3D printed prosthetic socket

3D Printing Prosthetics Allows ProsFit to Customize Devices - HP ProsFit Case study

Contact an HP 3D Print expert

Choose the phone number for your country to speak to a local HP 3D Printing sales expert today.

België/Belgique

+32 78 48 44 69

Czech Republic

+420 239 050 531

Deutschland

+49 7031 986 90 13

+49 7031 986 90 17

España

+34 93 003 45 95

France

+33 6 28 78 35 59

Italia

+39 02 8295 2406

Nederland

+31 20 241 5685

Norway

+47 23 96 00 13

Österreich

+43 720 117035

+43 1424 0091

Romania

+40 376 300 174

Sweden

+46 8 446 891 49

Suisse/Switzerland

+41 44 511 2308

+41 44 511 2333

United Kingdom

+44 20 7365 8158

United States

+1 877 468 8369

Industry

Healthcare: Custom prosthetics

Material

HP 3D High Reusability (HR)2 PA 12

Challenge

To leverage 3D printing to simplify and improve the manufacturing of 3D printed prosthetics.

Technology

HP Multi Jet Fusion technology

HP Jet Fusion 4200 3D Printer

Results

HP Multi Jet Fusion’s digital manufacturing solution help prosthetics clinics create custom 3D printed prosthetics.

CHALLENGE

Consistency and comfort issues with previous 3D printed prosthetic leg sockets

"The traditional process for creating and fitting a leg prosthetic is long, complex, and uncomfortable for the patient,” said ProsFit Co-founder and CTO, Christopher Hutchison. “It involves taking a plaster cast, creating a mold, and casting resin around it. Often this involves several visits to the prosthetist and results in multiple fittings to get a device that is only marginally effective."

Often this involves several visits to the prosthetist and results in multiple fittings to get a device that is only marginally effective."

Until recently, prosthetic sockets were made using a plaster mold. The process of fitting a prosthetic was expensive and could take several weeks, which was inconvenient for the patient.

Prior to working with HP, ProsFit successfully commercialized medically regulated ProsFit Original sockets using Fused Deposition Modeling (FDM) 3D printing technology. However, the company experienced several challenges, the greatest of which was output consistency. ProsFit estimated that two out of every 10 3D printed prosthetic leg sockets did not pass their rigorous quality assurance test. Furthermore, the surface finish of the end product was often likened to a prototype and did not meet patients’ expectations.

View solution

“Sockets made using HP 3D printing are flexible and strong, while at the same time more comfortable and natural to walk on.

”

” Christopher Hutchison, Co-founder and CTO, ProsFit

SOLUTION

The process of 3D printing prosthetics with HP MJF

At the core of ProsFit’s solution is a cloud-based software called PandoFit. Based on Computer-aided Design (CAD), the software allows prosthetists to design and 3D print lower limb sockets for patients. The clinician takes a 3D scan of the patient’s limb and uploads the information into PandoFit, where the prosthetist can modify the design of the prosthetic to best fit the patient. Once the design is reviewed with the patient, a 3D printed prosthetic socket can be ordered directly through the software. The final 3D printed prosthetic leg socket is then shipped to the clinician’s office for the final fitting.

The ProsFit Optimal 3D printed prosthetic leg sockets are manufactured using HP Jet Fusion 3D printing solutions, and each is sold as a regulated, custom-made medical device. Prior to launch, the prosthetic devices underwent significant regulatory testing in the European Union (EU), where they are regulated for weight bearing up to 125 kg.

Prior to launch, the prosthetic devices underwent significant regulatory testing in the European Union (EU), where they are regulated for weight bearing up to 125 kg.

View results

RESULTS

ProsFit’s 3D printed prosthetics leg socket enable confident mobility

By digitizing the process of creating a 3D printed prosthetic leg socket, ProsFit has reduced the time it takes to make and deliver a socket from weeks to days, which also results in lower costs and improved convenience for the patient. The final 3D printed prosthetic leg socket can now be made and fitted in only two visits.

For clinics and medical centers, ProsFit’s new digital solution for 3D printing prosthetics also has delivered a significant benefit in terms of productivity: Clinicians can fit five times as many patients with the same resources.

What’s more, "The fit and finish are what you'd expect from a finished product," Hutchinson said about the 3D printed prosthetic leg socket. "The aesthetics are a big deal for patients. A better-looking final product improves customer acceptance."

HP MJF allows ProsFit to choose how all their products are manufactured: With FDM, ProsFit was limited to vertical production, but with HP 3D printing, they can choose the orientation that provides the best combination of quality, strength, flexibility, and economics.

"HP’s 3D printing technology can easily be applied to other areas of medicine, as well, including orthotics, braces, exoskeletons, and even dentistry," said Alan Hutchison,

Co-founder and CEO of ProsFit.

The combination of 3D scanning, software, and 3D printing has enabled ProsFit to deliver on its promise of providing a fully digital solution for the prosthetics industry.

Interested in learning more about HP 3D Printing Solutions?

Disclaimers

- All images data courtesy of ProsFit

- HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PA 12 provide up to 80% powder reusability ratio, producing functional parts batch after batch.

For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

Researchers Create Perfect Fitting 3D Printed Transtibial Leg Socket for Prosthetic Legs - 3DPrint.com

I am fortunate enough to have both of my legs. I can run, jump, play football, and swim in the ocean. Unfortunately though, not everyone can say the same. There are individuals born with birth defects that bring them into this world with missing legs, and there are those who suffer an accident or disease which leave them missing one of their legs. Prosthetic legs have been increasing in popularity, and they have really been quite effective in providing amputees and others with missing legs, the opportunity to walk again.

I’ve spoken to many people over the years who use prosthetic legs. While they are typically pleased with the fact that they can now get around without the need for a wheelchair or crutches, there are still plenty of qualms on their behalf.

Quite simply put, it is usually a massive pain in the butt getting fitted for a prosthesis. This is because of the lack of customization provided by today’s sockets. The socket is the part of the prosthesis that meets the “stub” of the wearer’s leg. Usually it takes several fittings and adjustments, followed by several more, before a prosthetic leg will fit just right. Even then, “just right” is a term that can be overstated, as many times the fit never ends up being perfect.

For one biomedical engineer, named Lizbeth López, this simply was not enough. López has been working at Tec de Monterrey, in Monterrey City, Mexico under the guidance of her thesis advisor, Dr. Ciro Rodriguez. In a collaboration with Ottobock and cTI Renato Archer in Campinas, Brazil with Dr. Jorge V. Lopes’ guidance as well, López set out to create a 3D printed custom transtibial leg socket that fits just right.

“The main objective of this work was to fabricate a complete functional prosthesis, in this case oriented to transtibial amputees as the first group of test patients,” López tells 3DPrint.

com. “The project began as a personal motivation to design and fabricate prosthesis well adapted to health needs of the patient.”

López and her team worked with two patients. One of these patients was in Mexico, and López was able to test the use of laser scanners and computer tomography in order to create many different iterations in several different types of software. This allowed her to choose the best option that she would use in order to begin 3D printing the transtibial socket, with hopes of it being used on a final prosthesis.

López then moved her research from Mexico to Brazil and started working with a second patient, in compliance with Ottobock.

“We decided to use a laser scanner and CT to capture the stump of the patient,” López explained. “Later the DICOM data from [the] CT was reconstructed as a 3D structure in InVesalius software, and then it was compared with data acquired from the laser scanner. Subsequently, we imported the files in .

stl extension to CAD software to begin the process of design, based on the real anatomical data of the specific patient.”

One of the tremendous benefits of using this 3D data to create the socket, other than the customizability it provides, is that once the scans are taken, there really is no need to directly work with the patient any long, prior to the initial fitting. Once the team believed that they had the socket designed correctly, they had to put it through tests to ensure reliability.

“We tested the socket design with FEM analysis, just to make sure that load conditions were to show numerical results under the yield strength of material; so we can be confident about the mechanical resistance of [the] 3D printed socket before the patient tests it,” explained López.

Once the tests were complete, it was on to 3D printing the socket using an SLS HiQ 3D printer. Printed in polyamide, the process took about 17 hours to complete. The socket was then mounted and aligned to the complete prosthesis at Ottobock in Valinhos, Brazil, before the ultimate test was undertaken.

The socket was then mounted and aligned to the complete prosthesis at Ottobock in Valinhos, Brazil, before the ultimate test was undertaken.

The prosthesis and this incredible 3D printed socket were fitted to the patient, and the results surprised just about everyone. The patient, who has been involved in many other prosthetic leg tests for Ottobock, couldn’t believe the results. The socket was completely comfortable from the first time he put it on, only requiring the adjustment of one single screw. In the past, this same patient was required to try on the same prosthesis over and over again in order to get just the right fit. This could take days between fittings, causing quite a bit of frustration and aggravation.

With 3D printing technology and the tremendous work of López and her team, no adjustments were required.

“Technical [personnel at] Ottobock pointed [out] that this kind of result is not seen every day,” explained López. “That’s really good because then we have a great approximation to the fantastic and ‘futuristic’ idea that it’s going be possible to adapt many prosthesis to many patients in one single day.

”

3D printing is certainly showing its potential in the field of prostheses, allowing for complete customization on a one-to-one basis, making the entire process much faster and more efficient, leaving both patient and doctor happy.

What do you think about this potential that 3D printing has in the custom fitting of prostheses? Discuss in the 3D printed prosthetic leg socket forum thread on 3DPB.com. Check out the video provided to us below of López’s patient trying on his prosthetic leg.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printed prostheses • 3d printed prosthetic leg • brazil • Mexico • ottobock • prosthetic leg socket • Tec de Monterrey • transtibial leg socket

Please enable JavaScript to view the comments powered by Disqus.

MyFit TT | Designed to connect

MyFit TT

Both trial and permanent 3D printed MyFit TT prosthetic sockets help you speed up the prosthetic patient care process and increase your efficiency. With a fast and easy digital design process, MyFit TT allows you to achieve optimal fitting results in a shorter time. MyFit TT is designed to connect craftsmanship and digitalization, people and technology, quality and efficiency.

The scanning and modification software is intuitive to use and requires little training, making MyFit TT the ideal starting point for digitizing prosthetic patient care. We help you create unforgettable user experiences through exceptional patient care.

3D-printed permanent prosthetic socket

- Bionic structure for optimal weight-to-stability ratio

- Lightweight and thin walled

- Integrated 4-hole pre-aligned connection

Vacuum molded trial sleeve

- Available for passive and active vacuum prostheses

Scanning process

- Intuitive and easy to learn 9006

- Optimized for workflows in orthotics and prosthetics

- Save time on measurements

3D printed permanent prosthetic socket

- includes a pre -leveled connection with 4 holes and prepared nests for various valves

3D Printed Definitive Socket

- is provided for prostheses with passive vacuum (absorption)

114S1 - Classic sleeve 9000

.

Both trial and permanent 3D printed MyFit TT prosthetic sockets help you speed up the process of prosthetic patient care and increase your efficiency. With a fast and easy digital design process, MyFit TT allows you to achieve optimal fitting results in a shorter time. MyFit TT is designed to connect craftsmanship and digitalization, people and technology, quality and efficiency.

The scanning and modification software is intuitive to use and requires little training, making MyFit TT the ideal starting point for digitizing prosthetic patient care. We help you create unforgettable user experiences through exceptional patient care.

| 125 kg |

| 1, 2, 3, 40055 |

MyFit TT

Whether trial or permanent, 3D printed MyFit TT prosthetic sockets help you speed up your prosthetic and orthotic patient care process and increase your efficiency. With a fast and easy digital design process, MyFit TT allows you to achieve optimal fitting results in a shorter time. MyFit TT is designed to connect craftsmanship and digitalization, people and technology, quality and efficiency.

With a fast and easy digital design process, MyFit TT allows you to achieve optimal fitting results in a shorter time. MyFit TT is designed to connect craftsmanship and digitalization, people and technology, quality and efficiency.

The scanning and modification software is intuitive to use and requires little training, making MyFit TT the ideal starting point for digitizing prosthetic patient care. We help you create unforgettable user experiences through exceptional patient care.

3D-printed permanent prosthetic socket

- Bionic structure for optimal weight-to-stability ratio

- Lightweight and thin walled

- Integrated 4-hole pre-aligned connection

Vacuum molded trial sleeve

- Available for passive and active vacuum prostheses

Scanning process

- Intuitive and easy to learn 9006

- Optimized for workflows in orthotics and prosthetics

- Save time on measurements

3D printed permanent prosthetic socket

- Includes 4-hole pre-aligned connection and prepared sockets for various valves

3D printed definitive socket

- Available for prostheses with passive vacuum (suction)

All benefits at a glance

standards

Reliability you can count on

The sleeve has been tested to a load of 125 kg over 3 million walking cycles and remains stable to the familiar Ottobock quality standard.

Minimal weight for maximum comfort

Combining lightweight material and slim design, the sleeve is so light that it is comparable to prepreg and lightweight laminate sleeves.

Optimal stability due to lightweight bionic design

Cancellous bone simulation provides an ideal balance of weight and stability. Simultaneously with the weight reduction of the sleeve, high stability is achieved, which can be maintained even at higher flexion or lateral displacement values.

Always the right adjustment with 4-hole pre-aligned connection

Patient-specific flexion and lateral displacement can be incorporated into the sleeve design to ensure optimal alignment.

Available values: flexion up to 15° and lateral displacement by 25 mm.

Use verified data to speed up ordering

Trial sleeve fit well? Ordering a permanent prosthetic socket can be done very quickly because your data is at hand. And if a fit is required, it can be applied to a permanent sleeve or additional trial sleeves can be ordered—easy and affordable at any time.

Quick to learn, easy to use

You don't need prior knowledge to get started right away, with just a minimum of training. You will receive step-by-step instructions throughout the scanning and modification process. Simple and intuitive.

Smart assistance for customization

Based on specific patient data, our modification software provides automatic correction, i.e. downsizing or trimming margin, which can be checked, modified or adjusted at any time.

User experience

It fits perfectly

Beytullah's MyFit TT experience

MyFit TT fits me 100%. I can run, jump, accelerate. I have everything I need and I do whatever I want at any moment. That is what is important to me.

Beitulla, MyFit TT user

Wolid's MyFit TT experience

Patients who have experienced the traditional fitting process say they definitely won't miss the chaos of a plaster cast. Prosthetic and orthopedic support has become more convenient and efficient.

Volid Sharif, CPO, with patient Beitulla and his new 3D printed MyFit TT sleeve

Danuta's MyFit TT experience

For me, the most important thing in life is that the prosthesis fits me and provides comfort.

I like to walk a lot and train hard. In fact, I live intensively! I am immensely happy that I was able to get acquainted with this entire MyFit TT process. In a word, it's just "WOW"!

Danuta, MyFit TT 9 user0006

How it works

Scan. Change. Order. Get a perfect fit in less time

From 3D-scanning to the 3D-printed prosthesis

Digitally designed and 3D printed, the MyFit TT prosthetic socket is an easy way to digitize workflows and get well-fitted products in less time .

First, 3D scan the patient's residual limb with the iFab EasyScan. Then work on the scanned 3D model, fitting and optimizing it in the modification software. Based on the patient's specific data, the software provides automatic correction, i. e. downsizing or trimming margin, which can be checked, changed or adjusted at any time. Each step of the modification is saved and, if necessary, it can be reproduced and tracked.

e. downsizing or trimming margin, which can be checked, changed or adjusted at any time. Each step of the modification is saved and, if necessary, it can be reproduced and tracked.

Trial Sleeve or Permanent Prosthetic Sleeve can now be ordered through our iFab Customer Center (iCC). Did the trial sleeve fit well? Ordering a permanent prosthetic socket can be done very quickly because your data is at hand. And if customization is required, it can be applied to the permanent sleeve.

You don't need prior knowledge of scanning and editing to get started right away, with just a little training. Throughout the process, you will receive step-by-step instructions.

iFab EasyScan stands for accurate registration of patient measurements in real time and accurate visualization of the object, including its texture. This ensures a short scanning distance, an easy ability to continue scanning after interruptions, and work offline. iFab EasyScan is the solution for seamless workflows and flexible mobile work.

By directly connecting iFab EasyScan to iFab Customer Center (iCC), you can easily digitize downstream workflows from 3D design to order.

Detailed information about the product

See allHow a Tomsk startup uses 3D printers in the production of prostheses - Tribuna on vc.ru

=1&hash=01dcaa32cbd2ed02c6cdaed18792ca3506eef6a2a4d4f7d5d7454264379c0615","title":"\u0417\u0430\u0445\u0432\u0430\u0442\u044b\u0432\u0430\u044e\u0449\u0438\u0435 \u043f\u043e\u0434\u043a\u0430\u0441\ u0442\u044b \u043e \u043a\u0438\u0431\u0435\u0440\u043f\u0440\u0435\u0441\u0442\u0443\u043f\u043b\u0435\u043d\u0438\u044f\u0445","but"", "imageUuid":"","isPaidAndBannersEnabled":false}

594 views

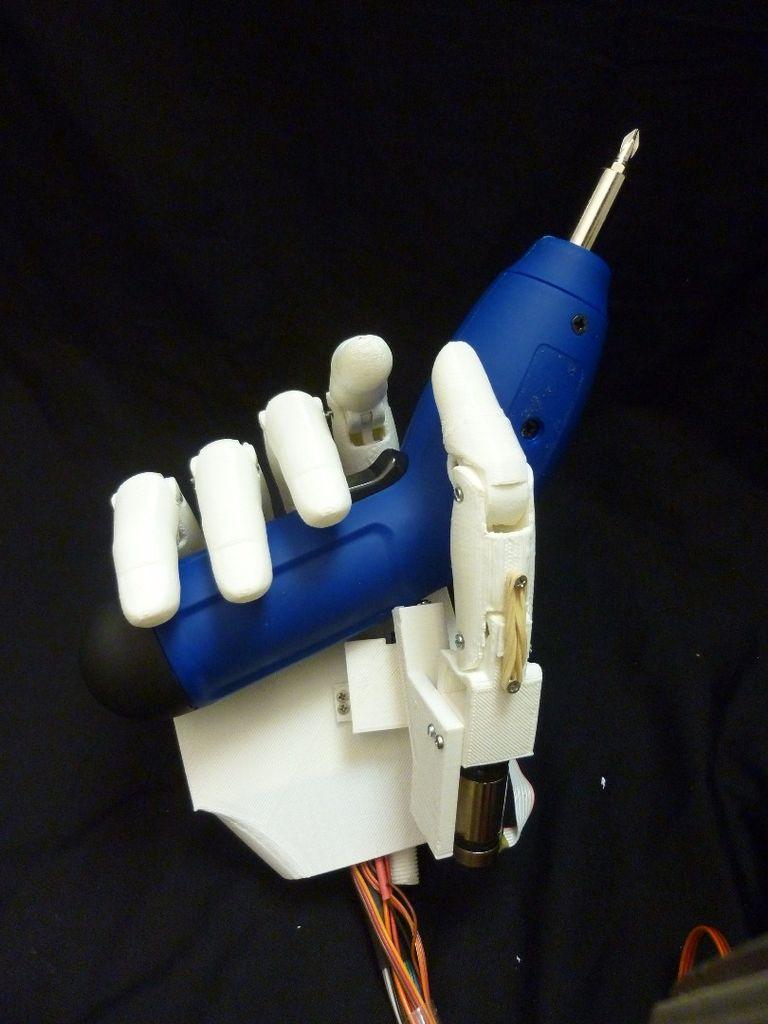

A startup from Tomsk makes parts of prostheses using 3D technologies. With the help of 3D scanning and high-resolution MRI, a model of the stump is created, for which a stump-receiving sleeve is designed and printed on a 3D printer.

Buzimov Alexander Yurievich, General Director of 3D Technology LLC

In 2016, I won the All-Russian engineering competition, which included the Business Debut program.

I became a graduate of this program and chose a nanotechnology center to build a venture business. In 2018, I headed a joint startup of the Sigma.Tomsk nanocenter and the Center for Nanotechnology and Nanomaterials of the Republic of Mordovia.

Buzimov Alexander Yurievich, General Director of 3D Technology LLC

The most important difference between such prostheses is the minimum human factor. The prosthetist works in a clean room without using plaster or other traditional materials. Thanks to new technologies, the process takes only one to two days, thanks to which the patient receives a new prosthesis quickly enough. In addition, this technology eliminates the inconvenience in using the prosthesis. The surface does not rub and the wearing of such a prosthesis is comfortable. A 3D printed prosthesis is more convenient due to its compactness and low weight, which facilitates movement and makes a person more mobile.

MRI is used to evaluate the internal structure of the stump. For example, if the bone is located close to the surface, then thanks to such a scan, the pressure on this area can be reduced. 3D scanning is used to build a model of the surface of the stump, and over time, comparing data from MRI and 3D scans, will be increasingly used.

For example, if the bone is located close to the surface, then thanks to such a scan, the pressure on this area can be reduced. 3D scanning is used to build a model of the surface of the stump, and over time, comparing data from MRI and 3D scans, will be increasingly used.

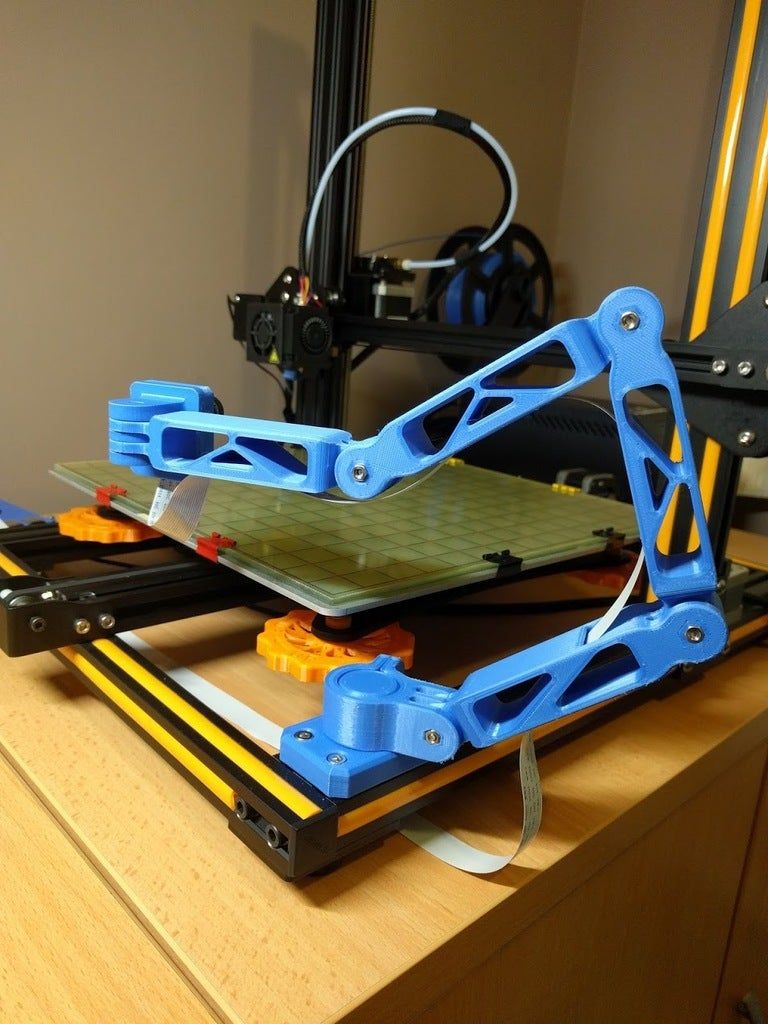

The process of printing a sleeve on a 3D printer

The sleeve is printed from industrial plastic with a hardening finish. Thus, the sleeve is superior to traditional models in many ways. With the introduction of this technology in traditional production, the process of prosthetics will become much easier.

I have been using dentures for 36 years. The difference between the old new prostheses is significant. The 3D printed prosthesis does not press or rub anywhere. Traditional dentures do not always fit the first time. The period of use of the prosthesis depends on how actively it is used

Andrey Stolyarov, The first person in the Russian Federation with a permanent prosthesis, the sleeve of which is made using 3D technology

Usov Vladimir Yurievich, Doctor of Medical Sciences, Professor, Head of the Department of ORITMD

The situation of each person is individual, it is in this matter that 3D printing technology helps a lot.

Learn more