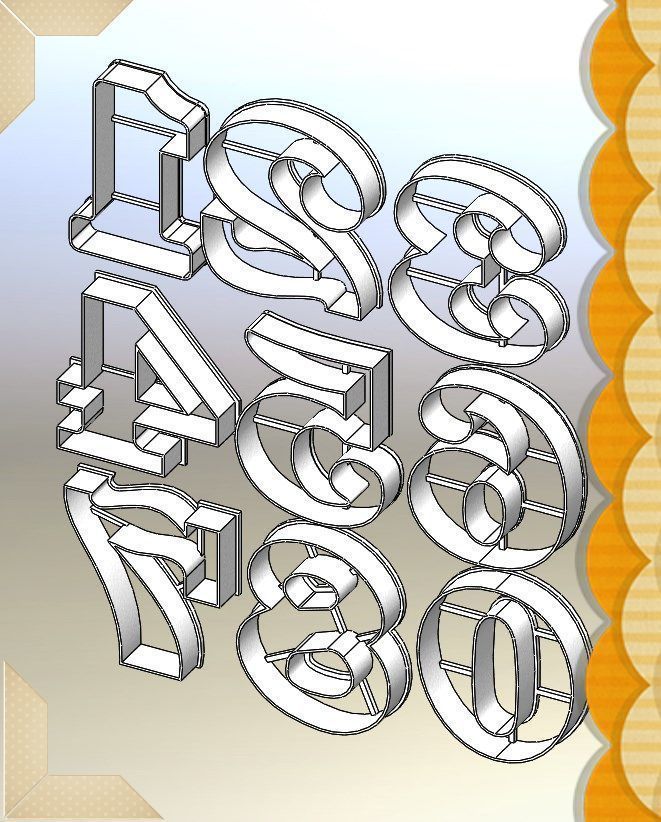

3D printed house numbers

Free STL file Custom text house number・Design to download and 3D print・Cults

Robot ARM 6 axis

€10

robot arm

Free

gripper robot arm

Free

TEXT LED COFFEE

Free

sensor ultrasonic HC

Free

Emblem led logo

Free

WALL KEY HOLDER LED

Free

Mini Robot EDUCATION

Free

Best 3D printer files of the Home category

Flower Pot

Free

Low Poly Pokemon Piggy Bank (Flowalistik design)

Free

Deactivated

Small hive entrance door - Opening 25% / 50% / 75%

Free

Dowel Lamp with low poly shade!

Free

Ad hoc lamp v2

Free

Mason Jar Pitcher

€0. 98

Bubble Trivet cnc/laser

Free

Best sellers of the category Home

Yet Another Quick Change Paper Towel Roll Holder (flip-up)

€1

Wall shelf “Oyster fungus”

€2.40

Wolf Coat Rack

€2.20

Xenomorph Pen/Stylus Holder

€1

Trash can with swing lid

€3.20

Gengar Pokemon Planter Vase Pencil Holder

€2.57

Fast-print modular storage drawer system

€5.74

Bordeaux, The Octopus

€2.45

Ghost nazgul the lord of the rings

€2. 60

60

Wall shelf “Tinder Fungus”

€2.40

Dinosaur gluttonous pencil holder

€1.92

Candlestick - Arbre de vie

€1.20

Wall shelf “Amanita Fungus”

€2.40

Pumpkin Girl

€2.90

Cardholder-wallet (universal package)

€1.33

Super Cute Paw Pen Cup

€1.39

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

House Numbers Print - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(244 relevant results)

Philippine Hotel's First Printed Suite Coming Soon With its task, according to Lewis Yakic, the owner of the hotel, the giant 3D printer coped brilliantly in 100 hours, while implementing a rather complex design concept.

The room printed in concrete at the Lewis Grand Hotel is the first comfortable hotel apartment in the history of mankind built in this way.

The room printed in concrete at the Lewis Grand Hotel is the first comfortable hotel apartment in the history of mankind built in this way. The owner of the hotel is Lewis Yakic from California, a structural engineer by profession, has accumulated solid experience in building houses in the United States to date. But the room built at the Lewis Grand Hotel most likely would not have been destined to go down in history if not for the idea of Lewis to involve Andrey Rudenko from Minnesota, widely known as the creator of a unique concrete 3D printer and the world's first 3D printed castle. from concrete.

A little about the author of the concrete 3D printer and his invention

A few words for those who are not familiar with the invention of Andrey Rudenko - a concrete 3D printer for the construction of large-scale building structures and solid houses. The first mentions of Rudenko's concrete 3D printer and the author of the invention are associated with Minnesota, where a concrete mini-castle was built as part of the experiment, which became Andrey's first experience.

Building a castle using 3D printing

Having successfully completed the castle project, Rudenko returned to the idea of 3D printing a residential building. Initially, he planned to build his first home in Minnesota, but due to harsh climatic conditions and harsh winters, the Philippines and the Lewis Grand Hotel were chosen as the site for a subsequent, larger experiment.

Some difficulties were associated with the transportation of a large 3D printer from Minnesota. Fortunately, one of the most important issues is that the ingredients for the production of building mixtures were found in abundance in the region. The main components of the composition used as a filler were sand and volcanic ash. All structural elements of the hotel building are built from them. Another factor in the successful implementation of the planned plan was the climate of the Philippines, which favors the rapid drying of the building mixture.

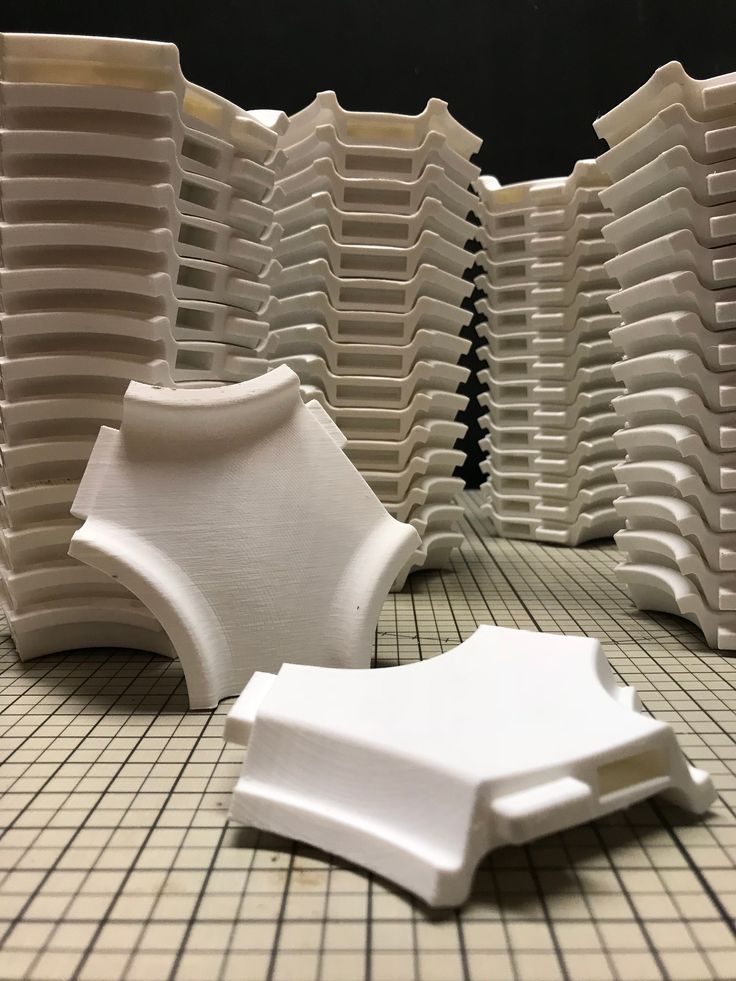

The dimensions of the Rudenko printer make it possible to carry out not element-by-element, but monolithic printing of structural elements, which eliminates the need for their subsequent assembly with the formation of joints.

Apartments in size of 10.5 m X 12.5 m and a height of 3 m are located in a separate extension to the main building of the hotel and have all the necessary for a comfortable rest - engineering communications, including water and power supply systems, modern plumbing kits, a jacuzzi, elements of heat and waterproofing systems and "Smart Home". The strength of the erected structure is increased due to reinforcement with steel reinforcement.

Perhaps using 3D printing at the current level of technology is not the fastest way to erect building structures with a predominance of rectilinear geometry, but where the concept of the architect and designer goes beyond the usual geometric shapes and involves the use of complex patterns, alternatives to 3D technology no. Using the Rudenko 3D printer, it is possible to apply layers of cement up to 10 mm high and up to 30 mm thick. The main advantages of the model are the speed, accuracy and accuracy of the operations performed.

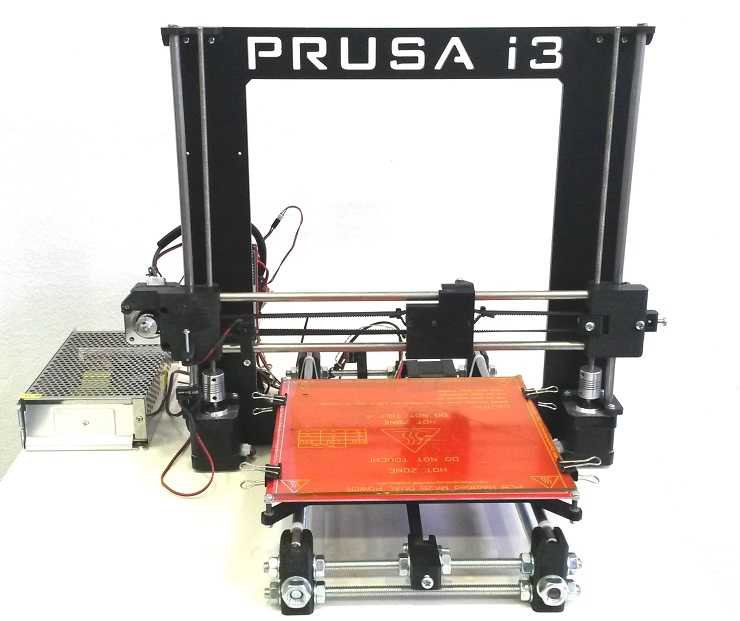

Serious help in optimizing the operation of the printer was provided to the inventor by the participants of the RepRap “self-copying 3D printer” project.

Larger 3D construction projects supported by professional construction companies are getting closer today in China, where the issue of cheap housing is most acute. The main research in the field of building 3D printing is carried out in Europe and the USA.

WinSun projects

In April last year, the Chinese company WinSun announced the successful completion of the construction of 10 houses with an area of 200 square meters. meters by 3D printing during the day! At the same time, the cost of each house made from industrial and construction waste was estimated at only 30,000 yuan = $ 4,800. For element-by-element printing, a printer 32 meters long, 10 meters wide and 6.6 meters high was used. The walls and the frame, printed separately, were assembled into a single structure at the final stage. Naturally, it is inappropriate to talk about any architectural value of the houses printed in one of the districts of Shanghai Qingpu, as is the case with the Rudenko hotel room, but the Chinese definitely managed to lay the foundation for solving the problem of cheap housing.

Naturally, it is inappropriate to talk about any architectural value of the houses printed in one of the districts of Shanghai Qingpu, as is the case with the Rudenko hotel room, but the Chinese definitely managed to lay the foundation for solving the problem of cheap housing.

To ensure the pace of printing, the company has planned to set up at least 100 factories to recycle construction debris into ultra-efficient inks for construction 3D printers.

Less than half a year

WinSun set another record in the construction of large-scale 3D-printed structures six months after the completion of a project of 10 houses. This time, during the implementation of the pilot project, specialists erected a 5-storey residential complex and a quite respectable two-storey mansion in the Suzhou Industrial Park area.

Building area 1100 sq. m.

After getting acquainted with the projects implemented by WinSun, Rudenko's achievement no longer looks like something incredible. At the same time, one of the main obstacles to the large-scale introduction of 3D construction technologies is the complete absence of unified national legislative and regulatory regulations. So far, the implementation of solid or prefabricated low-rise building structures looks much easier today, which Andrey Rudenko managed to brilliantly confirm by printing a chic room at the Lewis Grand Hotel in just 100 hours.

At the same time, one of the main obstacles to the large-scale introduction of 3D construction technologies is the complete absence of unified national legislative and regulatory regulations. So far, the implementation of solid or prefabricated low-rise building structures looks much easier today, which Andrey Rudenko managed to brilliantly confirm by printing a chic room at the Lewis Grand Hotel in just 100 hours.

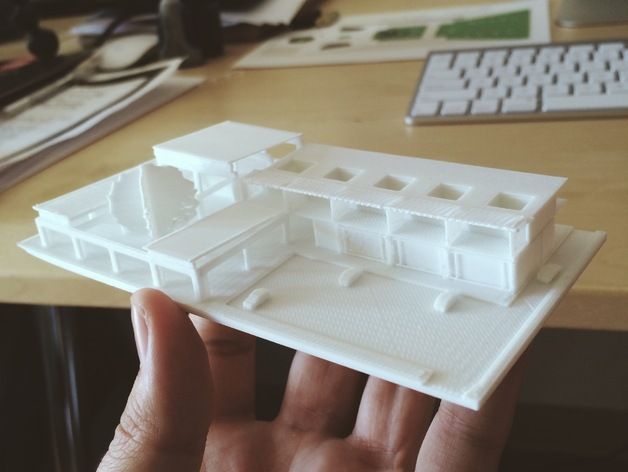

The successful completion of a suite at the Lewis Grand Hotel on a tight schedule is the best advertisement for Lewis Yakic, who has already signed a contract to build 20 more suites by November 2015. According to Rudenko himself, the use of an improved model of his 3D printer will allow printing up to 6 low-rise buildings per week using a similar technology, and, importantly, with a reduction of up to 60 percent in material and physical costs. Well, while someone enthusiastically masters 3D printing of toy houses using small-sized printers, ABS and PLA plastic, for someone an individual 3D reality is measured by the number of printed square meters.

However, it's better to see it once:

Dear readers, we are always happy to meet and look forward to seeing you on the pages of the iCover blog! We are ready to continue to delight you with our publications and will try to do everything possible to ensure that the time spent with us is also enjoyable for you.

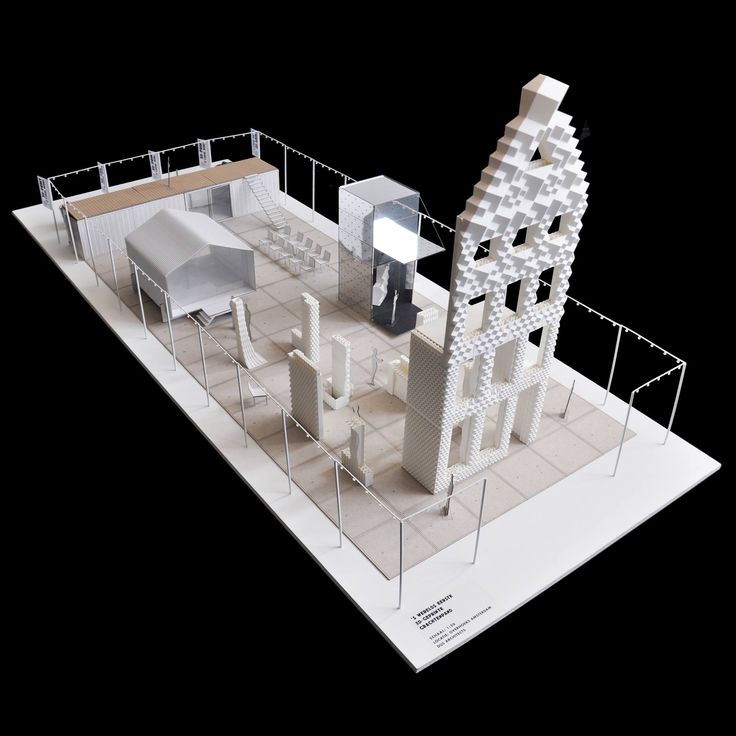

What Europe's first fully 3D printed house looks like

Trends

TV channel

Newspaper

Pro

Investments

RBC+

New economy

Trends

Real estate

Sport

Style

National projects

City

Crypto

Debating Club

Research

Credit ratings

Franchises

Conferences

Special projects St. Petersburg

Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library

Podcasts

ESG index

Politics

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

RBC Trends

Photo: Project Milestone

Europe's first 100% 3D printed home welcomes its new occupants, a couple from Amsterdam

What's happening

What it means 3D printer is just the beginning of a new stage in the industry.

Residential buildings built using 3D printing technology have a number of significant advantages over "classic" buildings. Firstly, the speed of the project, the first house was printed in five days, but going forward, the company plans to produce concrete elements on site, as well as use a 3D printer to create auxiliary installations, which will reduce construction time and costs.

Residential buildings built using 3D printing technology have a number of significant advantages over "classic" buildings. Firstly, the speed of the project, the first house was printed in five days, but going forward, the company plans to produce concrete elements on site, as well as use a 3D printer to create auxiliary installations, which will reduce construction time and costs. In addition, in an era of global concern for the state of the environment, such "green" technologies help reduce environmental damage to the environment - with 3D printing, the consumption of cement and waste of building materials is much less than with "traditional" construction.

Finally, with the help of a 3D printer, almost any design idea can be realized, which will allow you to move away from the concept of residential buildings in the form of "concrete boxes". The development of this technology makes it possible to erect buildings of such forms that are difficult and expensive to build using traditional methods.