Can you eat 3d printed food

7 Exciting 3D Printed Food Projects Changing How We Eat Forever

Foodies worldwide, rejoice. 3D printed food promises to transform how we perceive, prepare and eat food forever. Using a food 3D printer you can gift your friends sweets and chocolates in the shape of their face, create a delicious burger from scratch, or even 3D print heart-shaped pizza to celebrate your anniversary — all within a few minutes.

This article covers how 3D printing food works, the coolest current 3D printed food projects, which printable foods you can eat currently, how some Michelin-starred restaurants are already using food 3D printers, the health benefits of 3D printing food, and more.

- We have also written a separate article on the best food 3D printers.

- In addition, we have an article focused on chocolate 3D printers.

What is 3D printed food? And how can you 3D print food?

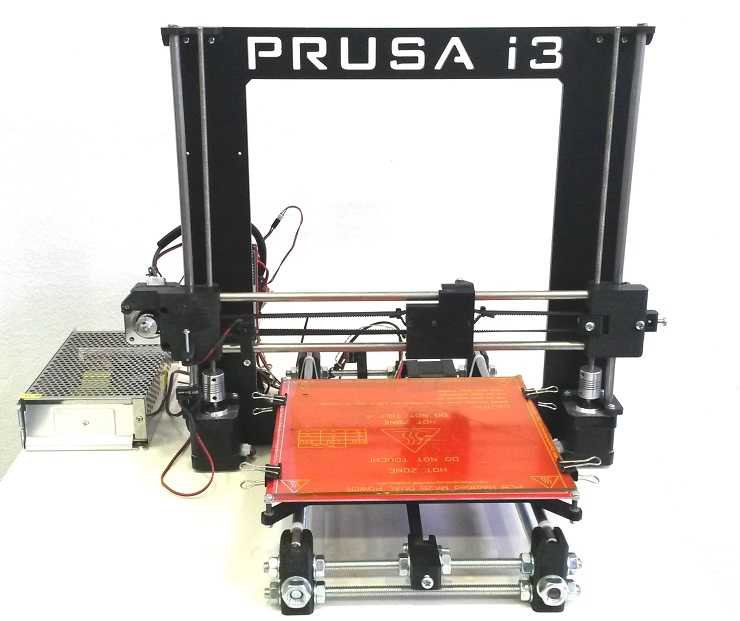

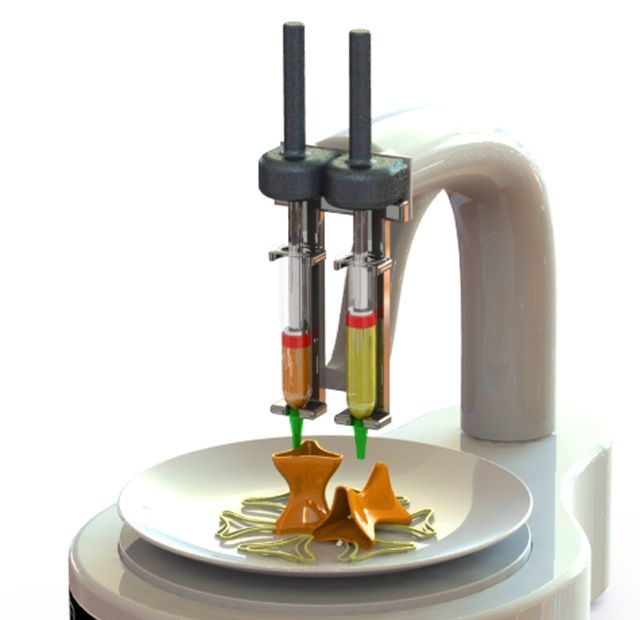

3D printed food means any type of food that has been printed via a food 3D printer. Most food 3D printers use a similar technique to FDM 3D printers, depositing a food-safe 3D printer filament such as chocolate onto a build plate based on a 3D printer model you can either download or design yourself.

Instead of plastic filament used in FDM printers, food 3D printers use edible, food-safe filaments such as chocolate, tomato sauce, and various other tasty flavors.

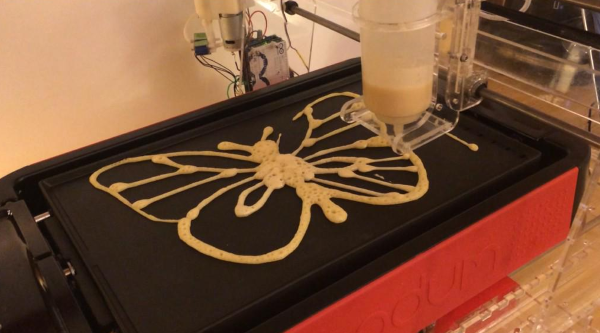

If you have ever iced a cake using a piping bag, these food printers are similar, except with robotic precision as they deposit edible filament in your desired shape. Once one layer of your edible model is finished, the food 3D printer starts on the layer above, creating a three-dimensional food model over time.A food 3D printer printing chocolate in the shape of a mug.

Food 3D printers extrude the food material out from a nozzle, though some use robotic arms, lasers, and other crazy inventions. Most food 3D printers currently focus on sugary desserts like chocolates and sweets, though some companies are creating 3D printed pizzas, spaghetti, and even burgers and meat.

But why choose 3D printed food?

7 Amazing 3D Printed Food Projects

Food Ink

Food Ink was a pop-up restaurant based in the hipster part of Shoreditch, London, bringing 3D printed food to the UK. Launched in 2016, the restaurant was entirely 3D printed; not just the food and desserts, but also all the restaurant’s chairs, lamps, and decorations.

Visitors were served nine small courses of 3D printed food printed on byFlow Focus food printers. Food Ink then brought their concept to Barcelona, with future planned launches in Singapore and Dubai. The Food Ink concept shows artistic 3D printed food could become the luxury dining experience of the future.

3D Printed Pizza for Space

Whether it’s enjoyed by ninja turtles or the cast of any NYC-based sitcom, pizza’s place within popular culture ensured that eventually someone would try and 3D print pizza.

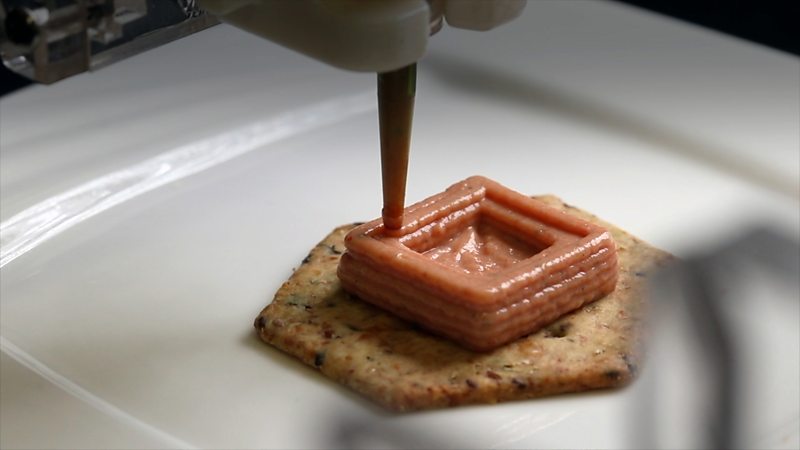

Already assembled in layers, pizza was a natural fit for 3D food printing, leading to it being printed on many of the first 3D food printers. The concept later gained significant attention once 3D printing company Beehex began presenting their NASA-funded pizza at trade shows.

The concept later gained significant attention once 3D printing company Beehex began presenting their NASA-funded pizza at trade shows.

NASA tasked Beehex with inventing alternative astronaut food; something less boring than current astronaut food bars, but still compact enough for space travel. Beehex proposed rehydrating and 3D printing pizza.

Their pizza prints like any other 3D printed food: the dough, tomato sauce, and cheese are laid down in layers before the pizza is cooked conventionally. This core technology captivated fans and the company raised $1 million to bring their pizza 3D printers to market. These printers would 3D print entire 12-inch pizzas in under five minutes, ideal for home use as well as in pizza restaurants and takeaways.

NASA ended up not pursuing the project further, with their collaboration ending in 2017. Despite potentially disappointing some astronauts, Beehex had succeeded in proving that 3D printed pizza could be almost indiscernible from its frozen alternatives… and delicious. Several years later, Beehex have pivoted toward 3D printing cakes, cake decorating, and cookies. But pizza 3D printing ideas live on.

Several years later, Beehex have pivoted toward 3D printing cakes, cake decorating, and cookies. But pizza 3D printing ideas live on.

We also have an article on 50+ fun 3D printed cookie cutters

A delicious 3D printed pizza being created.Outside of space travel, pizza’s next obstacle is the fact that currently only margaritas can be printed, with any additional toppings having to be applied by hand… unless puréed meat and vegetables are to your taste.

But the benefits are sure to excite. For example, at big sports events teams could 3D print pizzas with their team’s badge, and at promotional events companies could print their edible brand logo front and center. I’m sure we’d all love a pizza 3D printer to print our dinner while we relax and catch up on our favorite TV series.

Biometric 3D Printed Sushi

A project that has perhaps the most chance of changing the way we eat comes from Open-Meals, a company with a 100-year vision to completely digitize food.

The first step of this 100-year journey takes the form of their restaurant, Sushi Singularity, set to open in Tokyo, Japan.

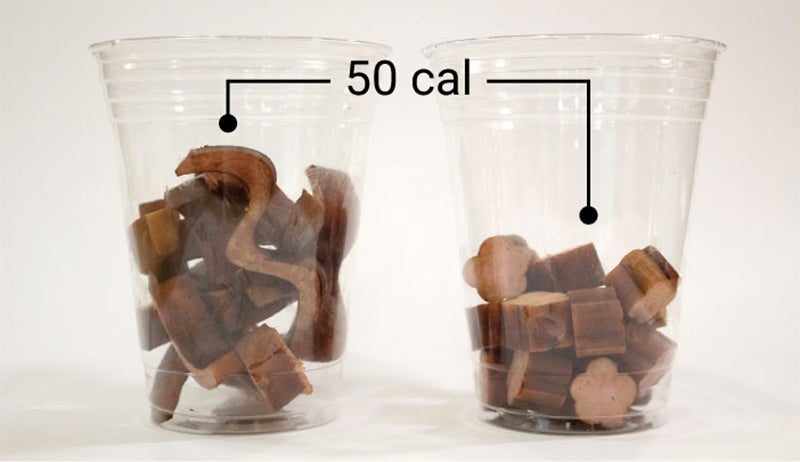

When making reservations guests submit their biometric data, including samples of their DNA, urine, and stools. When the guest arrives, Sushi Singularity uses this information to 3D print them a meal that addresses their specific nutritional needs.

The restaurant planned to open in 2020, and still intends to open soon despite missing this date; so, we’ll have to wait a while longer to see whether 3D printed biometrically-matched meals will catch on.

Sushi Singularity isn’t the end of Open-Meal’s plans for 3D printed food. Their 100-year vision includes service in medical facilities by 2023, restaurants and cafes by 2028, their own retail 3D printer by 2030, an autonomous delivery service by 2035, and an AI-controlled 3D printer becoming our household’s only kitchen appliance by 2040. Similar to Beehex’s vision, they aim to make astronaut food the same as terrestrial food by 2100.

3D printed cruelty-free and environmentally friendly meat

- We also have an in-depth feature story about 3D printed meat.

A number of startups are in the process creating 3D printed meat that mimics the taste, texture and even smell of real meat, but with 3D printable and plant-based materials.

Companies like Novameat and Redefine Meat are working on 3D printable beef steaks and other products using unique plant-based compounds that taste like the blood, fat and muscle that make up traditional meat flavors. Plant-based oils mimic the taste of fat, while legumes and beans create the muscle flavor. These are then 3D printed together using specialist meat 3D printers.

Novameat founder Giuseppe Scionti aims to be supplying national supermarkets by 2021 with his meat 3D printers, and with massive ethical advantages arising from getting our meat without killing farm animals, this could be 3D printed food’s biggest sector in the coming years.Redefine Meat’s 3D printed meat being sliced.

Recycled 3D Printed Biscuits Fighting Against Food Waste

Rather than looking to the future, Netherlands based company Upprinting Food believes that 3D printing can help combat our current issues with food waste.

Upprinting began as the graduation project of industrial design and food technology student Elzelinde Van Doleweerd. The company saves food from being wasted, and instead reconstitutes it into edible filament and biscuits.

Their process begins by collecting food destined for waste, most commonly due to ugliness or over-ripeness. Observing that bread is the most wasted product in the Netherlands, Elzelinde started with bread-based recipes.

After collection, the mixture is then puréed and fed into their 3D printer. 3D printing allows them to print intricate designs that are then baked and dehydrated, creating crunchy and long-lasting biscuits.

The company has seen much success since its launch in 2018. In addition to its own products, Upprinting offers design services to chefs, as well as training restaurants to utilize their own 3D printers and otherwise wasted food.

Sugar Lab: 3D printed sugary treats

A very different approach comes from Sugar Labs, a self-described team of LA-based “rogue chefs, architects-turned-designers, and tech geeks.” Using 3D printing, they have potentially created the most premium treats you’ll ever eat.

The company began in 2011 as the project of husband-and-wife team Liz and Kyle von Hasseln. Rather than using their 3D printer to print architectural models as it was supposed to, the pair began printing with sugar instead.

Speaking about the company’s origins, the pair explained:

“We both have a background in architecture. We bought our first 3D printer during grad school, then one day we printed a sugar tiara for a friend’s birthday cupcake. She loved it so much that it really got us thinking, maybe this could be a whole new territory for 3D printing. So, we kept experimenting with sugar.”

Liz & Kyle von Hasseln

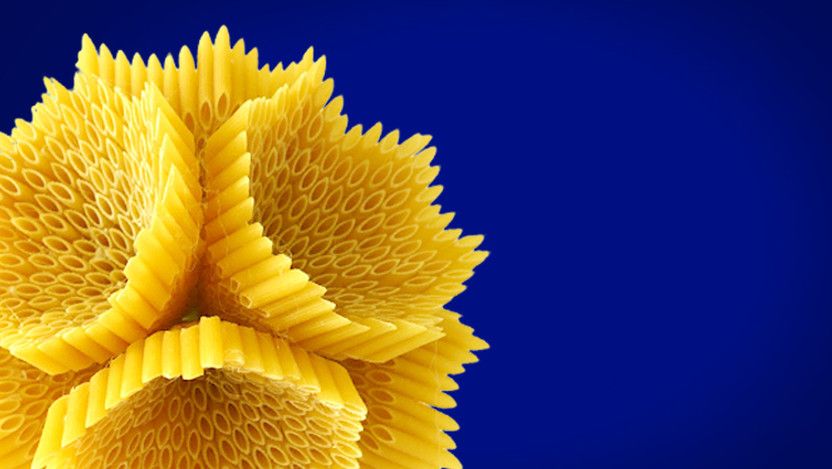

This experimentation would lead to what the company is now known for, sugar products so intricate that some are officially sold as “ornaments. ”

”

Their process begins by mixing sugar, water, and vegetable starch with the dry flavorings of the specific recipe being printed. This mixture is then printed with their own 3D printer to create complex and geometrically inspired sugar treats, some of which would be almost impossible to recreate by hand.

The company re-launched in October 2020, beginning the process of making its entire catalogue available online. Though, with their products starting at $15 for six cubes, their prints may remain unaffordable for all but the keenest 3D printing foodies.

6 sugary skulls cost $24.99 on the Sugar Lab webstore.Paco Pérez — Michelin-starred 3D printed food

Five-time Michelin-starred chef Paco Pérez has adopted 3D printed food in some of his restaurants. The world-renowned chef has introduced several Foodini food 3D printers into his two-Michelin-star restaurant La Enoteca to “recreate form and pieces” of food that are “exactly identical,” thus allowing cooks to do other tasks concurrently.

If a chef with 5 Michelin stars feels 3D printed food is good enough, then it’s good enough.

Advantages of 3D printing food

The benefits 3D printed food offers over traditional food varies from health, to saving time, and convenience. Here are the six main benefits of 3D printing food:

3D printed food can be healthier

In the future, experts have theorized that we will eat 3D printed sustenance made of hydrocolloids — substances that form gels with water. These include algae, duckweed, and types of grass.

Though they are not currently widely eaten, they are full of vitamins and proteins key to staying healthy. These could replace the base ingredients of future food dishes, providing a natural way to get your carbohydrates, antioxidants, proteins, and more.

3D printing food can be quicker and save you time and effort

Some aspects of cooking are monotonous and repetitive, like chopping vegetables. Food 3D printers create food autonomously once you have selected the dish you want, freeing up time to read a book, watch tv, or learn a language.

Additionally, some aspects of cooking have fairly steep learning curves. For example, it takes many years to master decorating wedding cakes. A food 3D printer can create these geometric shapes easily with a 100% success rate, and do it while you relax. This infinite shortening of the learning curve is one of the huge assets of 3D printing food.

3D printing food in space is the future

By 3D printing food we may be able to keep astronauts fed as we prepare to voyage through deep space. 3D printed food filaments are pastes created from the original, fresh ingredients, and these pastes can be kept in the right storage for years without spoiling.

Astronauts can keep a silo of food paste and 3D print the exact amount of food and vitamins they need for each meal, wasting nothing and neither under or overeating.

NASA have invested in creating food 3D printers such as this that can create food in space to feed astronauts.Though we have come an extraordinarily long way in aviation and spaceflight within the last century, compared to the speed of light we still move very slowly. Since we can send signals and therefore messages and files out into space at the speed of light, we can send custom designs to the 3D printers on board far away spaceships.

Since we can send signals and therefore messages and files out into space at the speed of light, we can send custom designs to the 3D printers on board far away spaceships.

This means that we can send new recipes to astronauts millions of kilometers away, and have their 3D food printer cook it for them minutes later.

Environmental benefits of 3D printed food

It is very likely that switching to 3D printed food would reduce fuel emissions. This is due to supermarkets switching over to selling ‘food cartridges’ rather than perishable foods which last months or years, rather than a few days. This reduces the amount of transportation undertaken by supermarket trucks, releasing less pollution into the atmosphere.

3D printing food saves money and reduces food waste

3D printers are some of the least wasteful machines around as additive manufacturing uses only what is required to print a model. A food 3D printer can print the exact amount of food filament required, with the exact amount of vitamins and supplements that you need for a meal. Not only is this efficient, but it saves you money compared to buying ingredients which may spoil and be thrown away.

Not only is this efficient, but it saves you money compared to buying ingredients which may spoil and be thrown away.

Download your dinner

Remember ‘You wouldn’t download a car?!’ Well now you can download dinner. Most major 3D food printer companies have communities of people who take great pleasure in designing their own meals and geometric patterns of food design. Many are on the internet for you to download and print for yourself. If you need something special for a birthday cake, just search for it, it’s probably there!

Being a new revelation, there are limitations however.

Limitations of 3D printed food

Firstly, 3D printed food ingredients are currently restricted to dry, shelf-stable ingredients that do not spoil quickly. These ingredients are ground into a paste and then kept, ready to be 3D printed later.Edible and printable food materials are extruded from syringe-like containers.

Each of these ingredients are different chemically and thus have different melting points. When 3D printing with plastics like ABS and PLA this is never a problem as each plastic has a set melting point and thus a set extruder temperature. However, melting different ingredients at different temperatures can cause problems, resulting in uneven food textures.

When 3D printing with plastics like ABS and PLA this is never a problem as each plastic has a set melting point and thus a set extruder temperature. However, melting different ingredients at different temperatures can cause problems, resulting in uneven food textures.

Moreover, though the food paste is melted when it is extruded, it is not cooked during the 3D printing process, and food must be cooked afterwards instead. This is only a problem for food pastes that cannot be eaten raw — chocolate 3D printers are fine. However, there are companies who are working on incorporating cooking into the printing process currently, and this may change in the near future.

The Essential Guide to Food Safe 3D Printing

3D printing offers unparalleled design freedom to produce custom parts and complex or organic shapes that would be costly or impossible to manufacture with traditional manufacturing methods.

These benefits can be compelling for a range of food-related applications. However, if 3D printed parts are intended for food contact items, you‘ll have to consider safety practices and regulations to avoid contact with toxic substances and prevent the buildup of harmful bacteria.

However, if 3D printed parts are intended for food contact items, you‘ll have to consider safety practices and regulations to avoid contact with toxic substances and prevent the buildup of harmful bacteria.

Food safe 3D printing is possible and the variety of materials approved as food safe is increasing, but there is a high degree of ambiguity around the workflows and finding the appropriate applicable regulations can be a challenge.

Read on for an introduction to food safety, food safety considerations for 3D printing, and a variety of methods to produce food safe products with common 3D printing processes, including stereolithography (SLA), fused deposition modeling (FDM), and selective laser sintering (SLS).

Please note

No Formlabs resins are food safe unless users take additional steps.

Video Guide

Having trouble finding the best 3D printing technology for your needs? In this video guide, we compare FDM, SLA, and SLS technologies across popular buying considerations.

Watch the Videos

To begin, it’s important to clarify a few key terms:

- Food grade means that the material is either safe for human consumption or permitted to come in contact with food.

- Food safe means that a food grade material meets the requirements determined by the intended use and will not create a food-safety hazard.

- Food contact surfaces include any surface that may come into direct contact with food. These surfaces must be made of nontoxic materials and designed to withstand the environment of their intended use, including exposure to cleaning compounds, sanitizing agents, and cleaning procedures.

Food grading and food safety concern a specific way to ingest parts, called migration. Particles as small as a few nanometers and up to several hundred nanometers may get transferred each time various materials encounter with each other, for example from components of the 3D printer to the 3D printed object, and from the object to the food.

Because migration levels are very low on occasional contact, food grading typically concerns items that are in prolonged contact with food such as containers, straws, utensils, plates, and food molds. Different testing institutions will adhere to different government-imposed risk tolerances and approved substances, which for the US is described by the FDA CFR 21 and for the EU in guidelines 10/2011.

Look for these labels indicating FDA and EU approval. Beware that a material being ‘compliant with’ doesn’t mean that it is explicitly approved by the institutions, so always check the technical datasheets for a certificate.

To be considered food safe according to the FDA Food Code, a material has to meet the following requirements:

- No migration of deleterious substances

- Does not impart colors, odors, or tastes

- Safe under normal use conditions

- Durable, corrosion-resistant, and nonabsorbent

- Sufficient in weight to withstand repeated washing

- Finished to have a smooth, easily cleanable surface without breaks and sharp internal angles

- Resistant to pitting, chipping, crazing, scratching, scoring, distortion, and decomposition

- Accessible to inspection

Any FDA or EU approved material includes not only the raw polymer but also the additives or masterbatch. These might contain components such as plasticizers, impact and heat distortion modifiers, UV-stabilizers, flame retardants, anti-fouling, anti-static, anti-slip, foaming and clarifying agents, anti-oxidants, aromatic nucleators, carbon alloys, phosphorescents, fillers, thickeners, chain extenders, metal deactivators, dyes, and a carrier resin.

These might contain components such as plasticizers, impact and heat distortion modifiers, UV-stabilizers, flame retardants, anti-fouling, anti-static, anti-slip, foaming and clarifying agents, anti-oxidants, aromatic nucleators, carbon alloys, phosphorescents, fillers, thickeners, chain extenders, metal deactivators, dyes, and a carrier resin.

A 3D printed part can turn into a petri dish squirming with bacteria within weeks. Even though some materials will survive the dishwasher, so will dangerous bacteria such as E. coli and salmonella that live in the little nooks and crannies. Some toxic molds find favorable growth conditions on several types of plastic and are hard to remove. Neither cleaning with bleach nor microwaving your polymers is an option for eliminating germs.

While bacteria buildup might not be an issue for disposable items, if you’re planning to create a part for long-term use, using a food safe coating is highly recommended.

The best option to reduce the risk of particle migration and bacteria buildup is by dip coating the 3D printed parts with a food grade epoxy or polyurethane resin, such as Masterbond’s EP42HT-2FG or ArtResin or an FDA approved PTFE (known as Teflon®) to seal their surface.

However, note that coating also doesn’t guarantee food safety for prolonged use as not all of these coatings are dishwasher safe, and they may degrade over time, exposing the original, potentially non-safe surface.

Most 3D printing materials have a low heat deflection temperature (HDT), which means that the 3D printed parts might become brittle and crack, or deform and warp at elevated temperatures. If you’re planning to clean a 3D printed part in a dishwasher, make sure to double check that the material is dishwasher safe and if there are any specific recommendations for washing temperature.

As particles might migrate from components of a 3D printer to 3D printed parts, it is crucial that any components that might come in contact with the 3D printing material or the part are food grade and do not contain or leach harmful chemicals.

This includes taking precautions when using multiple materials, as some materials previously used in the 3D printer might have contained toxic particles and made contact with some components.

Many 3D printing materials are not food safe and might contain toxic chemicals. Only use materials to 3D print parts intended for food contact that are certified for food safety.

As may be expected, the risk of migration is higher if the food is exposed to the 3D printed part for an extended time period. In general, try to limit food contact time and take further precautions for parts that will be in contact with food for longer periods of time.

Think about the reason why you’d like to use 3D printing for a food contact item. If it’s to create custom shapes and forms, in most cases, there are indirect ways to use 3D printing to create these custom parts, for example with molding. See an example in the next section.

SLA 3D printing uses a laser to cure liquid resin into hardened plastic in a process called photopolymerization, resulting in parts that have the highest resolution and accuracy, the clearest details, and the smoothest surface finish of all plastic 3D printing technologies.

Is resin food safe? The answer is no. Substances may migrate from SLA parts which makes none of the resins and printed parts food safe by default. While some resins for dental and medical applications are certified biocompatible, that doesn’t mean that they’re food safe. These materials are certified for specific applications and should not be used for food contact products.

SLA parts have a smooth surface finish that makes it easier to use coatings to seal their surface and prevent the buildup of bacteria. The factors which affect the ultimate smoothness of a part include resin type, layer thickness, build orientation, mesh triangulation resolution of the 3D model, and the curing profile of the SLA resin. Printed parts require washing and post-curing according to the manufacturer's instructions before the coating is applied. However, note that coatings don’t guarantee food safety, as the coating may interact with the resin or degrade over time, exposing the original, potentially non-safe surface.

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with incredible details.

Download the White Paper

Creating custom molds is a common way to leverage the benefits of SLA 3D printing to produce highly detailed custom parts without having the 3D printing parts come into direct contact with food. While SLA 3D prints aren’t suitable for directly molding foods, SLA 3D printers are perfect tools to create mold negatives, which can be vacuum formed using food safe plastic.

The tools and techniques for creating 3D printed food molds are easy to master, and the results are often stunning.

3D printed molds for thermoforming and silicone enabled the creation of unique shapes and designs.

Learn more about creating molds for vacuum forming in our in-depth tutorial.

Electroplating is the process of coating parts with metal using an electric current. The process is most commonly used for decorative purposes or to prevent corrosion by creating a durable surface.

SLA parts are ideal for electroplating due to their smooth surface finish. However, as plastics are nonconductive surfaces, SLA 3D prints have to be rendered conductive by coating with graphite, conductive lacquer, electroless plate, or a vaporized coating.

Food safe metal coatings are available, but as the process involves various chemicals, making sure that the workflow is approved for food contact is the developer’s own liability.

SLA 3D printing offers the unique possibility to produce ceramic parts. After 3D printing, parts can be fired in a kiln to burn out the resin and form a true ceramic part that is strong and heat-resistant. With subsequent food safe glazing, the parts will become more hygienic and resistant to most chemicals.

A variety of food safe glazes are available on the market, but make sure to follow the manufacturer’s instructions in accordance with food safety guidelines.

3D printing in ceramics is ideal for fabricating complex geometries that wouldn’t be possible by hand.

Learn More About Ceramics

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

FDM is a 3D printing process that builds parts by melting and extruding thermoplastic filament, which a print nozzle deposits layer by layer in the build area.

The extruded material is circular in cross-section, which leaves very narrow crevices in between layers with a depth directly proportional to layer height. It is recommended in any case to print at the lowest feasible layer height for food safe parts.

Consequently, the main challenge with FDM parts is avoiding the buildup of bacteria. To be truly food safe in the long term, an FDM 3D print needs to have a smooth surface. Chemical smoothing with solvents like acetone, d-Limonene, or ethyl acetate removes many of the irregularities of the print resulting in a smooth, glossy appearance. However, applying a subsequent food safe coating is still highly recommended.

However, applying a subsequent food safe coating is still highly recommended.

Layers showing on FDM (left) and SLA (right) 3D prints.

Food grade filaments do not contain any composite particles so will not wear down the nozzle into the print. Nevertheless, avoid brass nozzles that contain lead and use a dedicated stainless steel nozzle instead for all food contact items.

Always check the compatibility of your 3D printer’s components with the filament. For example, PEI is a material that is FDA compliant and offers great mechanical benefits but needs to be processed at over 300 °C, which requires a specific printer solution.

The most common questions around FDM food safety concern two popular materials. Is PLA food safe? Is ABS food safe? The answer is, it depends.

Food safe 3D printing filaments include PLA, PP, co-polyester, PET, PET-G, HIPS, and nylon-6, as well as some brands of ABS, ASA, and PEI. Having to run parts through the dishwasher rules out PET, nylon, and PLA because these plastics soften and distort around 60–70 °C. For applications involving hot liquids, co-polyester, High Temperature PLA or PEI are most suited.

For applications involving hot liquids, co-polyester, High Temperature PLA or PEI are most suited.

While not reflected in the regulations, some studies suspect that polystyrene may leach styrenes, co-polyesters might cause health concerns and that food grade FDM filaments might lose their safe status due to oxidation and thermal degradation from the printing process.

| Filament | Brand | FDA | EU | Smoothable | Dishwasher safe | Hot liquids |

|---|---|---|---|---|---|---|

| ABS | Adwire PRO | Approved | NA | Yes, acetone | Yes | Yes |

| Innofil3D | Approved except red, orange, and pink | Approved except red, orange, and pink | Yes, acetone | Yes | Yes | |

| ASA | Innofil3D | NA | Compliant | Yes | No | |

| Bendlay | Orbi-Tech | NA | Compliant | Yes, brake cleaner | No | No |

| Biocompound | Extrudr GreenTEC | NA | Compliant | |||

| Co-Polyester | Colorfabb XT | Approved | Compliant | No | Yes | Yes |

| HIPS | Easyfil | Compliant | Compliant | Yes, d-limonene | Yes | No |

| Fillamentum | NA | Compliant | Yes, d-limonene | Yes | No | |

| InnoFil3D | Approved | Approved | Yes, d-limonene | Yes | No | |

| Nylon | Taulman Nylon 680 | Compliant | NA | No | No | |

| PEI | ULTEM® 1000 | Compliant | NA | Yes | Yes | |

| PET | InnoPet EPR | Approved except red and orange | Approved except red and orange | Yes, ethyl acetate | No | No |

| Refil | Approved | NA | Yes, ethyl acetate | No | No | |

| Taulman T-Glase | Approved | NA | Yes, ethyl acetate | No | No | |

| Verbatim | Compliant | NA | Yes, ethyl acetate | No | No | |

| PET-G | Extrudr MF | NA | Approved | Yes, ethyl acetate | No | No |

| HDGlass | Approved | Approved | Yes, ethyl acetate | No | No | |

| PLA | Filaments. ca TrueFS ca TrueFS | Approved | NA | No | No | No |

| Fillamentum | NA | Compliant | No | No | No | |

| Innofil3D | Approved except red, orange, pink, apricot skin, grey, and magenta | Approved except red, orange, pink, apricot skin, grey, and magenta | No | No | No | |

| Copper3D PLActive Antibacterial | Approved | Compliant | No | No | No | |

| Makergeeks | Approved | NA | No | No | No | |

| Purement Antibacterial | Approved | Approved | No | No | No | |

| PLA-HT | Makergeeks Raptor | Approved | NA | No | Yes | Yes |

| Makergeeks Raptor | Approved | NA | No | Yes | Yes | |

| PP | Centaur | Compliant | Compliant | No | Yes | Yes |

| InnoFil3D | Approved | Approved | No | Yes | Yes | |

| Nunus | Compliant | Compliant | No | Yes | Yes | |

| Verbatim | Compliant | NA | No | Yes | Yes | |

| SBS | Filamentarno | NA | Approved only in Russia | Yes, d-limonene | Yes | Yes |

Selective Laser Sintering is a 3D printing process that use a high-powered laser to fuse small particles of polymer powder. The most common material for laser sintering is nylon, a popular engineering thermoplastic with excellent mechanical properties.

The most common material for laser sintering is nylon, a popular engineering thermoplastic with excellent mechanical properties.

While some SLS powders are graded food safe, the particles on the surface of printed parts might not fuse completely, resulting in parts that are inherently porous and do not deal well with moisture and mold growth. Even though the nylon 12 powder can be steam cleaned in an autoclave, it is best to coat SLS parts with food safe coatings to seal their surface.

A common post-processing step for SLS parts is dying. But note that after an SLS part has been dyed, the dye may leach into the printed part which renders the item not food safe.

White Paper

Looking for a 3D printer to create strong, functional parts? Download our white paper to learn how SLS printing works and why it's a popular 3D printing process for functional prototyping and end-use production.

Download the White Paper

Food safety with 3D printing is not a simple matter that will boil down to a clear yes or no answer. Producing 3D printed parts for food contact items requires careful consideration of the risks depending on their intended use.

Producing 3D printed parts for food contact items requires careful consideration of the risks depending on their intended use.

For further information on food safety and 3D printing, we recommend reading the following:

- FDA Regulations CFR 21

- EU Guidelines 10/2011

- Risk Assessment of 3D Printers and 3D Printed Products

- The Tricky Business of Choosing Plastic for Food Contact Applications

how 3D food printers can help you maintain a healthy diet April 24, 2018, 23:54

Anastasia Ksenofontova

Scientists from Ewha Women's University (South Korea) have created a 3D printer that prints products with a given nutrient content and predetermined taste properties. The author of the development, Jin-Kyu Lee, presented his invention on April 24, 2018 at the annual meeting of the American Society for Biochemistry and Molecular Biology in San Diego. About the prospect of using "smart" food - in the material RT.

from 3 d- Products up to 3 D- kitchens

South Korean university of the NIGHA Women's University developed a 3D printer that turns powder ingredients into full-fledged food products with a given content of nutritional substances predetermined taste properties.

Related

A spoon for the Earth: how a healthy diet can improve the ecology of the planet

June 2 is Healthy Eating Day. Research scientists show that changing eating habits and accustoming yourself to the right...

Key nutrients (such as carbohydrates and proteins) are ground into powder at a temperature of -100 °C. Then the resulting raw material is heated and turns into a porous film. After that, a three-dimensional product is created from several layers of films. The uniqueness of the development lies in the fact that by combining films with different content of proteins, carbohydrates, trace elements and vitamins, you can get a product saturated with nutrients in the required proportion. In addition, you can experiment with the flavor palette of the product, combining, for example, powdered pear and apple.

“We believe that one day anyone will be able to purchase cartridges containing powdered analogues of various ingredients that can be “collected” together using 3D printing and prepared a “dish” according to individual needs and preferences,” said the author of the development, the researcher from Ewha Women's University Jin-Kyu Lee.

A balanced diet

The developers believe the new technology will significantly reduce the amount of food waste and the financial costs of storing and transporting food. Also, according to scientists, their invention will help meet the food needs of the growing population of the planet. According to the Food and Agriculture Organization of the United Nations, by 2050 the world's population will increase from the current 7.6 billion people to 9.8 billion, and in 2100 it will reach 11.2 billion.

“If a family gets a 3D printer, then they don't have to be afraid of hunger. Of course, we are only at the beginning of the journey. We continue to optimize our development to create customized products that last longer than usual,” said Jin-Kyu Lee.

- © 3D Systems Corporation

The first 3D food printers appeared in 2015 and could only prepare simple meals. One of these devices works in the FoodInk 3D kitchen restaurant, opened in London in 2016. Everything in this establishment - from food to furniture and cutlery - is created on a 3D printer. The restaurant offers a nine-course menu to visitors. The 3D printer used here works on the principle of a conventional one, the role of ink is played by a paste of edible ingredients, such as cottage cheese or chocolate mousse.

One of these devices works in the FoodInk 3D kitchen restaurant, opened in London in 2016. Everything in this establishment - from food to furniture and cutlery - is created on a 3D printer. The restaurant offers a nine-course menu to visitors. The 3D printer used here works on the principle of a conventional one, the role of ink is played by a paste of edible ingredients, such as cottage cheese or chocolate mousse.

According to Russian nutritionists, the development of Korean scientists will help people maintain a balanced diet. However, experts emphasize that it is not worth doing “self-healing” with the help of a 3D printer - first you need to seek advice from a specialist.

“On complex developments that provide for a certain nutrient content, a person will not last long. In addition, it deprives him of the pleasure of eating. Such 3D food can be balanced and healthy, but quickly get bored. And of course, it’s better not to prescribe a diet for yourself, but to turn to a competent nutritionist who will make up a diet based on the state of your body, ”said Alla Pogozheva, professor at the Research Institute of Nutrition of the Russian Academy of Medical Sciences, in an interview with RT.

Russian developments

“In Russia, printers for printing products are not yet manufactured. For now, they remain a luxury item. However, in ten years, printers for printing products will most likely become more affordable for the average consumer, ”said Alexander Vinogradov, director of the chemical and biological cluster at ITMO University, in an interview with RT.

Related

"Printed" organ: Chinese scientists have grown and transplanted auricles to five children at once

Scientists from China have grown new ears for five children born with microtia - insufficient development or complete absence of the ear...

At the same time, 3D printing methods are actively developing in Russia, but in a more fundamental direction. So, domestic researchers from the Federal Research Center "Crystallography and Photonics" of the Russian Academy of Sciences developed in April 2018 the first 3D printer that immediately creates a three-dimensional structure. The development of Russian scientists can be used in tissue engineering. The resulting structures made of polymers can replace damaged areas of human tissues and organs.

The development of Russian scientists can be used in tissue engineering. The resulting structures made of polymers can replace damaged areas of human tissues and organs.

And scientists from Tomsk Polytechnic University use 3D printing technologies to develop the space industry. They made the first nanosatellite, the body of which is printed on a 3D printer, and they are also creating a printer for work on the ISS, which will help astronauts print the necessary part in the event of a breakdown. In addition, improved technology will make it possible to build bases and stations on the Moon using lunar soil as a material for three-dimensional printing.

Experts told when food can be printed on a 3D printer directly from home - news from the "Technology and devices" section on Food.ru

New technologies do not stand still - it turns out that soon it will be possible to print food on a printer, and this will be as common as ordering delivery from a supermarket. Only more environmentally friendly and faster. We tell you when to expect changes.

We tell you when to expect changes.

Dmitry Peskov, Special Representative of the President of the Russian Federation for Digital and Technological Development, said that in 5-7 years the technology of food printed on a printer will become mass, and the printers themselves will be available to people just like vacuum cleaners.

Even now, food can be printed, but so far the technology is used on a small scale, for example, for decorating cakes. Peskov said:

“The stage is still very early, but I think that another 5-7 years are needed to find solutions that we want to put in our kitchens ... These will definitely be mass-produced cheap devices, something like vacuum cleaners” .

Plant-based ingredients will be used in printed products to help reduce our carbon footprint and help the environment.

They, according to Peskov, will not be expensive and they can be purchased without any problems.

It is planned that by 2028 in Russia it will be possible to independently produce food using a printer at home. For example, "print" meat from vegetable protein.

For example, "print" meat from vegetable protein.

KFC is planning to print food on an industrial scale with a printer, which wants to produce chicken nuggets in this way. It is planned that the nuggets will consist of a mixture of vegetable proteins and cellular meat - the result will be a product that resembles the texture of chicken meat.

KFC PR director Irina Gushchina said that initially the company planned to print wings on a bioprinter, but this turned out to be impossible, since there is a bone inside. In the future, KFC plans to use the printer for other products, such as strips.

Abroad, the technology of creating food on a bioprinter has become popular for a long time. For example, one of the Austrian companies is going to print salmon on a 3D printer, and there is a restaurant in London where almost everything - from food to cutlery - is printed. In early 2021, an Israeli company unveiled the world's first 3D printed ribeye steak.

Russian restaurateurs Ivan and Sergey Berezutsky also print ingredients for dishes, such as bean protein squid.