Lsu 3d printing

3d printing | COLLEGE OF ART & DESIGN

Research, Honors & Awards, Architecture, Faculty, Donors, Doctor of Design3d printing, architecture, niloufar emami, design

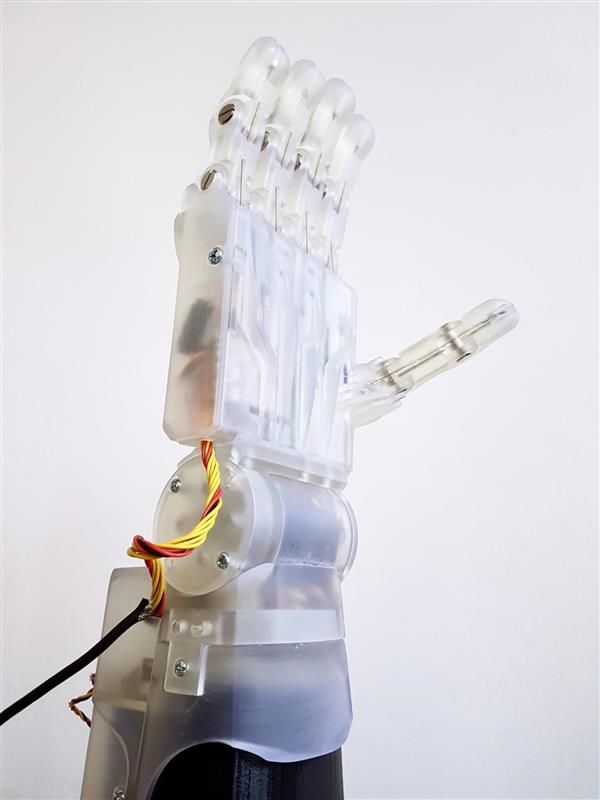

Niloufar Emami, PhD, A. Hays Town Professor in the LSU College of Art & Design, is using 3D printing to bridge the gap between engineering and design.

Read MoreArt & Design, Research, Community Outreach, Architecture, Faculty, Doctor of Designtechnology, 3d printing, digital fabrication, covid-19

In response to the global shortage of personal protective equipment (PPE) due to the COVID-19 pandemic, LSU faculty, staff, and students are joining the worldwide effort to create PPE to donate to those in…

Read MoreArt & Design, Research, Honors & Awards, Architecture, Faculty, Doctor of Design3d printing, niloufar emami

Niloufar Emami, assistant professor of architecture and holder of the A. Hays Town Professorship, has received the 2020 ARCC Research Incentive Award from the Architectural Research Centers Consortium for a research project on how…

Art & Design, Students, Landscape Architecture, Resources3d printing, LAM

The March 2014 issue of Landscape Architecture Magazine (LAM), the magazine of the American Society of Landscape Architects (ASLA), featured the work of Robert Reich School of Landscape Architecture students in an article about…

Read MoreArt & Design, Students, Events, Community Outreach, Architecture, Exhibitions, Resources, Communication across the Curriculum3d printing, shelby elizabeth doyle, Student Work, studios, digital fabrication

[portfolio_slideshow id=3809] Edges: Analog and Digital Fabrication by LSU School of Architecture ARCH 5004 Students December 8–13, 2013 | Middleton Library Lobby The work of fourth- and fifth-year architecture students in Visiting Assistant Professor…

Read MoreArt & Design, Resources, Communication across the Curriculumgrants, 3d printing, digital fabrication

Students in the LSU College of Art + Design now have additional state-of-the-art tools to help them develop their visual communication and design skills in preparation for future career opportunities. Through a $70,000 grant…

Through a $70,000 grant…

Art & Design, Resources, Communication across the Curriculumgrants, 3d printing

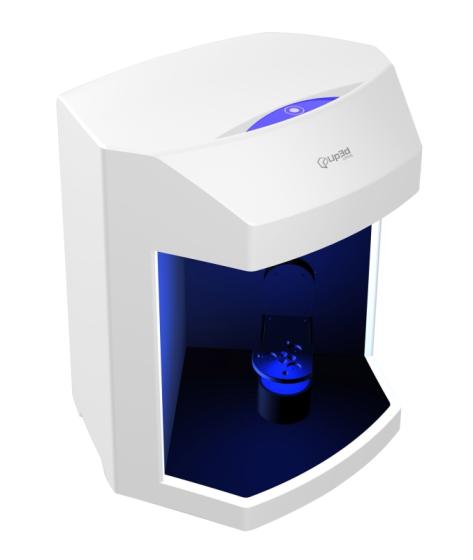

A recent $70,000 Board of Regents grant has provided the College of Art + Design with a state-of-the-art scanner and fabrication unit currently in use by students and faculty to produce three dimensional (3D)…

Read MoreCOLLEGE OF ART & DESIGN

College of Art + Design FacilitiesThe College of Art & Design’s facilities provide students access to the equipment they need to create and learn. Facilities include:

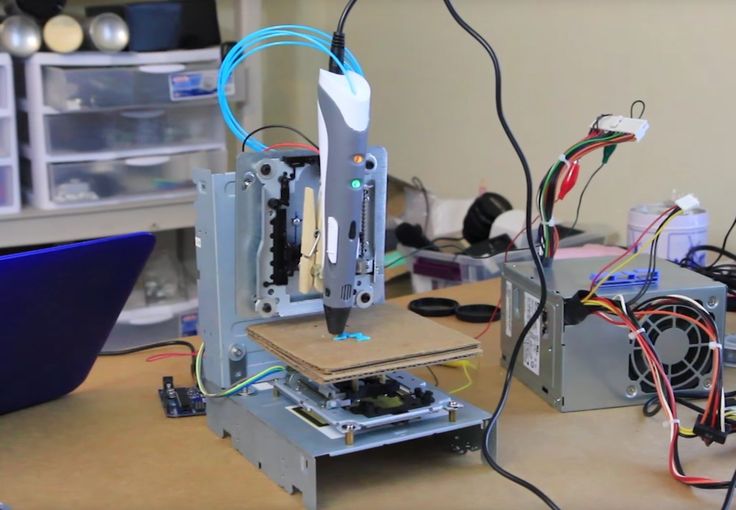

- the Design Shop, a traditional wood-working studio where students have access to state-of-the-art digital fabrication equipment including a 3D printer, a laser cutter, and a CNC mill;

- the Communication across the Curriculum (CxC) studio, where students can rent photography and lighting equipment and access 3D printers and a 3D scanner while learning affective communication skills specific to their individual disciplines;

- the Fabrication Laboratory, a digital lab where students and faculty have the capacity to create a multidisciplinary, active, team-learning environment by leveraging large-scale digital fabrication equipment;

- Hilltop Arboretum, a 14-acre, off-site museum of native plants, where students and faculty conduct research, and meet for teaching and service activities;

- the School of Art IDEA Hub, featuring high-end equipment and cutting-edge technologies, where faculty, graduate students, upper-level undergraduates, and other users can connect to digital resources with networked laptops and mobile devices to transport content between workstations, studios, and multiple presentation environments;

- the Materials Lab, where students and faculty can research materials, finishes, and furnishings and browse a full range of samples; and

- the VizLab, which offers large-scale printing, scanning, and other computer services as well as specialty software such as AutoDesk, Adobe Creative Suite, and Rhino.

The College of Art & Design also offers dedicated exhibition and lecture spaces, including two galleries that frequently display student and faculty work and exhibitions by visiting artists. The LSU Museum of Art boasts a robust exhibition schedule featuring national and international artists and collections. Visit Galleries for more information.

LSU LibrariesStudents will find everything they need to complete projects right here on LSU’s campus. LSU Libraries offer students and faculty strong support for instruction and research through collections containing more than three million volumes, microform holdings of more than four million, manuscripts of more than twelve million items, hundreds of electronic databases, and tens of thousands of electronic books and serials.

Middleton Library houses the main collections and LSU Libraries Special Collections in Hill Memorial Library provides a center for research in the humanities, social sciences, and fine arts. Hill Memorial Library houses the University Archives, the E.A. McIlhenny Natural History Collection, and the T. Harry Williams Center for Oral History as well as exhibition space. For material not found in the libraries, faculty, staff, and students may borrow materials through Interlibrary Borrowing.

Hill Memorial Library houses the University Archives, the E.A. McIlhenny Natural History Collection, and the T. Harry Williams Center for Oral History as well as exhibition space. For material not found in the libraries, faculty, staff, and students may borrow materials through Interlibrary Borrowing.

Visit lib.lsu.edu for more information about LSU Libraries.

STL file LU name・3D print and download model・Cults

Name LOIK

1 €

Name Kevin

1 €

Name OCEAN

1 €

Name KIARA

1 €

Fortnite 9 Lamp Stand0004

€0.80

Harry Potter Lamp

0.80 €

Darth Vader lamp base

2 €

Birthday cake topper

0,50 €

Born inkendi / Fire hydrant

5 €

Signature lamp LUNA

1 €

Name Timeo

1 €

Name Noam

1 €

Best 3D Printer Files in Home Category

piggy bank

Free

Pasta dryer

Free

Yuki Air Cooler

Free

Easter bunny with trolley

0. 64 €

64 €

SPONGE HOLDER OR SOAP DISCHARGE PERRY platypus

2,75 €

Tree cookie cutter

Free

Cat feeder

Free

beach cookie cutters pack surf pineapple flamingo

3,43 €

Bestsellers in the Home category

Yet Another Quick Change Toilet roll holder (fold-out)

1 €

Wall shelf "Oyster mushroom"

2,40 €

Super cute paw pen cup

1.39 €

Die Hard Advent Calendar

6.38 €

Wall shelf "Amanita mushroom"

2,40 €

Cat in pencil holder

1. 05 €

05 €

Venus and Aphrodite

3.60 €

Lion Fu, wall keychain

€3.80

Pumpkin girl

2,90 €

Christmas gnome decor COMBO PACK -Crex

13 € -62% 4.94 €

Clothes hanger "Wolf"

2,20 €

Pencil with dinosaur gluttony

1.92 €

PARROT BEAK HANGER

2.04 €

Pen/stylus holder Xenomorph

1 €

1/14 Excavator - Vulpa 505

65.09 €

Pokemon Ball Key Rack (Pikachu, Gengar)

2. 03 €

03 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Nano-Resolution Silicon Electronics 3D Printing / Sudo Null IT News0001

Fine structures printed under a microscope by Rice University scientists. During the sintering process, they are converted into either glass or cristobalite. Source: Rice University Laboratory of Nanomaterials, Nanomechanics, and Nanodevices

During the sintering process, they are converted into either glass or cristobalite. Source: Rice University Laboratory of Nanomaterials, Nanomechanics, and Nanodevices

Rice University engineers demonstrate the ability to 3D print glass and crystal nanostructures to build electronics or photonic devices in a bottom-up fashion.

Materials scientists at Rice University create silicon nanostructures using a sophisticated 3D printer, demonstrating a bottom-up method for building microscale electronics, as well as mechanical and photonic devices.

Weaving intricate microscopic structures of crystals or glass is now possible. At the same time, it is also possible to print products on a 3D printer that allow doping and adjustment of crystal structures for various purposes.

A related study by Jun Lu, Professor of Materials Science and Nanoengineering at the George R. Brown School of Engineering, was published in the journal Nature Materials.

The modern electronics industry is built around silicon, the basic semiconductor substrate that has been used for decades to build microprocessors. The results of the study overcome the limitations of top-down manufacturing technology by turning the entire process on its head with a 3D printer.

The results of the study overcome the limitations of top-down manufacturing technology by turning the entire process on its head with a 3D printer.

“It's very difficult to create complex, three-dimensional geometric structures with traditional photolithography techniques,” Lu says. “In addition, it is not environmentally friendly, since the process requires the use of a large amount of chemicals and is multi-stage. And even with all these technological efforts, some structures cannot be created.”"In principle, we can print arbitrary 3D shapes, which will play an important role in the creation of exotic photonic devices." he added.

In the lab, a two-photon polymerization process is used to print structures with lines only a few hundred nanometers wide, which is smaller than the wavelength of light.

“Conventional polymerization uses polymers and photoinitiators, molecules that absorb light to generate free radicals,” Rice University graduate and co-author Boyu Jang explains the process in which UV light is used to cure materials in 3D printing and dentistry .

“In our process, photoinitiators absorb two photons at the same time, which requires a lot of energy,” he says. “Only a very small peak of this energy causes polymerization, which eventually covers a tiny area, allowing us to go beyond the diffraction limit of light.”

To implement such a printing technique, the laboratory specialists had to develop a unique ink. Zhang and his colleague Xiven Wen created resins containing silica nanospheres doped with polyethylene glycol, giving them the property of solubility.

After printing, the structure is cured by high temperature sintering, which removes all polymers from the product, leaving amorphous glass or polycrystalline cristobalite.

"When heated, the material goes through phases of transformation from glass to crystal, and the higher the temperatures, the more ordered the crystals become." Lou says.

The lab also demonstrated doping the material with various rare salts to make the end products photoluminescent, a property required for optical applications.