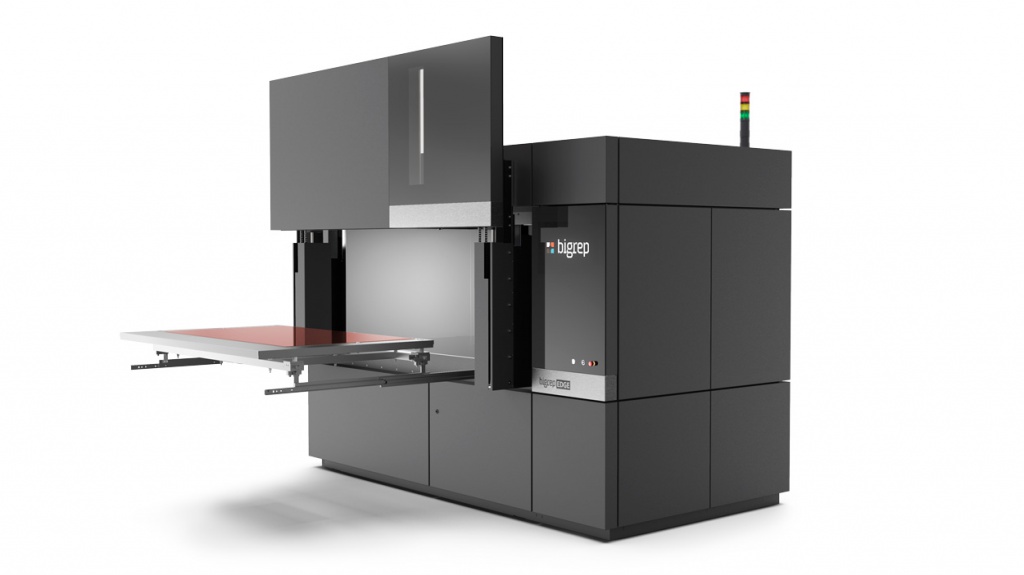

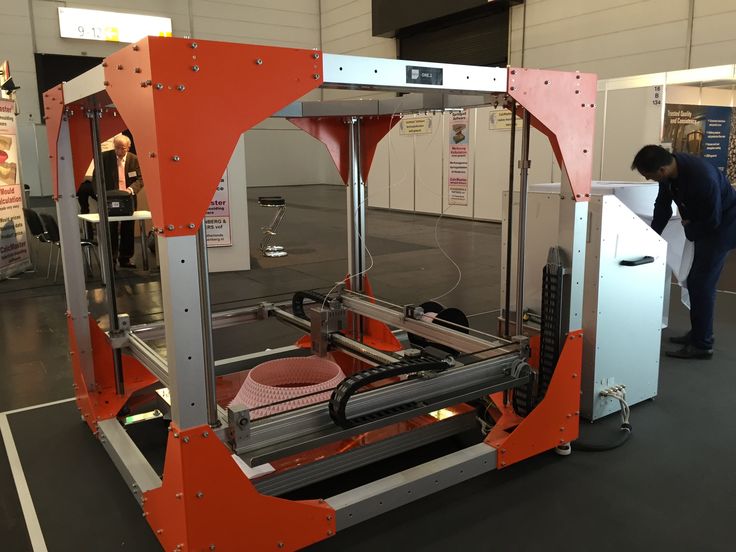

Bigrep 3d printer

Large-Format 3D Printers: Industrial & Professional

INTRODUCING THE NEW

ITERATE FAST.PRODUCE FASTER.

GET TO MARKET FASTEST.

Explore the PRO

INTRODUCING THE NEW

ITERATE FAST.

PRODUCE FASTER.

GET TO MARKET FASTEST.

Explore the PRO

Play Video

There was an opportunity to not only fill SAS's need for this tool they couldn't acquire through the normal supply chain, but we also saw the opportunity to make it better."

Nathan Brown, Managing Director at CNE Engineering

Read more about the case study here

BigRep makes big, industrial 3D printers for big, full-scale parts (and even big batches of smaller parts). Our commercial 3D printers are up to 1 m3 in build volume, which in fact is big enough to hold 2 baby elephants or equals the build volume of about 40 desktop printers!

With a large 3D printer, you can advance your manufacturing capabilities with 3D printed prototypes, jigs and fixtures, patterns and molds and end use parts. Where size isn’t a limiting factor, BigRep industrial 3D printers are built to make you faster and more agile, getting your products to market ahead of the competition.

ITERATE FAST. PRODUCE FASTER. GET TO MARKET FASTEST.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

Explore the PRO

ITERATE FAST. PRODUCE FASTER. GET TO MARKET FASTEST.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

Explore the PRO

GRADUATE FROM DESKTOP. GET INDUSTRIAL.

The BigRep STUDIO G2 gets 3D printing off your desk and takes it to the next level. Operating with the same ease as a desktop 3D printer and with 10 times the build volume, the STUDIO G2 provides large-scale industrial manufacturing capabilities in a compact “fits everywhere” build.

Explore the STUDIO

GRADUATE FROM DESKTOP.

GET INDUSTRIAL.

GET INDUSTRIAL.The BigRep STUDIO G2 gets 3D printing off your desk and takes it to the next level. Operating with the same ease as a desktop 3D printer and with 10 times the build volume, the STUDIO G2 provides large-scale industrial manufacturing capabilities in a compact “fits everywhere” build.

Explore the STUDIO

LARGE-SCALE INNOVATION. LIMITLESS CREATIVITY.

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 500 systems installed worldwide, it's a trusted tool of designers, innovators, and manufacturers alike. With a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

Explore the ONE

LARGE-SCALE INNOVATION. LIMITLESS CREATIVITY.

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 500 systems installed worldwide, it's a trusted tool of designers, innovators, and manufacturers alike. With a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

With a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

Explore the ONE

INDUSTRIAL 3D PRINTING MATERIALS

WIDE VARIETY

INDUSTRIAL QUALITY

LARGE-FORMAT OPTIMIZED

BigRep's portfolio of industrial 3D printing filaments are created under carefully controlled conditions to guarantee uniform diameters and consistent composition. They are sealed in controlled, low-humidity conditions for safe storage and transportation - ensuring reliable, even extrusion regardless of whether they're used today or after a reasonable shelf life.

With a wide variety of offerings from affordable, general use filaments to high-quality, engineering-grade materials for demanding industrial applications, BigRep has what you need - specialized for large-format 3D printing to bring your designs to life in full scale.

FIND YOUR FILAMENTS

INDUSTRIAL 3D PRINTING MATERIALS

WIDE VARIETY

INDUSTRIAL QUALITY

LARGE-FORMAT OPTIMIZED

BigRep's portfolio of industrial additive 3D printing filaments are created under carefully controlled conditions to guarantee uniform diameters and consistent composition. They are sealed in controlled, low-humidity conditions for safe storage and transportation - ensuring reliable, even extrusion regardless of whether they're used today or after a reasonable shelf life.

With a wide variety of offerings from affordable, general use filaments to high-quality, engineering-grade materials for demanding industrial applications, BigRep has was your need - specialized for large-format 3D printing to bring your designs to life in full-scale.

FIND YOUR FILAMENTS

INTRODUCING

A new customizable SaaS solution that makes application engineering for 3D printed jigs, fixtures, and manufacturing aids easier than ever, with no design skills or 3D printing experience required.

Learn More

INTRODUCING

A new customizable SaaS solution that makes application engineering for 3D printed jigs, fixtures, and manufacturing aids easier than ever, with no design skills or 3D printing experience required.

Learn More

Request Pricing or Talk to a 3D Printing ExpertHelp Us Understand Your Needs

REQUEST PRICING

Large Industrial 3D Printers - Large Format AM

BigRep's large 3D printers are your partner for industrial additive manufacturing, whether for functional rapid prototyping, tooling, or end products.

The industrial 3D printers offer a number of state-of-the-art features that enable a wide range of professional applications. Benefit from expert advice on your 3D printer purchase and the wide selection of 3D printing filaments.

ITERATE FAST. PRODUCE FASTER. GET TO MARKET FASTEST.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

Explore the PRO

ITERATE FAST. PRODUCE FASTER. GET TO MARKET FASTEST.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

Explore the PRO

GRADUATE FROM DESKTOP. GET INDUSTRIAL.

The BigRep STUDIO G2 gets 3D printing off your desk and takes it to the next level. Operating with the same ease as a desktop 3D printer and with 10 times the build volume, the STUDIO G2 provides large-scale industrial manufacturing capabilities in a compact “fits everywhere” build.

Explore the STUDIO

GRADUATE FROM DESKTOP. GET INDUSTRIAL.

The BigRep STUDIO G2 gets 3D printing off your desk and takes it to the next level. Operating with the same ease as a desktop 3D printer and with 10 times the build volume, the STUDIO G2 provides large-scale industrial manufacturing capabilities in a compact “fits everywhere” build.

Explore the STUDIO

LARGE-SCALE INNOVATION. LIMITLESS CREATIVITY.

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 500 systems installed worldwide, it's a trusted tool of designers, innovators, and manufacturers alike. With a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

Explore the ONE

LARGE-SCALE INNOVATION. LIMITLESS CREATIVITY.

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 500 systems installed worldwide, it's a trusted tool of designers, innovators, and manufacturers alike. With a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

With a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

Explore the ONE

Request Pricing or Talk to a 3D Printing ExpertHelp Us Understand Your Needs

REQUEST PRICING

What is 3D Printing?

3D printing, also called additive manufacturing (AM), is a technology used to manufacture three-dimensional objects. 3D printers usually use plastic polymer materials (but also occasionally metal) and form objects by adhering layers to each other in succession.

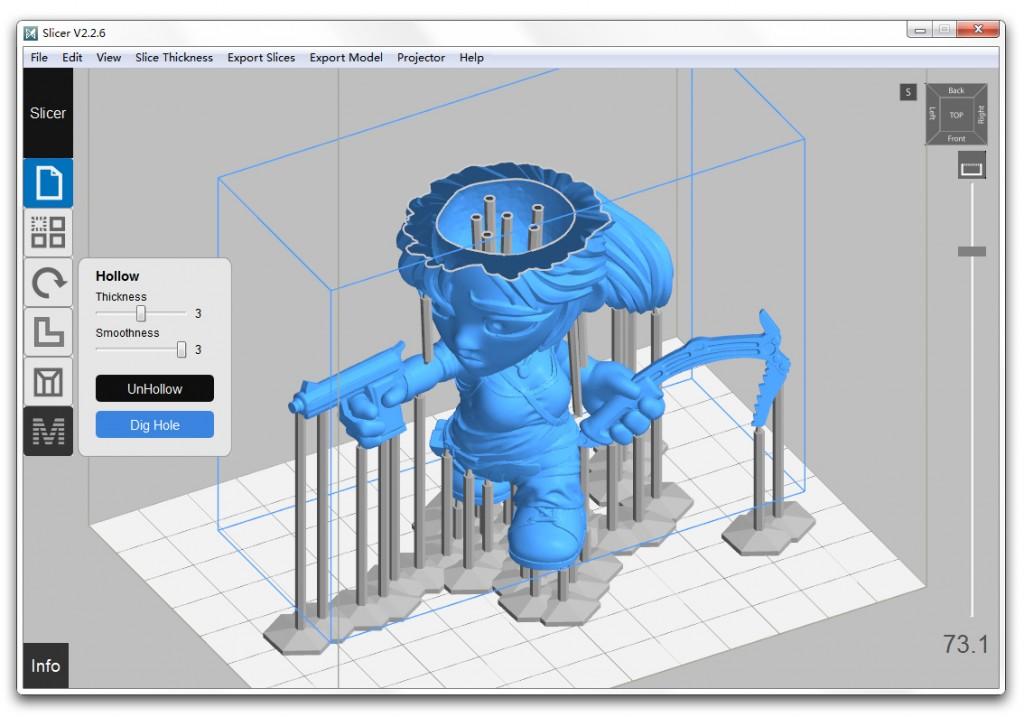

Like many other manufacturing technologies, a 3D printer’s production is mapped with computer-aided designs, or CAD models. Digital models are “sliced” by specialized 3D printing software (called slicers) into individual layers and accompanying support structures, then printed.

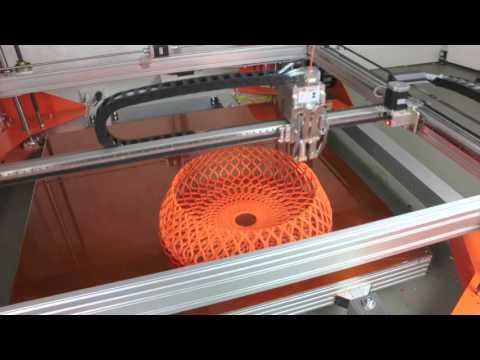

How does a 3D Printer work?How a 3D printer works depends on the specific technology it employs, the most common being FFF (FDM), SLA, and SLS in that order.

1

FFF - Fused Filament FabricationFused Filament Fabrication (FFF), also commonly known by its trademarked name; Fused Deposition Modeling (FDM), works by depositing molten filament on top of itself in individual layers until the desired object’s final geometry is formed. FFF is the most common – and usually most affordable – form of additive manufacturing technology available today.

In FFF 3D printing, polymer filament is pushed through an extruder that melts the material at a hot-end – similar to a hot-glue gun pushing solid glue sticks through its hot nozzle. The polymer material is then “printed” in layers as it is pushed through its nozzle, the diameter of which determines the layer size, and deposited onto a build platform (or “print bed”) or preceding layers.

There is usually minimal post-processing required for parts printed with FFF technology beyond support structure removal – if they were necessary at all.

What are some features of an FFF 3D printer?

- Usually fastest of common 3D printing technologies

- Lowest cost in both purchase price and consumables

- Extremely easy post-processing and minimal cleanup

2

SLA - StereolithographyStereolithography (SLA), the second most common additive manufacturing technology, works by curing liquid resin to itself in successive layers to form the desired object.

In SLA 3D printing, a build platform is lowered into a tray of liquid resin where it compresses the material against the bottom of a transparent tray before being cured by a mirrored UV laser. The process repeats, pushing each previous layer against the bottom of the tray until complete.

SLA is capable of incredibly detailed parts but is a material-intensive process. Significantly more of the resin material is normally required than the final object demands for the process to be effective. With excess material usually left in the tray, failed prints risk contamination. Dedicated trays are usually required for each liquid resin – which are themselves consumable as they are worn by light exposure from the UV laser.

What are some features of an SLA 3D printer?

- Capable of very small layer sizes for intricate model details

- Time-consuming process, increased exponentially with smaller layers

- Requires heavy clean up and post-processing with additional curing

3

SLS - Selective Laser SinteringSelective Laser Sintering (SLS) works by curing powdered material in successive layers as it is repeatedly spread throughout a build volume until the final object is formed. It is significantly less common than the other plastic technologies listed here, but is commonly used in metal additive manufacturing.

It is significantly less common than the other plastic technologies listed here, but is commonly used in metal additive manufacturing.

Similarly to SLA technology, the SLS process requires an abundance more material than is used to form the final object. However, there is little chance of material contamination and the required excess material serves a secondary purpose as a natural support structure.

Because SLS uses its powder material as a support for printed objects, it requires virtually no post-processing after the print has completed. It is capable of intricate detail but is a relatively slow and expensive process.

What are some features of an SLS 3D printer?

- No post-processing required since excess material serves as supports

- Typically the most expensive of the common 3D printing technologies

- Time-consuming process, increased exponentially with smaller layers

DESIGN

3D printed objects are designed with computer-aided design software (CAD). Knowledgeable designers and engineers use CAD software to form entirely new designs, or use 3D scanners to capture real-world objects digitally. Increasingly, artificial intelligence and parametric design software is used to automate design processes.

Knowledgeable designers and engineers use CAD software to form entirely new designs, or use 3D scanners to capture real-world objects digitally. Increasingly, artificial intelligence and parametric design software is used to automate design processes.

3D PRINT

To be 3D printed CAD models must be broken down into individual layers and the printing process mapped with slicing software (or “slicers”). Slicers generate G-code, a computer-aided manufacturing control language, from CAD models that directs a 3D printer’s movements as it recreates the digital model as a physical object.

POST PROCESS

Depending on your design and 3D printing technology, you’ll likely want to improve your print with some post-processing. Post-processing is anything that is done to an object after the 3D printer has finished producing it. Additional curing, support removal, sanding, painting and other coatings are all examples of common post-processing used to achieve a perfect, final 3D printed object.

Advantages of 3D Printing

3D printing offers many advantages over traditional manufacturing technologies. As a uniquely disruptive technology, businesses who invest in additive manufacturing are rewarded with exceptional efficiencies in their production. As 3D printing methods improve and new polymer materials with increased capabilities are introduced to the ever-growing additive manufacturing market, the technology’s possible applications continue to increase exponentially.

3D printers work exceptionally fast to produce impressive, geometrically complex objects – often in a matter of hours, depending on the size.

Traditional manufacturing methods are notorious for long lead times that hold up dependent workflows, often for weeks at a time. As a highly reliable unattended process, 3D printing can produce even full scale objects overnight to be ready for use the next day.

FLEXIBILITY

Because 3D printing uses digital files (CAD models) instead of physical tooling like patterns and molds, it’s a highly flexible technology.

Small series or 100% personalized manufacturing and design processes with many iterations benefit greatly in both speed and cost when compared to traditional manufacturing processes that require manually machined tooling to operate.

Manufacturing costs can be determined by three metrics - material, operating and labor expenses. Unlike wasteful reductive manufacturing techniques, 3D printing is an “additive” process that uses just enough material to produce an object.

As a single unattended process, operating and labor expenses are eliminated by a consolidated process that frees staff for other tasks. Since 3D printers don’t require object-specific tooling, manufacturers also save whenever implementing product changes.

ENVIRONMENTALLY FRIENDLY

Though some forms of 3D printing are more ecological than others, the nature of additive manufacturing technologies – which use just enough material to produce an object – make them all significantly more environmentally friendly than reductive techniques.

In FFF 3D printing “closed-loop” material processes are becoming increasingly common, where polymer shredders are used to recycle filament in-house to be reused in the 3D printing process.

Advantages of Industrial 3D PrintersWith industrial 3D printers you can create functional, full-scale objects or industrial parts beyond the limitations of more standard build volumes.

In smaller build sizes large-format parts must be divided before slicing, printed separately and adhered together in an imperfect manual process. By manufacturing in full scale, you save time by not only avoiding multiple print jobs and post-processing, but also make parts exceptionally stronger. Objects printed with industrial 3D printers are often highly functional parts ranging from end-use products like furniture and recreational vehicles to high-strength industrial tooling.

What is a

large-format 3D Printer used for?3D printers are used for a wide variety of applications, with more becoming a reality every day. The three most common additive manufacturing applications are…

The three most common additive manufacturing applications are…

Increasingly, 3D printers are being used to create end-use parts and even consumer products. Because of the flexibility inherent in additive manufacturing, businesses offering highly personalized products have been using additive manufacturing to create small series or completely unique products for a long time. Today, even industrial manufacturers use 3D printing for serial production and to create affordable, industrial parts.

Tooling / FixturesThough 3D printers don’t require any tooling themselves, they’re fantastic at producing it. Manufacturers can use 3D printing technology to create molds, patterns, or even jigs and fixtures to aid other manufacturing processes.

Unlike traditional tooling production, which usually requires excessive lead times, creating tooling with 3D printing is a fast and simple process. Even larger tooling can be additively manufacturing in an unattended process and be quickly in use on the factory floor.

Because 3D printers can manufacture objects so quickly without specially designed tooling, it’s widely recognized as an ideal technology for product development. Products can be manufactured and redesigned at incredible speed allowing designers to create more iterations and perfect their product.

Later in the design process, the same technology and design files can be used to create functional prototypes, allowing a team to experience their product in the real world.

3D-Printer FAQ

What is considered a large 3D printer?

Large 3D printers are too big to fit on a desk and usually offer a build volume bigger than 500x500x500 mm.

Small or large 3D printers can be sorted into two categories:

- Desktop 3D printers

- Large-format 3D printers

BigRep 3D printers provide a build volume of up to 1000x1000x1000 mm.

Which 3D printer has the biggest bed size?

With serial production 3D printers the print bed size can be up to 1000x1000 mm like in the BigRep PRO.

However, there is no real limit to bed sizes as there are custom made 3D printers like the University of Maine's 100 feet (30,5 m) long printer.

Can you 3D print large objects?

The size of a 3D printed object depends on the size of the 3D printer. With a BigRep ONE you can 3D print large objects up to 1000x1000x1000 mm or 35 cubic feet.

What does an industrial 3D printer do?

An industrial 3D printer saves time and money in product development, engineering and manufacturing.

What sets an industrial 3D printer apart from an entry level 3D printer is:

- High reliability

- Faster 3D printing

- High repeatability

- No assembly required

- Factory service

What is 3D printing? How does it work?

3D printing is a process for generating three dimensional objects by creating a cross sectional pattern of the object to be formed. 3D printing is a subset of broader term additive Manufacturing. In loose terms technology used here is slicing CAD model of part geometry in layers using software and producing one layer at a time. Each layer sticks to previous layer and thus building the whole solid part in layers.

In loose terms technology used here is slicing CAD model of part geometry in layers using software and producing one layer at a time. Each layer sticks to previous layer and thus building the whole solid part in layers.

What technology is used in 3D printing?

Over the last few years, high-resolution 3D printers have become more affordable, easier to use, and more reliable. As a result, 3D printing technology is now accessible to more businesses, but choosing between the various competing 3D printing solutions can be difficult.

Which technology is suitable for your application? What materials and equipment’s are available to get started? How about costs and return on investment?

There are three most established plastic 3D printing technologies for plastic: fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS).

How many types of 3D printing are there?

There are 7 different types of 3D printing formulated by ASTM International officially in the ISO/ASTM 52900 standard:

- Material extrusion

- Material jetting

- Binder jetting

- Sheet lamination

- Vat photopolymerization

- Powder bed fusion

- Directed energy deposition

What materials can be used in 3d printing?

Plastics are the most widely adopted 3D printed material - and it comes in filament, resin, granule, and powder forms. Most thermoplastic 3D printing materials can be used in home 3D printing technology and professional applications as well. Below materials are also used widely:

Most thermoplastic 3D printing materials can be used in home 3D printing technology and professional applications as well. Below materials are also used widely:

- Acrylonitrile Butadiene Styrene (ABS)

- Polylactic Acid (PLA)

- Polyvinyl Alcohol (PVA)

- Nylon

- High-density polyethylene (HDPE)

What could an industrial 3D printer do for you?

Help Us Understand Your Needs

Get your quote now

BigRep One

Description

Upgraded version of the 3D printer BigRep ONE.3 from the leading German manufacturer - BigRep GmbH, Berlin. The device is built on the principle of a high-precision carrier frame and a movable print head for two extruders. The printer uses an economical printing technology - plastic wire melting (FFF 3D Printing). Due to the large printing chamber (more than one cubic meter), high printing accuracy and competitive price, the device is optimal as a studio application for the production of fragments of exhibition structures, outdoor advertising elements, life-size models of furniture and fittings, prototypes and final products in aircraft. , car-, ship- and mechanical engineering.

, car-, ship- and mechanical engineering.

Printer BigRep ONE.3 has practically no analogues available for printing large-sized master models and equipment in foundry production: casting on burnt models, casting into the ground, casting into cold hardening mixtures, casting plasticized concrete, casting into silicone molds and etc.

Printers BigRep ONE - serially produced equipment with a well-established service system, stable channels for the supply of spare parts and consumables. To date, more than 180 devices have been launched and are operating in the world.

New version From BigRep ONE.3 printer:

- Open and safe frame design

The open design gives the operator a better view of the printing process. To ensure the safety of use, the moving parts are completely enclosed and equipped with built-in sensors for positioning accuracy and user convenience.![]()

- Modular extruder

The new modular extruder can print both support material and two colors. It is equipped with a filament sensor that will automatically pause printing before the printer runs out of media.

- New Power Extruder (option)

The new high performance extruder features 0.6mm, 1mm or 2mm nozzles that can be easily adjusted without tools. During the printing process, the inactive printhead moves up to avoid contact with the object. The printheads have been developed by BigRep's in-house team and are optimized for large scale printing projects. Maximum performance up to 6 kg of plastic per day .

- Semi-automatic work platform leveling

The Advanced Heated Work Platform has a polyimide coating that provides optimum adhesion from the very first coats. Thanks to the built-in automatic inductive sensor, leveling the work platform is quick and easy, significantly reducing the time to prepare for printing.

- Universal holder

The spool holder is designed to easily fit any size spool. The holder allows you to place several coils weighing up to 8 kg. The thread consumption control system informs the user that the spool is about to run out. A protective box for the coils is also available to order, preventing the ingress of dust and moisture.

- Integrated touch control panel with new GUI

The new BigRep ONE.3 features an integrated controller for a more user friendly interface. Now g-code files can be downloaded not only from a USB stick, but also via a local network remotely with control over the process of sending a print job.

Extruder versions for BigRep ONE.3 ver. C

Standard extruder (current version):

1mm nozzle (for 0.5mm layer thickness):

Print speed: 40mm/s

Filament feed speed: 3-4mm/s

Extrusion speed: 22 mm³/s

Power Extruder (output option):

Nozzle 0. 6 mm (for 0.3 mm layer thickness):

6 mm (for 0.3 mm layer thickness):

Print speed: ~ 60 mm/s

filament: ~ 3-4 mm/s

Extrusion speed: ~ 22 mm³/s

: ~ 6.5mm/s

Extrusion speed: ~ 41.5 mm³/s

Stop 2 mm (for layer thickness 1 mm):

Print speed: ~ 30mm/s

FIRS ~ 8MM/S

EXTRUSION OPTION: ~ 51 mm³/s

7 Other benefits:

- Improved blower design - the airflow from the plastic cooling fan is focused in the area under the nozzle, high-quality development of the "arches"

- Additional mounting screw - for a more rigid mounting and tight fit

- The hole for the thread release key is protected at the edges

- New version of the extruder is compatible with all versions of the BigRep ONE.3 printer

Characteristics

type 3D Printer

Classification:

Professional

Scope:

Press technology

Press technology:

FDM/FFF 9000 Pro HS, Soluble Support BigRep PVA

accuracy:

100 μm

Platform alignment accuracy:

<100 μm

Linear head acceleration:

to 400 mm / s2

Extruders:

2 modular extruders / 1mm (standard) 0. 6mm 0.6mm 0.6mm 0.6mm , 1 mm and 2 mm (Option Power Extruder)

6mm 0.6mm 0.6mm 0.6mm , 1 mm and 2 mm (Option Power Extruder)

Heated platform:

yes

Bottom surface of the print chamber:

massive platform with heating 60-80C

Construction area

Working area width (mm):

1005

Working area depth (mm):

1005

Working area height (mm):

1005

without packaging:

1850 x 2250 x 1725 mm

Weight:

~ 460 kg

Power Subject:

208 - 240V, 16A, 50/60Hz

Display:

built -in, the ability to load tasks for printing according to local networks

Hardware Warranty:

1 year

German Railway uses BigRep 3D printer

Skip to content

- home

- industries

- Transport

- German railway uses BigRep 3D printer

Deutsche Bahn turned to BigRep for an innovative solution to the problem of train repairs.

For Deutsche Bahn, BigRep was an innovation that saved millions.

For Deutsche Bahn, BigRep was an innovation that saved millions. How a German railway uses a BigRep 3D printer to print spare parts and save millions of euros in warehouse space.

Deutsche Bahn (DB) is one of the largest transport companies in the world. The company offers transportation and logistics services in more than 130 countries. There are thousands of trains in DB and not all of them are modern.

There is a huge list of spare parts for trains, stations and infrastructure that have to be updated and replaced regularly. Stocks are stored in specially equipped warehouses, spending millions of euros on maintenance. Blueprints for many parts have been lost, and it is impossible to recreate such spare parts in the usual way.

Deutsche Bahn turned to BigRep for an innovative solution to the issue of train repair.

BigRep recreated parts without blueprints using 3D scanning technology.

Parts without drawings were dealt with simply - they scanned the original. The resulting model was checked on a computer and sent to print.

The resulting model was checked on a computer and sent to print.

The BigRep printer printed off-the-shelf parts, not prototypes. The BigRep is one of the few printers specifically designed to print work pieces. It prints objects up to 1m³.

We have developed a special material that meets all safety standards.

DB has strict security requirements. Ordinary plastic is not suitable for printing - it ignites. The BigRep laboratory created a non-flammable material that passed quality control.

You can use materials that are convenient for you to print on BigRep. There are no chipped cartridges and threats to remove the printer from the warranty. BigRep is a platform for experiments.

Why did Deutsche Bahn choose the BigRep printer?

BigRep is the standard among professional 3D printers in Europe. It is reliable, all mechanisms are thought out and tested. The printer is designed to print finished workpieces with customer-friendly materials.