Fff 3d printing meaning

Fused filament fabrication technology for 3D printing

David Roberson7 January 2021

Trends

FFF 3D printing, or fused filament fabrication, is an additive manufacturing (AM) process in which thermoplastic material is pushed through a heated nozzle to create objects layer by layer.

What Is FFF 3D Printing?

While it has its origins as a proprietary manufacturing technology from the 1980s, desktop FFF really took off just over 10 years ago when patents expired and projects like the open-source RepRap initiative led to greater innovation and affordability.

Today, FFF technology is typically a lower-cost solution compared to other 3D printing processes, both in terms of initial investment and running costs. It’s also renowned for being easy to understand and use – making it ideal for busy engineers and elementary school kids alike.

But it has proven so reliable, accurate, and capable of producing robust parts over the years that most of the world’s leading manufacturing, design, and education organizations now use it to drive innovation.

The FFF 3D printing process

FFF 3D printing uses

Let’s look more closely at the applications of FFF 3D printing:

Manufacturing. With faster lead times than outsourcing and a wide range of engineering materials, FFF 3D printing is used widely in manufacturing industries. 3D printers deliver rapid tooling and replacement parts to maintain maximum uptime and productivity on the production line. And they are used to flexibly create end-use parts, such as bespoke quality gauges or small batch first runs, to speed up time to market of a product

Prototyping. Low-cost materials and short print times make FFF 3D printing ideal for the iterative design process. 3D printed prototypes can be used to visualise concepts or functionally test technical parts

Education. Affordable and easy-to-use FFF hardware enables a variety of education applications – from engaging younger students with STEAM basics to providing production labs for college and university students to work on engineering projects and develop skills for the modern workplace

Ford saved roughly $1,000 per tool by developing 3D printed manufacturing aids using Ultimaker printers

Learn more about the range of 3D printing applications and how experienced AM engineers identify them in this episode of the Talking Additive podcast.

FFF materials

Plastic polymers are the most used materials for FFF technology, of which there are many for countless uses.

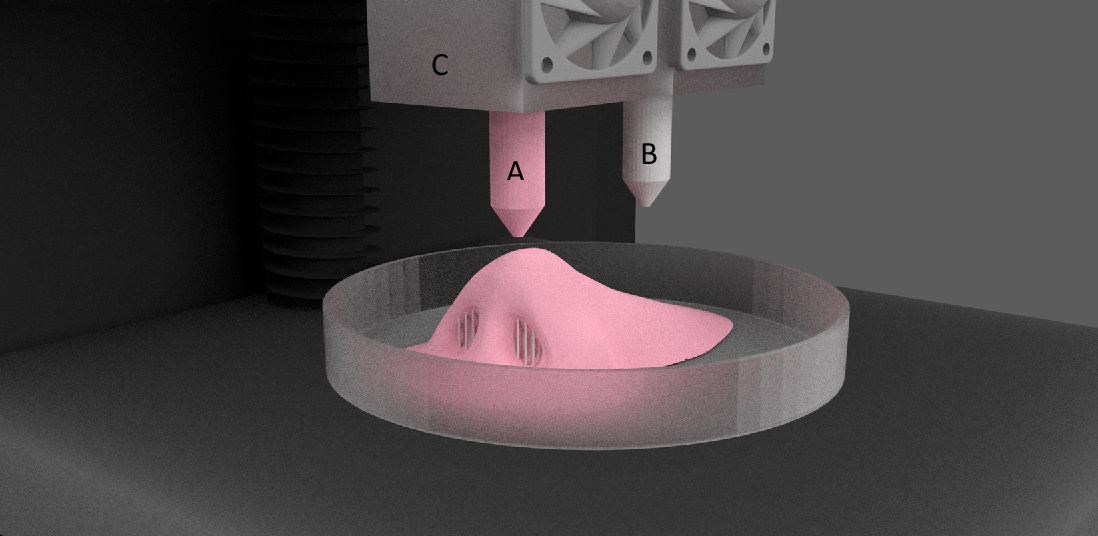

Composites that combine a polymer with fibers of carbon, metal, glass, or other materials are also widely used for various structural benefits, although these cannot be printed reliably on all FFF 3D printers. Technically it is also possible to print food and biological pastes using 3D printing technology, although this is typically reserved for experimental or research applications.

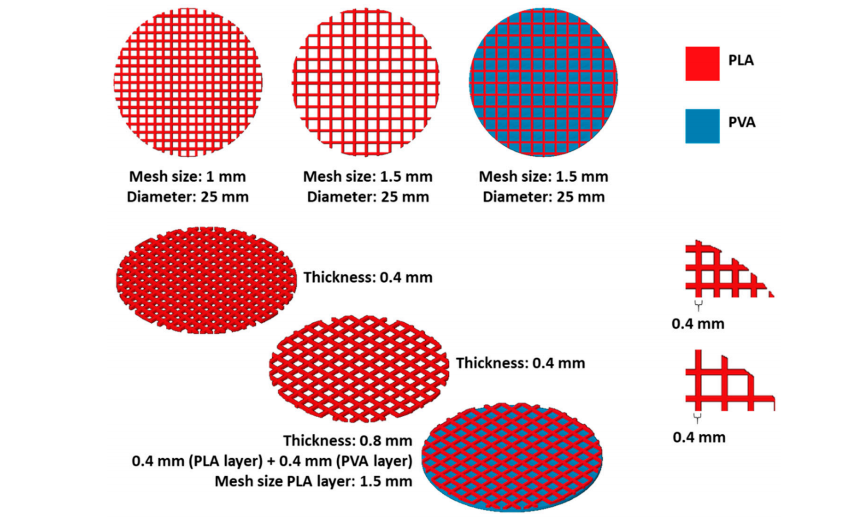

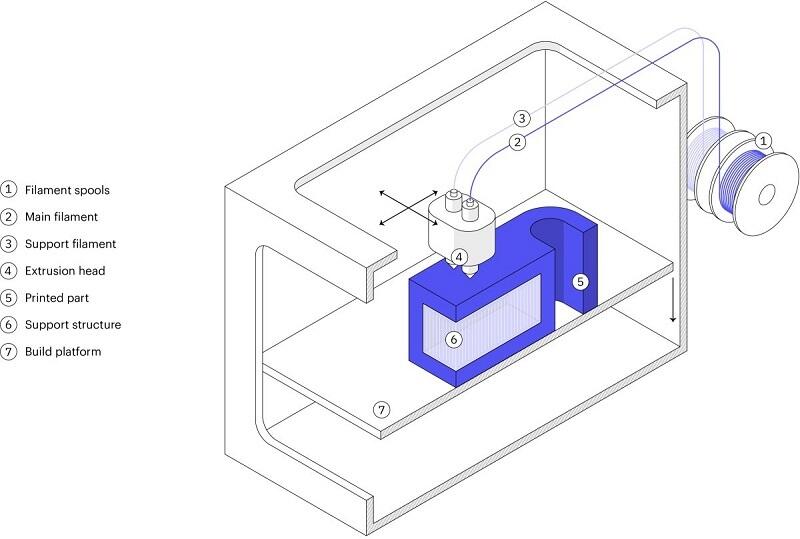

Another important category of material for FFF printers is known as “support” material. This is needed when the orientation or shape of a part makes it impossible to print from bottom to top – for example, a part with a large overhang. Support materials are designed to be easy to remove.

Material for FFF 3D printers is typically sold as spools of filament, each containing from 250 g to 1 kg of material.

Some 3D printers can print parts with multiple materials or colors

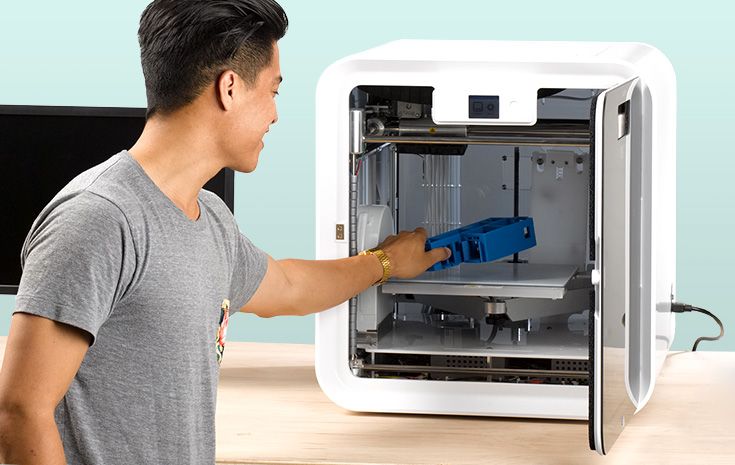

Loading filament on an Ultimaker S5 Pro Bundle printer

If you’re thinking of buying a 3D printer, always check the compatible materials.

For some, you may be limited to using two or three materials. Other printers may claim to work with any material, but soon develop technical issues from wearing caused by printing abrasive composite materials. And some FFF 3D printers are limited to using the manufacturer’s proprietary materials only, while others offer an open filament system (like Ultimaker) compatible with third-party products.

Some of the most common FFF 3D printing polymers are PLA (polylactic acid), which is often used as a “beginners” material due to its ease of use, and ABS (acrylonitrile butadiene styrene), which offers some superior mechanical properties and heat resistance.

But with thousands of filaments on the market, it’s worth diving a little deeper into their properties to get an understanding of how many applications are possible with a high-quality FFF 3D printer.

| Material | Properties |

|---|---|

| PLA (polylactic acid) | Excellent surface quality and detail. Mechanical and heat properties not suitable for some applications Mechanical and heat properties not suitable for some applications |

| ABS (acrylonitrile butadiene styrene) | Strong, ductile material with wear resistance and heat tolerance |

| Nylon (polyamide) | Strong yet flexible, with good chemical, impact, and abrasion resistance |

| PETG (polyethylene terephthalate glycol-modified) | Good toughness and wear resistance, with chemical resistance against many industrial fluids. |

| CPE (copolyester) | Durable and flexible with a glossy finish and good impact and heat resistance |

| PC (polycarbonate) | Strong and tough material with heat resistance up to 110 °C |

| TPU (thermoplastic polyurethane) | Flexible material with rubber-like properties. Provides high impact and wear resistance |

| PP (polypropylene) | Durable, tough, and fatigue resistant. Retains shape after torsion, bending, or flexing |

| PVA (polyvinyl alcohol) | Water-soluble material used to create supports for overhangs and cavities |

The table above covers the main polymers you can print on a professional 3D printer. Want to find the right composite material for your 3D printing applications? Watch our webinar on composites for 3D printing.

Want to find the right composite material for your 3D printing applications? Watch our webinar on composites for 3D printing.

FFF 3D printers

Although FFF 3D printers are all built on the same process, their capabilities differ a lot.

One of the biggest differences can be in material compatibility (see the section above), with the hardware being especially important in defining what sort of composites can be printed.

Size is another key differentiator of FFF 3D printers. The printable space (which limits the size of a single print or batch) is called the build volume or build envelope. This can vary considerably – from 10 cm (3.9 inches) of printable space in the X, Y, and Z dimensions, up to around 1 meter (39 inches) in one or more of these dimensions in the largest units. Note that a stiff, stable build platform aids the FFF process – so large format printers generally mean a trade-off in quality.

An example of the different sizes and configurations possible with FFF 3D printers

The different features of a FFF printer are too many to highlight in an introduction, so here are definitions of a few of the most important:

Build plate or platform.

The surface onto which the material is extruded and then cools to form the printed part. It is typically made of glass or metal. A professional standard 3D printer should offer a heated build plate, which enables use of more materials

The surface onto which the material is extruded and then cools to form the printed part. It is typically made of glass or metal. A professional standard 3D printer should offer a heated build plate, which enables use of more materials Nozzle. The nozzle extrudes the molten material. It is housed in the print head and positioned via a gantry operated by stepper motors. The number of nozzles a printer has will determine how many materials can be combined in one print – typically one or two (known as single or double extrusion)

Feeder. The mechanism that feeds filament from the spool to the printer

Display. The interface through which the printer is controlled

Connectivity. Many 3D printers offer local network or cloud connectivity for remote operation

Environment control. While some FFF 3D printers are little more than open platforms, enclosing the build chamber and adding environment control (such as the Ultimaker S5 Pro Bundle) offer both print quality and safety benefits

Material handling.

Filament is loaded and stored in many different ways on FFF 3D printers. This can range from basic printers, where the spool must sit separately, to professional solutions that offer front-loading and automatically switch spools when a filament finishes

Filament is loaded and stored in many different ways on FFF 3D printers. This can range from basic printers, where the spool must sit separately, to professional solutions that offer front-loading and automatically switch spools when a filament finishes

You can compare the features of Ultimaker 3D printers here.

Finally, it’s important to mention software. Unless you have all the 3D prints you will ever need sitting on a USB stick, you will not be able to do much without the right software.

In 3D printing, software plays two important roles. First, a “slicing” program like Ultimaker Cura is essential for preparing a design file (such as an STL) for print. Load the file into this software, choose your desired print settings (such as fast or extra detail), and it will “slice” it into layers then create a file format the printer understands.

Preparing a model to be 3D printed using Ultimaker Cura software

This print job can then be transferred to the printer manually (such as on a USB stick) or sent remotely over the network or cloud. This is where software can play the role of sending, queuing, and tracking these print jobs. Cloud software such as the Ultimaker Digital Factory is enabling the next generation of FFF technology, delivering distributed manufacturing across multiple locations.

This is where software can play the role of sending, queuing, and tracking these print jobs. Cloud software such as the Ultimaker Digital Factory is enabling the next generation of FFF technology, delivering distributed manufacturing across multiple locations.

Watch this video to see how one manufacturer has created a "digital warehouse" by combining FFF 3D printers and software.

Watch the videoWant to learn more about how the 3D printing workflow could look for you?

Read our ‘How to design for FFF 3D printing’ white paper for valuable tips for getting started with an FFF printer, more detail about the role of support materials, and design for FFF insights from 3D printing experts.

Learn the modeling tips and tricks that we use to maximize our print success, including:

• How to 3D print faster

• Easy ways to use less support material

• Best practices for finer print details

• And lots more!

Introduction to Fused Filament Fabrication (FFF) 3D printing technology

This White Paper will get you familiar with the process of Fused Filament Fabrication (FFF) for plastics, in which layers of material are built up to create a solid object.

Download the full White Paper here>

What does FFF mean in 3D printing?

Fused Filament Fabrication (FFF) is an extrusion process where the object is built by depositing melted material layer-by-layer. The plastics used correspond to the same thermoplastics that can be found in conventional manufacturing processes, like ABS and Nylon.

FFF led the expansion of desktop 3D printers and is now the most widespread 3D Printing Technology, essentially due to the low initial investment needed, the immense variety of applications offered, and the little specific knowledge required to successfully use this technology.

How does FFF work?

As mentioned above, FFF consists of an extrusion process of melted plastic. In order to generate the part, a print head travels around the printing surface depositing the material.

The workflow is as follows:

- The first stage consists of generating the 3D model with any design software, such as Solidworks or Catia.

The 3D model needs to be exported in STL format.

The 3D model needs to be exported in STL format. - In file preparation, the model is configured using a slicing software including all the printing requirements. This configuration will contain the material selection and the nozzle size. The software also separates the model into layers, and you can configure the printing quality, and movement commands.

- The printing phase is the deposition of the melted plastic.

In-house desktop 3D printers: FFF vs SLA

The most popular 3D printing technologies are FFF and SLA. SLA is a liquid photopolymer selectively cured by UV light.

Both technologies have their own benefits and disadvantages depending on your business’ needs.

Professional desktop 3D printers compared to industrial printers and outsourcing

Within the FFF technology market, there are different printer categories based on the relation between price and printing quality.

Should the number of parts to produce be low and the usage planned to be sporadic, there is the option to outsource the 3D printing service through a 3D printing service bureau.

If the plan is to work on a medium-long term project, the acquisition of 3D printers can reduce costs significantly. This acquisition implies an initial investment, but then the price per part becomes approximately 30 times cheaper.

Which solution best fits your needs

It is important to take into consideration parameters such as cost and lead time:

In-house FFF printers offer the best combination of costs and lead times. However, investing in both FFF and SLA printing technologies will give your company full versatility when producing parts. To weigh the benefits for your company, read our white paper and have a think about your answers to these questions:

- What is my budget?

- Does my company have specialized equipment to support a 3D printer?

- Do I need to print mechanically demanding parts?

- Will there be designing and application versatility?

- How many printed parts does my company require?

- What is the lead time my company requires?

Would you like to know more about 3D printing? Check out the following white papers:

• Introduction to FFF technology and its most important parameters

• Anatomy of Sigma & Sigmax R19 extrusion system

Ready to save time and cut costs with a BCN3D printer? Request a customized quotation for a BCN3D Printer.

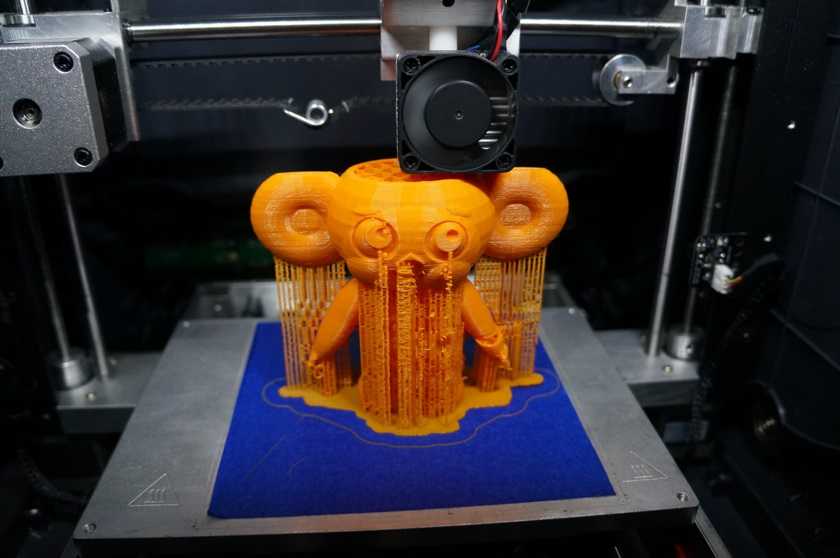

FDM printing technology in 3D printers. Pros and Cons, Applications

FDM or FFF technology involves the creation of objects by layer-by-layer application of molten material. FDM literally stands for fused deposition modeling or layer-by-layer deposition technology.

It sounds complicated, but the technology is actually very simple. It's basically like a hot glue gun. On the one hand, thermoplastic or any other material is pushed through, which melts from heat, and then solidifies without losing its properties. The thermoplastic passes through a hot nozzle, melts and solidifies immediately. The extruder and table are driven by stepper motors, leaving plastic behind them, layer by layer, from bottom to top, recreating a 3D model. nine0003

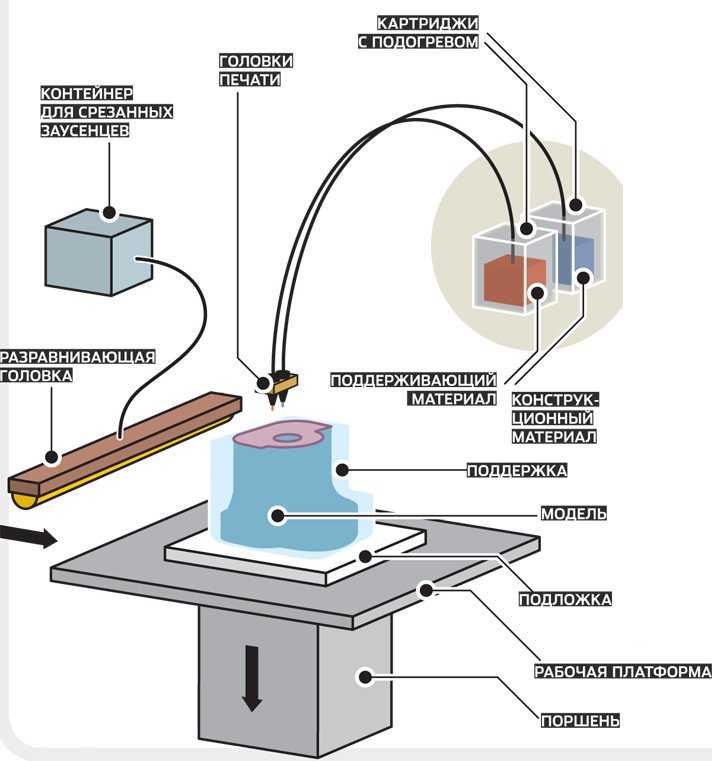

MJM technology can be called an analogue of FDM. Only MJM uses wax or photopolymer. On the print head there are many small nozzles (from 96 to 448) through which molten wax is supplied, or droplets of photopolymer that are immediately illuminated by the lamp.

Plastic thread is used as a material for making models. There are 2 diameters of plastic thread - 1.75 and 2.85 (3mm). Printers that need 3mm filament are rare, mostly Ultimaker and its clones. Most printers use 1.75 filament for printing. nine0003

The first material for 3D printing was a plastic welding filament with a diameter of 3mm, so for a long time this size was the standard for 3D printing.

A 3D model is prepared using a slicer program before printing. The slicer separates the model into layers and prepares commands for moving the print head. The sliced model can be saved in different formats, but GCode is used by default. Therefore, the printer is basically a CNC machine. nine0003

History

The method was invented by S. Scott Crump in the late 1980s. The patent was received in 1988. And already in 1990, Stratasys appeared on the market with the first industrial 3D printer using FDM technology.

Scott Crump is one of the founders of Stratasys.

The first 3D printers were rather expensive industrial machines designed for large companies. Everything began to change in 2006, after the founding of the RepRap project (from the English Replicating Rapid Prototyper - a self-replicating mechanism for rapid prototyping). nine0003

First version of RepRap 3D printer.

The goal of the project was to create a self-copying 3D printer. Shafts were used as a frame and guides. Almost all parts were connected by printed parts. The extruder and table were driven by stepper motors. The source code was open. Of course, visually, it looked like a homemade “made from improvised materials”, but it worked. The printer uses about 50% of printed parts. nine0003

Since the term FDM was patented by Stratasys, 3D printing enthusiasts and RepRap project contributors have coined their own term - FFF.

Literally stands for - fused filament fabrication (production by fusing threads). The meaning remained the same, but it helped to avoid legal problems.

As RepRap has developed, projects based on OpenSource (open source code) have developed. The most prominent representative of the OpenSource movement was MakerBot. In addition to developing their 3D printer, MakerBot is actively developing the Thingiverse website. On Thingiverse you can find a huge number of free 3D printable models. nine0003

MakerBot founders Zack Smith and Bre Pettis with the final MakerBot Cupcake prototypes.

Separately, it is worth highlighting the company Ultimaker. If in the ideology of RepRap the printer was supposed to reproduce itself, then Ultimaker went the other way. They designed their printer from laser-cut plywood parts. This was much faster and more affordable than the manufacture of printed parts. In 2013, the first Ultimaker Original was released. It was sold as a KIT - a set (assemble it yourself). nine0003

It was sold as a KIT - a set (assemble it yourself). nine0003

All the drawings and developments were posted on the network. This made it possible for anyone who wanted to purchase all the necessary components and electronics, order cutting of the case and some components anywhere and assemble their printer. And after assembly, it was possible to print upgrades on the same printer and replace plywood parts with plastic ones.

Quite quickly, Ultimaker had a large and friendly community. Many free 3D models of various Ultimaker Original nodes have been posted online. A lot of upgrades appeared, many unpleasant “sores” of the design were removed. nine0003

Plywood Ultimaker Original

In addition to Ultimaker 3D printers, based on the Replicator-G, they developed their own CURA slicer. Due to its versatility and affordability, CURA has become a favorite among 3D maker slicers. In addition to Ultimaker printers, a bunch of ready-made profiles for other 3D printers have been added there. It is easy to set up CURA for a self-assembly printer.

It is easy to set up CURA for a self-assembly printer.

nine0031 Modern CURA

There were many more different projects - large and small, but it was the RepRap and OpenSource projects that made FDM 3D printing more accessible. Due to the mass character, not only 3D printers themselves, but also consumables for them, have become cheaper and more affordable.

Of course, there are several differences between FDM and FFF technology. The main thing is the presence of a heated chamber for more stable printing. FFF abandoned it in order to make 3D printers cheaper and more affordable. Later, a closed case appeared in some printers. Together with the heated table, a passive heating chamber is obtained. nine0003

FDM pros and cons

The most important advantage of FDM printing is affordability. The cost of a home printer is comparable to the cost of a smartphone. With a very limited budget, you can find OpenSource projects and build a printer yourself.

Large variety of models.

You can easily choose a printer for a specific task. For example, Flashforge Adventurer 3, due to the closed case and the absence of a heating table, will be a great gift for a child. Anycubic Mega is suitable as a home assistant for a person who loves upgrades and experiments. And Raise3D Pro2 is suitable for production tasks. nine0003

Variety of materials for 3D printing.

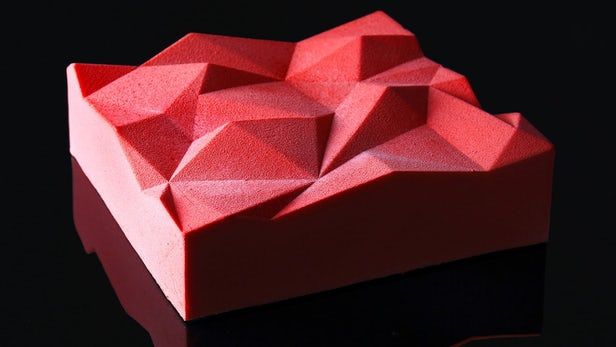

Due to the mass application, in addition to the standard ABS and PLA, a variety of plastics began to appear. For example, decorative plastics with imitation of various materials.

Decorative laminates imitating copper and bronze.

Engineering - with improved physical and mechanical properties. These materials can be used to create functional products and prototypes. nine0005

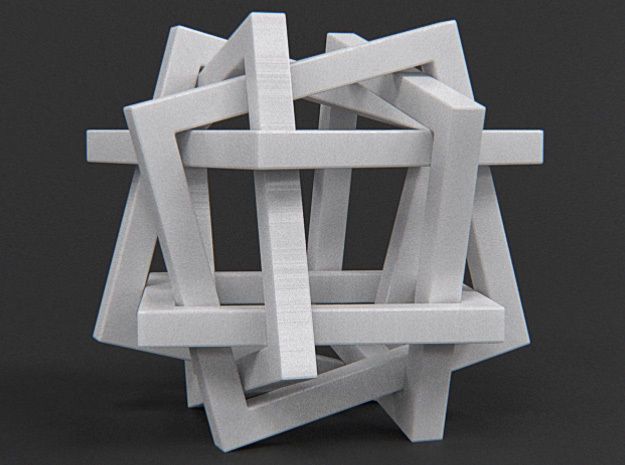

Printing example for functional products

Or special. plastics for specific tasks. For example, burnable with low ash content or melted wax.

For example, burnable with low ash content or melted wax.

Blank cast from 3D burnout model

But there are also disadvantages.

Poor accuracy compared to other printing technologies. nine0003

The discrepancy with the 3D model is usually no more than 0.1mm. This value depends on the mechanics of the printer and the characteristics of the media. For ordinary gears and domestic needs, such accuracy is quite enough. But in some industries (for example, jewelry), the accuracy of the finished model should be higher.

Layered surface.

It is impossible to get a perfectly smooth surface on an FDM 3D printer. Layers on the model can be smoothed out by sanding, puttying, or by treating with a solvent. nine0003

On the left is a printed model on an FDM 3D printer, and on the right is the same model after processing.

Applications

With a wide variety of printers and materials, FDM 3D printing has a very wide range of applications.

Prototyping

The most popular is prototyping. FDM printing has made it much faster and easier to create test models and mechanisms.

From 3D printed model to finished product

FDM printing allows you to quickly prototype anything and quickly make changes.

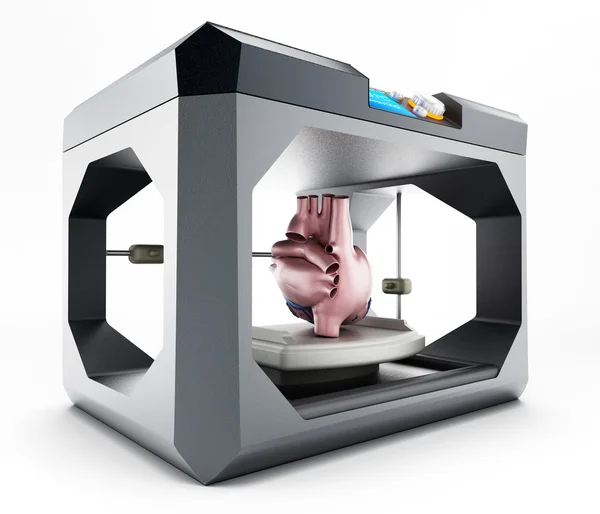

Medicine

In medicine, using 3D printers, they began to create comfortable, breathable orthoses for fixing fractures.

3D printed orthosis.

Printed orthoses can be fixed much faster than a classic plaster cast. And the process itself is less time-consuming and dirty. nine0003

Creation of simple traction mechanical prostheses. This is especially true for children. After all, children grow quickly and they need to change the prosthesis often. Thanks to FDM printing, the process of creating a prosthesis has been made cheaper and faster.

Child traction prosthesis

Dentures are lighter and more comfortable than those made by the classical method.

Film industry

In the film industry, FDM printing is used to print props and costume elements, masks, mechanisms, and other items. nine0003

Geisha robot from the movie "Ghost in the Shell"

Sometimes 3D printing is used to create small prototypes of models on a reduced scale, for more accurate calculation of proportions, staging scenes, lighting and further rendering.

Hobby

FDM printers have helped to simplify the creation of RC models of boats, cars, aircraft and spare parts for them.

3D printed RC aircraft

Websites have even appeared with models of radio-controlled aircraft, machines adapted for 3D printing.

Cosplayers have also fallen in love with 3D printing due to the variety of materials and the faster and easier production of masks, functional elements, and some pieces of armor.

Cosplay from the movie "Pacific Rim 2"

Previously, it was necessary to select material for a long time and painstakingly, prepare patterns, carefully prepare the surface for priming and painting. Now it is enough to model a 3D model of the desired costume, it can even be adjusted to the figure of the cosplayer and printed. Simplified manufacturing of complex, moving elements and parts of mechanisms.

Now it is enough to model a 3D model of the desired costume, it can even be adjusted to the figure of the cosplayer and printed. Simplified manufacturing of complex, moving elements and parts of mechanisms.

Modeling

In breadboarding, the 3D printer made it possible to speed up the creation of complex models of buildings and landscapes by several times. Previously, many elements had to be painstakingly made by hand. nine0003

Block layout

A three-dimensional physical model helps the customer to see the future object more fully, compared to the digital environment. You can quickly change the layout if necessary.

Short run

If you need a small batch, for example, key rings with a company logo or a piece product, it will be faster and cheaper to print it on a 3D printer.

nine0005

Small batch of spare parts

Making a master model with subsequent casting is a laborious and expensive process. If the part is of a complex shape with various protrusions and undercuts, then casting may not be possible, and a 3D printer can easily cope with this task.

If the part is of a complex shape with various protrusions and undercuts, then casting may not be possible, and a 3D printer can easily cope with this task.

Education

The use of 3D printers in the educational process allows students to develop imaginative thinking, to make the learning process more visual. On paper, it is difficult to notice the flaws of the part, and by creating a test part, you can clearly see all the flaws. nine0003

Children assemble 3D printer

In robotics, a 3D printer allows you to quickly create various mechanisms and simple robots.

A child assembles a robot in a robotics circle

3D printing is becoming popular for creating visual aids. For example, for visually impaired or blind children. They “see” with their hands, and thanks to 3D printed models, they can perceive information more fully. nine0003

Home

At home, a 3D printer can turn out to be not just a toy, but a useful tool. For example, for the repair of household appliances. In some household appliances, plastic gears are erased or broken from the load. With the help of 3D printing, a replacement can be easily made.

For example, for the repair of household appliances. In some household appliances, plastic gears are erased or broken from the load. With the help of 3D printing, a replacement can be easily made.

Printed and original gears

Or print interior items: coasters, vases, lamps, boxes for small items. Everything is limited only by 3D modeling skills and imagination. nine0003

Totals

FDM printing technology, thanks to a wide variety of 3D printers and materials, is very versatile. The main thing is to choose the right tool - a printer suitable for the given tasks.

Despite its youth and active development, FDM has already found many areas for application. From year to year, mechanics are being improved - printers are becoming faster and more accurate. The software is constantly updated so that the novice user is comfortable and does not have to read long instructions before starting the printer, as well as understand millions of settings. nine0003

nine0003

Various plastics appear, helping to obtain more accurate and durable products. Or imitating a different texture and material. This allows you to expand the scope of 3D printers using FDM technology.

FDM technology. How it works.

Hello everyone, 3DTool is with you!

In this article on 3D printing, we will look at the basic principles of FDM (Fused Deposition Modeling) technology. Let's deal with the basic mechanics of this process. Its advantages and limitations. nine0003

FDM technology

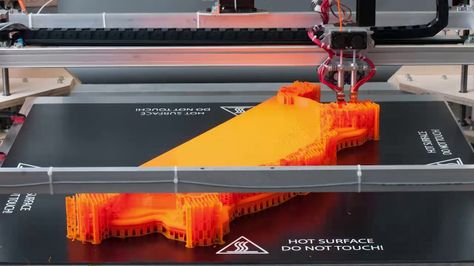

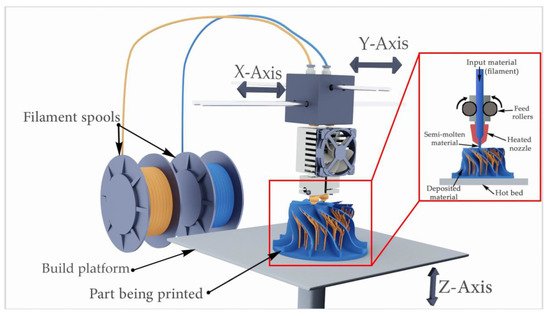

Overlay printing (FDM) is an additive manufacturing process that is realized through the extrusion of materials. In FDM, an object is built by applying molten material according to a predetermined algorithm, layer by layer. The materials used are thermoplastic polymers and are filament-shaped.

FDM is the most widely used 3D printing technology. FDM printers are on the market in a wide variety. It's basically the first technology people come across when they start working with 3D. The main principles and key aspects of this printing method will be presented next. nine0003

It's basically the first technology people come across when they start working with 3D. The main principles and key aspects of this printing method will be presented next. nine0003

An engineer who is designing a 3D model should take into account the possibilities of technology when manufacturing a part with FDM, this knowledge will help him achieve the best result.

Process FDM printing

Here is how the FDM process works:

A spool of thermoplastic filament is loaded into the printer. Once the nozzle reaches the required temperature, the filament is fed into the extruder and into the nozzle where it is melted. nine0003

The extruder is attached to a 3-axis system that allows it to move in the X, Y and Z directions. The molten material is extruded in thin filaments and melted in layers at predetermined locations where it then cools and solidifies. Sometimes the cooling of the material is accelerated by the use of fans attached to the extruder.

The extruder requires several passes to fill the printable area. When the layer is finished, the platform moves down (or, as in some printer models, the extruder moves up), and a new layer is welded onto the already set one. This process is repeated until the entire model is printed. nine0003

FDM printer specifications

Most FDM systems allow you to adjust several parameters of the printing process. Such as nozzle temperature, platforms, print speed, layer height and cooling fan speed. These are usually set by the printer operator and do not bother the modeler.

What is important from a modeling standpoint is to consider the size of the table and the layer height of the part itself:

The standard printable area of a desktop 3D printer is usually 200 x 200 x 200 mm, while for industrial machines it can be up to 1000 x 1000 x 1000 mm. If a desktop 3D printer is preferable (e.g. for cost reasons), the large model can be broken down into smaller pieces and then reassembled/glued together.

The typical layer height used in FDM varies from 50 to 400 microns and can be determined during the software slicing step. A lower layer height will provide a smoother detail and more accurately represent complex geometry, while a higher layer height will print the part faster and at a lower cost. The layer height of 150-200 microns is optimal in terms of the ratio of printing time and its quality. nine0003

Part deformation

Warp is one of the most common defects in the FDM printing process. Some plastics shrink during cooling after extrusion. Since different regions cool at different rates, their dimensions can also change at different rates. Differential cooling causes an accumulation of internal stresses that pull the layer, the one from the bottom - up, deforming it, as shown in the figure below. From a technical point of view, deformation can be prevented by more careful control of the temperature of the platform and the chamber as a whole. By increasing the adhesion between the part and the platform. nine0003

By increasing the adhesion between the part and the platform. nine0003

The modeler can also reduce the chance of peeling and other warp-related defects:

Large flat areas (such as a rectangular box) are more prone to deformation and should be avoided if possible.

Thin protruding elements (for example, battlements, spiers) are also prone to deformation. In this case, it can be avoided by adding some support material around the edge of the thin element (for example, a 200 micron thick rectangle) to increase the contact area. nine0003

Sharp corners deform more often than rounded shapes, so smoothing the corners slightly can achieve a good result.

Different plastics are more susceptible to deformation: ABS is generally more sensitive to this factor than PLA or PETG due to its higher glass transition temperature and relatively high coefficient of thermal expansion.

Adhesion between layers

Good adhesion between layers is very important for an FDM printed part. As the molten plastic is extruded through the nozzle, it is pressed against the previous layer. High temperature and pressure remelt the surface of the previous layer and allow the new layer to bond with the old one. nine0003

As the molten plastic is extruded through the nozzle, it is pressed against the previous layer. High temperature and pressure remelt the surface of the previous layer and allow the new layer to bond with the old one. nine0003

The strength of the bond between different layers is always lower than the basic strength of the material.

This means that FDM parts are inherently anisotropic: their Z strength is always less than their X/Y strength. For this reason, it is important to keep the orientation of parts in mind when designing.

For example, tensile test specimens printed horizontally with ABS at 50% infill were compared with test specimens printed vertically and found to have nearly 4 times higher tensile strength in the X, Y axis compared to the Z axis ( 17.0 MPa compared to 4.4 MPa). Such a part is stretched to failure, almost 10 times more (4.8% compared to 0.5%). nine0003

Moreover, since the molten material is pressed against the previous layer, its shape is deformed to an oval. This means that parts will always have a wavy surface, even at low layer heights, and that small features, such as small holes, may need post-printing post-processing.

This means that parts will always have a wavy surface, even at low layer heights, and that small features, such as small holes, may need post-printing post-processing.

Supports

The support structure is essential for creating tab geometries. Because plastic cannot be applied to air, some geometries require a support structure. nine0003

Surfaces printed with supports are usually of lower quality than the rest of the part. For this reason, it is recommended that the part be modeled in such a way as to minimize the need for support.

Supports are usually printed from the same material as the part. There are also special materials that dissolve in a liquid, but they are mostly used in high-end desktop or industrial 3D printers. Printing on soluble supports greatly improves the surface quality of the part, but increases the overall cost of printing because a special printer with two print heads is required and because the cost of soluble material is relatively high. nine0003

nine0003

Filling and shell thickness

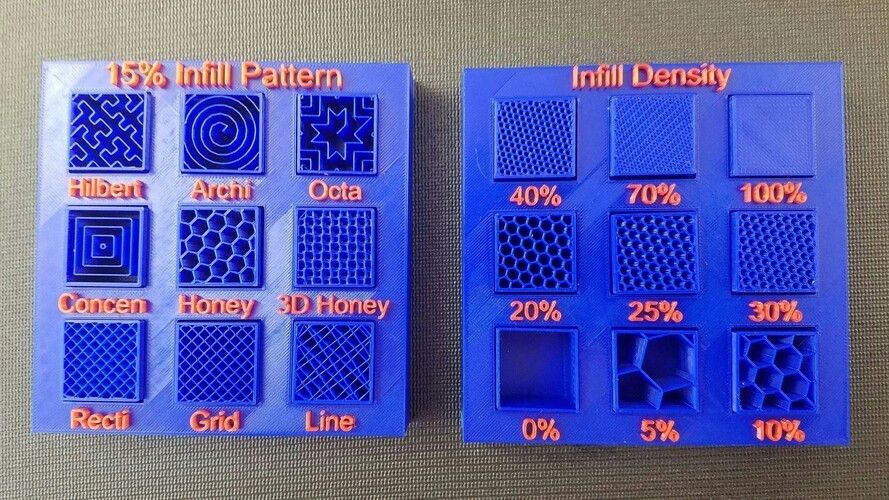

FDM parts are usually not printed full in order to reduce printing time and save material. Instead, the outer perimeter is made with several passes, it is called a shell, and the inner part is filled with a low density structure called infill.

The filling and thickness of the body greatly affect the strength of the part. For desktop FDM printers, 25% infill density and 1mm body thickness are mostly suitable. Usually, these are the standard settings for fast printing and a good compromise between strength and speed. nine0005

Above you see the internal geometry of parts with different degrees of filling

FDM Essential Consumables

One of the strengths of FDM printing is the wide range of materials available. They can range from conventional plastics (such as PLA and ABS) to engineering plastics (such as TPU and PETG) and high strength materials (such as PEEK).

Below is a pyramid of materials most available in FDM printing. nine0096

The material used directly affects the mechanical properties and accuracy of printing, as well as its price. The most common FDM printing materials are listed below. We will also consider the pros and cons of certain plastics. An overview of the main differences between PLA and ABS, and a detailed comparison of all common types of filament is a very extensive topic and can be found in special articles on the Internet and on thematic forums.

ABS

pros

· Durability

Good temperature resistance

Minuses

Shrinks when printed

PLA

pros

Excellent visual quality

Easy to print

· Unharmful. May come into contact with food nine0003

Minuses

· Low impact strength

· Longevity

Nylon

pros

· Very high strength

Excellent wear and chemical resistance

Minuses

· Actively absorbs water

PET-G

pros

· Unharmful. May come into contact with food nine0003

May come into contact with food nine0003

Sufficiently strong

Minuses

Capable of precise temperature print settings

TPU

pros

· Very flexible

Minuses

Printing accuracy is very difficult to achieve

PE EK

pros

· Extremely durable and lightweight

Excellent flame retardant and chemical resistance

Minus

· High price

Need a specialized 3D printer whose extruder is capable of reaching temperatures above 300C

Postprocessing

FDM parts can be processed to high standards. When using various methods such as: sanding, polishing, priming, painting, cold welding, acetone bath (to smooth the surface and create a glossy surface), epoxy coating and plating. nine0003

Advantages and disadvantages of FDM printing

+

· FDM printing is the most economical way to produce custom thermoplastic parts and prototypes.

· FDM printing lead time is acceptable. The technology is quite affordable these days.

Wide range of materials suitable for both prototyping and some non-commercial functional applications. nine0003

-

FDM printing has the lowest dimensional accuracy and resolution compared to other 3D printing technologies, so it is not suitable for models with complex geometry and fine details

The final product will have visible layer lines, so post-processing is required for a better look

Layer adhesion mechanism makes FDM printed parts anisotropic

Highlights

· With FDM printing, prototypes and functional parts can be produced quickly and at a low cost. There is a wide range of filaments on the market with different physical properties.

· The typical platform size of a desktop FDM 3D printer is 200 x 200 x 200mm.