Romer 3d scanner

Hexagon (ROMER) Absolute Arm | Exact Metrology

Portable CMM Measuring Arms

Portable measuring arms allow you measure on the machine or shop floor. They feature no homing procedures, simplicity of operation and reliable 3D measurements. Articulated arms can be equipped with different length probes and scan heads to measure even difficult-to-access points either optically or by touch.

The Hexagon (ROMER) Absolute Arm product range is built on four core models, each designed to meet the demands of customers across a wide array of industries and applications.

The all-in-one choice for versatile portable 3D measurement.

The choice optimized for portable probing.

The choice for ultra-high accuracy probing of smaller items.

The RS6 is a productivity machine that makes the Absolute Arm more powerful than any other portable measuring arm on the market.

The world’s fastest portable measuring arm scanner.

Choose Accuracy

Meeting the Demands of Measurement

Each Hexagon (ROMER) Absolute Arm model is available at different accuracy levels to ensure the right configuration is available for any measurement application.

- The 83 Series is the perfect solution for users looking for entry-level measurement accuracy.

- For applications that demand greater precision, the 85 Series strikes the perfect balance between value and accurate measurement.

- Designed as the ultimate solution for portable high-end measurement, the 87 Series is the most accurate Hexagon (ROMER) Absolute Arm ever developed.

Defining Absolute Accuracy

Central to Excellent Measurement

Several comprehensive tests are used to define the accuracy of every Hexagon (ROMER) Absolute Arm model, each designed to ensure users can be absolutely certain of the accuracy level their portable measuring arm provides.

- Point Repeatability Test

- Volumetric Accuracy Test

- Scanning System Accuracy Test

- Certification

Defining Features

Every Hexagon (ROMER) Absolute Arm is built on a foundation of advanced technology and innovation that sets a new standard for what’s possible when it comes to portable measurement.

Measure

- Available in seven sizes providing measurement volumes between 1.2 and 4.5 metres.

More

- Probing accuracy as fine as only 20 microns and scanning accuracy to within 50 microns.

- High-tech carbon-fibre construction ensures strength and thermal stability under any environmental condition.

- Proprietary RDS software featuring SMART – Self-Monitoring Analysis and Reporting Technology – provides diagnostics monitoring, including shocks and temperature.

- Probing and scanning accuracy certified to B89.4.22 standard, with alternative certifications for probing functions according to VDI/VDE 2617-9 and ISO 10360-2 standards also available.

Connect

- Easily interchangeable Feature Packs allow for WiFi connection to a standard laptop or desktop PC, as well as laser scanning over WiFi and full battery-powered operation.

More

- Access to simple measurements and diagnostics on WiFi enabled arms through a mobile device with the RDS Mobile app.

- Fully compatible with all major portable metrology software packages.

- Further enhance arm functionality with a range of accessories, from probing attachments to measurement volume expansion systems.

- High-speed laser scanning accessories make total analysis of parts simpler and more accessible – choose a scanner according to required accuracy and level of 3D point cloud definition.

Form

- Light and agile operation facilitated by a highly optimised design echoing the uneven arm ratio typical of industrial robot design.

More

- Sophisticated counterbalance system eliminates torque at the base of the arm, allowing for effortless movement, better accuracy and a wider range of mounting options.

- Ergonomically designed wrist and control buttons allow for complete one-handed operation.

- Rotating low-friction handling grips minimise user fatigue and maximise accuracy as well as ensuring thermal stability.

Function

- Absolute Encoders within articulation joints eliminate referencing and warm-up times.

More

- No touch-probe or laser scanner calibrations required in the field.

- Haptic, visual and acoustic feedback allows for easy user interaction in even the harshest industrial environments.

- Added WiFi connectivity reduces hazards by removing inconvenient cabling.

- SmartLock allows the arm to be fixed in a convenient position during measurement, as well as allowing it to be safely locked into the rest position while not in use.

Metrology Equipment

Ready for Anything

The Hexagon Absolute Arm range provides measurement solutions relevant across a wide range of industries and applications.

Industries

- Automotive

- Aerospace

- Power generation / wind energy

- Forming industry

- Casting and forging

- Fabricated metal products

- Machinery manufacturing

- Sports equipment

- Piping and tubing

- Agriculture and heavy equipment

- Ship and boat building

- Railways

- Archaeological and historic preservation

- Precision machining

- Tooling and dies

- Medical

Applications

- Sheet metal inspection

- Mold tool inspection

- Flush and gap analysis

- Jigs/fixture set-up and alignment

- Build and inspect

- Tube and tube assembly inspection

- CAD-to-part comparison

- Reverse engineering

- Virtual assembly

- On-machine verification (OMV)

- Composite inspection

- Maintenance, repair and overhaul (MRO)

- Machined part inspection

- In-process quality checks

- Digitizing / virtual archiving

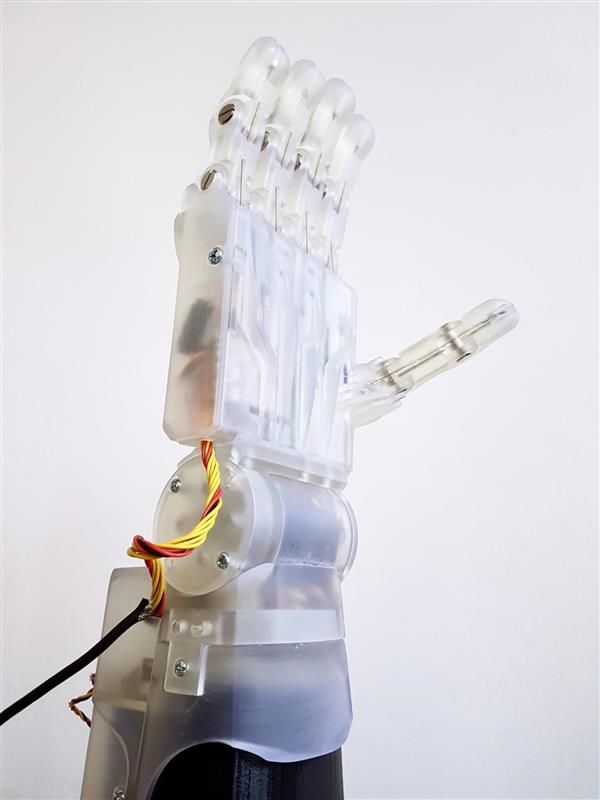

Hire The Romer Scan Arm

The ROMER Absolute Arm with Integrated Scanner is an all-purpose portable measuring arm system designed to meet the needs of almost any measurement application, whether scanning or touch-probing. It has a fully-certified and integrated RS4 laser scanner designed for faster-than-ever 3D data capture across a range of surfaces and applications.

It has a fully-certified and integrated RS4 laser scanner designed for faster-than-ever 3D data capture across a range of surfaces and applications.

Data capture: up to 400,000 points per second

Fast set up and no warm up time required

Switch between probe and scan with a flick of a button

Available in various sizes; 2 to 4.5 meters in work diameter

Thermally stable under any environmental condition

Repeatable probe mounting

CONTACT US TO HIRE

INSTRUMENT FEATURES

Switching seamlessly between tactile probe measurement and laser scanning at any time, the ROMER Absolute Arm with Integrated Scanner is ideally suited to point-cloud inspection, product benchmarking, reverse engineering, rapid prototyping, virtual assembly and CNC milling.

The fully-certified and integrated RS4 laser scanner is designed to capture 3D point data across a range of surface types. It requires no calibrations, warm-up time or additional cables and controllers. It is totally integrated. With a ultra-wide laser stripe of up to 150 mm, the RS4 can capture 752,000 points per second, reducing the number of passes required to fully scan a part and minimising overall measurement time.

It is totally integrated. With a ultra-wide laser stripe of up to 150 mm, the RS4 can capture 752,000 points per second, reducing the number of passes required to fully scan a part and minimising overall measurement time.

The accuracy of the complete scanning system is fully verifiable and traceable, ensuring users always have complete confidence in the exactness of their measurements. The ROMER Absolute Arm with Integrated Scanner is available at three different accuracy levels – 73, 75 and 77 series – to ensure the right configuration is available for any measurement application.

View All Features

Measurement Volume

Available in six sizes providing measurement volumes with diameters between 2.0 m and 4.5 m.

Automatic Probe Recognition

Swap probes at any time without the need to recalibrate – repeatable mounting allows probe changes on the fly according to measurement needs.

Robust Feedback

Instant visual, acoustic and haptic feedback allows the system to be used accurately and efficiently in even the harshest industrial environments.

Total System Certification

Full B89.4.22 certification for the entire arm and scanner system, with additional certification according to VDI/VDE 2617-9 also available.

Absolute Encoders

Referencing and warm-up time is a thing of the past – just switch on and start measuring.

Arm Balance

Optimised design echoing the uneven arm-length ratio typical in industrial robot design makes the arm lighter and easier to use.

Zero G

Counterbalance system minimises torque in the base of the arm, allowing effortless user movement, greater accuracy and a wealth of mounting options, including lightweight tripods and magnetic and vacuum bases.

SmartLock

Lock the arm safely in the rest position when not in use, or conveniently fix the arm in any intermediate position during measurement.

Carbon-fibre Structure

High-tech materials make arm measurement secure and thermally stable under any environmental condition.

SpinGrip and SpinKnob

Rotating low-friction handling grips improve ergonomics, minimise user fatigue, provide thermal stability and maximise accuracy.

Ergonomics

Wrist structure, hand grip design and intelligent button positioning allow for total control over arm alignment and adjustment.

RDS

Proprietary software featuring SMART – Self-Monitoring Analysis and Reporting Technology – that manages the arm in the field by monitoring diagnostics including shocks and temperature.

RDS Mobile

Compatible with all WiFi enabled systems, the RDS Mobile app allows users to connect directly from a mobile device to access simple probing and scanning functions and diagnostic operations.

Feature Packs

Easily interchangeable Feature Packs enhance functionality for all arm models, from WiFi connection and laser scanning to full battery-powered operation.

Compatibility

Works with all major metrology software packages.

TECHNICAL DATA

View All Technical Data

| 75 Series | Model | Measuring Range | Point Repeatability1 | Volumetric Accuracy2 | Arm Weights |

| 7530 | 3.0 m / 9.8 ft. | 0.042 mm / 0.0017 in. | ± 0.058 mm / 0.0023 in. | 9.2 kg / 20.3 lbs | |

| 7535 | 3.5 m / 11.5 ft. | 0.055 mm / 0.0022 in. | ± 0.081 mm / 0.0032 in. | 9.5 kg / 20.9 lbs |

Scanning Sensor Specifications: Integrated Scanner RS4

Point acquisition rate: 752 000 points/s

Points per line: Max. 7520

Line rate: Max. 100 Hz

Line width:

• Min: 80 mm

• Mid: 115 mm

• Max: 150 mm

Stand off: 165 ± 50 mm

Accuracy: 0.028 mm (2σ)

Minimum point spacing: 0.011mm (line)

System scanning certification: Yes

Laser class: 2M

Operating temperature: 5–40°C

HIRE THE ROMER SCAN ARM

To enquire about the Romer Scan Arm please fill out the form below or call +44 (0) 1455 251251

I'm happy for you to contact me via PhoneEmail

I allow PES to store and use the data provided in order to respond. PES will not share with 3rd parties. Privacy Policy.

Privacy Policy.

I have read and understand the Terms of Service.

3D surface scanning | nms

-

Laser tracker with hand scanner

The Leica Absolute Tracker AT901, combined with the T-Scan TS50 handheld laser scanner, is a powerful mobile device for high volume scanning. The third generation of Leica T-Scan scanners provides high accuracy and resolution, and thanks to the innovative Flying Dot technology, T-Scan can scan a wide range of different types of surfaces without spray painting.

More

-

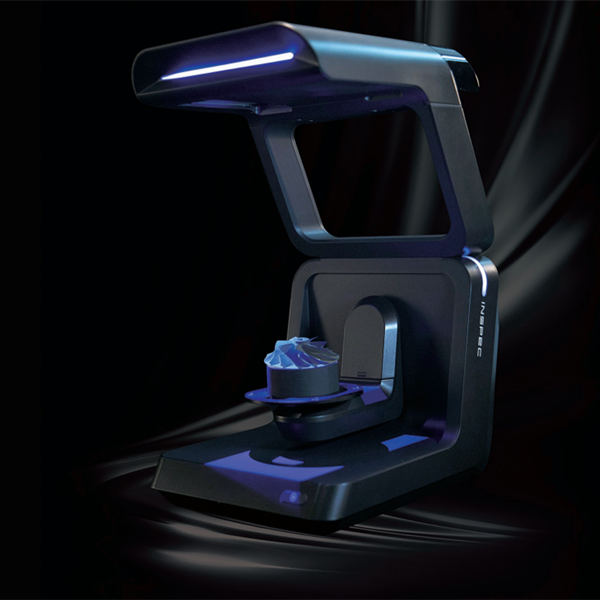

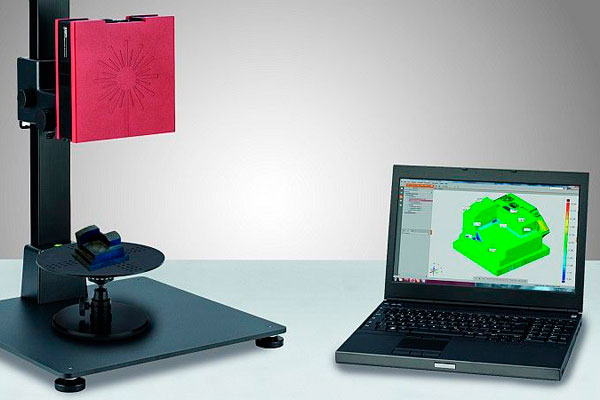

Optical scanner

Scanners of the Comet V line, in addition to high resolution, also have high quality of scanned data. These scanners set the standard in their category. The unique characteristics of the scanner are achieved due to the perfect technical performance of the optics, housing and thermal stability. The new control unit allows you to scan optically complex surfaces.

More

-

Optical scanner

The Comet LƎD 5M optical scanner offers a unique compactness, handling and speed at even higher resolution than ever before.

Comet LƎD has a resolution of up to 8Mpx, which provides high resolution when scanning the smallest details. The scanned data is extremely low noise and high quality.

Comet LƎD has a resolution of up to 8Mpx, which provides high resolution when scanning the smallest details. The scanned data is extremely low noise and high quality. More

-

Optical tracker with hand scanner

The new generation of Steinbichler T-Scan CS scanners brings a revolution in line laser scanners. It is characterized by convenient use on surfaces with various reflective characteristics, high-quality data with low noise and high accuracy. No moving parts! It is smaller, lighter and more reliable than any other scanner with similar features.

More

-

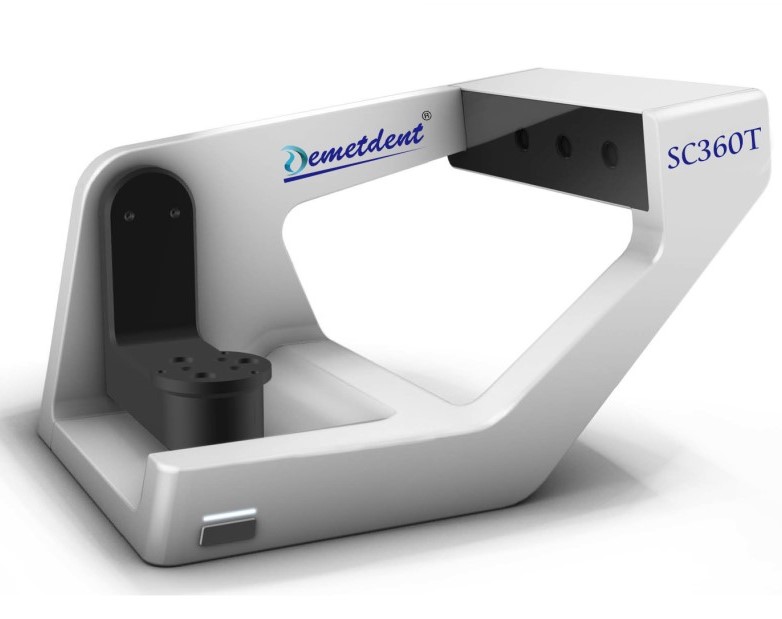

Measuring arm with integrated scanner

Unique Features of 3D Measuring Arms The Romer Absolute Arm, equipped with an integrated high resolution scanner, is a versatile 3D measuring system. 3D digitizing, 3D modeling, surface inspection, reverse engineering, rapid prototyping or copy milling: this system is a versatile metrology tool for a wide range of applications.

More

-

Measuring arm with external scanner

The ROMER Absolute Arm can also be equipped with Hexagon Metrology's high performance CMS 108 laser scanner. You can also connect scanners from other manufacturers. The ROMER Absolute Arm in combination with the CMS 108 laser scanner offers high performance even on difficult surfaces and workpieces of the most difficult to scan material types.

More

Industrial 3D scanning of objects and details

Measurement of large items (airplanes, helicopters, ships, submarines). Laser, optical, contact 3D scanning to obtain original data, restore lost documentation or make copies of products. Performance of work on reverse engineering of the product and its production technology.

Reverse engineering is often based on 3D scanning. There are scanning of large, medium and small-sized products. From this point of view, the most impressive is the scanning of large objects, such as a boat, car body, aircraft fuselage, train interior details, etc.

In cases where the customer requires the modernization of production equipment, the laying of new large technological complexes in an existing mode in order to avoid collisions and overlaps, as well as control of the accuracy of systems before installation, 3D scanning is used

Before any modernization associated with the movement of large objects, simulation of this operation in compliance with the high accuracy of the parametric model of objects is mandatory. It is especially important to simulate the movement of objects, on the accurate and safe operation of which the life and health of people depend. Such objects include large-sized transport: trains, planes, ships. In this case, the use of 3D scanning technologies is more than justified.

For large-scale 3D scanning, INNOVAX specialists use a Faro Focus 3D 120S 3D scanner. This basic version of 3D scanners is designed to work at a distance of up to 120 meters. The device uses a laser scanning system. Despite its extremely compact dimensions (240x200x200mm), the scanner has a wide range of capabilities, including color recording up to 70MP with automatic brightness adjustment.

However, when scanning large-sized objects, the most time-consuming process is the process of stitching scanned point clouds of product surfaces. The larger the size of the object, the more difficult this work is. Graphic stations with special software used for these purposes allow not to delay this stage of reverse engineering of large-sized objects.

For medium and small objects, INNOVAX uses the ROMER Absolute Arm scanner. The instrument provides first-class measurement results even on complex surfaces with inhomogeneous properties, as well as on machined parts made from the most advanced materials. The machine does not require adjustment of the system to the material, since the scanner head uses automatic laser power control. Adaptation of the power level to the measurement conditions on the surface is also provided automatically.

The ROMER Absolute Arm is the first laser scanner with a zoom function that allows you to use three scan lines of different widths when scanning.

The technical characteristics of the scanner are impressive:

- measuring range - 3m,

- point probing repeatability - +/- 0.042 mm,

- spatial accuracy when probing -+/- 0.058 mm mm,

- system error - 0.078 mm.

With this scanner, you can solve such production tasks as

- recover lost documents,

- making copies of products,

- obtaining initial data for further design.

INNOVAKS is engaged in reverse engineering of both individual parts and assemblies, machines, systems and complexes.

In the process of reverse engineering of one part, not only its geometry is determined, but also the material, quality, manufacturing technology.

Reverse engineering of a node or system is much more labor intensive. At its core, this is practically the development of a completely new mechanism.

Reverse engineering steps:

- mechanism disassembly;

- scanning complex or measuring simple parts and obtaining their parametric models;

- setting tolerances;

- calculation of dimensional chains;

- Create assembly drawing.

Learn more