3D printed songbird

The Songbird 3D Printed Pistol with a Nylon BarrelThe Firearm Blog

Posted in Editorial, Pistols, Rimfire by Luke C. with No Comments

Tags: 22LR, 3d printing, Songbird, The Rimfire Report

Hello and welcome back to The Rimfire Report! This weekly series focuses on the rimfire firearm world and its various ammunitions and sports in addition to the wealth of rimfire firearms out there. This week we’re taking a look at a 3D printed 22LR firearm – The Songbird. The Songbird was created by 3D printers and is made from nearly 100% 3D printed parts but also makes use of some simple office supplies as part of its operation.

A big hurdle in the effort to disconnect homemade firearms from the mainstream firearms industry is the need for quality barrels and other items. We’ve seen in more recent times that practices such as electrochemical machining to make rifled barrels with homemade supplies. Although this practice exists, it is still far more complicated and time-consuming than most 3D printers are willing to put into their homemade firearms.

The Songbird takes a unique approach in that this particular design makes use of almost 100% 3D printed parts – including the barrel. The barrel itself is made from Taulman Bridge Nylon. This material takes the strength properties of standard Nylon 645 and combines it with the price points of ABS and PLA plastics. In addition Bridge Nylon also provides a lab certified measure of tensile strength which is something that the 3D printing community was in high demand for.

The parts for the Songbird are simple. While the barrel is printed from the Bridge Nylon, the frame as well as the other parts including the trigger pins, trigger assembly, and grip are all made from regular ABS filament. The pistol is printed from the side (as if you were laying the gun on a table) and is one uniform piece. This design necessitates the need to remove several support structures leftover from the printing process.

The remainder of the pieces including the “spring” and firing pin are made from rubber bands and a roofing nail respectively. In order to make the firearm legal within the United States, there is a required certain weight of the metal in the firearm in order to make it legal. See the Undetectable Firearms Act of 1988 for more information on that.

The legally required amount of metal was epoxied into the grip of the pistol.

Durability

Many 3D printed firearms tend to break easily due to the inherent weakness of 3D printed plastics when compared to their more conventional steel and aluminum counterparts. This probably is even more pronounced for pressure bearing parts such as the barrel and chamber. However, using the Bridge Nylon, YouTube user “Guy in a garage” was able to get upwards of 60+ rounds through his nylon printed barrel. For those curious, the infill density of the barrel was pushed to 100% for maximum strength.

In fact, the barrel was so durable, he decided to upgrade the system to handle 357 magnum loads. Initial tests on this design had the structure fail but subsequent tests after repairs allowed him to fire several Federal 357 hollow points through the repaired gun without sustaining any additional cracks.

Initial tests on this design had the structure fail but subsequent tests after repairs allowed him to fire several Federal 357 hollow points through the repaired gun without sustaining any additional cracks.

The 357 Magnum version of the Songbird

Although this is promising, the big negative to the 3D printed nylon barrel is that it does not stabilize the bullets in any way shape, or form despite rifling being incorporated into the print. In a pinch this may not be a problem, however if you’re planning on using the Songbird as a target pistol I’d rethink the 3D printed barrel.

The barrel itself is more or less a smoothbore barrel and thus has no twist to stabilize the bullets. This does make me wonder, however, if projectiles like rifled slugs but miniaturized are on the horizon somewhere as this would eliminate the need for a complicated rifling process.

Field Test/ Accuracy

As stated before, the Songbird features no type of bullet stabilization in the 3D printed barrel. This unfortunately leads to the pistol being very inaccurate even at short distances (in the below video it seems that he’s at a distance of about 5 to 10 yards). “Guy in a garage” did say that the pistol was more accurate when the barrel was freshly printed so perhaps his initial tests had better accuracy results.

This unfortunately leads to the pistol being very inaccurate even at short distances (in the below video it seems that he’s at a distance of about 5 to 10 yards). “Guy in a garage” did say that the pistol was more accurate when the barrel was freshly printed so perhaps his initial tests had better accuracy results.

The Songbird also does not feature any type of extractor and with the exception of the 357 Magnum version of the gun, it seems like each time the gun was fired and the barrel was removed, you had to use a tool to remove the spent casing before loading another one. Once the barrel was loaded, the hammer would need to be pre-cocked before the loaded barrel was placed back into the gun.

Without changing anything with the design I think a great way to make the setup slightly more practical would be to print several barrels and perform a “New York Reload” in-between shots. This would ensure that a fresh barrel was available and provided more accuracy and would reduce reload times between shots.

This would ensure that a fresh barrel was available and provided more accuracy and would reduce reload times between shots.

Can’t Stop The Signal

I love 3D printing for the simple fact that it is a great way for many minds to produce so many different designs. Each print furthers the technology of firearms in one way or another and further subverts the controls put in place to keep arms out of the hands of free people.

Note the roofing nail firing pin.

I love the concept of a sleeveless barrel and I think it has a lot of potential. If there was a way to introduce some sort of stabilization into the projectiles, it would make the Songbird much more practical. Thoughts and comments always welcome below and thanks again for stopping by to read The Rimfire Report!

All pictures and info for this article were gathered from Guy in a Garage, please go check out his work on other 3D printed firearm projects!

Songbird, A Mostly 3D Printed Pistol That Appears To Actually Work

- by: Gerrit Coetzee

[Guy in a garage] has made a 3D printed gun that not only appears to fire in the direction pointed, it can also do it multiple times. Which, by the standard of 3D printed guns, is an astounding feat. He started with .22 rifle cartridges but has since upgraded and tested the gun with .357 rounds. The link above is a playlist which starts of with an in-depth explanation of the .22 version and moves through design iterations

Which, by the standard of 3D printed guns, is an astounding feat. He started with .22 rifle cartridges but has since upgraded and tested the gun with .357 rounds. The link above is a playlist which starts of with an in-depth explanation of the .22 version and moves through design iterations

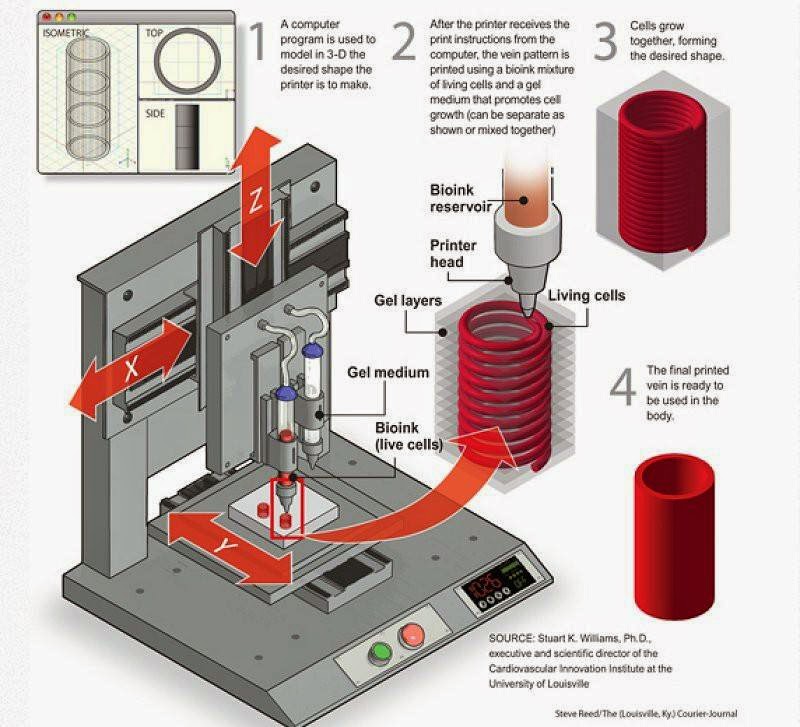

This gun prints on a standard FDM printer. Other 3D printable guns such as the infamous Liberator or the 3D printed metal gun need more exotic or precise 3D printing to work effectively. The secret to this gun’s ability is the barrel, which can be printed in nylon for .22 cartridges, or in ABS plus a barrel liner for .22 and .357 caliber.

A barrel liner is one way to repair a gun that has aged and is no longer shooting properly. Simply put, it is a long hardened metal tube with rifling on the inside. Some guns come out of the factory with one, and a gunsmith simply has to remove the old one and replace it. Other guns need to be bored out before a liner can be installed.

The metal liner surrounded by plastic offers enough mechanical strength for repeat firings without anyone losing a hand or an eye; though we’re not sure if we recommend firing any 3D printed gun as it’s still risky business. It’s basically like old stories of wrapping a cracked cannon in twine. The metal tries to expand out under the force of firing, but the twine, which would seem like a terrible material for cannon making, is good in tension and when wrapped tightly offers more than enough strength to hold it all together.

It’s basically like old stories of wrapping a cracked cannon in twine. The metal tries to expand out under the force of firing, but the twine, which would seem like a terrible material for cannon making, is good in tension and when wrapped tightly offers more than enough strength to hold it all together.

This is also how he got the .357 version to work. The barrel slots into the gun frame and locates itself with a rounded end. However, with the higher energy from a .357 round, this rounded end would act as a wedge and split the 3D printed frame. The fix for this was simple. Glue it back together with ABS glue, and then wrap the end of the assembly with a cable tie.

This is the first 3D printed gun we’ve seen that doesn’t look like a fantastic way to instantly lose your hand. It’s a clever trick that took some knowledge of guns and gunsmithing to put together. Despite the inevitable ethical, moral, and political debate that will ensue as this sort of thing becomes more prevalent, it is a pretty solid hack and a sign that 3D printing is starting to work with more formidable engineering challenges.

3D-printed prosthesis helped save the falcon

News

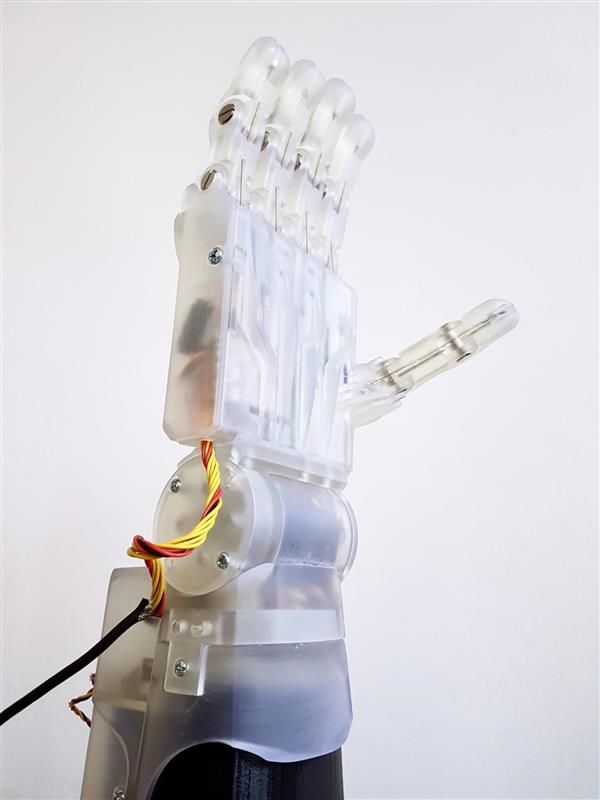

Siberian startup 3D-BimImplant has 3D-printed a prosthesis for a falcon that lost a leg after a collision with a car. Several enterprises from Novosibirsk and St. Petersburg helped to put the bird of prey on its feet at once.

The injured falcon fell into the hands of the staff of the Birds of Prey Rehabilitation Center, who immediately realized the threat to the bird's life: the loss of a leg leads to changes in the stance and gait, which in turn causes displacement of internal organs and serious complications, usually leading to death. Wildlife activists have asked Novosibirsk-based hybrid drone developer Optiplane to come up with a way to equip a bird with an artificial limb.

Wildlife activists have asked Novosibirsk-based hybrid drone developer Optiplane to come up with a way to equip a bird with an artificial limb.

The Optiplane bureau made measurements and drew up a technical assignment, after which it handed over the matter to the designers of the St. Petersburg technological engineering company LVM AT (CompMechLab AT), who created a digital model of the prosthesis based on the received documentation. Then another Novosibirsk company, the startup 3D-BimImplant, took up the business, together with Optiplane, formed on the basis of the SIGMA.Novosibirsk nanotechnology center, which is part of the venture network of the Rosnano Fund for Infrastructure and Educational Programs.

3D-BimImplant specialists have made an experimental hinged prosthesis on a 3D printer using polyamide as a consumable material. In February, the fitting and refinement of the prosthesis and fixtures was carried out, and in March the bird received a permanent artificial limb. The staff of the Center for the Rehabilitation of Birds of Prey were satisfied with the results: the bird is gradually getting used to the prosthesis, the asymmetry of the body has disappeared, and it is not yet possible to gnaw at the strong nylon foot.

The staff of the Center for the Rehabilitation of Birds of Prey were satisfied with the results: the bird is gradually getting used to the prosthesis, the asymmetry of the body has disappeared, and it is not yet possible to gnaw at the strong nylon foot.

“The most important thing is the orderly reduction in the speed of designing and manufacturing individual prostheses, which has become possible with the development of 3D printing and digital design technologies. The work on the project showed that ultra-fast prosthetics have a huge potential,” concludes Oleg Lysak, director of CompMechLab AT.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

Subscribe to the author

Subscribe

Don't want

12

Article comments

More interesting articles

ten

Follow author

Subscribe

Don't want

The project is experiential and symbolic: the structure was erected by 3D4Art to celebrate. ..

..

Read more

6

Subscribe to the author

Subscribe

Don't want

REC, one of the leading Russian manufacturers of consumables for FDM/FFF 3D printer...

Read more

44

Subscribe to the author

Subscribe to the author

Don't want to

American startup Iro3D shipped the first 3D printers for printing metal products using the village method...

Read more

— AgroXXI

Andrew Z.

"Arms race" leads to the emergence of sophisticated and bizarre systems to protect birds from nest parasites

3D-printed dummies of eggs have helped scientists uncover the strategies American thrushes use to distinguish their own eggs from those laid by the cuckoo, according to an article published in PeerJ, RIA Novosti reported.

Such an unusual application of 3D printing was first proposed and tested in practice by a group of ornithologists led by Mark Hauber of the City University of New York (USA), which has long been following the "war" between cuckoos and unwitting adoptive parents of their chicks.

This war, and the arms race that goes with it, results in sophisticated and bizarre anti-parasite defense systems that invent their own "asymmetric responses" to these countermeasures.

For example, songbirds literally "teach" the eggs of their future chicks special trills - "passwords", which they later use to detect cuckoos. In turn, cuckoos have learned to lay several eggs in the nests of other birds, which increases the chance that the future parent will make a mistake and throw out their own eggs, and not planted ones.

In response to this, songbirds, on which cuckoos parasitize, switched to “collective defense” - childless relatives and neighbors help nesting couples guard the nest and drive away the cuckoos. Some species of cuckoos, such as brown-headed troupials, developed a response to this move - they began to unite in "mafia" and punish those birds that throw their eggs out of their nests.

Some species of cuckoos, such as brown-headed troupials, developed a response to this move - they began to unite in "mafia" and punish those birds that throw their eggs out of their nests.

As Huber and his colleagues note, these strategies are of great interest to evolutionary scientists, but their study is difficult because plausible dummies of eggs are extremely difficult to make due to the attention to their weight, color and other features that birds pay to them.

The authors of the article found an unexpected and very simple solution to all these problems - they created a program that allows you to get a virtual "cast" of an egg using a three-dimensional scanner and print it using a 3D printer. As scientists explain, such dummies can be printed hollow from the inside, and filled with gel or water to the mass that real cuckoo eggs have.

Having printed out a batch of such dummies, scientists painted half of them in the same colors as the eggs of wandering thrushes, and the rest in the image and likeness of the eggs of the brown-headed thrushes mentioned above.