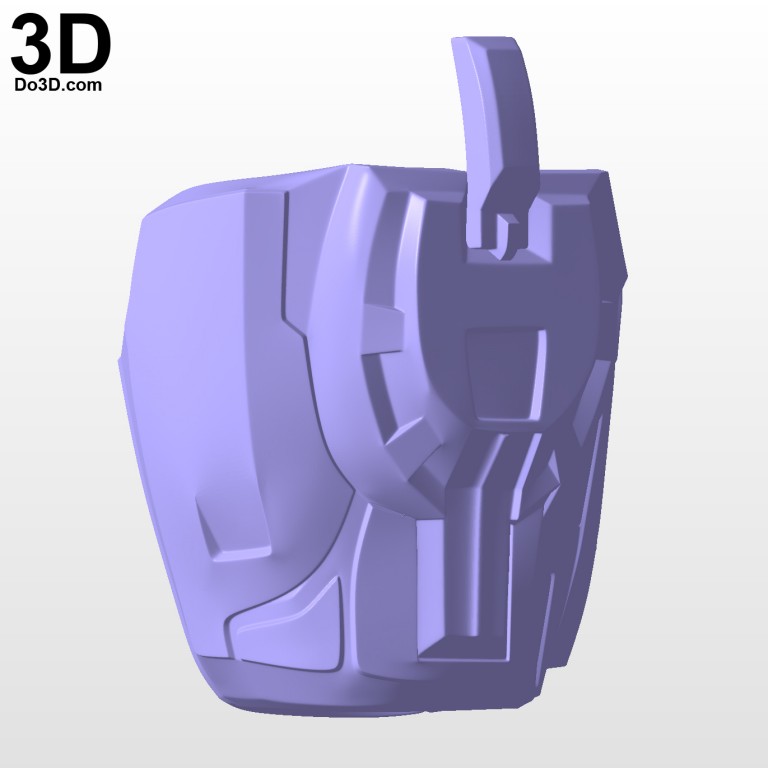

Mercy halo 3d print

▷ mercy halo 3d models 【 STLFinder 】

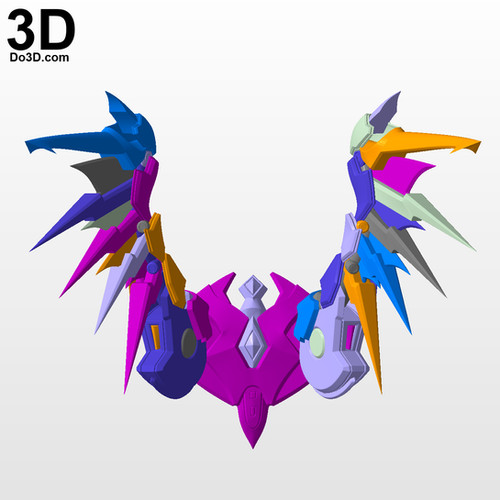

All star Mercy Crown halo overwatch league for printing 3D print model

cgtrader

Purchase of this 3D file grants a license for personal use only. Any commercial use is prohibited. Redistribution or resale of the file in any way, shape or form is prohibited. Printing of this file for sell or resell is prohibited. ...If you need a...

Halo

thingiverse

Halo

HALO

thingiverse

HALO

halo

sketchfab

halo

Halo

thingiverse

Halo

Halo

grabcad

HALO

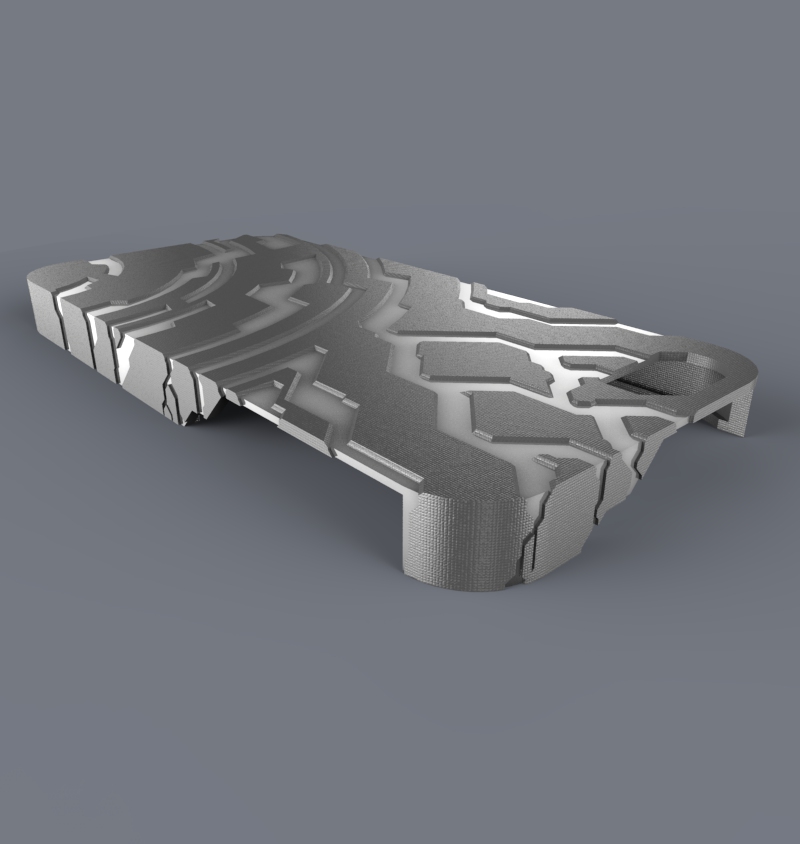

Halo Machete

grabcad

Halo Machete

LEGENDARY HALO

cults3d

LEGENDARY HALO

Halo UNSC

thingiverse

Halo Logo

halo-warthog

thingiverse

halo-warthog

Halo Helmet

thingiverse

Halo Helmet

mercusys halo

thingiverse

mercusys halo

halo magnum

grabcad

halo magnum

halo rims

grabcad

halo painting

halo HIGH

thingiverse

halo high

halo masterchief

thingiverse

masterchief from halo

halo neddeler

grabcad

a halo covenant neddeler

Halo rifle

cults3d

Rifle from halo

Halo Headshot

pinshape

Halo Headshot medal

halo turret

grabcad

a halo 3 turret

SWORD HALO

cults3d

Halo Sword Keychain

HALO helmet

cults3d

HALO master chief helmet

Halo Monitor

thingiverse

Halo 1 Monitor

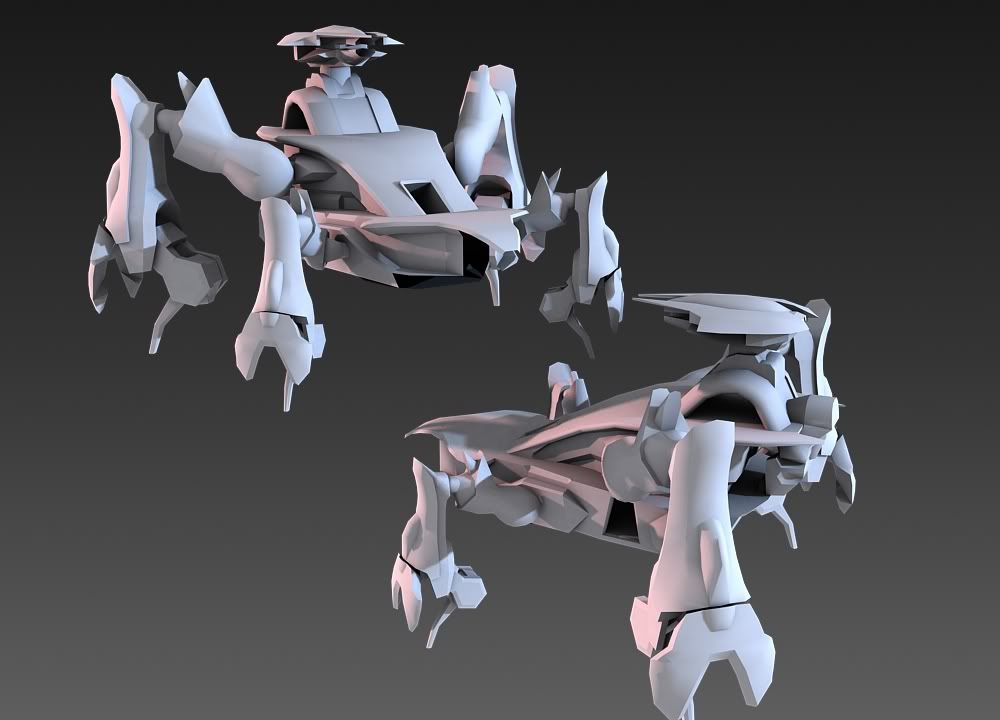

Halo Hunter

thingiverse

Model of a Halo Hunter.

HALO FRET

cults3d

... personal artificial intelligence used by Spartan-IV. ... MORE HALO DESIGNS -HALO CIRC -BANISHED HALO KEYCHAIN -BUTLER HALO INFINITE -HALO ACADEMY OF MILITARY SCIENCES CORBULO -HALO FRET -HALO SUPERINTENDENT IA FOLLOW US ON -INSTAGRAM -FACEBOOK -WEBSITE

Halo sword

pinshape

This a sword from the game "Halo".

MA5C Halo

grabcad

Arme mythique de l'univers Halo

Yolo Halo

myminifactory

A halo helmet master chief skull.

warthog- halo

grabcad

reproduction of halo war like machine

Halo

cults3d

an attempt at a realistic female face

▷ mercy halo 3d print 【 STLFinder 】

All star Mercy Crown halo overwatch league for printing 3D print model

cgtrader

Purchase of this 3D file grants a license for personal use only. Any commercial use is prohibited. Redistribution or resale of the file in any way, shape or form is prohibited. Printing of this file for sell or resell is prohibited. ...If you need a...

Printing of this file for sell or resell is prohibited. ...If you need a...

ring halo 3D print model

cgtrader

3D model ready to print. waterproof Totally functional ring halo designed by professional jeweler. ...

Halo Magnum for 3D Print

grabcad

Halo Magnum for 3D Printing Challenge. :D This is the one model i want 3d printed. ...So guys like this model.

Halo ring 3D print model

cgtrader

Halo ring

Halo Earrings 3D print model

cgtrader

Halo Earrings All parts are seperate so you can make change on it. ...Pave setting style with azzure Ready for 3D printing Includes: STL and 3DM files so you can make changes on it. ... Please also check my models to see more Art Pieces :)

...Pave setting style with azzure Ready for 3D printing Includes: STL and 3DM files so you can make changes on it. ... Please also check my models to see more Art Pieces :)

Halo Ring 3D print model

cgtrader

Halo Ring suitable for 1 x 6mm to 6.7mm Round centre StoneSmalls are 34 x 1.3mm the weight in 18k is approx 4.4grThe print volume is 279mmand the finger size is a UK size "M"

halo helmet 3D print model

cgtrader

this is a halo helmet that should fit a 50 to 55 cm head

Halo ring 3D print model

cgtrader

Halo Ring ,engagement ring 0,50ct center stone and 1. 25mm smalls

25mm smalls

Halo ring002 3D print model

cgtrader

Halo ring 002 All my models are tested. If you have any questions,please contact me. ...

Halo Ring 3D print model

cgtrader

... 5.85mm Round stone With 18 x 1.3mm round stones around the centre & 14 x 1.3mm round stones down the shank. The print volume is 243mm and the estimated weights are: Silver: 2.40gr 9K Gold: 2.90gr 14K Gold: 3.10gr 18K Gold: 3.80gr Platinum: 5.30gr

halo ring 3D print model

cgtrader

size m weight 4 grams possibilty to print band size 2,2 mm center stone half carat

Unique Halo ring design 3dmodel Cushion halo 3D print model

cgtrader

. .. gr in Silver 925 (NOTE : this is just model for printing, NOT ring in GOLD) File format: STL and 3dm . SKU: 0382v2 Ready for 3d printing 3d model Cushion Halo ring without any supports (because each 3d printer needs special supports for 3dmodel)

.. gr in Silver 925 (NOTE : this is just model for printing, NOT ring in GOLD) File format: STL and 3dm . SKU: 0382v2 Ready for 3d printing 3d model Cushion Halo ring without any supports (because each 3d printer needs special supports for 3dmodel)

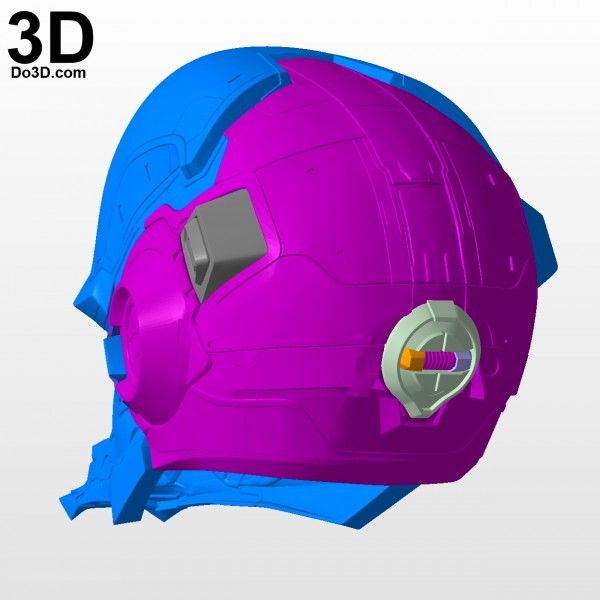

Printable Halo Anubis - Halo Wars 3D print model

myminifactory

The 3D model of the Halo Anubis helmet is designed for printing with absolutely any printers. You can print the helmet as a whole or separately, in parts. In total, there are 5 parts in the model for high-quality printing. You can change the...

Halo Beads Earring 3D print model

cgtrader

Halo Beads Earring 3D print model Halo Beads Earring Measurement : Height 12. 70mm Rhinoceros 5.0 file Model is ready for prototyping on CNC and 3D Printing. ...

70mm Rhinoceros 5.0 file Model is ready for prototyping on CNC and 3D Printing. ...

Classic Halo Ring 3D print model

cgtrader

Classic Halo Ring 3D print model Classic Halo Ring Size : 6 Measurement : 16.5mm Rhinoceros 5.0 file Model is ready for prototyping on CNC and 3D Printing. ...

Ring leaves halo 3D print model

cgtrader

3D model ready to print. waterproof Totally functional Ring leaves halo designed by professional jeweler. ...

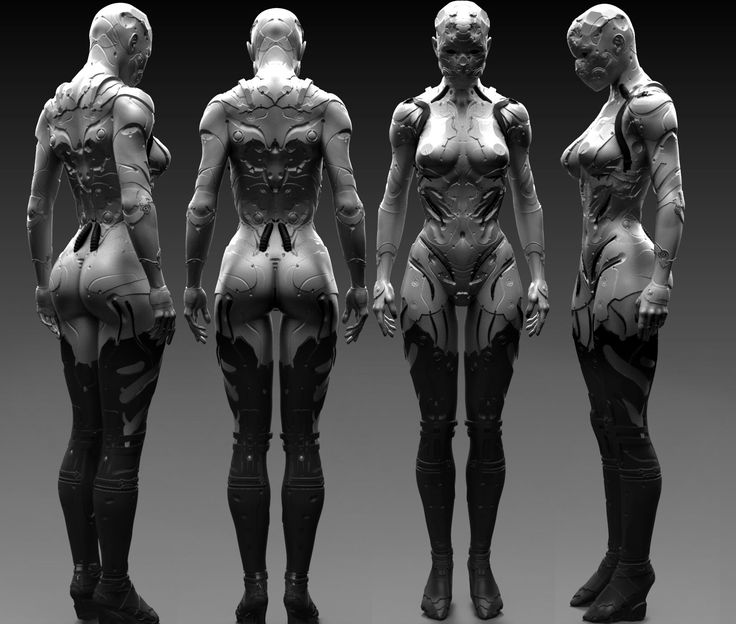

Halo 4 armor 3D print model

cgtrader

This armor is made for 3D printing. ...Wall thickness about 4 mm. The inspiration was the movie Halo 4 forward unto dawn. ...

...Wall thickness about 4 mm. The inspiration was the movie Halo 4 forward unto dawn. ...

Halo scorpion tank 3D print model

cgtrader

print it to add to your halo board games

Halo Plate Earrings 3D print model

cgtrader

Halo Plate Earrings 3D print model Halo Plate Earrings Details : Measurement : Height 10.11 mm Width 10.11 mm Approximate Metal Weight 5.4 gms Diamond Weight 0.1 ct Rhinoceros 5.0 file Model is ready for prototyping on CNC and 3D Printing. ...

Halo Stud Earring 3D print model

cgtrader

Halo Stud Earring 3D print model Halo Stud Earring Details : Measurement : Width - 12. 2 mm Height - 12.2 mm Approximate Metal Weight 3.92 gms Diamond Weight 0.49 ct Rhinoceros 5.0 file Model is ready for prototyping on CNC and 3D Printing. ...

2 mm Height - 12.2 mm Approximate Metal Weight 3.92 gms Diamond Weight 0.49 ct Rhinoceros 5.0 file Model is ready for prototyping on CNC and 3D Printing. ...

Halo Plate Pendant 3D print model

cgtrader

Halo Plate Pendant 3D print model Halo Plate Pendant Details : Measurement : Height - 12.65 mm Width - 12.65 mm Approximate Metal Weight 3.19 gms Diamond Weight 0.05 ct Rhinoceros 5.0 file Model is ready for prototyping on CNC and 3D Printing. ...

Halo Beads Pendant 3D print model

cgtrader

Halo Beads Pendant 3D print model Halo Beads Pendant Details : Measurement : Height - 21. 7 mm Width - 13.9 mm Approximate Metal Weight 2.57 gms Diamond Weight 0.35 ct Rhinoceros 5.0 file Model is ready for prototyping on CNC and 3D Printing. ...

7 mm Width - 13.9 mm Approximate Metal Weight 2.57 gms Diamond Weight 0.35 ct Rhinoceros 5.0 file Model is ready for prototyping on CNC and 3D Printing. ...

Halo Plate Pendant 3D print model

cgtrader

Halo Plate Pendant 3D print model Halo Plate Pendant Details : Measurement : Height - 12.65 mm Width - 12.65 mm Approximate Metal Weight 3.19 gms Diamond Weight 0.05 ct Rhinoceros 5.0 file Model is ready for prototyping on CNC and 3D Printing. ...

Halo Miracle Plate Earrings 3D print model

cgtrader

Halo Miracle Plate Earrings 3D print model Halo Miracle Plate Earrings Details : Measurement : Height 10. 11 mm Width 10.11 mm Approximate Metal Weight 5.4 gms Diamond Weight 0.1 ct Rhinoceros 5.0 file Model is ready for prototyping on CNC and 3D...

11 mm Width 10.11 mm Approximate Metal Weight 5.4 gms Diamond Weight 0.1 ct Rhinoceros 5.0 file Model is ready for prototyping on CNC and 3D...

Halo Pear Tanzanite Ring 3D print model

cgtrader

Halo Pear Tanzanite Ring 3D print model Ring size: 6 (16.51mm). Model is ready for 3D Printing. Center stone â Pear cut tanzanite - 9,00mm x 6,00mm. Halo stones - 16 Round by 0,0175carat 1,6mm x 1,6mm â 0,28 carat. Weight of metal on photo.

Halo Beads Stud Earring 3D print model

cgtrader

Halo Beads Stud Earring 3D print model Halo Beads Stud Earring Details : Measurement : Width - 12. 2 mm Height - 12.2 mm Approximate Metal Weight 3.92 gms Diamond Weight 0.49 ct Rhinoceros 5.0 file Model is ready for prototyping on CNC and 3D...

2 mm Height - 12.2 mm Approximate Metal Weight 3.92 gms Diamond Weight 0.49 ct Rhinoceros 5.0 file Model is ready for prototyping on CNC and 3D...

Halo Beads Pendant 3D print model

cgtrader

Halo Beads Pendant 3D print model Halo Beads Pendant Details : Measurement : Height - 21.7 mm Width - 13.9 mm Approximate Metal Weight 2.57 gms Diamond Weight 0.35 ct Rhinoceros 5.0 file Model is ready for prototyping on CNC and 3D Printing. ...

Halo and Cluster Earrings 3D print model

cgtrader

Earring with Halo and Cluster Gems 3D model. Size 9 x 9 x 3 mm 24 round gems 1. 0 mm on the Halo. Center Cluster Stones: 3.0 mm - 1; 2.0 mm - 4; 1.5 mm - 4 Pcs. Weight yellow gold 14K - 1.64 gr (one Earring) Ready for 3d printing. ...

0 mm on the Halo. Center Cluster Stones: 3.0 mm - 1; 2.0 mm - 4; 1.5 mm - 4 Pcs. Weight yellow gold 14K - 1.64 gr (one Earring) Ready for 3d printing. ...

Star Halo Ring Free 3D print model

cgtrader

Halo Ring. ...

Halo Pear Gold Ring 3D print model

3docean

Halo Pear Gold Ring 3D print model Ring size: 16.51mm Center stone – Pear 0,83 carat 7,80mm x 5,68mm. Side stones – 12 Round by 0,0195 carat 1,72mm x 1,72mm – 0,234 carat. Halo stones – 21 Round by 0,008 carat 1,35mm x 1,35mm – 0,168 carat. ...Total...

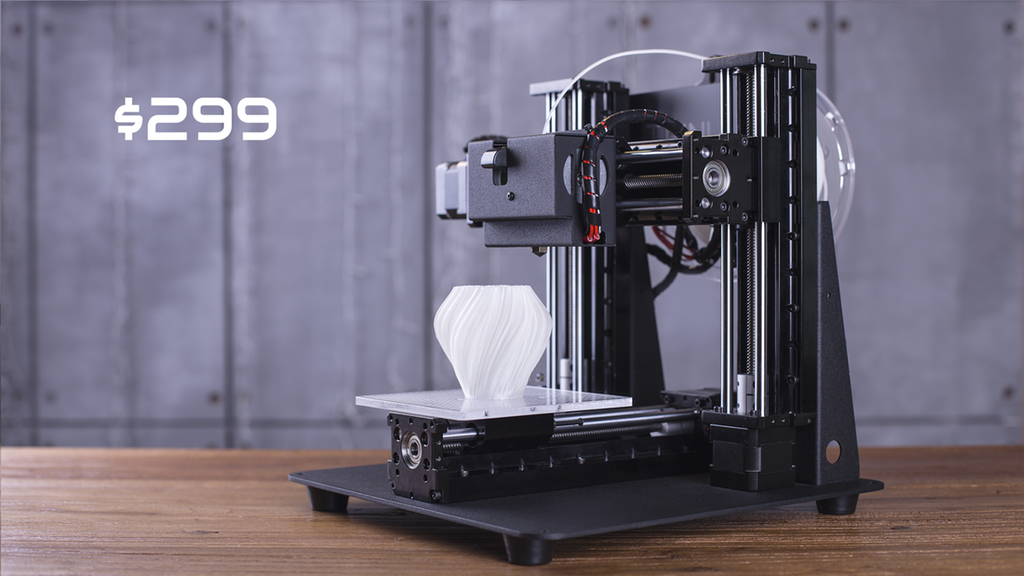

3D printing. What are we breathing?

Hello dear. In this article, I will try to tell you about what and in what quantities can be released from plastics during the FDM 3D printing process. The issue will be considered not from the side of global environmental pollution, but from the side of possible pollution of the room or workshop in which the FDM 3D printer directly operates.

In this article, I will try to tell you about what and in what quantities can be released from plastics during the FDM 3D printing process. The issue will be considered not from the side of global environmental pollution, but from the side of possible pollution of the room or workshop in which the FDM 3D printer directly operates.

I recommend that you read at least the fourth and fifth sections. Link to the video version of the article at the end. Here is the content of the article: nine0008

1 What and how much is released from plastics?

2 At what point in time is the emission of suspended particles maximum?

3 Effect of print settings

4 Particulate matter and VOC control methods

5 Pins

I must say right away that all the data is again for foreign plastics. In the comments, you write to me that it would be interesting to read about our materials, and not about foreign ones. Yes, I agree, perhaps the conclusions drawn from my work may not be applicable to "our" plastics. But in defense, I note that, firstly: the conditional foreign ABS should not radically differ from “our” ABS. Secondly, our major producers say that they buy raw materials from European firms. In this regard, I believe that the voiced data should be relevant for domestic filaments. nine0003

Yes, I agree, perhaps the conclusions drawn from my work may not be applicable to "our" plastics. But in defense, I note that, firstly: the conditional foreign ABS should not radically differ from “our” ABS. Secondly, our major producers say that they buy raw materials from European firms. In this regard, I believe that the voiced data should be relevant for domestic filaments. nine0003

1 What and how much is released from plastics?

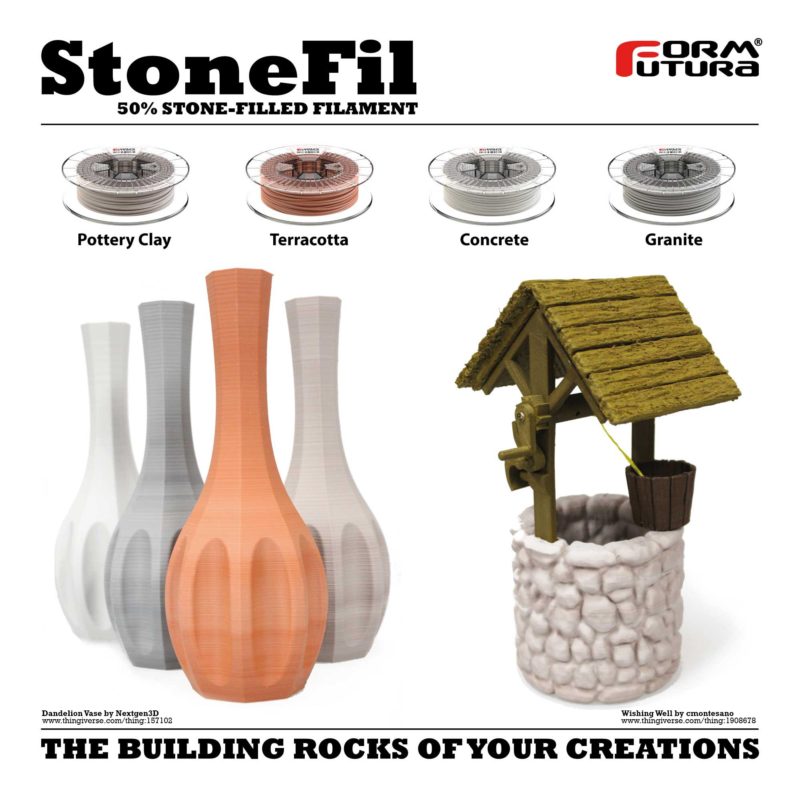

Two types of air pollutants are emitted from any plastic during operation of a 3D printer. Firstly, these are ultra- and finely dispersed (or suspended) particles, the size of which ranges from several nanometers to several micrometers. The second is volatile organic compounds.

In fact, the first group is micro dust, consisting of fragments of plastic, as well as fragments of fillers. In [1], an analysis was made of the release of suspended particles from various plastics during printing of a cylindrical sample with a duration of 60 minutes. Plastics PLA, PVA, ABS, PC, ASA, nylon were analyzed. An analysis of the results showed an interesting regularity in the intensity of the release of suspended particles during the operation of a 3D printer. Look at this chart: nine0003

Plastics PLA, PVA, ABS, PC, ASA, nylon were analyzed. An analysis of the results showed an interesting regularity in the intensity of the release of suspended particles during the operation of a 3D printer. Look at this chart: nine0003

Zero is the start of printing. It is clearly seen that it is at the very beginning of printing that there is a sharp increase in the concentration of suspended particles, then the concentration gradually decreases. The researchers attribute the initial peak to the nozzle's heating period to operating temperature. At this point, the plastic, which is motionless inside the nozzle, is subjected to prolonged heating and, consequently, thermal degradation. It can be seen from the graphs that such a picture is typical for absolutely all plastics. In support of this, the researchers from [2] come to similar conclusions. nine0003

Now let's look at each plastic separately. I think it will be most interesting for you to find out which plastics are leaders in terms of the number of emitted particles. ASA took first place, followed by nylon, PC and ABS, respectively. PLA and PVA turned out to be the most environmentally friendly.

ASA took first place, followed by nylon, PC and ABS, respectively. PLA and PVA turned out to be the most environmentally friendly.

This is how the size distribution of emitted particles looks like when printing a sample for pollution leaders:

And this is how the graphs for PLA of various companies and PVA look like: nine0003

The difference in the graphs is obvious. Please note that PLA and PVA emit particles at the very beginning of printing, and then, after a while, the release of particles almost stops.

Here are the results of measurements made by the authors of another study [3]:

On this graph, manufacturers and the type of plastic are labeled at the bottom, and the intensity of the release of suspended particles is measured along the vertical axis. Again, ABS and PC are among the leaders in terms of pollution. Additionally, HIPS and nylon joined them in this study. The most environmentally friendly again turned out to be PLA. nine0003

nine0003

As far as carbon- or fiberglass-reinforced plastics are concerned, they are practically unexplored. In one of the works [4], along with other plastics, I was able to find this:

Underlined in red is PETG with 8-12% fiberglass. As you can see, such plastic is the leader in the selection of large particles. Once again I will say that this is the only result that I could find, so I can’t draw serious conclusions here, but anyway I decided to add it to the publication. nine0003

Now let's move on to the isolation of volatile organic compounds. In short, when printing with almost any filament, dozens of different compounds are released. Here, for example, is a table from [4]:

Plastics are signed in the table above. The first column lists the names of the chemical compounds. If there is no number for some connection, it means that it was not fixed by the device during printing with a specific plastic. Analyzing the table, we see that ASA and ABS plastics again become leaders in the anti-rating (ULTRAT is ABS with the addition of 3% polycarbonate). PETG becomes the most environmentally friendly (GLASS Transparent is also PETG, but with the addition of fiberglass). nine0003

PETG becomes the most environmentally friendly (GLASS Transparent is also PETG, but with the addition of fiberglass). nine0003

Now let's turn to the results of research from another work [3], which examines a slightly different set of plastics:

This figure shows two histograms. The left histogram shows plastics with a maximum release of volatile organic compounds up to 40 micrograms per minute, and on the right - with an intensity of more than 40 micrograms per minute. The name of each column indicates the printer on which the material was printed.

Polycarbonate and TGlase (PETT plastic) are the most environmentally friendly. PLA looks a little worse. And nylon turned out to be the worst in terms of the number of emissions. It is interesting to note that for ABS plastics, the amount of emissions is highly dependent on the 3D printer on which they are printed, and can differ by as much as five times. nine0003

Pay attention to polycarbonate. If it is one of the most polluting in terms of the release of suspended particles, then it is the most environmentally friendly in terms of the release of volatile organic compounds.

2 At what point in time is the emission of suspended particles maximum?

Let's look at two graphs from [5]:

The left graph shows the particulate concentration inside the MakerBot 3D Printer, while the right graph shows the particulate concentration in the room where the 3D printer is located. Two peaks on the graphs mean two consecutively printed parts. Again, we see that a sharp increase in the number of suspended particles occurs at the very beginning of the printing of the part. nine0003

And here is another graph from another work [2]:

Shown here are three graphs showing the change in the concentration of suspended solids when printed with ABS plastic. According to the legend, the graphs differ in nozzle temperature. As in the previous work, it can also be seen here that after heating, at the moment of printing, an increase in the concentration of suspended particles occurs. From these graphs, another interesting point is visible.

3 Effect of print settings nine0034

These three graphs show that as the temperature of the nozzle increases, the concentration of suspended particles increases. However, the difference between the charts is significant. Other scientific works [4] confirm this:

This graph shows particulate matter concentration versus ABS nozzle temperature. It can be seen that at a nozzle temperature above 250 degrees there is a sharp increase in the number of ejected particles.

It is interesting to note the effect of printing speed on the concentration of suspended particles. Here is a graph from [2]: nine0003

These graphs show the dependence of the concentration of suspended particles when printing with ABS plastic at different print speeds. We compared printing at speeds of 30 mm/s (FR30 in the graph), 60 mm/s (FR60) and 90 mm/s (FR90). It is interesting to note that the maximum concentrations are observed at an average printing speed. In this case, the minimum concentration is observed for a speed of 90 mm/s.

In this case, the minimum concentration is observed for a speed of 90 mm/s.

4 Particulate matter and VOC control techniques nine0034

4.1 Studies have shown that reducing nozzle temperature reduces the amount of suspended particles released. Therefore, do not raise the nozzle temperature unnecessarily.

4.2 Increasing the print speed reduces the concentration of suspended particles. Another positive effect of increasing the printing speed is to reduce the printing time, which leads to a decrease in the time during which suspended particles are released. nine0003

4.3 Filtration. HEPA filters are effective for almost all sizes of particulate matter, but to be useful, you need a 3D printer with a closed chamber. In addition, HEPA filters generally do not capture volatile organic compounds, which, as it turns out, are emitted in abundance from some plastics. They need charcoal filters.

4.4 Ventilation or ventilation. I think this is the most efficient way for most conventional FDM 3D printers used at home and in workshops. Here are pictures from [5], showing the distribution of the concentration of suspended particles in a room with a 3D printer: nine0003

I think this is the most efficient way for most conventional FDM 3D printers used at home and in workshops. Here are pictures from [5], showing the distribution of the concentration of suspended particles in a room with a 3D printer: nine0003

In a well-ventilated room, the concentration of particles is an order of magnitude lower and at a distance of more than a meter from the printer, only slightly higher than the background level.

4.5 Optimize printer performance. In paragraphs 4.1 and 4.2, I have already touched on the printing modes, but the authors of the scientific work [2] went further and proposed an interesting way to reduce the amount of suspended particles released. Its essence lies in the fact that we first heat up the empty nozzle to operating temperature, then load the filament and immediately start printing. After printing is completed, remove the filament. Here are graphs from [2] showing the result of such manipulations: nine0003

Both graphs show the emission of suspended particles when printing ABS with a nozzle temperature of 240°C and a speed of 60 mm/s. The top graph is printing without loading/unloading the filament.

The top graph is printing without loading/unloading the filament.

5 Conclusions

As a conclusion, firstly, I would like to note that such plastics as ASA, ABS and nylon are leaders in terms of the amount of emitted particles and volatile organic compounds. The average highlights are polycarbonate and HIPS. The most environmentally friendly and in terms of suspended particles and volatile organic compounds are PLA and PETG. nine0003

Second, print in a well-ventilated room or ventilate the room while printing. Try not to increase the temperature of the nozzle unnecessarily.

You may have noticed that I didn't say a word about how harmful it all is. The fact is that the assessment of the harmfulness of all this required quite a lot of time. I haven't been able to get definitive answers yet. Now I’ll just say that it’s rather harmful, especially with regular contact. Therefore, in this article, I deliberately did not touch on the topic of harmfulness. I hope that I will be able to deal with this issue to the end and then I will publish all the results. nine0003

I hope that I will be able to deal with this issue to the end and then I will publish all the results. nine0003

Video version of the article:

That's all for now.

Sources:

1. Chýlek, R., Kudela, L., Pospíšil, J., Šnajdárek, L. (2019). Fine particle emission during fused deposition modeling and thermogravimetric analysis for various filaments. Journal of Cleaner Production, 117790. doi:10.1016/j.jclepro.2019.117790

2. Deng, Y., Cao, S.-J., Chen, A., Guo, Y. (2016). The impact of manufacturing parameters on submicron particle emissions from a desktop 3D printer in the perspective of emission reduction. Building and Environment, 104, 311–319. doi:10.1016/j.buildenv.2016.05.02

3. Azimi, P., Zhao, D., Pouzet, C., Crain, N. E., Stephens, B. (2016). Emissions of Ultrafine Particles and Volatile Organic Compounds from Commercially Available Desktop Three-Dimensional Printers with Multiple Filaments. Environmental Science & Technology, 50(3), 1260–1268. doi:10.1021/acs.est.5b04983

Environmental Science & Technology, 50(3), 1260–1268. doi:10.1021/acs.est.5b04983

4. Gu, J., Wensing, M., Uhde, E., Salthammer, T. (2019). Characterization of particulate and gaseous pollutants emitted during operation of a desktop 3D printer. Environment International, 123, 476–485. doi:10.1016/j.envint.2018.12.014 nine0003

5. Zontek, T. L., Ogle, B. R., Jankovic, J. T., Hollenbeck, S. M. (2017). An exposure assessment of desktop 3D printing. Journal of Chemical Health and Safety, 24(2), 15–25. doi:10.1016/j.jchas.2016.05.008

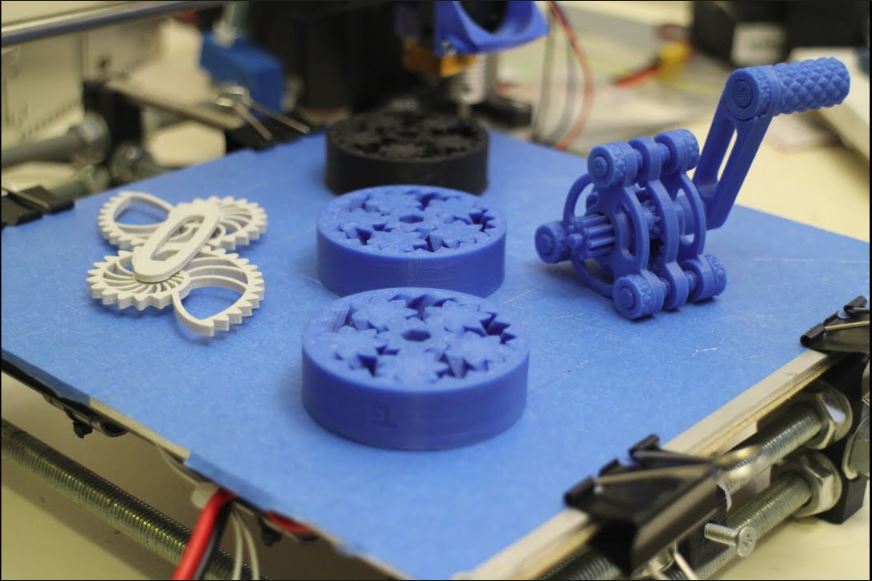

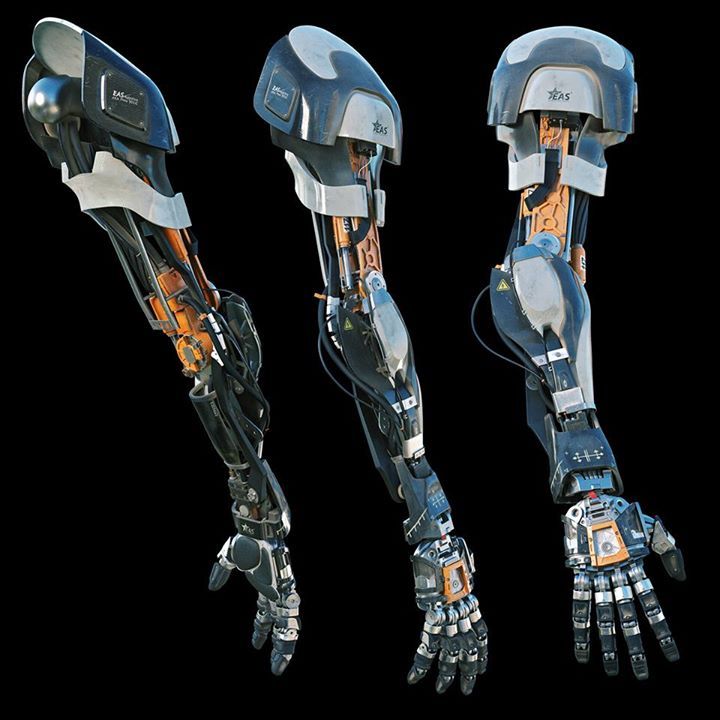

A 3D printed leg costs $100. The prosthesis is always individual, it must take into account the personal characteristics and needs of the consumer, be durable, serving the owner for a number of years, and at the same time relatively light and comfortable. All these requirements are not easy to fulfill, and the manufacture of a prosthesis is delayed for weeks, or even months, and is quite expensive even in the developed countries of the world.

nine0003

nine0003 The situation is more complicated for children: firstly, they grow up, and secondly, they break things more often than adults, which means that they have to update their prostheses regularly, and this becomes a difficult financial burden for the family or insurance authorities if the replacement of the prosthesis is covered insurance.

Apparently, the future is not far away when many of these difficulties will be left behind.

Bioengineers from the Japanese company SHC Design have developed a system for 3D printing medical leg prostheses at home. One of the first patients to receive such a prosthesis was 41-year-old Fuminori Ando, who lost his leg below the knee shortly after birth. nine0003

Photo courtesy of wsj.com

He received an artificial leg made of soft and light polymer material, outwardly almost exactly copying the real one, reproducing the natural curve of the heel, and even the distance between the toes. This is important for Ando: he has long dreamed of wearing sandals to match his Japanese-style summer suit.

And one more important advantage: now a man can go to the pool and swim with a beautiful and comfortable artificial leg.

Once he gave up swimming because of the weight and unaesthetic appearance of the old prosthesis. nine0003

A high-quality, custom-made prosthesis costs about $4,200 in Japan. SHC Design senior Yutaka Tokushima predicts the price of a new prosthesis printed on their company's 3D printer to be around $100.

Photo courtesy of wsj.com

This was made possible not only by their development, but also by the creation of a new material - elastic polymer - rubber manufacturer JSR, who joined forces with SHC Design.

So, first, the patient's healthy leg is scanned, then, using a computer program, a template of a symmetrical prosthesis is created that takes into account the parameters of the shoe at the request of the patient, the feeder supplies the material for printing, and after a while, a soft but strong prosthesis is ready. Its low cost will allow the patient to have several spare prostheses for different shoes and different activities.

However, SHC Design is not only going to meet the needs of patients who care about greater comfort and aesthetics. In a poor country like the Philippines, where their 3D printer is currently being tested, nearly 350,000 people need a prosthetic leg and 90% cannot get it because of the high price and lack of specialists.

“I would like to deliver my product to those who are really in need,” says SHC Design CEO Tsuneo Masuda, who founded the company after 26 years of medical device manufacturing experience. The company received subsidies from the Japanese government to develop a system for printing prostheses.

Senior developer Yutaka Tokushima believes that the company will start selling its 3D printers bundled with software in Japan and the Philippines as early as April next year. They will cost $ 2,000, but the scanner will need to be purchased separately from another provider. nine0003

Major prosthesis manufacturers are also interested in 3D printing. Its elements are used by the German company Ottobock, which prints coatings for prostheses that make it possible to hide its mechanical parts from the eye.