3D printed telescope mirror

I Designed and 3D-Printed a Newtonian Reflector Telescope. The Views Are Amazing | by Rafael Fiol | The Startup

When I pointed this thing towards the sky for the first time and peered through the eyepiece, two thoughts immediately struck me: 1) holy s*** it works!, and 2) wow, space is awesome.

Regarding my first thought… I wasn’t so much shocked that it worked, but I was shocked that it worked so very well. There’s a lot that goes into engineering a good telescope, and I was not sure if 3D-printing with plastic filaments would measure up. To my surprise, this thing works great.

To be fair, with its 6" (153 mm) primary mirror, this is considered a small reflector telescope, and the engineering problems increase dramatically with larger telescopes. Nevertheless, even in this size class, mirrors have to be collimated, the optical tube can’t flex when you tilt it, the focal length has to be measured and engineered accurately, and the primary mirror has to have proper plate and edge support.

I’ll show you how I solved for these engineering requirements, but first it’s time for a little background.

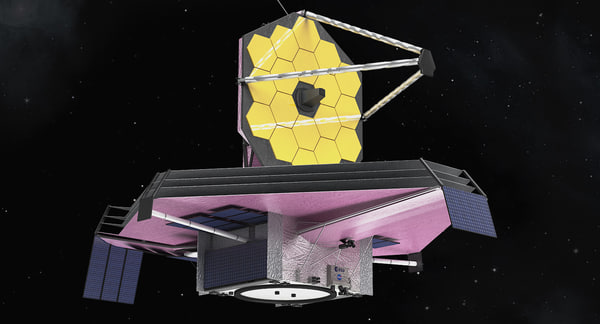

A Newtonian telescope is a type of Reflector telescope invented by Sir Isaac Newton in or around 1668. Today, this type of telescope is popular with amateur and DIY telescope makers because it has a relatively simple design (when compared to Refractor telescopes). Newtonian telescopes are usually less expensive than comparable quality/size telescopes of other types.

Generally speaking, there are two broad categories of telescopes: Reflector and Refractor. As a reminder, the 3D printed telescope we will be discussing is a Reflector. There are tons of great resources online that go into great detail about differences (and similarities) between the two. But for this article, I’ll keep it simple and say that Refractors use lenses to gather and focus light, while Reflectors instead use mirrors.

A Reflector telescope has two mirrors: the Primary (also called the Objective) and the Secondary. The primary mirror has a concave or parabolic surface and it is located at the tail end of the telescope. Its job is to reflect incoming light (which enters through the front of the telescope) towards a smaller secondary mirror positioned closer to the front of the telescope. Because of the parabolic shape of the primary mirror’s surface, the light is reflected along a cone-shaped path, towards a very specific focal point near (but just beyond) the secondary mirror. That secondary mirror is positioned at a 45-degree angle so as to reflect that light out towards the side of the telescope tube, where an eyepiece is attached. If the positions of the mirrors are accurate, the cone-shaped light comes to a point (the focal point) within the viewing limits of the eyepiece.

The primary mirror has a concave or parabolic surface and it is located at the tail end of the telescope. Its job is to reflect incoming light (which enters through the front of the telescope) towards a smaller secondary mirror positioned closer to the front of the telescope. Because of the parabolic shape of the primary mirror’s surface, the light is reflected along a cone-shaped path, towards a very specific focal point near (but just beyond) the secondary mirror. That secondary mirror is positioned at a 45-degree angle so as to reflect that light out towards the side of the telescope tube, where an eyepiece is attached. If the positions of the mirrors are accurate, the cone-shaped light comes to a point (the focal point) within the viewing limits of the eyepiece.

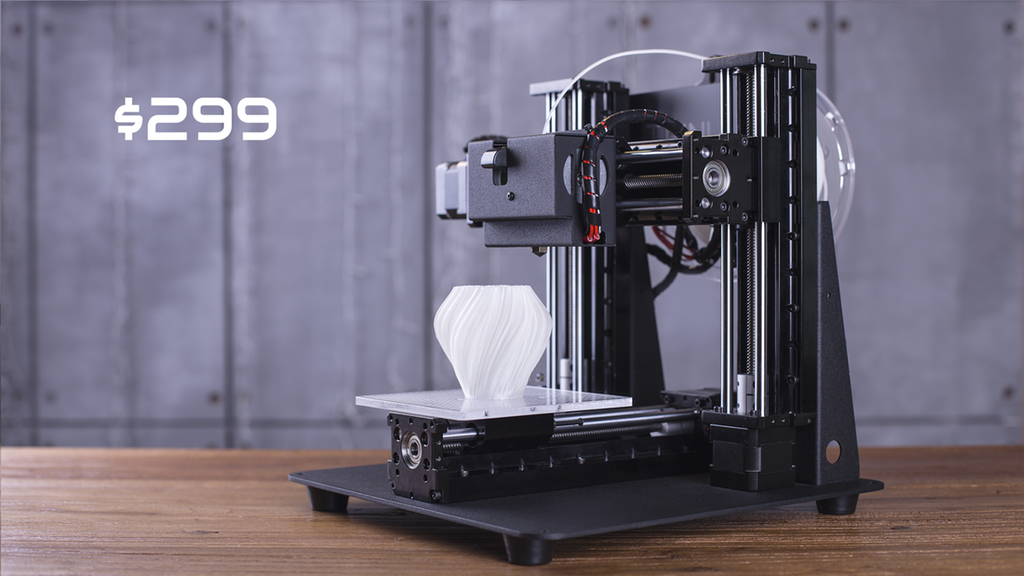

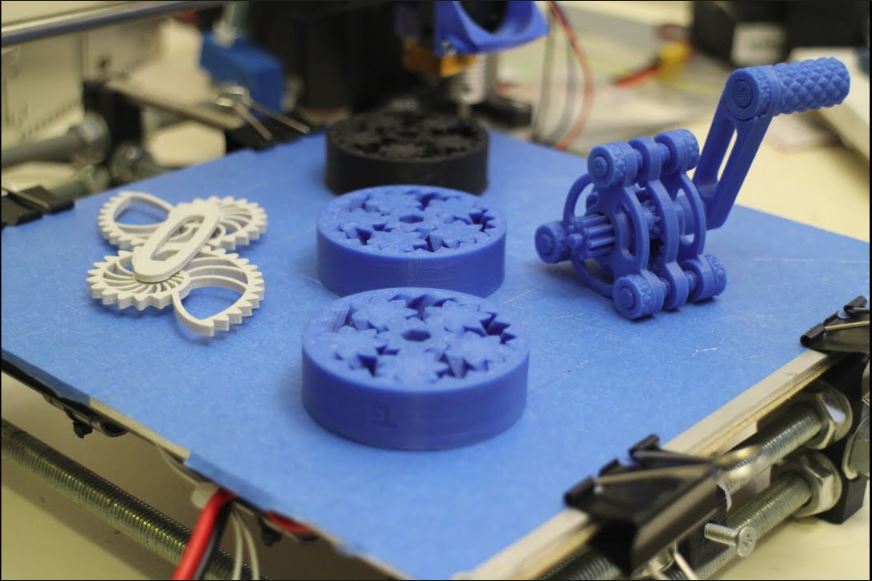

I designed this telescope using Autodesk Fusion 360. It’s an absolutely amazing piece of software. If you’re a Fusion 360 user, you can download my Fusion 360 project file and customize the design as needed. Or, you can simply download the STL files and send them directly to your 3D printer.

Or, you can simply download the STL files and send them directly to your 3D printer.

All of the project files are available on my website www.BigBigSpace.com. You’ll see two telescopes (at the time of this writing) on that website. The article you are reading now will focus on the telescope titled “Newton to See Here.” This scope is the second iteration of my 6" Newtonian telescopes, and a significant improvement over the first scope.

My first scope, named “Reflector? I Hardly Newt Her!”, is available for free. It’s a fine scope and works great, but I’ve learned a lot since then through field tests and studying proper telescope design. Those learnings are applied in the newer scope.

The two mirrors and the eyepiece (focuser) are not 3D-printed. Additionally, the truss tubes are also not 3D printed. The truss tubes in my project are 16mm (outer diameter) x 500mm (length) carbon fiber tubes which I purchased from Amazon. I chose them because they are light and very strong. You can substitute extruded aluminum tubes if you want to save a few bucks. Everything else (except for some screws and fasteners) is 3D-printed.

You can substitute extruded aluminum tubes if you want to save a few bucks. Everything else (except for some screws and fasteners) is 3D-printed.

Obviously, you can’t print a mirror (yet). You’ll have to purchase a mirror or source one from a refurbished or discarded telescope. I purchased my mirror new from AngenaAstro.com. This one is guaranteed to fit the dimensions of the telescope, and has the proper focal length (750mm) for the truss tube design in this project.

Knowing the focal length of your mirror is critical. The focal length and tube diameter will determine your mirror placement. For our mirror with a 750mm focal length, we’ve placed our secondary mirror 540mm away from the primary mirror, leaving us 210mm to account for the radius of the tube and the length of the focuser.

The 3D-printable mirror box and upper optical assembly (UOA) includes truss tube connectors angled precisely so that our truss tubes (positioned at angles for rigidity) separate our mirrors by 540mm.

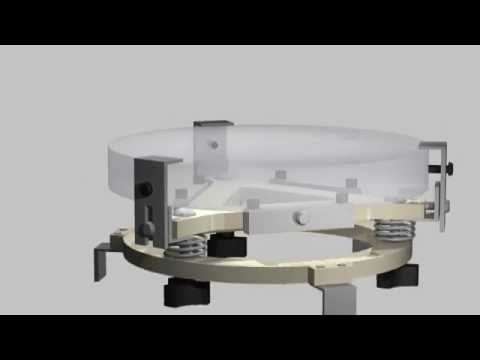

The primary mirror rests securely in the Primary Mirror Cell. This is an important part of the telescope that has a lot of responsibility. It must hold the mirror in place, making sure that it does not misalign as the telescope is moved on your alt-azimuth mount.

Primary Mirror Cell with 3-Point PLOP and Whiffletree Edge SupportThe mirror cell has to hold the mirror very gently and only touch the mirror in certain spots. Because as it turns out, mirrors are solids but not solid enough! They actually flex and change shape as pressure is applied. If the primary mirror flexes too much or in the wrong way, your view of the stars and planets will go from Wow! to Blah.

Fortunately, people way smarter than me have created formulae and software to help us design the optimal mirror cell. The most popular software is PLOP (PLate OPtimizer). PLOP can be used to calculate floating support points for the rear of the mirror. In other words, the primary mirror will rest on the support points (which are calculated to precise locations) in order to minimize deflection.

Using PLOP, I opted for a simple 3-point support design. PLOP tells us that the support points should be 31.4mm from the center. With our 6" primary mirror, this is more than adequate. Larger mirrors typically require more complex arrangements and floating 18-point designs are very common.

In addition to the rear support, the edge of the mirror must also be supported so that as the telescope is tilted, the mirror stays in place and does not warp (too much) as the pressure shifts to the edges. PLOP won’t help us here, but there are other tools and well-established best practices that will. Read this if you want to learn more. With our scope, I went with a modified whiffletree design — four edge support points separated by 45° (22.5° and 67.5° from the vertical).

Note that a true whiffletree design should pivot at the midpoint (45°), but I opted to keep it simple (no pivot), since this is a small mirror.

I chose to use Carbon Fiber tubes on this telescope, which I purchased from Amazon. I chose them because they are light and very strong. You can substitute extruded aluminum tubes if you want to save a few bucks. The trusses need to be 480mm. The tubes I found on Amazon are 500mm, which means you’ll need to cut those down 20mm. No big deal. Easy to do.

I chose them because they are light and very strong. You can substitute extruded aluminum tubes if you want to save a few bucks. The trusses need to be 480mm. The tubes I found on Amazon are 500mm, which means you’ll need to cut those down 20mm. No big deal. Easy to do.

Here’s a short video showing the assembly. It took me about 45 minutes. Most of that time was spent fighting the screws on the Upper Optical Assembly (UOA), because I didn’t have the right tools.

Enjoy a few photos taken with this telescope.

Conjunction 2020 — Jupiter, four Galilean Moons, Saturn + Earth’s MoonHead over to www.BigBigSpace.com. You’ll find all the files and a parts list. If you make one, leave me a message and let me know! Enjoy.

UPDATE: I posted step-by-step build instructions on Instructables.com. Oh, by the way, this project won the Grand Prize on a recent contest.

optics - Is it possible to 3D print a mirror to create a high quality telescope?

Asked

Modified 6 years, 11 months ago

Viewed 9k times

$\begingroup$

Is it possible to 3D print a mirror with todays available materials?

If so, would there be a reduction in image quality?

- optics

- astronomy

- reflection

- telescopes

$\endgroup$

2

$\begingroup$

The highest resolution 3d printers I know of are around 1600dpi, which is a resolution of about 15$\mu m$. Telescope mirrors have to be smooth to fractions of a wavelength of light, so the resolution of current printers is nowhere near good enough.

Telescope mirrors have to be smooth to fractions of a wavelength of light, so the resolution of current printers is nowhere near good enough.

Whether 3D printers could one day be good enough is a different question, but given that the improvement in resolution required is at least a factor of 1,000 I think it's not likely because 3D printers are designed to address quick manufacture rather than precision manufacture. In any case, making mirrors is a well established procedure. The difficulty is making them large, and it's not obvious how 3D printers would help with this.

$\endgroup$

5

$\begingroup$

The answer is "Yes" but not the way you might expect. It is possible to construct a telescope mirror from rotating liquid metal.Mercury used to be used but something like Gallium is safer and better.

So print a cradle for it, put in the Gallium, raise the equipment past the melting point (about 30 degC), spin gently to get a parabolic surface, and then cool.

$\endgroup$

$\begingroup$

Can't be done, yet. But don't expect 3d printing to stand still, it's only recently been born, wait till it starts walking, and running! My hope was that there could be a vacuum process that was usable in just enough vacuum to form a perfect mirror shape over a perfect mirror mold of some kind, then start the vapor deposition on the cheap, lightweight material that was drawn into the perfect mirror mold. Maybe you could make a lot of them before the mirror was harmed. Maybe a cousin of mylar. Large cheap mirrors would do wonders for science and astronomy, and people.

$\endgroup$

1

| 3DNews Technologies and IT market. Interesting news from the world of high-tech Photo of the day: pictures of the lunar surface of the tele... The most interesting in the reviews 09/24/2014 [06:33], Dmitry Prikhodko The mysterious and attracting attention of the Moon again fell into the lens of the telescope. However, unlike in all previous cases, this time photographs of its surface with an abundance of lunar craters were taken for the first time by a telescope made using 3D printing technology. nine0007 The model of the device called Pikon is interesting, first of all, because its cost is only $160. At the same time, the quality of images from the telescope is comparable to photographs obtained using equipment ten times more expensive. Taking into account the production method, which is not quite usual for this class of devices, Pikon has one more indisputable advantage in comparison with classical space observation devices. The design of the Pikon is made according to the scheme of an optical telescope invented by Isaac Newton with a light-collecting element in the form of a mirror. In addition, the author of the idea, physicist Mark Wrigley, equipped his brainchild with a $ 40 camera module that connects to the Raspberry Pi microcomputer board. The layout of the world's first 3D printed telescope also includes a concave parabolic mirror, which is needed to form and transmit a focused image directly to the Raspberry Pi's camera sensor. Due to its miniature size, the camera module can be located as close to the mirror as possible. nine0007 The telescope, if we continue to consider its technical side, boasts a 160x magnification. Therefore, on a cloudless night, the owner of Pikon will have the opportunity to examine in sufficient detail both the only natural satellite of the Earth and begin to study other celestial bodies. Scientists began to jokingly call the affordable telescope project "subversive technology". This means that despite the low prevalence of the presented solution, it will play a key role in the future. Telescopes from a 3D printer are captivating with their versatility, so the day is not far off when they will help to consign classic models to oblivion. And the main reason for this will be the growing popularity and availability of 3D printing to the general public. nine0007 Source: If you notice an error, select it with the mouse and press CTRL+ENTER. Related materials Permanent URL: https://3dnews.ru/8 Headings: Hardware news, photo, video, phrase of the day, interesting things from the world of hi-tech, space, 3D technologies, Tags: hardware, 3d printer, 3d printing, 3d technologies, telescope, specular, space, moon, raspberry pi, photography, photosensor ← В past To the future → |

Free STL file Optical Test Bench for 4-8 Inch Telescope Mirrors・Template for download and 3D printing・Cults

Bogen Manfrotto quick release plate 329PL-14

Free

Wyze 3 Camera Pole Mount

Free

nine0066 Quick release plate for Manfrotto 200PL tripodFree

Parametric electronic design Case

Free

Extension cord spool with filament spool

Free

Tilt head for CamTilt mini camera

Free

nine0066 Ball head for photographic tripodFree

The best files for 3D printers in the Tools category

Spinning machine for knitwear or yarn

3 €

Large sample removable coil

2 €

Pegboard Tray for hex bit holder

Free

Mini Vise

Free

Radiator Hook

1,25 €

IoT Gmailbox

Free

Flsun Kossel Delta Mini Lightweight Fan Duct

Free

Multi-Color Owl Bookmark

Free

Bestsellers in the Tools category

Ender 3 Briss fang Gen2, red lizard, spider, nf crazy, dragonfly, etc.

€1.74

ARTEMIS -> Shop for Alligator 2 || 6.5" arrows || Repeating crossbow

6.25 €

ENDER 3 S1, S1 PRO, SPRITE, V3 AIR DUCT FAN 5015, ACCELEROMETER, LED strip

€2.68 -twenty% 2.14 €

Ender 3 S1 pro fan duct 5015 4020

1,30 €

Quick print stackable parts containers / storage boxes

2.83 €

SUPERBOX

1,50 €

nine0066 PET-Machine, make your own plastic bottle filament at home!15 €

UNIVERSAL BED LEVELING INDICATOR FOR VERY ALL PRINTERS

2,81 €

Quick Print Paint Bottle Rack (6 sizes)

2. 83 €

83 €

Armadillo - flexible wire conduit

€1.67 -10% 1.50 €

Business card embossing system

3 €

ENDER 3 S1/S1 PRO COIL HOLDER AND DEPORTED COIL

€2.12 -twenty% 1.70€

PRECISION CALIPER 3D PRINT DIY

3,12 €

'ELEGANCE' Bambu lab set and general 3d printers

5 €

Paint stand with scissors

5.19 €

Fire hydrant storage container

1.88 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy.

The developers of the unique telescope have uploaded to their website the source files needed to make all the elements of the frame on a 3D printer at home. The latter, by the way, will cost about $650. nine0007

The developers of the unique telescope have uploaded to their website the source files needed to make all the elements of the frame on a 3D printer at home. The latter, by the way, will cost about $650. nine0007