Print on 3d objects

How to print directly on to 3D objects - FESPA

We’ve heard a lot about 3D in the past three or four years. But, clever though it is, it’s hard to see it playing a big part in the established 2D printing sector.

Instead we’re starting to see a much quieter but more significant mix of 2D printing straight onto three-dimensional objects. It’s called “direct-to-shape,” (DTS) and it’s happening now.

The headline makers have been big and specialised industrial units, for printing digitally on bottling lines, beverage cans, industrial tubes and tile edges. However Heidelberg, the big German offset press maker, has plans to take a direct-to-shape product family into retail/consumer markets as well as commercial and industrial print.

At the entry level, direct-to-shape can increasingly be done on a smaller scale by small A3/A2 deep-bed flatbed printers that are the digital equivalents of small screen and pad printers.

Beer makes a splash

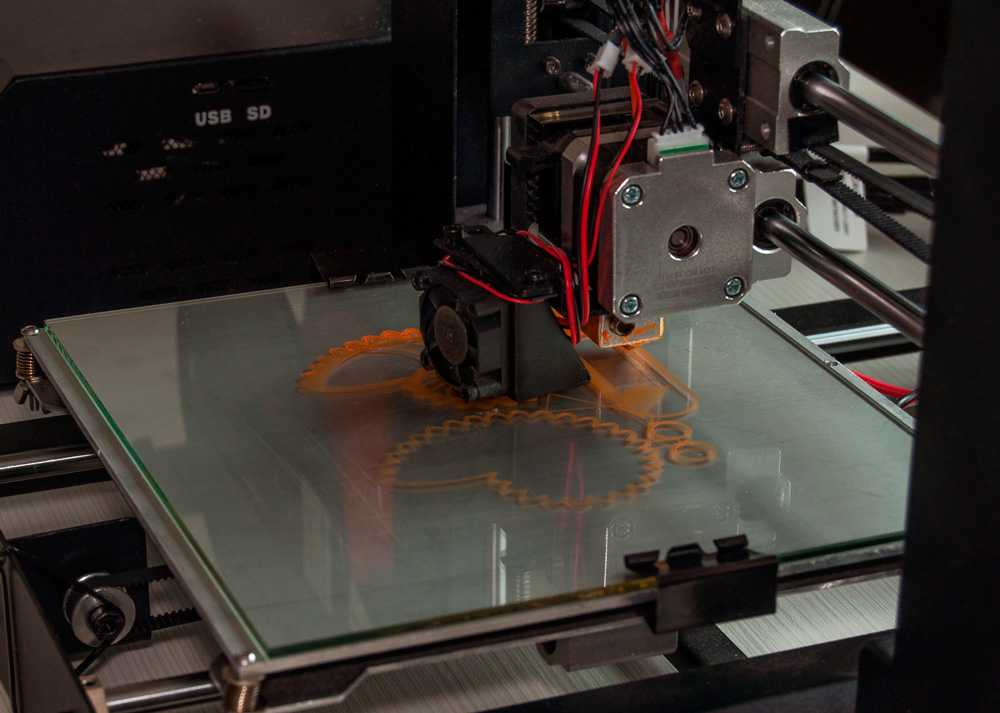

The heavy-industrial end of direct-to-shape saw a publicity splash in August 2015 when KHS, a big German maker of bottle filling lines, announced the first commercial installation of its “Direct Print Powered by KHS” system, first announced at the Dr inktec exhibition in Munich a couple of years ago.

This uses Xaar 1002 printheads arranged in an unusual vertical “skyscraper” arrangement, firing horizontally onto the straight cylindrical sides of the bottles. The bottles are rotated as they pass the print stations, giving wraparound graphics up to 70mm high on to bottles ranging from 40-125mm.

The first installation is at Browerij Martens, Belgium, the second largest beer brewer in Belgium. This is being used for relatively short, versioned print runs on PET beer bottles. PET isn’t much used for beer in Western Europe, though it’s more common in Eastern European countries.

The first publicly announced job was a promotional launch of a beer that showed a range of actors from the Belgian TV sitcom “FC De Kampioenen” to promote an October 2015 “Jubilee Generale. ” The Dagschotel PET beer bottles carry images of different actors which come to life using a special smartphone app and interact with one another if two bottles are placed next to each other.

” The Dagschotel PET beer bottles carry images of different actors which come to life using a special smartphone app and interact with one another if two bottles are placed next to each other.

Printed cardboard six-pack sleeves, Martens will be printing in tens of thousands if not more, but that’s still small beer in the drinks industry.

Krones, another big German bottle-filling line maker, announced an inkjet DTS project at Interpack in 2014. Its DecoType system has been developed in co-operation with Heidelberg, which has adapted its 4D technology with vertical Xaar 1002 heads, to print UV-cured ink on empty bottles made from PET, PP or PE. The printer is based on a carousel that takes bottles from a standard line and returns them after printing. Print heights up to 200 mm are possible.

The KHS installation at Browerij Martens.

According to project manager Andreas Kraus: “the advantage is flexibility. Each print can be different, you can integrate variable data to individualise and personalise products. A special advantage is that areas can be printed on in areas that cannot be printed today with conventional labels, like embossings, grooves or structure. This adds value to the container and we think and believe that this is the technology for the future.”

A special advantage is that areas can be printed on in areas that cannot be printed today with conventional labels, like embossings, grooves or structure. This adds value to the container and we think and believe that this is the technology for the future.”

A YouTube video shows the system printing on the flatter sides of oval plastic bottles. There is a DecoType at a Beta site already, according to Jason Oliver, Heidelberg.

Tubes in a spin

Tube printing so far has seen more development than bottles. The German company Hinterkopf claims to be the first to have developed a digital tube printer, which it calls the D240. It is intended for printing on plastic and aluminium tubes, aluminium cans, cartridges, bottles, cups and other containers.

The price is about €2.5 million depending on the configuration and specification. Hinterkopf’s first production system was installed in July 2015 at Ritter, an Austrian company to the south of Augsberg. Ritter makes plastic products for sectors such as medical technology, road construction and landscaping. It has used screen printing and thermo transfers, but wanted something that could change between jobs faster.

It has used screen printing and thermo transfers, but wanted something that could change between jobs faster.

“Customers buy ever smaller quantities to be delivered in shorter periods, so that we have to offer the service of stock keeping and just-in-time deliveries,“ says joint managing director Ralf Ritter. “We wish to be trend-setters in the print-on-demand business of plastic cartridges.”

Another tube printer has been developed by the Italian company Martinenghi, whose Michelangelo KX48P was announced in 2014. This can print in up to seven colours, including white, on tubes from 13.5 to 66 mm diameter and 50 to 280 mm in length.

In Switzerland, Wifag-Polytype has developed DigiCup, a direct printing system for square-sided plastic tubs, such as margarine containers. It uses Konica Minolta heads and was developed with help from UK integrator Industrial Inkjet Ltd. This treats the tubs as a combination of flat sides and conical side sections. It’s seen as an alternative to in-mould labels, where pre-printed plastic labels are placed into the injection moulds for the containers. Several have been installed already, the company says.

Several have been installed already, the company says.

Heidelberg targets retailers

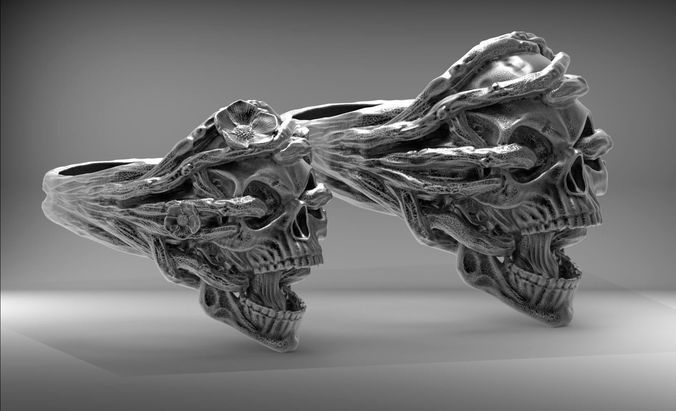

All the systems we’ve mentioned so far have been for “industrial” use and runs on standardised products such as bottles or tubes. Heidelberg in Germany has put a lot of effort into DTS and the first commercial product to carry its own name is for very short runs aimed at consumer good with online personalisation via web ordering. Heidelberg calls its DTS systems “4D” meaning 3D objects with an extra dimension of print applied to them.

In early 2014 it announced a DTS printer called Jetmaster Dimension, which has a robotic holder that rotates objects beneath an inkjet head. The first two commercial installations were made at the end of 2014, to Liechtenstein-based BVD Druck + Verlag and German Druckhaus Mainfranken, a print partner of web-to-print firm Flyeralarm.. Both are used to produce personalised footballs which can be ordered, customised and paid for online.

These two machines only print in black UV cured ink. However at the inPrint show in Munich in November 2015 Heidelberg is due to announce a four-colour model, with plans to introduce further types in 2016 including one with six axes of rotation, allowing a greater range of shapes to be moved under the print heads.

However at the inPrint show in Munich in November 2015 Heidelberg is due to announce a four-colour model, with plans to introduce further types in 2016 including one with six axes of rotation, allowing a greater range of shapes to be moved under the print heads.

The company sees great potential for direct-to-shape in the longer term, saying “It will make the process of customising mass-produced goods faster, cheaper, and more flexible. End users are increasingly looking for personalized design options when shopping for mass-produced items such as sporting goods, footwear, furniture, and cars. High-quality printing with logos, text, and other graphic elements is usually their first choice.

“Inkjet printing offers the ideal solution, as it can deliver high-quality results in a wide range of colours on a huge variety of surfaces, without having to come into contact with the product.”

Oliver says that Heidelberg is already talking to retail organisations about installing in-store printers that will be able to offer customisation onto a range of objects, according to Jason Oliver.

Affordable DTS

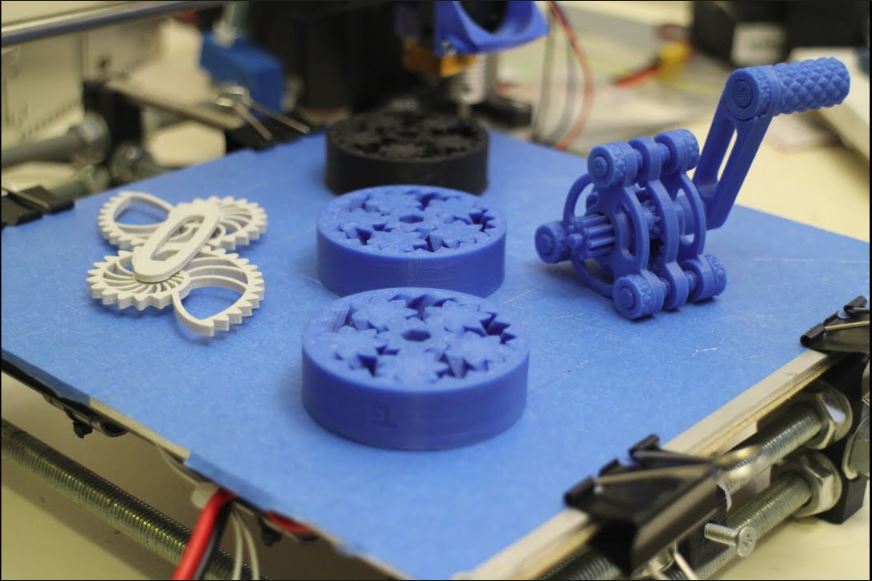

In the past seven years a family of small format UV-LED flatbed inkjets have pioneered by Mimaki (and followed by Roland DG, Mutoh and some clever third party Mimaki-hackers). These will not print 100,000 items per hour, but they cost €20,000 to €40,000 and not millions.

They are typically used for small promotional print work, onto pens, gold balls, key gags, phone covers and similar. They can also be used for more conventional industrial applications such as switch and instrument panels.

Jigs can be used to hold multiple items in position for the printed image to register on top, and in some cases the jogs can rotate under the heads so for instance the edges of phone cases can be printed. Cylinder rotators can be used with single bottles and tubes.

Mimaki originally produced the A3 format UJF-3042 for objects up to 50 mm deep, but later models have increased this to 150mm. It has added the A2+ format UJF-6042 and the new UJF-7151 (710x510 mm bed format).

Roland DG first introduced the 305mm by 280mm format LEF-12 and later added the A3+ VersaUV LEF-20. Most recently Mutoh introduced the A3+ ValueJet 426UV. Several third party suppliers take existing small flatbeds (mostly Mimakis) and re-engineer them with deeper beds.

Mixed blessing?

Direct to shape printing has huge significance for several established sectors of the printing industry that today mostly use pad printing, screen process, self-adhesive labels or a variety of transfer methods such as dye sublimation or water-slide decals. It removes the separate print and application stage.

This may be a mixed blessing for established printers. On the one hand if they can adopt it themselves for items such as giftware, then it brings the usual digital advantages of short run and personalisation in an efficient package.

Inkjet printed PET bottles produced by Browerij Martens.

On the other hand, as KHS and Krones demonstrate, these DTS digital printers may end up going onto manufacturing and filling lines and cut out the need for outside print services. Probably what we’ll see is a mix of both, with small customers using outside services and the bigger ones being able to make the investment to bring the work inhouse.

Probably what we’ll see is a mix of both, with small customers using outside services and the bigger ones being able to make the investment to bring the work inhouse.

by FESPA Back to News

Cults・Download free 3D printer models・STL, OBJ, 3MF, CAD

Top design

By FlexiFactory

This "Kangaroo and Joey" is an articulated Print-in-Place model that requires no supports, what an amazing modeling job! The included Joey is also print-in-place and unsupported, and can be printed with his mom, or separately if you want him in a different color.

Download 3D model

01

Bro Hammerhead Shark - Print-in-Place

€2.35 -40% €1.41

Renault C460 Hybrid Rally Dakar

€1. 79

79

4x5 Microchess set

Free

04SLITHE

€17.33

05spray paint can toys SKILL WORKS fat cap

€2.67 -35% €1.73

Elephant

€2.04 -10% €1.84

LincBot

€2.77

08420 COOKIE HOLDER

€2.56

09Little magnetic monster magsafe charging base

€4. 05

05

1:5 SCALE 2022 F1 CAR - FULLY PRINTABLE

€15 -10% €13.50

glasses new year 2023

€1.22

12CALYPSO

Free

13Barded Tyrannosaur

Free

14ROBBIE planter

€5 -50% €2.50

BOX / STORAGE CASE

€2.25

16Frankenstein's Dino Monster

€4. 60

60

Robot Hand Controller Holder

€2.35

18Blaze, The Dragon Phone Guardian

€2.35

19PS5 Video Game Bookend Organizer

€7.05

20Cali-Dragon Cave

Free

01

Bambu AMS Colour 2 Tier Stand (for 2 AMS Units 1 Above 1 Below)

€2.26

02Nice Flexi Unicorn

€1.05

03Tractor (+keychain)

€0.99

04Voidwalker Exosuits Truescale

€14. 79

79

FLEXI GIRAFFE

€0.92

06santa stormTrooper keychain

€0.50

07Chill Buddy Lighter Case

€0.93

08KUPPA, THE HAIRY FLEXI GNOME TO PRINT IN PLACE WITH HANDS UP

€2.35

01

Pasta Keychain Set

€1.99 -35% €1.29

Nes Keychain (snes keychain)

€0.92

03Nice Flexi Monkey

€1. 05

05

Trombone Mouthpiece

€1.88 -37% €1.18

VISTAPRINT 25 CARD STAND

Free

06Electrode And Voltorb

€2.49

07Steampunk lizard

€1.50

08Flexy Shrimp Print In Place No Support

€2.50 -50% €1.25

Ruffian Modular Mecha

€3.76

10Tiny New Years Hat 2023

€0. 61

61

Totoro pin display

€1.50

12Bitcoin Christmas tree balls

Free

13Tower Of Terror Disneyland Paris

€3.50

14Flexy Baby Kangaroo Print In Place No Support

€2.50

15TOY CAR / TOY CAR / BOUNANA 2

Free

16Lords of Vegas buildings and risers

Free

17Fifa World Cup-Golf Tee #SPORTXCULTS

Free

18Sailplane - Control Surface Deflection Gauge

Free

19Colossal Truig, troll mixed with squigg

€14

20Tie Fighter Super High Detail 28 cm high

€35

01

Cute Mini Octopus

Free

02Enormous Heavy Tank Alternate Turret (Kitbash/Remix)

Free

03Harold (Mark of Change)

Free

04flexi turtle

Free

05Thing

Free

06Thing Addams (Fingers)

Free

07Corrupted Blu-Rays

Free

08World Cup

Free

🔁 Updated

Umbra Sniper Rifles

Free

Classical Leman Russ

Free

Happy New Year topper

Free

Barbie cutter

Free

FERISIA Small farmer's House

Dark Sister - Show Accurate: House of the Dragon - Game of thrones

Cybertruck with sliding bed cover

RACK N' RUIN- ADVENT CALENDAR DAY 19

YuGiOh Card : Granmarg the Rock Monarch(high Poly)

€4

Wine glasses with hearts Stl File

€3. 29

29

Power Supply cover with switch and mounting tabs

Free

2020 Extrusion 45 degree Frame support (z-axis)

Free

Cleaner daber, bad, banger, wax

€1

Halo 5 Chip_Cortana

€2.41

Women Studs Drops Hoops Earring Diamond 3dm STL Model 32-37

€36.14

Interactive touch terminal 📱

€0.50

See all 3D models

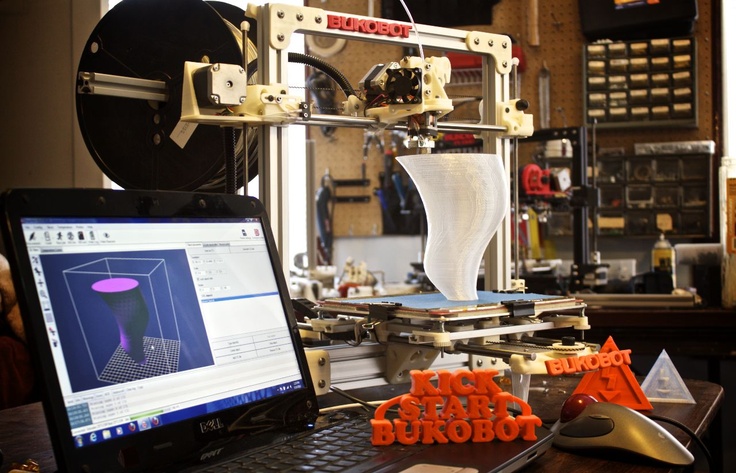

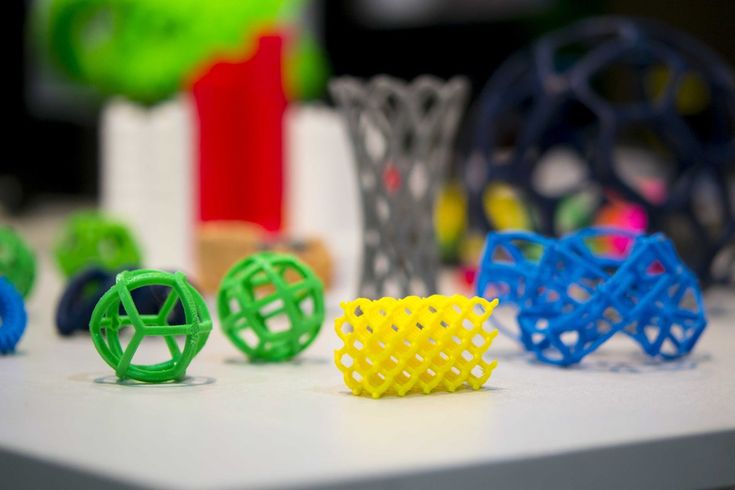

Cults, the 3D printing platform

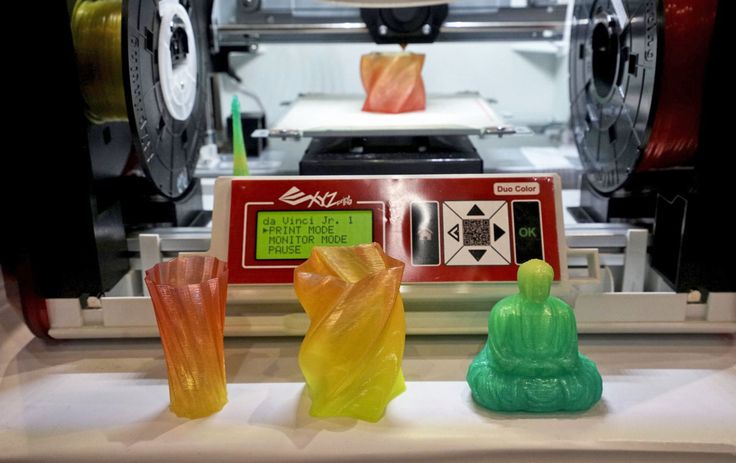

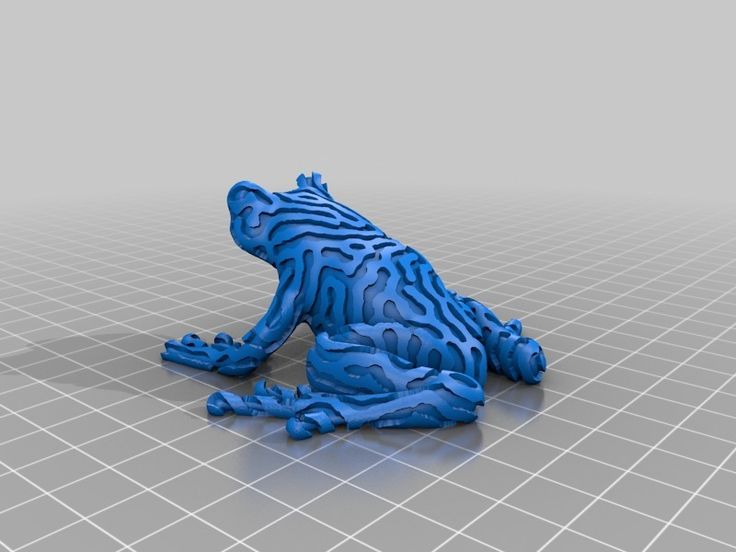

Welcome to Cults, the world’s leading independent website for 3D printer files. Discover and download the best 3D models for all your 3D printing & DIY projects.

Cults is a digital marketplace for 3D printing and design. Use our 3D model library to discover everything you can do with a 3D printer (FDM, SLA, DLP, SLS) event with CNC machining and laser cutting. You don’t know how to make a 3D file but you want to 3D print objects? Cults is for you! Browse our different categories and download the best 3D printer models for free, open-source or paid mode. The formats you can download are in STL, OBJ, 3MF, CAD, STEP, SCAD or DXF, DWG, SVG format, they are all 3D printable guaranteed or CNC compatible.

Use our 3D model library to discover everything you can do with a 3D printer (FDM, SLA, DLP, SLS) event with CNC machining and laser cutting. You don’t know how to make a 3D file but you want to 3D print objects? Cults is for you! Browse our different categories and download the best 3D printer models for free, open-source or paid mode. The formats you can download are in STL, OBJ, 3MF, CAD, STEP, SCAD or DXF, DWG, SVG format, they are all 3D printable guaranteed or CNC compatible.

We are connecting 3D print files makers with people who want to use their 3D printer. Our 3D model repository acts as a real source of inspiration since the best designers share their best STL files daily to offer you their latest inventions!

On Cults you can also find a 3D printer nearby, get voucher codes to buy cheap 3D printers or filaments at best prices and also a whole series of 3D printing contests. Cults is a joyful community that brings together all 3D printing fans to dialogue and create together.

Cults is a joyful community that brings together all 3D printing fans to dialogue and create together.

Commission system

You are a designer and you want to sell your 3D models optimized for 3D printing? Thanks to Cults you can earn money with your files STL, OBJ, CAD, 3MF, etc.! For each download, you will receive 80% of the net selling price (excluding VAT) via PayPal. Cults keeps 20% of commission which is used to finance bank fees (about 5%) and then all the costs related to the technical maintenance of the platform: hosting, bandwidth, accounting, email communications, translations, etc. There is no subscription system or fixed fee to pay. You sell, you win!

If you are still hesitating to share your models on Cults, feel free to read this article Why publish my designs on Cults? List of advantages and benefits to get an idea.

- Designers 80%

- Cults 15%

- Banking fees 5%

Upload a 3D model

3D Printing Technology

Wayne Buchar, Chief Engineer at Xerox, talks about the new industry of direct on-site printing.

Change Agents

Wayne Buchar: 3D Printing

"Applications in this area can only be limited by the imagination - it's a blue ocean, as no one has yet worked in this direction"

New industries outside the printed pages

Wayne Buchar is Xerox's chief engineer and project manager and has always been interested in inventions and problem solving. He is interested in how certain things work. So at the age of eight he built a transmitter to control model airplanes, in college he invented the award-winning ultrasonic microscope, and as an adult he developed direct-to-object printing technology. nine0003

What is Direct Printing on Objects? Imagine a 3D object. For example, a cup, a water bottle or a ball. Now imagine that the image can be printed directly on the surface of these objects, even if the surface is uneven and curved. The Xerox® Direct to Objects Inkjet Printer, co-designed by Wayne Buchar, can print custom images on plastic, metal, glass and ceramic surfaces in just minutes. Direct on-site printing takes personalization to the next level and is a game-changer for retailers, print service providers and event planners. Read the interview with Wayne Buchar to learn more about his passion for innovation and how he came up with direct object printing. nine0003

Direct on-site printing takes personalization to the next level and is a game-changer for retailers, print service providers and event planners. Read the interview with Wayne Buchar to learn more about his passion for innovation and how he came up with direct object printing. nine0003

Wayne, have you always been an inventor? Even as a child?

Yes it's true. I was fond of radio-controlled model aircraft. In all circles, I was always the youngest of the participants. In the aeromodelling club too. When I was eight, I built my own transmitter with my father. I have always been interested in electronics. In college, I received the National Technology Award for inventing the ultrasonic microscope. After that, I was invited for an interview at Xerox. Because I got a national award. nine0003

Were your parents engineers?

Yes, my father was an engineer. He was in software. He started teaching me from a very young age. When I was eight, I helped him fix the car. He always took me with him and taught me everything he knew. He never gave things for repair to other people. Never. Therefore, when a color TV broke down, we repaired it together. I sat and watched him work. And he explained everything he did. I remember that at the age of 12 he explained to me what magnetic domain memory is. He then worked on the creation of such a memory at IBM. I was very lucky that my father liked to explain everything to me and allowed him to help. It has always been so. nine0003

He always took me with him and taught me everything he knew. He never gave things for repair to other people. Never. Therefore, when a color TV broke down, we repaired it together. I sat and watched him work. And he explained everything he did. I remember that at the age of 12 he explained to me what magnetic domain memory is. He then worked on the creation of such a memory at IBM. I was very lucky that my father liked to explain everything to me and allowed him to help. It has always been so. nine0003

Tell us about your career at Xerox.

For many years I led the scanner development division. We created image processing technologies. I have always been very interested in innovation. Then I became the program manager and chief engineer of CiPress. When this product was ready, I went back to work on new ideas. I am referring to the NewStarts program led by Brendan Casey. That's when we came up with the idea to create an industrial Brenva inkjet press. nine0003

At Xerox in Wilsonville, Oregon, there were several engineers who attended various inkjet conferences. They said, "Our printheads and our inkjet technologies can do a lot more than just print on paper." They came with burning eyes and said: “Listen, there is a huge opportunity in this! Why are we obsessed with only printing on paper?”

They said, "Our printheads and our inkjet technologies can do a lot more than just print on paper." They came with burning eyes and said: “Listen, there is a huge opportunity in this! Why are we obsessed with only printing on paper?”

I called my friend David Tate, who worked in Wilsonville as director of business development. I told him, "Dave, have you ever been in a situation where a customer is completely satisfied with your printheads, and they need a team of engineers to create a new product based on these printheads?" He said, "Wayne, it happens all the time." Then I said, "Next time you have a client like that, ask him to call me." nine0003

Three days later I got a call from Chuck Hull. He invented 3D printing. It was he who launched the production of 3D systems. He called me personally and said: “Wayne, I heard that you can help us. Together we can achieve amazing results. I saw your CiPress machine with all those printheads. Just imagine what you can do with a 3D printer. ” It fascinated me. I called the project Engineering Services and said, "If we get people who need help integrating printheads, send them here." And we were getting calls. nine0003

” It fascinated me. I called the project Engineering Services and said, "If we get people who need help integrating printheads, send them here." And we were getting calls. nine0003

How did you contribute to the development of direct object printing technology?

I put together a team and we had to overcome some technological difficulties. For example, learn to send drops of paint over a fairly long distance. Many people misunderstood the principle of inkjet printing. Even our inkjet specialists told me, "Nothing will come of this."

After many attempts and experiments, we still learned how to send ink drops at a distance of 5 to 7 mm. In normal printing, this distance is from 0.5 to 1 mm, sometimes even up to 2 mm. But 5-7 millimeters is almost a full-color digital airbrush. It was this achievement that formed the basis of the Xerox inkjet printer on objects. Now we are spraying ink not on a flat surface, but on a curved one, for this we need to correctly send drops to the surface and ensure that they hit accurately. nine0003

nine0003

How do you see the future of this technology?

Yes, sure. This is just one of the new technology platforms we are working on. For example, we installed a print head on a robotic arm, and now we can print on buildings and airplanes. We are working on a wide variety of projects here. That is why I started working in the Engineering Services project. If you walk in and say, "We're Xerox engineering and we want to help you," you're getting all sorts of requests. nine0003

Our object inkjet printer was the first in the world. I think retailers will appreciate it. This is a completely new technology, so we are still trying to understand all the potential applications. And these spheres are countless, a whole ocean. After all, no one has done this before. Technology can develop in different directions.

Direct print printers can be useful in retail stores, distribution centers, and manufacturing plants. In addition, this technology, which can send ink droplets over such a distance, can be used on production lines for label printing. We are currently working to further improve this technology and make it cheaper. And to create such versions of the device that can be successfully introduced into production. nine0003

We are currently working to further improve this technology and make it cheaper. And to create such versions of the device that can be successfully introduced into production. nine0003

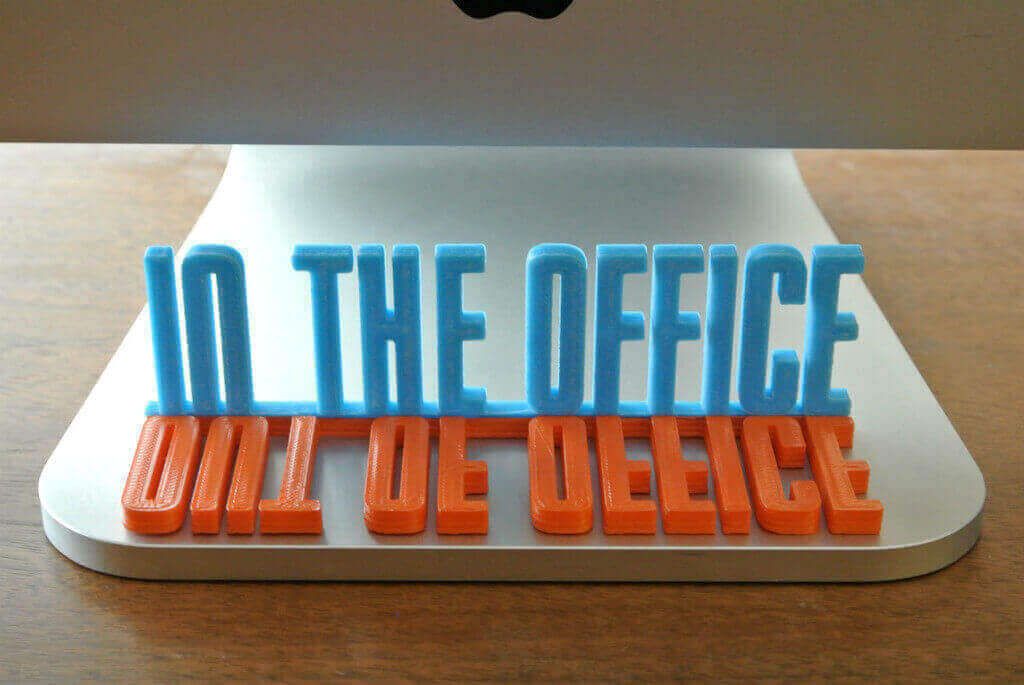

Right now, the main demand comes from graphics companies that want to showcase their work to clients. For example, they have created a series of new logos for a client and want the technology to print them on items. Today they have to go and order stamps. Labels, stencils, stamps - everything needs to be ordered.

This is a rather long and expensive process. And then the client says: “Everything is fine, but I don’t quite like the color. And yet, let's add a couple of stars in the right corner, or something like that. And the process has to start all over again. The Xerox Inkjet Object Printer lets you simply place the desired object in the printer and the image is ready in two seconds. Graphic designers can immediately show clients what the created logo will look like and quickly make changes. And this is a very important difference. Most likely, this will completely change the way graphic designers work. nine0003

And this is a very important difference. Most likely, this will completely change the way graphic designers work. nine0003

Sports grounds, such as baseball and football stadiums, are showing great interest in our invention. They like the idea that the device can be put on wheels and brought directly to the stadium or trade show. Several cruise ships were also interested in our printer. The idea is to install one or two printers on the ship that will help people capture their memorable moments. So far, there is nothing like it in the world, so we will learn more and more potential applications. nine0003

Could this device be the forerunner of 3D printing?

This could be a good addition. One of our clients is a large shopping center. When their people saw this printer, they said, “This makes a lot more sense than trying to 3D print things completely. In essence, this is printing on finished three-dimensional objects. And you can print an image in less than a minute, you don’t have to wait a whole day to create an item on a 3D printer. Then you need to remove the product from the mold. Often it is covered with wax. Then it must be placed in acid. That is why they told me so. nine0003

Then you need to remove the product from the mold. Often it is covered with wax. Then it must be placed in acid. That is why they told me so. nine0003

Xerox inkjet object printers use proprietary printhead technology. And our printheads are truly unique. They are made of stainless steel and plated with gold. Therefore, many people are interested in cooperation with us. Since there are no plastic components in the print heads that come into contact with the ink, we can use them to spray acid and various other liquids. None of the competitors can offer this. In addition, the heads were designed to work with molten solid ink, which resembles wax in structure. So they can be used at high temperatures. As the temperature rises, liquids become less viscous. One of the biggest challenges in inkjet printing is getting the ink through very thin holes. Therefore, the viscosity of the liquid must be minimal. And if you heat liquids, they become very fluid. nine0003

We are not aware of any other manufacturers whose printheads can operate at 105 degrees Celsius. Now we can create specialized products, for example, for medicine. You can sterilize the items you print on because the head operates at a temperature above the boiling point. Who would even think of that when we discussed the idea of wax printing? Thanks to our learning to print with solid ink technology, we are now able to expand into other markets. nine0003

Now we can create specialized products, for example, for medicine. You can sterilize the items you print on because the head operates at a temperature above the boiling point. Who would even think of that when we discussed the idea of wax printing? Thanks to our learning to print with solid ink technology, we are now able to expand into other markets. nine0003

We are changing the world together. Each of us. With every breath, our presence sets off a chain reaction in the world around us.

But only a few of us are able to change the lives of others for the better. And only a few do it day after day. Every day, Xerox R&D centers test new technologies that make a difference.

The company creates opportunities for them and gives them time to dream. And also resources to turn dreams into reality. Whether it's inventing new materials with incredible performance or using virtual reality to improve memory in people with Alzheimer's. nine0003

We are proud of our people who drive change at Xerox R&D centers around the world.

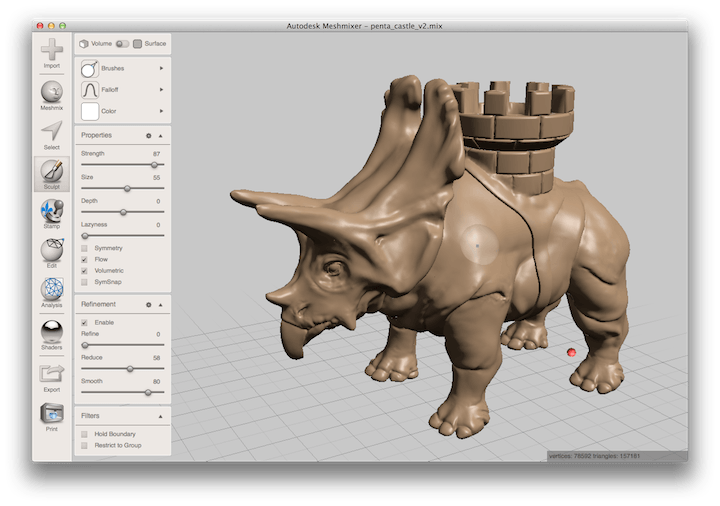

3d modeling (Moscow) at the 3D printing laboratory

Today it is difficult to imagine many spheres of life without the possibility of creating three-dimensional virtual images that allow one to imagine an object in its environment, its size and shape. Modeling for a 3d printer is just one of many situations where you need to build a realistic computer model. Options for designing a room, choosing a kitchen for a new apartment, planning a residential complex under construction, computer games, films, training videos - any of us is faced with three-dimensional models almost daily. nine0003

Computer 3d modeling is in demand in medicine, construction, various industries, entertainment and design. The ability to imagine how the final product will look like from all angles saves resources and allows you to reduce the time for its release - a significant part of the defects can be detected before the actual production.

Before you can print a product or model, you must create a digital 3D model in the editor. In other words, you need a print sketch. Our company has been successfully working in the field of 3D modeling and prototyping for a long time. All that is required of you is to provide a drawing of the future 3D model or the product itself, according to which we will model its three-dimensional version in the editor. nine0003

In other words, you need a print sketch. Our company has been successfully working in the field of 3D modeling and prototyping for a long time. All that is required of you is to provide a drawing of the future 3D model or the product itself, according to which we will model its three-dimensional version in the editor. nine0003

The bespoke digital 3D models that we create are designed not only for printing on printers, but also for creating architectural objects, and design items. Not a single car, not a single aircraft can do without preliminary 3D modeling, according to which the final object will be manufactured.

The specialists of our 3D Laboratory are mastering new principles of custom-made 3D modeling day by day, so that the work is more detailed every time. nine0003

Many business projects are implemented based on 3d graphic modeling - the speed of their launch has been significantly reduced, thanks to the chance to look into the future through the visualization of ideas.

If you need to restore the lost fragment of the whole, three-dimensional 3d modeling will also help. And molds for production by casting are made by building an image of a future part or product. Mouthguards for bite correction, which must change their configuration over time, individually made prostheses, implants - today their creation is also based on 3d model modeling. nine0003

To develop an electronic image, you can limit yourself to a polygonal version (an object is recreated based on points and lines combined into so-called polygons), or use computer-aided design systems so that you have an electronic geometric digital 3d model at your disposal. The latter allows you to take into account not only all the dimensions of the object, but also the properties of the material, manufacturing technology, sections and gaps. The choice of method depends on the end goal. nine0003

We have various programs to provide 3d modeling services: Fusion 360, Inventor, 3DS Max, SolidWorks.

This software is both for relatively simple visualization and for creating working models, on the basis of which it will be possible to change the characteristics, observing what will happen to the object; make calculations, as well as embody it in physical form using 3d printing.

If you plan to use 3d modeling (Moscow), take a closer look at us, our portfolio and team. We have been working on building virtual models for a long time and are constantly improving our skills - your task will be completed in the shortest possible time and with the highest accuracy. nine0003

To carry out 3D modeling (Moscow), we need a sketch or drawing of the object being designed. In the event that we are talking about something that really exists, a photograph or 3D scan data will be enough for us. It is also among our standard services - with its help we transfer physical objects, including engineering structures and structures, into a digital format.

The final cost of your order will be affected by what you provide to fulfill it and your end goal.