Sears 3d printer

Free 3D file Sears Tower・3D printer model to download・Cults

Best 3D printer files of the Tools category

Simon Says Game - 3D Printable | Arduino Nano | DIY Project

Free

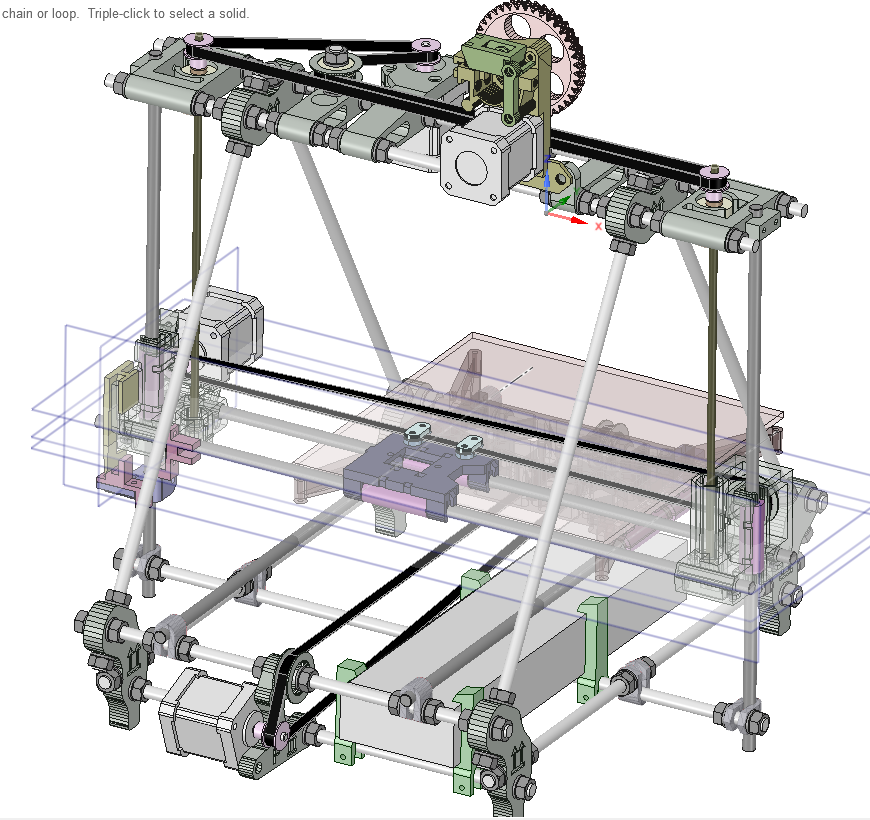

FDM Printer de Kleine Reus 300x300x900

Free

Raspberry Pi Snug Case

Free

CORONA MASK VERSION OF 28/03/2020

Free

Organizer Base

Free

Deactivated

Holder for Screwdriver Set 6pcs 030 I for screws or peg board

Free

Square planter

Free

Best sellers of the category Tools

Armadillo - Flex Wire Conduit

€1. -10% €1.50 67

SUPERBOX

€1.50

FLSUN v400 display holder

€9.99 -50% €4.99

3D Printed Strain Wave Gear (Harmonic Drive)

€4.99

Spartan 4mm Hex tool bit holder

€1.80

PRECISION CALIPER 3D PRINTING DIY

€3.12

ENDER 3 S1/S1 PRO SPOOL HOLDER AND DEPORTED SPOOL

€2.12 -20% €1.70

Fast-Print Stackable Parts Bins / Storage Boxes

€2. 83

83

Phone holder

€2.43

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang. CR-10, Micro Swiss direct drive and bowden compatible. No support needed for printing

€1.56

Minimus Hotend Cooler System

€2.33 -10% €2.10

'ELEGANCE' set for Bambu lab and generic 3d printers

€5

Ender 3 S1 pro fan duct 5015 4020

€1.30

Fast-Print Paint Bottle Rack (6 Sizes)

€2.83

ENDER 3 S1, S1 PRO, SPRITE, HOT END DUCT 4020 OR 5015 FAN, PROBE NO Y OFFSET

€2.28 -20% €1. 82

82

Chill Buddy Lighter Case

€0.93

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

Minneapolis man charged with making 3D-printed devices to create fully-automatic "ghost guns"

Crime

By WCCO Staff

/ CBS Minnesota

How untraceable ghost guns are impacting crime in the Twin Cities

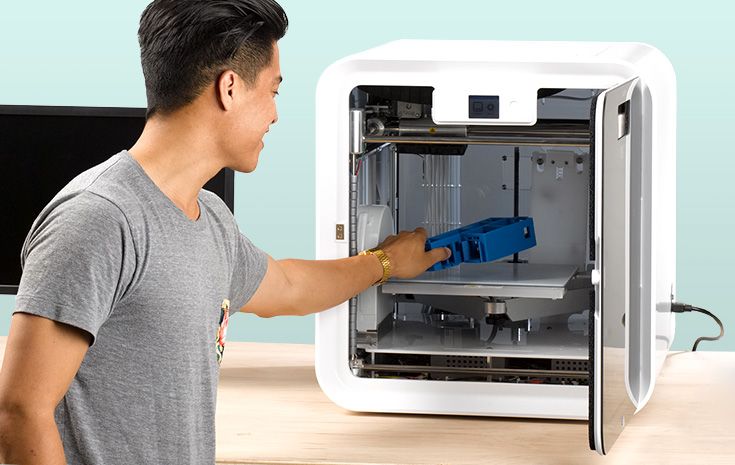

How untraceable ghost guns are impacting crime in the Twin Cities 03:47MINNEAPOLIS – A 25-year-old Minneapolis man is accused of using 3D printers to make auto sears, a device that turns semi-automatic weapons into fully-automatic machine guns.

The U.S. Attorney's Office says Aaron Malik Cato is charged with possession of machine guns stemming from a "controlled delivery" of a package shipped from Taiwan to his home late last month that contained "enough [firearm] parts to create 10 auto sears."

Aaron Cato Sheburne County JailThe package was seized by Customs and Border Protection agents, who tipped off federal and local authorities. Upon delivery to Cato's home, authorities also executed a search warrant and found several handguns and two AR-15-style rifles. Three of the guns had auto sears, and authorities classified the weapons as "ghost guns," which are also known as PMFs, or "privately made firearms."

Authorities say four 3D printers and several 3D-printed auto sears were also found in his home during the search.

Cato made his first court appearance Wednesday, and will remain in custody.

RELATED: Fire Sale: Dealers rush to sell ghost gun parts before restrictions take effect

- In:

- Ghost Guns

WCCO Staff

The WCCO Staff is a group of experienced journalists who bring you the content on WCCO. com.

com.

Twitter Facebook Instagram

First published on September 7, 2022 / 5:20 PM

© 2022 CBS Broadcasting Inc. All Rights Reserved.

Thanks for reading CBS NEWS.

Create your free account or log in

for more features.

Please enter email address to continue

Please enter valid email address to continue

Free 3D file of Sears Tower・3D printing plan for download・Cults

The best files for 3D printers in the Tools category

Clean Canon EF mount ring

Free

Sand Carving Tools

Free

Raspberry Pi B+ Face Case

Free

nine0007 Support for Filo3D wire crown 1. 25 €

25 €

Cali Dog (with long muzzle)

Free

Tool holder for 3D printer V3.0

1.03 €

Simple Universal 3in1 Lens Kit Phone Mount

Free

Door opener, bags holder, button pusher and other

0.50 €

Bestsellers in the Tools category

PET-Machine, make your own plastic bottle filament at home!

15 €

Ender 3 Briss fang Gen2, red lizard, spider, nf crazy, dragonfly, etc.

1.74 €

Fast print ink bottle rack (6 sizes)

2.83 €

ENDER 3 S1/S1 PRO COIL HOLDER AND DEPORTED COIL

€2. -twenty% 1.70 €  12

12

Quick print stackable parts containers / storage boxes

2.83 €

Case for Chill Buddy 9 Lighter0008

0.93 €

Ender 3 S1 pro fan duct 5015 4020

1,30 €

Paint stand with scissors

5.19 €

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang. CR-10, Micro Swiss direct drive and bowden compatible. No support required for printing

1.56 €

nine0007 Cooling system Minimus Hotend €2.33 -10% 2.10 €

Ender 3 S1 BEST cable guide - vertical

2,50 €

well designed: Hemera fan duct

2. 50 €

50 €

5 €

Armadillo - flexible wire conduit

€1.67 -10% 1.50 €

PRECISE DIAL INDICATOR 3D PRINT DIY

1.91 €

nine0007 Fire hydrant storage container1.88 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community! nine0006

What is SLS 3D printing. How does an SLS 3D printer work? Overview of additive technologies.

What is SLS?

Hello everyone, Friends! 3DTool is with you!

In this article, we will talk in detail about one of the most promising technologies 3D printing . Selective laser sintering.

Selective Laser Sintering (SLS) is an additive manufacturing process , which belongs to a wide family of supported synthesis methods. In SLS, a laser selectively sinters polymer powder particles, fusing them together to create layer after layer. Granular thermoplastic polymers are used as construction material. Options for such devices can be considered in our catalog. For example, the Sintratec 3D printer.

Granular thermoplastic polymers are used as construction material. Options for such devices can be considered in our catalog. For example, the Sintratec 3D printer.

This technology is used both for prototyping functional polymer products and for integration into small production runs, as it offers complete design freedom, high precision and produces parts with good and stable mechanical properties, unlike FDM or SLA .

Naturally, as in any other case, the possibilities of technology can be used to the full only if its key advantages and disadvantages are taken into account, so let's take a closer look at its features and principle of operation.

SLS printing process

How does SLS work?

The SLS fabrication process works as follows:

I. The powder chamber, as well as the entire printable area, is heated to just below the melting temperature of the resin, after which the leveling blade distributes a thin layer of powder over the build platform.

II. The CO2 laser scans the contour of the next layer and selectively sinters (melts) the polymer powder particles. The cross section of the component is scanned ( sintered ) completely, so the part is monolithic. nine0006

III. When the layer is completed, the work platform moves down and the blade re-coats the surface with powder.

The process is repeated until the entire part is completed.

After printing, the part is completely sealed in the non-sintered powder, so the chamber and powder must cool before being removed. Cooling down can take a significant amount of time, up to 12 hours. Then the resulting part is cleaned of powder residues with compressed air. The unsintered powder is collected for further reuse. nine0006

Schematic diagram of an SLS 3D printer.

SLS print specifications

Printer settings

In SLS, almost all print options are set by the printer manufacturer. The default layer height for is 100-120 µm . For example, the Sintratec 3D printer we mentioned above allows you to print a much thinner layer, the layer thickness declared by the manufacturer varies from 50 to 150 micron.

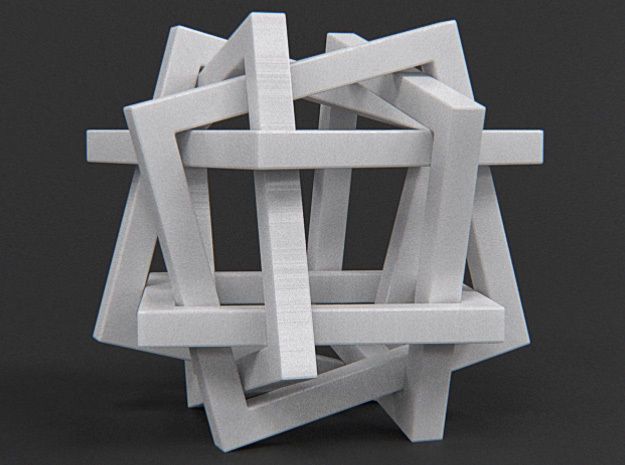

The main advantage of method SLS is that the part does not need supports. In this case, the non-sintered powder plays the role of the necessary support. For this reason, the SLS method can print geometries of any shape that are impossible to print with any other additive or subtractive manufacturing method.

When printing with this method, it is very important to use as much of the printable area as possible, especially in small-scale production. Regardless of the amount of detail in the printable area, if the overall height is the same, printing will take the same amount of time. This is because it is the recoating step that determines the total print time ( the laser scanning and sintering itself is very fast ), and the printer has to cycle through the same number of layers. Also, you need to take into account the time for refilling the hopper with powder, because the same amount is poured into the chamber, regardless of the size of the printed part.

This is because it is the recoating step that determines the total print time ( the laser scanning and sintering itself is very fast ), and the printer has to cycle through the same number of layers. Also, you need to take into account the time for refilling the hopper with powder, because the same amount is poured into the chamber, regardless of the size of the printed part.

Layer caking

When using method SLS , the sintering strength of the layers to each other is excellent. This means that printed on SLS printer parts have almost isotropic mechanical properties.

As an example, the mechanical properties of samples printed on SLS using standard polyamide powder ( PA12 or Nylon12 ), the most commonly used material in SLS printing , are shown in the table in comparison with the properties of solid nylon:

Parts printed on SLS have superior tensile strength and modulus comparable to solid material, but are more brittle ( their elongation at break is much lower than ). This is due to the internal porosity of the resulting part.

!A typical SLS part has a porosity of about 30%!

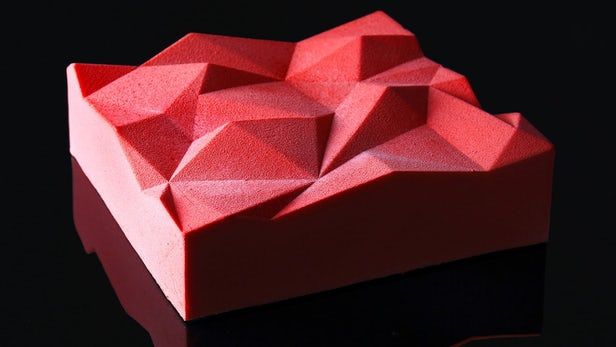

Porosity gives parts printed on SLS a characteristic grainy surface. This porosity also means that the parts can easily absorb water and are easy to paint. At the same time, such parts require special post-processing if they are to be used in a humid environment. nine0006

Shrinkage and deformation

SLS-parts are subject to shrinkage and deformation: when the newly sintered layer cools, its dimensions decrease and internal stress accumulates in it, due to which the underlying layer is pulled upwards.

Shrinkage of 3 to 3.5% is typical for SLS printing and printer operators should take this into account during model preparation.

Large flat surfaces are most prone to deformation. This problem can be slightly mitigated by orienting the part vertically on the build bed. But still, the best way to reduce deformation is to minimize the thickness of the flat areas of the part, and add cutouts to the model where the design allows. These actions will also reduce the overall cost of the part, as less material will be used. nine0006

But still, the best way to reduce deformation is to minimize the thickness of the flat areas of the part, and add cutouts to the model where the design allows. These actions will also reduce the overall cost of the part, as less material will be used. nine0006

Finished sls-part with embedded embedded elements.

Excessive caking

Over-sintering occurs when excess heat around the contour of the part melts the unsintered powder around. This is fraught with loss of detail on small objects such as slots and holes.

Excessive sintering depends on both element size and wall thickness. For example, a slot with a width of 0.5mm or hole diameter 1mm will print successfully on wall thickness 2mm but will not print if wall thickness is 4mm or greater. As a general rule, slot widths from 0.8mm and holes from from 2mm in diameter can be safely printed in SLS without fear of excessive sintering.

Powder removal

Since printing method SLS no supports required, parts with hollow sections print quickly and accurately.

Hollow sections in this case reduce the weight and cost of the part, as less material is ultimately used. But you will need to make outlet holes in the part to remove unsintered powder from the internal cavities. The general recommendation in this case is to add at least 2 outlet holes with a diameter of at least 5 mm to your part.

If high rigidity is required, the parts must be printed solid. An alternative here would be to make the structure hollow, with no outlets. In this way, the powder will be compacted tightly into the part, increasing its mass and providing some additional support when mechanical loads increase, without affecting print time. Also, instead of one solid internal cavity, you can add a honeycomb structure ( similar to the infill patterns used in FDM ) to further increase the rigidity of the model. Laying out the part in this way will also help reduce warping.

Laying out the part in this way will also help reduce warping.

Removing powder from an SLS part

General materials SLS

The most commonly used material for SLS is Polyamide 12 (PA 12) , also known as Nylon 12 . At the moment, there are more and more materials with different properties for SLS 3D printing every day, for example, elastic polymers are represented by TPE powder and its analogues. Other technical thermoplastics such as PA11 and PEEK are also available but are not as widely used.

As an example, you can see the list of materials used in our catalog: Sintratec Powder Sls.

Polyamide powder can be supplemented with various additives ( such as carbon fibers, glass fibers or aluminum) to improve the mechanical and thermal properties of the printed part. Materials supplemented with additives are usually more brittle and have higher anisotropy. nine0006

nine0006

Post-processing

SLS produces parts with a powdery, grainy finish that is easy to paint. The appearance of printed parts of SLS can be improved to a very high standard using a variety of post-processing methods such as polishing, classic painting, spray painting and varnishing. Their functionality can also be improved by applying a waterproof coating or metal coating. nine0006

SLS advantages and limitations

Summarizing the above, the key advantages and disadvantages of the technology are given below:

- SLS parts have good, isotropic mechanical properties, making them ideal for functional parts and prototypes.

- SLS does not require support, so complex geometries are easy to print.

- SLS' manufacturing capabilities are excellent for small to medium series production. nine0133

- Only industrial SLS systems are currently widely available, so lead times are longer than other 3D printing technologies such as FDM and SLA.

Learn more