, depending on the objects. When I printed something thin, such as an iPhone case, the Nobel 1.0 was about as fast as the Da Vinci Jr. But when I printed an object with thicker parts, such as a little puppy, the Nobel 1.0 took much longer.

This is because the Nobel 1.0 can't hollow out the middle. With an FFF printer you can choose the level of filling from 10 percent (mostly hollow) to 100 percent (solid). But an SLA printer such as the Nobel 1.0 prints only solid forms, which not only makes it take much more time to finish an object, it also means the printer needs more materials than an FFF printer. Depending on the object, the Nobel 1.0 can use up to three times the amount of materials for the same object.

Enlarge Image

While looking smaller, the Incredible Hulk printed by the Nobel 1.0 (left) uses much more material than the other one. Josh Miller/CNET In my testing with a 500ml bottle of resin, I could print just three copies of the Incredible Hulk (see picture), while the da Vinci Jr could print about eight of them, each about 15 percent larger. With the bottle of resin costing about $60 each, effectively each Hulk print costs about $20 worth of materials with the Nobel 1.0.

With the bottle of resin costing about $60 each, effectively each Hulk print costs about $20 worth of materials with the Nobel 1.0.

Note that the Nobel 1.0 never uses up the amount of resin it has pumped into the build tank, either: the resin in the tanks needs to remain at certain level for the building process. In other words, once you've finished making an object, no matter how small, there will be about 50ml of resin left in the build tank, which will go to waste if you don't use the printer for a few days. So if you don't intend to print a lot of things, be prepared to waste a sizable portion of the resin.

On the other hand, the print quality of the Nobel 1.0 is significantly superior to that of any FFF printer I've worked with. Even at the Normal quality setting (which is the lowest and has a resolution of 0.1 micron), the printed object has incredible detail. The higher quality setting will increase the level of detail to up to 0.025 micron resolution. However, in this case the printer will take much longer to build the object.

In short, with the Nobel 1.0, you're accepting the expense of the material and the slow print speed in exchange for the extremely high-quality print. Also, since the resin is sticky, you will need a pair of gloves to work with the printer, especially when you remove the finished object off from the print platform. You will also need to rinse it with alcohol right away. In my testing, when left alone, the object would remain wet and sticky for longer than a week.

Conclusion

Despite being the least expensive SLA 3D printer on the market, the Nobel 1.0's $1,500 price tag still makes it cost prohibitive for most consumers. On top of that, the resin is not cheap, either, at $60 per 500ml bottle. And keep in mind XYZPrinting currently only sells the resin in kits of two bottles at a time, meaning in order to get more resin, you'll need to spend at least another $120.

However, my biggest problem with the printer is not the cost but its print speed. If the printer could print as fast as a regular laser printer, I would totally recommend it. Unfortunately, its print speed is disappointingly slow.

Unfortunately, its print speed is disappointingly slow.

So at the end of the day, the Nobel 1.0 is an expensive 3D printer to own and its special capability of producing complex and highly detailed objects is outweighed by the cost. That said, if you're a 3D-printing enthusiast willing to spend the money, the Nobel 1.0 has its appeal. The combination of compact design, ease of use, high-quality prints and the fascinating way it build objects makes the printer a really fun and satisfying machine to have.

For those who just want to try out 3D printing, the Da Vinci Jr, the Da Vinci AiO 1.0 or the 3D System Cube 3 would be a much better choice. Though none of these FFF printers can produce a level of detail even close to that of the Nobel 1.0, they are significantly cheaper -- costing from just $350 to $800 -- and won't require you to clean the prints with alcohol.

XYZprinting Nobel 1.0 Review - Affordable Resin 3D Printer

Skip to main contentTom's Guide is supported by its audience. When you purchase through links on our site, we may earn an affiliate commission. Here’s why you can trust us.

When you purchase through links on our site, we may earn an affiliate commission. Here’s why you can trust us.

The XYZ Nobel 1.0 is a promising device that brings SLA printing to a new, low price point of $1,500. But there are too many quirks and problems to make it a winner.

Tom's Guide Verdict

The XYZ Nobel 1.0 is a promising device that brings SLA printing to a new, low price point of $1,500. But there are too many quirks and problems to make it a winner.

Pros

- +

Produced attractive, clean prints

- +

Simple to set up

- +

Printing process is straightforward

Cons

- -

Prints showed some layering

- -

Some fine details were not well printed

- -

Much slower than other SLA printers

- -

No Mac software support

Why you can trust Tom's Guide Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

Find out more about how we test.

Today's best XYZ Nobel 1.0 3D Printer deals

No price information

For more information visit their website

Who it's for: Designers and artists who want to produce fine prints of small models.

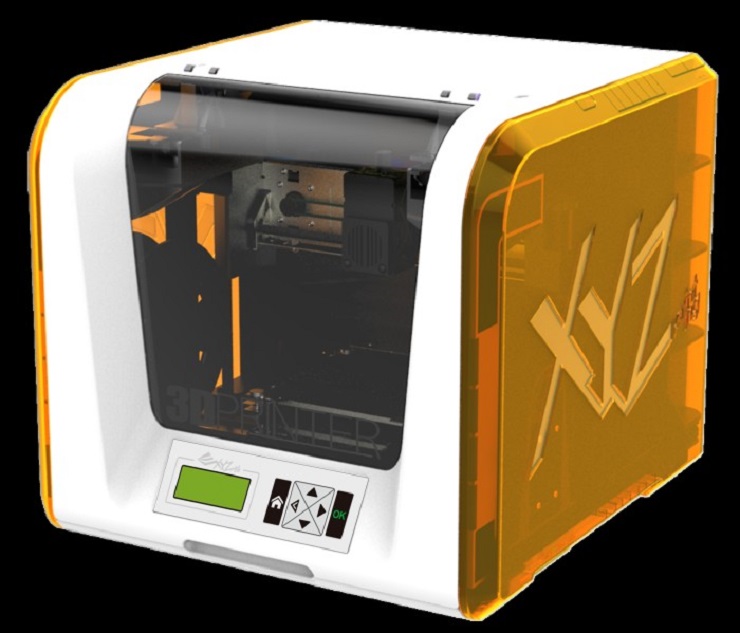

XYZprinting is breaking new ground with the Nobel 1.0, a stereolithography (SLA) resin printer that costs just $1,499 and can produce far more-detailed objects than mainstream FDM (plastic) printers can. With other SLA models costing a lot more — take, for example, the $3,299 price tag of the Form Labs 1+ — the Nobel 1.0 puts resin printing into the hands of home users. The Nobel 1.0 does a good job of producing intricately detailed 3D prints for objects like jewelry, engineering models or other models, although there are some compromises: It is much slower than other SLA printers, supports a limited range of materials and struggles with some fine details.

- Best 3D printers

The Nobel 1.0 has a fairly simple, straightforward design. A translucent-orange plastic hood covers the print area to block harmful UV light, while still allowing you to look inside and check a print's progress. Underneath the hood, you'll find a support holding the removable print bed. This bed moves up and down via a motor in the base; as the print bed is raised one layer at a time, the print is gradually formed. You remove the print bed by twisting the large knob and sliding the bed out.

The resin sits under the print head in a tray with a clear bottom that allows the UV laser to shine through, solidifying each layer of resin. The print bed rises for each layer of the print. Most SLA printers require you to manually fill the resin tray, but XYZprinting has come up with a neat mechanism that automatically pumps resin from the container into the tray, refilling the tray as required during printing.

The largest print that the Nobel 1. 0 can create is a cube measuring 5 x 5 x 7.9 inches, for a total of 197.5 cubic inches. That's a decent size for an SLA printer, as these devices tend to be smaller than their filament-melting cousins. For example, the $1,299 Lulzbot Mini, which prints with filament, can manage 6.2 x 6 x 6 inches, a total of 223 cubic inches. The Form 1+ SLA printer can manage 4.9 x 4.9 x 6.5 inches, a total of 156 cubic inches. That said, SLA printers are usually used for smaller models, so print volume isn't a major criterion.

0 can create is a cube measuring 5 x 5 x 7.9 inches, for a total of 197.5 cubic inches. That's a decent size for an SLA printer, as these devices tend to be smaller than their filament-melting cousins. For example, the $1,299 Lulzbot Mini, which prints with filament, can manage 6.2 x 6 x 6 inches, a total of 223 cubic inches. The Form 1+ SLA printer can manage 4.9 x 4.9 x 6.5 inches, a total of 156 cubic inches. That said, SLA printers are usually used for smaller models, so print volume isn't a major criterion.

If you lift the hood in any direction other than straight up after the Nobel 1.0 finishes the print, you can knock into the print or the print bed, possibly damaging them. The Form One+ has a better solution: a hood on a hinge that tilts the cover back.

MORE: Top-Rated 3D Printers on the Market Now

It is not easy to switch resins with the Nobel 1.0, either, as this requires draining the auto-fill system and cleaning out the resin tray. XYZprinting also recommends doing this if you are not going to be using the printer for a few days, so the resin doesn't set. XYZ recommends disposing of this resin rather than using it later. The Form 1+, on the other hand, has resin trays that can be removed, covered and stored, so you don't lose any trays. If you often change resin colors, the Form 1+ approach will be easier. But the Nobel 1.0 auto-fill system makes it quicker and easier to produce multiple prints.

XYZ recommends disposing of this resin rather than using it later. The Form 1+, on the other hand, has resin trays that can be removed, covered and stored, so you don't lose any trays. If you often change resin colors, the Form 1+ approach will be easier. But the Nobel 1.0 auto-fill system makes it quicker and easier to produce multiple prints.

Print Quality: Excellent, with soft resin

The Nobel 1.0 delivered excellent quality for most of our tests, creating clean models with fine detail, though some layering was visible on close examination. We tested the printer using the clear Crystal resin that XYZ provided.

Prints of both our Thinker and geometric sculpture test models had good detail and smooth, natural curves. The Nobel 1.0 managed all of the complex geometry of the sculptures, producing overhanging surfaces and sharp, clean edges. The supports that the printer added to keep the print in place were easy to remove with a knife, leaving little or no trace.

I did notice some layering, with individual layers of both prints visible using all three of the quality settings that this printer offers. Layers were more visible than in the same prints from other, more expensive SLA printers, such as the Form 1+, and they detracted somewhat from the clear look of the Crystal resin.

Layers were more visible than in the same prints from other, more expensive SLA printers, such as the Form 1+, and they detracted somewhat from the clear look of the Crystal resin.

The resin can be very soft straight out of the Nobel 1.0. On our test model of a set of gears, for instance, most printers produce rigid prints of the outer rings that hold the gears in place. With the Nobel 1.0, after printing and washing in alcohol, the rings were so soft that they could be easily squished.

The resin did get harder after curing the prints with UV light, by leaving them outside on a sunny day for a couple of hours. But I still could not build the set of gears because of another problem: The holes in some of the parts were inconsistent. The mechanism is built around three small cogwheels that have to fit onto pins on another part. But when I examined our printed gears closely, I found that some of the central holes were almost filled with resin, so they would not fit onto the pins.

I didn't receive any of the other color resins that XYZprinting offers, but I was able to successfully print these gears on the Form 1+ using a similar clear resin. It is possible that the other colors of resin may perform better, but it seems that XYZ still has some work to do.

Print Materials: Very limited

The Nobel 1.0 works only with resins from XYZprinting, sold in 500-ml bottles that cost $119 for two bottles. (You can't buy the bottles individually.) That's not cheap, though it's a little less expensive than the resin used in the Form1+, which costs $149 a liter, and the bottles last a fairly long time. For reference, our test model of the Thinker statue, which is about 4.5 inches high, used approximately 130 grams of resin, about $16 worth. I could produce three prints from each bottle, with some resin left over.

MORE: 8 Awesome 3D Printing Trends to Watch

XYZprinting sells five resin colors: Crystal (clear), Gray, White, Blue and Magenta. The bottles these materials come in have an NFC tag on the bottom, which the printer reads to verify them as genuine, and to track how much resin is left. This tagging prevents you from using resins from other manufacturers.

The bottles these materials come in have an NFC tag on the bottom, which the printer reads to verify them as genuine, and to track how much resin is left. This tagging prevents you from using resins from other manufacturers.

Setup: Simple and Straightforward

There are more steps involved in getting the Nobel 1.0 up and running than there would be for an FDM printer. After unpacking and turning the device on, you have to wait 10 minutes while the Nobel 1.0 runs a diagnostic test. Then you have to level the print bed, which involves waiting for it to lower before adjusting four screws that hold the print bed in place to get it flat against the base of the resin tray. After that, you put the resin bottle in place and connect it to the auto-fill mechanism with a couple of tubes. None of these steps are difficult, but they do involve a fair amount of waiting around: It took about an hour before I could set the first test print running. That's about twice as long as with an FDM printer, but roughly the same as on other SLA printers, which tend to be more complex than FDM versions. A model of a ring is built into the device, and this is a good first test.

A model of a ring is built into the device, and this is a good first test.

Print Process: Straightforward

The Nobel 1.0 can print from a connected PC or from a file on a USB thumb drive. Frustratingly, there is no front USB port for the latter: I had to reach around the back of the Nobel 1.0 to plug the drive in. With an open tray of resin in this printer, you should avoid moving it, to keep from causing spills. As a result, it's easiest to print from a connected PC using the XYZWareNobel software, which is available for Windows only. Mac owners are left in the cold.

This program is quite straightforward, with all of the basic features easily available from the icons on the left. With XYZWareNobel, you can load models (in STL format only), move and scale them, and export the files for printing from a USB drive. The software also controls the printing process, but you don't get much feedback on this. Other software like MatterControl shows how the print is progressing in exquisite detail, showing you exactly which bit of the print is being created; XYZWareNobel gives you only basic information, like how much longer the print has to run and how much resin is left.

After you remove the completed print from the print bed, you wash it in alcohol to remove any unset resin. XYZ includes a scraper, plastic tub and gloves for this purpose, but no alcohol. That's easy to find, though: A standard bottle from the drug store with more than 75 percent alcohol content does the job. After you wash the print for 10 minutes and dry it, your print is ready. This process was very easy, if a little messy. I had no problems removing the prints from the print bed with the included scraper and washing them.

Print Speed: Slow

The Nobel 1.0 is not a fast printer, taking between 10 hours and 21 minutes on the 0.1mm preset and a lengthy 29 hours and 6 minutes on the highest-quality, 0.05mm preset to print out a 4.5-inch-high Thinker model. That makes this printer much slower than the Form Labs 1+, which took 6.5 and 12.5 hours on those two presets, respectively, with similar layer heights. FDM printers are generally much faster: The LulzBot Mini took a little more than 7 hours to produce a similarly sized print.

The Nobel 1.0 brings resin SLA printing to a new price point that competes with FDM printers — offering the advantages of different materials and cleaner prints. The Nobel 1.0 does a decent job of printing in resin: Larger prints like our Thinker figure are undeniably attractive, but it is slow and struggles with the fine details that models like our gear set require. The printer is also considerably slower than more-expensive SLA models like the Formlabs Form 1+. So, the XYZprinting Nobel 1.0 is a significant step forward in making SLA printing cheaper, but there are compromises.

- 3D Printing Services Reviewed: Do They Really Work?

- How to Buy the Right 3D Printer

- Watch This 3D Printer Make Objects From Liquid

Follow Richard Baguley @rbaguley or on Google+. Follow us @TomsGuide, on Facebook and on Google+.

Today's best XYZ Nobel 1.0 3D Printer deals

No price information

For more information visit their website

Richard Baguley has been working as a technology writer and journalist since 1993. As well as contributing to Tom's Guide, he writes for Cnet, T3, Wired and many other publications.

As well as contributing to Tom's Guide, he writes for Cnet, T3, Wired and many other publications.

Tom's Guide is part of Future US Inc, an international media group and leading digital publisher. Visit our corporate site .

© Future US, Inc. Full 7th Floor, 130 West 42nd Street, New York, NY 10036.

3D printer XYZPrinting Nobel 1.0 A

Out of stock

Add to compare

Item added to compare Go

Free shipping within Russia

227 700 ₽

Notify me of admission

Official distributor

We work directly with manufacturers.

Any form of payment

The opportunity to see the 3D printer in action in our demo room.

Own warranty service

Warranty and post-warranty service for equipment purchased from us.

Permanent 10% discount on consumables

When you buy a 3D printer from us,

you get a 10% discount on all consumables.

3D printer XYZPrinting Nobel 1.0 A - uses ultra-precise laser stereolithography technology. Nobel 1.0 A delivers high print quality with a wide range of different resins including flexible, rigid and castable. With a layer resolution of 25 microns, the printer excels in complex jewelery and art applications.

The smart design of Nobel 1.0 A optimizes printer performance, increases productivity and ease of use.

Functions such as: automatic determination of the level of resin in the bath and automatic supply of material, if necessary, will make working with the printer as easy and comfortable as possible.

Software XYZware Nobel contains information about resins and optimal settings for printing, as well as automatically arranges the necessary supports for overhanging areas of the model.

To expand the use of third-party materials, you can additionally install the Open Smart Tag component

Scale of delivery

Delivery to all regions of Russia and countries of the Customs Union.

Free shipping

When you buy a 3D printer (except assembly kits) you get free shipping.

Cash

In our store you can pay for your order in cash.

Online payment on the website

You can pay for orders with a bank card on the website of our online store.

Product catalog XYZprinting

Sort: DefaultBy Name (A - Z)By Name (Z - A)By Price (Ascending)By Price (Descending)By Rating (Descent)By Rating (Ascending)By Model (A - Z)By Model (Z - A)

Display: 12255075100

3D printer XYZPrinting Nobel 1.

0

0 XYZprinting Nobel 1.0 is a personal SLA 3D printer weighing 9.6 kg and with a total dimensions of 2..

139,000 Without tax: 139,000

In stock

3D printer XYZPrinting Nobel 1.0A

XYZPrinting Nobel 1.0A is an advanced version of the high-precision personal stereo lithography lithograph..

245 600 Without tax: 245 600

In stock

XYZprinting da Vinci 1.0 Pro 3-in-1

The XYZprinting da Vinci 1.0 Pro 3-in-1 3D printer is a professional multifunction printer..

194 700 Without tax: 194 700

Available

3D printer XYZprinting da Vinci Color

XYZprinting da Vinci Color uses inkjet, full color 3D printing technology, which is...

630,000 Without tax: 630,000

Available on request

XYZprinting Da Vinci Junior 3D printer

XYZprinting Da Vinci Junior is a small desktop 3D printer with a build area of 150 x 150 x 1. .

.

40 600 Without tax: 40 600

Available on request

XYZPrinting da Vinci MiniMaker 3D Printer

The XYZPrinting MiniMaker is a compact, bright and easy to use 3D printer, ..

28,700 Without tax: 28,700

Available on request

XYZprinting 3D Scanner 2.0 3D Scanner

Capture real objects in high detail with XYZprinting 3D Scanner 2.0 - handheld..

47,500 Without tax: 47,500

Available on request

XYZPrinting curing chamber

XYZPrinting curing chamber is a professional device for light curing printing..

39,000 Without tax: 39,000

Available on request

XYZ da Vinci 1.0 AiO 1.0 3D MFP

Printer combines 3D scanning and 3D printing.