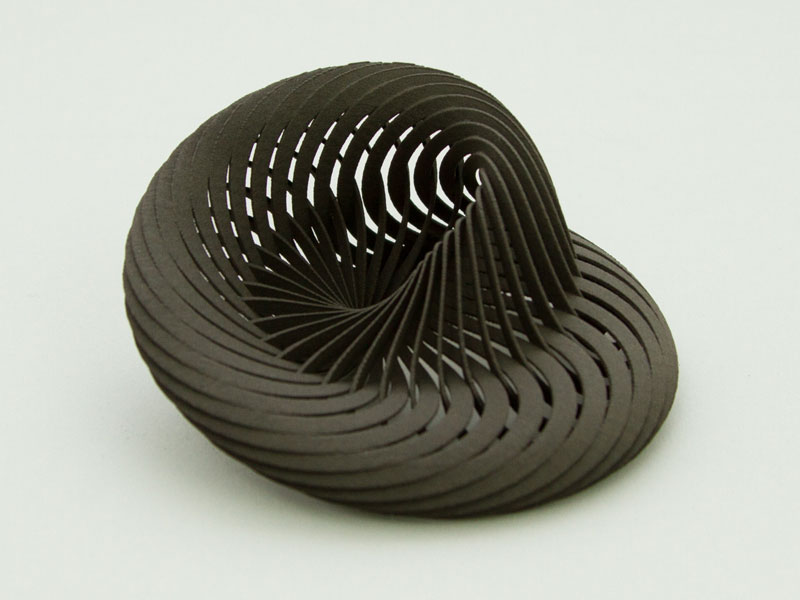

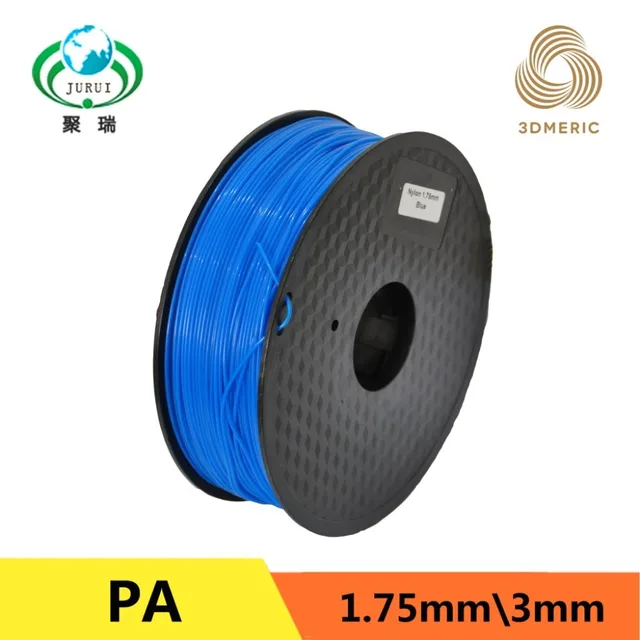

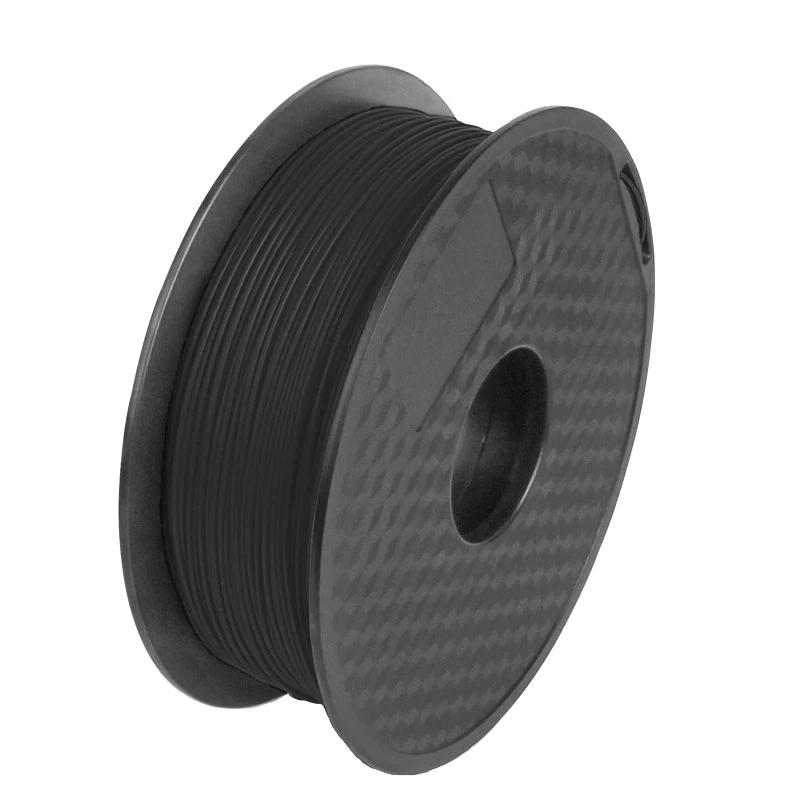

Black nylon 3d printer filament

1.75mm Nylon Filament | MatterHackers

Nylon is an incredibly strong, durable, and versatile 3D printing material. Flexible when thin, but with very high inter-layer adhesion, nylon lends itself well to things like living hinges and other functional parts. Nylon filament prints as a bright natural white with a translucent surface, and can absorb color added post process with most common, acid-based clothing dyes or synthetic cloth specific dyes. Nylon filament is extremely sensitive to moisture, so taking drying measures during storage and immediately prior to printing (using desiccant, vacuum, or elevated temperature) is highly recommended for best results. For tips and tricks on 3D printing Nylon, check out How To Succeed When Printing With Nylon.

Nylon Filament

PRO Series Nylon

The strength and durability of Nylon now in vibrant colors.

NylonX

The durability of Nylon combined with the stiffness of carbon fiber

NylonG

Glass infused nylon for strong, functional prints

Ultimaker Nylon Filament

Get impact and abrasion resistance with Ultimaker Nylon filament

Kodak Nylon 3D Printing Filament

Kodak Nylon 3D Printing Filament

Taulman Nylon 645, 680, 230

eSUN Nylon Filament

Material designed for high tensile strength and heat resistance

DSM Novamid 3D Printing Filament

Advanced material for automotive and electrical 3D printing applications.

Guides & Articles

5 Reasons Why You Should Start 3D Printing with Nylon

It's time to start 3D printing with Nylon filament - embrace the unique characteristics that make this material so versatile in a wide range of applications.

How To Succeed with LayerLock Garolite Build Surfaces

Successfully achieve strong bed adhesion for NylonX, NylonG, and standard filaments using LayerLock Garolite Build Surfaces.

Living Hinge: Design Guidelines and Material Selection

Bring your prints to life by adding an additional degree of motion to your designs - living hinges are the foundation of expanded mechanical solutions.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

3D Printer Troubleshooting Guide

Use this guide to help you identify and solve the most common issues that may occur while 3D printing.

Retraction: Just say "No" to oozing

By understanding a little more about the 3D printing process, and how settings in MatterControl affect extrusion, we can help you reduce and even eliminate oozing and stringing from your 3D prints. This should be a part of the regular maintenance and calibration program for your 3d printer.

How To Clear and Prevent Jams on Your 3D Printer

At some point you may encounter a filament jam or a clogged nozzle where your 3D printer is not extruding. This guide is intended to help you prevent such jams, or fix with them as painlessly as possible.

How to Succeed with NylonX

NylonX has quickly become one of our favorite filaments for strong, durable, and ready-to-use parts. Here's an in-depth look at Nylon X, and some printing tips to get the most out of this great new material.

Black PRO Series Nylon Filament - 1.75mm (0.75kg)

- Home

- Store

- 3D Printer Filament

- PRO Series Filament

- PRO Series Nylon

- 1.

75mm PRO Series Nylon

75mm PRO Series Nylon

MatterHackers PRO Series Nylon 3D printing filament is a great solution for 3D printed parts that require strength and durability. PRO Series Nylon is a versatile material that is characteristically flexible but can also be exceptionally tough, making it perfect for impact-resistant parts that require shock absorption. Engineers, designers, and manufacturers turn to PRO Series Nylon filament for its mechanical stability, low coefficient of friction, and natural chemical resistance.

20% off - use code BESTDEALS during checkout - offer ends 12/31/2022

Remove from wishlist Add to wishlist loading...

Product No. loading...

Notify me when this item becomes available Success You will be notified when ... becomes available. When Reliability Counts - Be a PROMatterHackers PRO Series filament is all about quality. When the performance of a 3D printed component is the ultimate goal, you need to know you’re printing with a material you can trust. MatterHackers’ PRO Series filament is meticulously refined and continuously tested to provide optimal results for every application. That’s why our material experts have developed a range of responsive high-performance thermoplastics that maintain reliability through your process of rough prototyping to sophisticated, end-use designs. No matter your end goal, PRO Series filament delivers your parts exactly as you intended them.

When the performance of a 3D printed component is the ultimate goal, you need to know you’re printing with a material you can trust. MatterHackers’ PRO Series filament is meticulously refined and continuously tested to provide optimal results for every application. That’s why our material experts have developed a range of responsive high-performance thermoplastics that maintain reliability through your process of rough prototyping to sophisticated, end-use designs. No matter your end goal, PRO Series filament delivers your parts exactly as you intended them.

MatterHackers PRO Series materials are formulated for functional 3D printing. Because of its precisely detailed chemical blueprint, PRO Series 3D printing filament provides the consistency needed for repeatable part-production. Kawasaki’s Supercross Racing Team Engineers use PRO Series materials for both prototyping and end-use parts. Using PRO Series materials for essential components on their teams’ motorcycles has not only helped them fabricate in low volume, but it’s also reduced cost by 95% and time by 86%. They turn to PRO Series because they know it works well.

They turn to PRO Series because they know it works well.

PRO Series materials are formulated with zero compromises. The base resin, and all performance-enhancing additives, are carefully sourced to include only those of the highest purity and provenance The consistent colors curated from quality sources combined with the exact manufacturing environment needed to maintain an industry-leading ±0.02mm diameter tolerance create materials you can use confidently. Experience smooth, uniform filament for all your important projects - experience PRO Series.

PRO Series Nylon has excellent Impact Resistance as well as high Chemical Resistance

It’s Not Just Filament, It’s a Results-Driven Experience - With OptionsNot only is our PRO Series line of filament carefully crafted, but we have an extensive collection of materials to choose from that fit every need and specific applications. From Tough PLA for serious prototyping to vibrant Nylons for sturdy, lasting products, PRO Series 3D printing materials deliver quality parts, time after time. PRO Series filament is created with end-use results as the main priority, ensuring that your finished 3D printed parts are as clean, sturdy, and functional as possible.

From Tough PLA for serious prototyping to vibrant Nylons for sturdy, lasting products, PRO Series 3D printing materials deliver quality parts, time after time. PRO Series filament is created with end-use results as the main priority, ensuring that your finished 3D printed parts are as clean, sturdy, and functional as possible.

MatterHackers PRO Series filament has remained the quintessential choice for anyone that demands exacting results for their business, products, and projects. Our attention to precise filament tolerance, strict coloration guidelines, and definitive chemical patterns are reflected directly in your completed products.

Mechanical Properties that are Tuned for PerformanceWe know that end-use products are only as good as the materials and tools used to create them - that’s why we put our PRO Series filament through rigorous testing before it makes its way to your workshop or manufacturing floor. Having high-quality materials is essential when creating functional or product-ready components, therefore all MatterHackers PRO Series materials are analyzed using in-house testing equipment, including a Universal Testing System and a Melt Flow Indexer. These machines are used specifically to measure tensile and flexural properties, as well as the melt flow index of each material ensuring that all PRO Series filament is dependable and performing at its peak capabilities. MatterHackers PRO Series materials are tested and measured using ASTM 638 and D790 or ISO 527-1, 527-2, and 178.

Having high-quality materials is essential when creating functional or product-ready components, therefore all MatterHackers PRO Series materials are analyzed using in-house testing equipment, including a Universal Testing System and a Melt Flow Indexer. These machines are used specifically to measure tensile and flexural properties, as well as the melt flow index of each material ensuring that all PRO Series filament is dependable and performing at its peak capabilities. MatterHackers PRO Series materials are tested and measured using ASTM 638 and D790 or ISO 527-1, 527-2, and 178.

With PRO Series materials, you know you’re getting the most accurate filament diameter and ovality available. Having a consistent diameter of 3D printing filament is very important - it directly impacts the print quality of your designs. The slicing engine calculates the volume of filament that will be deposited on each layer. The critical value that is input into the slicing engine for that volume is the diameter of the material (either 1.75mm or 2.85mm). Therefore, any variation in that diameter can cause the print to over or under extrude. In terms of raw materials - the filament diameter is one that requires a high level of confidence that you KNOW what you’re using.

The critical value that is input into the slicing engine for that volume is the diameter of the material (either 1.75mm or 2.85mm). Therefore, any variation in that diameter can cause the print to over or under extrude. In terms of raw materials - the filament diameter is one that requires a high level of confidence that you KNOW what you’re using.

Since we know diameter matters, we obsess over ensuring that PRO Series materials are on the mark so you can create perfectly printed parts. MatterHackers uses two and three-axis laser systems to measure and maintain the accuracy of the filament diameter at 40 hertz (40 times per second) - that way we know the filament diameter is consistent and within our 0.02mm diameter tolerance guarantee. Not only that, but the data for each production run is recorded and stored so we have traceability on all PRO Series materials to establish further confidence in each batch we produce..jpg)

Rest assured knowing that MatterHackers controls and actively analyzes the compounding and coloration of each filament batch, ensuring that your projects are the same from spool to spool. Color continuity between batches is controlled and confirmed with a color-analyzing spectrometer running in line during filament production. Your PRO Series filament will always be the same color PRO Series filament.

Technical Specifications- Recommended Extrusion Temperatures: 240±10°C

- Recommended Bed Temperature: 60±5°C

- Spool Dimensions: 6.875" OD x 2.125" ID x 2.31" Height

- Dimensional Accuracy: ±0.02mm

- Density: 1.14 g/cm3

- Volume: 0.66 L

- Length: 275m (1.75mm) or 100m (2.85mm)

- Download the Technical Data Sheet

- Download the Safety Data Sheet

Content

-

- Pla

- ABS

- HIPS

- PVA

- Petg

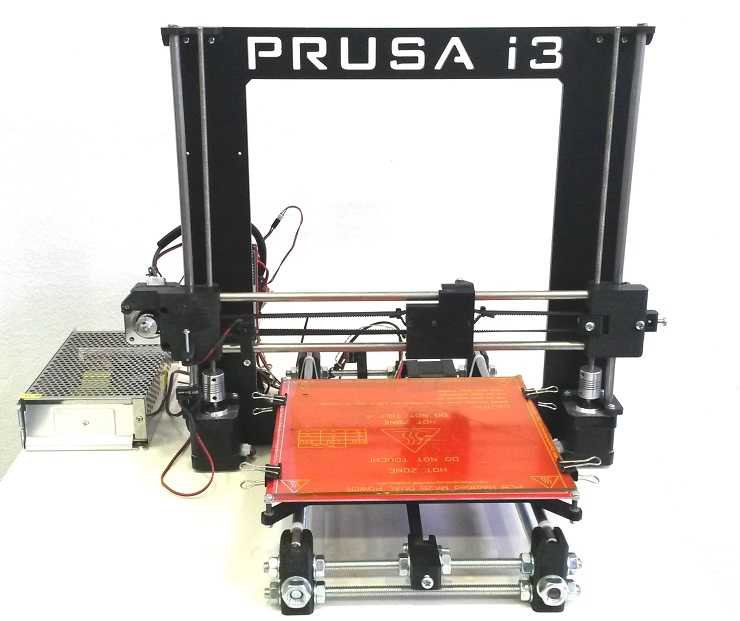

- SBS 9000

Every year 3D printing becomes more popular and accessible. Previously, a 3D printer was more like a complex CNC machine, but now manufacturers are meeting users. Simplified and automated settings that many beginners drove into a stupor. Despite this, it can be difficult for a novice user to understand the variety of constantly appearing plastics for a 3D printer.

Previously, a 3D printer was more like a complex CNC machine, but now manufacturers are meeting users. Simplified and automated settings that many beginners drove into a stupor. Despite this, it can be difficult for a novice user to understand the variety of constantly appearing plastics for a 3D printer.

The choice of plastic for a 3D printer is very important, especially when the goal is to print a functional model with certain properties. It will be a shame if the printed gear breaks almost immediately, or the decorative model quickly loses its beauty.

It is important to understand whether the printer will be able to work with the selected plastic. Some materials (most often engineering) require certain conditions for successful printing.

First, decide which model you want to print. What properties should it have? Does the model need to be durable? Or is it a master model for further replication, in which the quality of the surface is important?

90% of 3D printers use 1.

75 diameter filament. 3mm diameter is rare, but it is better to check in advance which size is used in your printer.

PLA

PLA (Polylactide) is the most popular and affordable 3D printer plastic. PLA is made from sugar cane, corn, or other natural raw materials. Therefore, it is considered a non-toxic, biodegradable material.

Extruder temperature - 190-220 degrees. Table heating is not needed, but if the printer's table has a "heater" for better adhesion, you can heat it up to 50-60 degrees. PLA is very easy to work with. The only requirement is to blow the model. There is practically no shrinkage in this material. When printed, it is practically odorless, and if it smells, it smells like burnt caramel.

Pros:

-

Does not shrink. This makes it easy to build prefabricated or huge models without changing dimensions.

-

There are no specific requirements for a 3D printer. Any working 3D printer will do.

PLA doesn't need a heated table or a closed case.

PLA doesn't need a heated table or a closed case. -

Non-toxic. Due to this, during printing it does not smell or has a barely perceptible aroma of burnt caramel.

-

Diverse color palette.

Cons:

-

PLA is poorly sanded and machined.

-

It begins to deform already with a slight heating (about 50 degrees).

-

Fragility. Compared to other materials, PLA is very brittle and breaks easily.

-

Decomposes under the influence of ultraviolet radiation. Of course, it will not fall apart into dust, but it can become more brittle and fade.

PLA is perfect for making dimensional or composite models. For example, decorative interior items, prototyping, electronics cases, etc.

Recently, PLA+ has appeared on the market. It may differ from conventional PLA in improved performance.For example, more durable, with improved layer adhesion.

Dummy turbine

Decorative coasters

ABS

ABS (acrylonitrile butadiene styrene) is the second most popular plastic for 3D printing due to its properties, availability and low price.

Extruder temperature - 220-240 degrees. The temperature of the table is 80-100 degrees. For printing, a heated table is required at the printer. It is desirable to have a closed chamber, because ABS "does not like" drafts. Due to a sharp temperature drop, it can “unstick” from the table or crack in layers. ABS can smell bad when printing, so it is recommended to use the printer with a closed chamber and filters, or print in a well-ventilated area.

Pros:

-

Good strength characteristics allow the production of functional prototypes from ABS.

-

Simple mechanical and chemical processing.

ABS is easy to sand and drill, and with an acetone bath you can achieve a perfectly smooth surface.

ABS is easy to sand and drill, and with an acetone bath you can achieve a perfectly smooth surface. -

It is currently the most inexpensive type of plastic for 3D printing.

-

Large selection of colors and shades.

Cons:

-

High shrinkage. Because of this, it can be problematic to manufacture overall products.

-

Printing requires a heated bed and a closed chamber. Without this, the ABS may peel off the table or crack in layers.

-

During the printing process, ABS can smell bad. Therefore, it is recommended that you print in a ventilated area or use the printer with a sealed chamber and filter.

ABS is an engineering plastic. It is suitable for the manufacture of simple functional products.

ABS after chemical treatment in an acetone bath

RU model made of ABS

ABS+ differs from conventional ABS in improved strength characteristics (elasticity, rigidity, hardness), less shrinkage and sometimes resistance to certain oils and solvents (eg gasoline).

HIPS

HIPS (high impact polystyrene) - originally conceived as a soluble support plastic for materials with high printing temperatures. For example for ABS or Nylon.

The extruder temperature is 230-260 degrees. The temperature of the table is 80-100 degrees. It is desirable to have a closed camera for a 3D printer.

Pros:

-

Less shrinkage than ABS.

-

Ease of machining.

-

The matte surface looks very advantageous on decorative products.

-

Food contact allowed (but be sure to check with a specific manufacturer for certificates)

Cons:

-

For printing, you need a printer with a heated table and a closed chamber.

-

More flexible and less durable than ABS. Because of this, it will not be possible to produce functional products.

-

Small palette of colors.

Most often, HIPS is used for its intended purpose for printing on 2x extruder printers as a support for ABS. It dissolves perfectly (though not very quickly) in limonel.

Sometimes HIPS is used as an independent material. Products from it are not very durable, but this plastic is loved for easy post-processing. HIPS can be used for models that will subsequently come into contact with food (not hot).

Using HIPS as a Soluble Support

Decorative vase made of HIPS

PVA

PVA (polyvinyl alcohol) is a material that was developed as a water-soluble support for PLA.

Extruder temperature - 190-210. Table heating is not required. PVA is a slightly "capricious" material, it is not recommended to overheat it and print at high speeds.

PVA is very hygroscopic and dissolves in plain water. Therefore, it is only used as a support for PLA or other plastics with print temperatures close to PVA.

Soluble PVA Support

Add to compare

Item added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

PETG

PETG (polyethylene terephthalate) combines the best properties of PLA and ABS. It is easy to work with, it has a low percentage of shrinkage and excellent sintering of the layers.

Extruder temperature - 220-240 degrees. Table temperature - 80-100 degrees. During the printing process, the model must be well blown.

Pros:

-

Excellent sinterability of layers.

-

PETG is very strong and wear resistant. Good impact resistance.

-

Virtually no smell when printing.

-

Non-toxic.

-

Little shrinkage.

Cons:

PETG is perfect for printing functional models. Due to its low shrinkage, it is often used to make large or composite models. Due to its low toxicity, PETG is often used for products that will come into contact with food.

Cookie cutters and patterned rolling pin

SBS

It is a highly transparent material. At the same time, it is durable and resilient. SBS is a low toxicity plastic. It can be used to print food contact models.

Extruder temperature - 230 -260 degrees. Table temperature - 60-100 degrees. You can print without the closed case on the printer.

Pros:

-

slight shrinkage

-

Transparency.

After treatment with solvent, limonel or dichloromethane, beautiful transparent products with an almost smooth surface can be obtained.

After treatment with solvent, limonel or dichloromethane, beautiful transparent products with an almost smooth surface can be obtained. -

Easily processed mechanically or chemically.

-

Allowed contact with food.

Cons:

SBS is excellent for translucent vases, children's toys and food containers. Or functional things that require transparency, such as custom turn signals for a motorcycle or car, lamps or bottle prototypes.

Vases are perfectly printed with a thick nozzle (0.7-0.8) in one pass (printing in 1 wall or spiral printing in a slicer).

Models of bottles after chemical treatment

Nylon

Nylon (polyamide) is considered the most durable material available for home 3D printing. In addition to good abrasion resistance and strength, it has a high slip coefficient.

Extruder temperature - 240-260 degrees. The temperature of the table is 80-100 degrees. Nylon is a very capricious and hygroscopic material - it is recommended to dry the coil with plastic before use. For printing, you need a printer with a heated table and a closed chamber, without this it will be difficult to print something larger than a small gear.

The temperature of the table is 80-100 degrees. Nylon is a very capricious and hygroscopic material - it is recommended to dry the coil with plastic before use. For printing, you need a printer with a heated table and a closed chamber, without this it will be difficult to print something larger than a small gear.

Pros:

-

High strength and wear resistance.

-

High slip factor.

-

Heat resistance compared to other 3D printing plastics.

-

High resistance to many solvents.

-

Good for mechanical processing. Perfectly polished and drilled.

Cons:

Nylon is perfect for making wear-resistant parts - gears, functional models, etc. Sometimes nylon is used to print bushings.

Nylon gear

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

Add to compare

Product added to compare Go

| Manufacturer | Bestfilament |

Soft plastics

FLEX (TPU, TPE, TPC) is a material similar to silicone or rubber. It is flexible and elastic, but at the same time tear-resistant. For example, TPE is a rubbery plastic, while TPU is more rigid.

It is flexible and elastic, but at the same time tear-resistant. For example, TPE is a rubbery plastic, while TPU is more rigid.

FLEX are printed at a temperature of 200-240 (depending on the material). A heated table is not required. On printers with direct material feed (feed mechanism on the print head), there are usually no problems with printing. On a bowden feeder (the feed mechanism is located on the body), printing with very soft plastics can be difficult. Usually it is necessary to additionally adjust the clamping of the bar. The main nuance is the very low print speeds - 20-40mm.

Pros:

Cons:

Depending on the type of FLEXa, the models can be flexible or rubber-like. This material, depending on its softness, can be used to print gaskets, insoles, belts, tracks or other models that require flexibility or softness.

FLEX belt

Trainers with flexible soles

Wheel for switchgear model

Decorative plastics

Decorative plastics are PLA plastics with various fillers (wood or metal shavings). Or with dyes selected to imitate different materials. Since the base of the plastic is PLA, it is very easy to print.

Or with dyes selected to imitate different materials. Since the base of the plastic is PLA, it is very easy to print.

Extruder temperature - 200-220 degrees (depending on the manufacturer). A heated table is not required.

Pros:

Cons:

-

Some fillers (eg clay) are abrasive. For such plastics, the standard brass nozzle cannot be used. Will have to buy a harder steel nozzle.

-

Some decorative plastics can clog the small nozzle (0.4 or less). For them, you need to use a “thicker” nozzle.

Depending on the filler, different material properties are obtained. Plastics that use only dye do not require additional processing. Materials with "fillers" may sometimes require additional post-processing.

Plastics with metal fillers after printing must be processed with a metal brush. Then the Metal content will show through and the model will resemble a metal casting.

Plastics with metallic powder

These plastics are often used for printing key chains, decorative models and interior details.

If the plastic has a high content of wood dust, then it is recommended to use a larger nozzle diameter (0.5 or more), a smaller nozzle can quickly become clogged during printing.

Wood-filled plastic ground

Plastic key rings with copper dust

Engineering plastics

These are nylon-based plastics with fillers that improve strength, heat-resistant and other characteristics, help to achieve less shrinkage of the material. For example - carbon fiber, carbon fiber or fiberglass.

Extruder temperature - 240-300 degrees (depending on the manufacturer). Table temperature - 90-110 degrees. Since plastics are based on nylon, the requirements for printing are similar. This is a heated table and a closed printer case.

Pros:

-

Hardness and strength.

-

Low flammability or non-combustibility.

-

High precision due to low shrinkage.

Cons:

3D printers use brass nozzles, some plastics can quickly “waste” it during printing. For such materials it is recommended to use steel nozzles.

These are highly specialized plastics used for a specific task, depending on the filler. For example, functional parts that do not lose their shape when heated, are resistant to many solvents, etc.

Functional Carbon Fiber Composite Prototype

Composite frame

Polycarbonate ashtray

Totals

This is of course not the whole list of materials for 3D printing. There are many highly specialized engineering and decorative plastics for specific tasks.

Manufacturers are constantly trying to replenish the range of materials for 3D printing. Already familiar materials are improved for more comfortable printing. There are many interesting decorative plastics imitating different materials - ceramics, clay, wood, metals.

And of course, the assortment of engineering plastics is constantly updated. Now there are many interesting materials for highly specialized tasks - for example, burnable plastic with a low ash content for subsequent casting in metal.

Burnout plastic

Before buying a coil, read the information on the website of the manufacturer or seller. There you can find some nuances of printing for a particular plastic. The manufacturer indicates the recommended temperature range on the box. Sometimes, for quality printing, it is recommended to print several tests to adjust the temperature settings, retract, etc.

Try to store the started coil in silica gel bags. It is recommended to additionally dry high-temperature plastics before printing to remove excess moisture.

It is recommended to additionally dry high-temperature plastics before printing to remove excess moisture.

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

Add to compare

Product added to compare Go

| Manufacturer | FlashForge |

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail.