Double head 3d printer

The Best Dual Extruder 3D Printers in 2022 (for Dual 3D Printing and Multicolor 3D Printing)

Welcome to the Thomas guide to the best dual extruder 3D printers 2022. Thomas has been connecting North American industrial buyers and suppliers for more than 120 years. When you purchase products through our independent recommendations, we may earn an affiliate commission.

3D printing in itself is a progressive technology that is extremely useful in many businesses, but it's also a fun activity for DIY hobbyists too. With rapid advancements taking place in the sector regularly, we have seen a lot of impressive things from this industry and can expect to see a lot more in the near future.

Dual extruder 3D printers can produce colorful and creative projects with two different filamentsImage credit: Shutterstock/Alex_Traksel

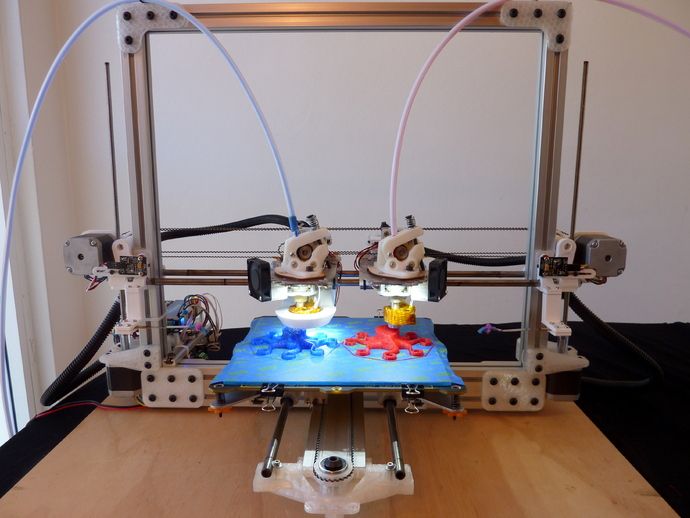

Although it's been around for a long time in the professional 3D printing world, one of the newer technologies introduced to at-home 3D printers is dual extrusion which allows users to print with two filaments at the same time, meaning you can mix colors and multiple materials—from PETG, ABS, PLA, and carbon, to metal, wood fill, and multicolor printing filaments—to produce extremely creative projects that can even be created simultaneously.

What is a Dual Extruder 3D Printer?

Dual extrusion in 3D printing refers to the art of printing using different materials, whether you choose different colors or different types of filaments with various effects, such as plastic filaments with metallic, or wooden effects.

This gives you the ability to make superior and more impressive products, and many professionals, as well as 3D printing enthusiasts, and those who own small businesses, i.e. Etsy shops selling 3D printed creations, swear by it.

Dual Extruder Printer—Buying Guide

3D printers with dual extruding capacity are, understandably, slightly pricier than single extruders, but it is a major upgrade from the single types, and there are many dual extruder 3D printers on the market at reasonable prices of around US$300-US$400. Since you’ll be spending quite a bit on this impressive piece of equipment, you want to make sure you’re buying the best one for your needs.

Types of Dual Extruder 3D Printers

Though most dual printing machines allow for multi-color printing with different materials, there are two main types of dual extruder 3D printers available:

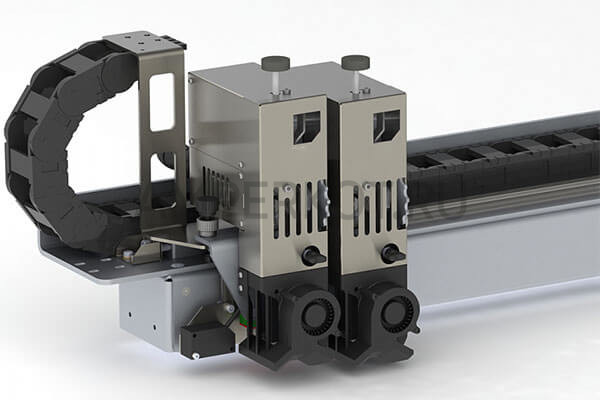

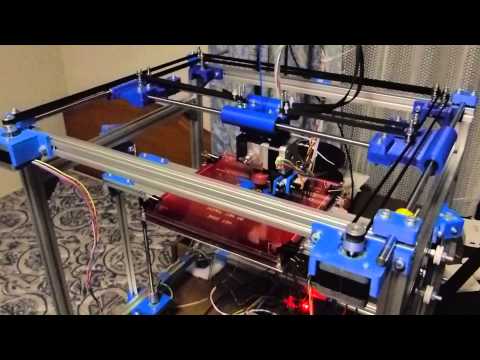

Independent dual extruder system

IDEX printers have two print heads and two nozzles with each print head able to either mirror the other in mirror mode, duplicate items with duplication mode, or print two completely separate objects.

Dependant dual extruders

These dual extruders have two extruders that are connected and move together to create one object using two different filaments. Two spools are loaded on the 3D printer and the printer alternates using them. These printers have the key advantage of reducing printing time since more print material can be produced than with just a single print head.

Dual Extrusion Printers—Considerations

Here are some other factors to consider why trying to find the best dual extruder 3D printers for your needs.

Print bed

As with regular 3D printers, print beds in dual extruder printers come in heated or non-heated options. A 3D printer with a heated print bed is, understandably, usually more expensive than a non-heated option but a heating plate can offer better print quality by keeping the bottom layers warm and reduce the chances of your prints warping during the printing process.

Print heads

Whereas a regular 3D printer just has one print head, a dual extruder printer will have more than one print head, with either two extruders, and sometimes even three. Some dual extruder 3D printers might have just one print head but a dual nozzle that can use two separate filaments on one print. A dual nozzle is great for printing an object in several materials or colors.

Print volume

Print volume, also referred to as the printing volume or the build volume, is how big an object you can build on any given printer. For an at-home printer, projects that would need a huge build volume would likely involve a printing process that would see the object printed off in separate parts and then stuck together afterward. The average size of a 3D printer with a larger build plate would be around 300 x 300 x 400mm.

For an at-home printer, projects that would need a huge build volume would likely involve a printing process that would see the object printed off in separate parts and then stuck together afterward. The average size of a 3D printer with a larger build plate would be around 300 x 300 x 400mm.

Calibration

If you’re a beginner to the world of 3D printing, a printer with automatic calibration is highly recommended. As with most aspects in 3D printing, calibrating a 3D printer has a learning curve and an automatic calibration feature can save you time and hassle and do the hard work for you.

Other factors

Another consideration you may want to keep in mind is cost. A dual extruding printer will be priced higher than a regular single head printer, plus maintenance costs will be higher, too, because there are more parts to this machine. In addition, if you’ll be working with various filaments at the same time (or even the same filament but with two extruders), factoring in higher costs for different materials is also a must.

Some machines even come with an added laser engraver feature or you could buy a compatible laser engraver to use with it. Whatever you’re after in a dual extruding 3D printer, our below list has some of the best models on the market to suit an array of styles, needs, and budgets.

Thomas’ Top Picks for the Best Dual Extruder 3D Printers 2022

We've scoured around and found some of the best 3D dual extruders worth taking a look at.

Best-Rated Dual Extruder 3D Printer: BIBO 3D Dual Extruder Printer | Buy Now

Best Dual Independent Extruder 3D Printer: TENLOG TL-D3 Pro Dual Extruder 3D Printer | Buy Now

Best Enclosed Dual Extruder 3D Printer: FlashForge Dreamer Dual Extruder 3D Printer | Buy Now

Best Cheap Dual Extruder 3D Printer: Sovol SV02 3D Printer | Buy Now

Best Professional Dual Extruder 3D Printer: Raise3D E2 Desktop 3D Printer | Buy Now

Best Quiet Dual Extrusion Machine: JG AURORA Artist-D Pro IDEX 3D Printer | Buy Now

Scroll down to read more about our top picks for the best dual extruder 3D printers according to thousands of happy buyers.

*Prices listed in this article were as shown in US$ on Amazon.com (USA) as of April 2022

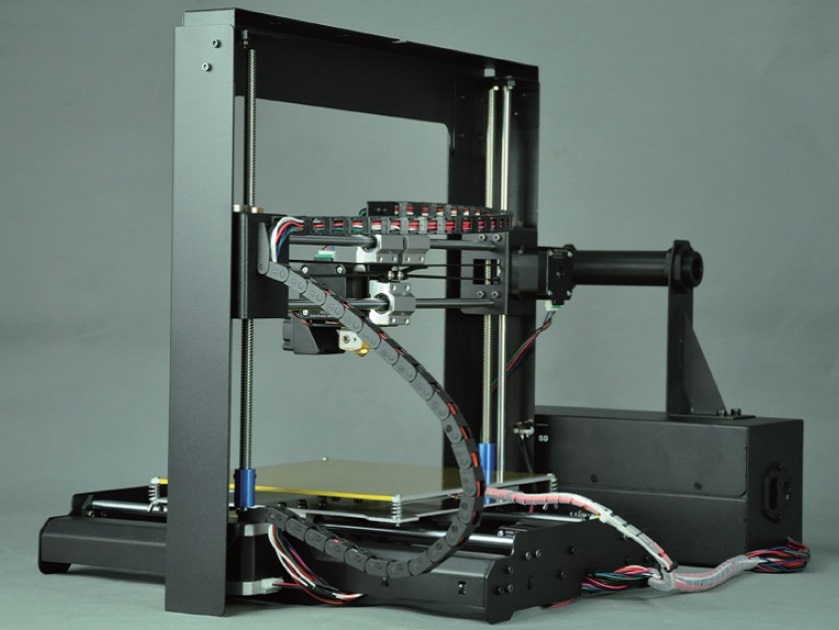

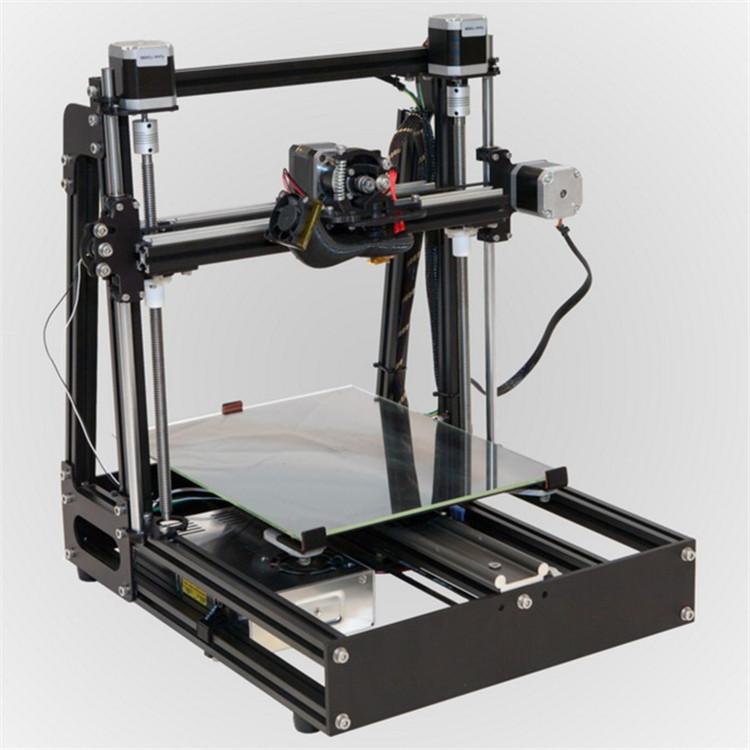

1. Best-Rated Dual Extruder 3D Printer—BIBO 3D Printer Dual Extrusion

A great printer well under the US$1000 mark, is this BIBO dual extruding 3D printer; a fully enclosed model with a very sturdy frame, full-color touch screen, WiFi capabilities, a demountable glass bed, and a low filament detector to let you know when you need to replace it before it's too late.

You can operate it via your phone or tablet if you so wish, and, in addition to printing two colors, it also has the ability to print two objects at the same time. This printer can print in two colors or filament materials, and can also print the dissolvable filament for support material.

One five-star review reads, "The dual extruder function is great, I'm able to use PLA filament and a soluble filament to print out some gears that impressed my friends and coworkers. .. Customer support is AMAZING. Every problem I had is solved very promptly and professionally, even though my printer is well out of their warranty."

.. Customer support is AMAZING. Every problem I had is solved very promptly and professionally, even though my printer is well out of their warranty."

Specifications

Build volume: 8.4 x 7.3 x 6.3 inches

Layer resolution: 0.05-0.3mm

Filament compatibility: multiple filaments including ABS, PLA, HIPS, TPU, PETG, nylon, PC, carbon fiber

BUY NOW:

US$579, Amazon2. Best Independent Dual Extruder 3D Printer—TENLOG Independent Dual Extrusion 3D Printer with Dual Nozzle

Whereas other dual extruding printers have one nozzle that can print from two pre-loaded filament spools, a 3D printer with independent dual extruding capabilities, like this model from TENLOG, has two separate nozzles, each with its own spool, that print at the same time but independently from each other.

This dual nozzle printer can print a duplicate in one go with its duplication or mirroring print modes, in the same or multiple colors, and many customers were left impressed with the high print quality this printer offers.

One happy buyer who described himself as a "3D printing veteran", wrote that the printer is "amazing" and that its print quality is "gorgeous", while another reviewer added "the touch screen and print quality are excellent."

Specifications

Build volume: 11.8 x 11.8 x 13.8 inches

Print speed: 10-150mm/s

Layer thickness: 0.1-0.4mm

Filament compatibility: PVA, TPU, ABS, PLA, nylon

BUY NOW:

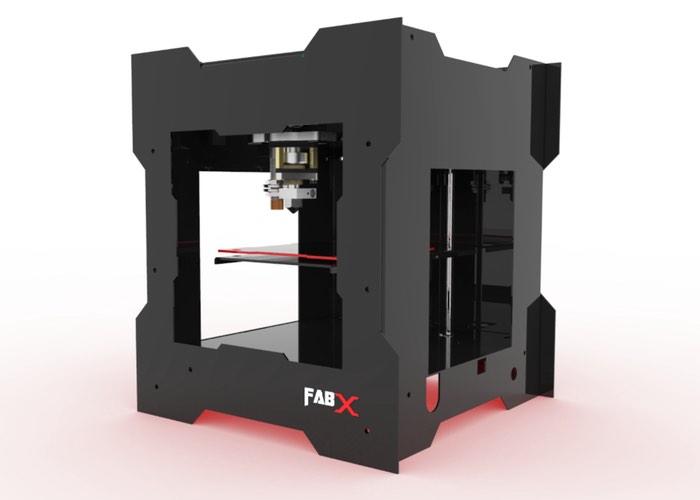

US$499.99, Amazon3. Best Enclosed Dual Extruder 3D Printer—FlashForge Dreamer Dual Extruder 3D Printer

The Dreamer by FlashForge is a fan favorite for many reasons; its fully enclosed design and sleek look, WiFi connectivity, user-friendly and high-res color touch screen, built-in 4G memory, full manufacturer's warranty, FlashForge's superior customer service, and, of course, it's dual extruder capabilities.

In addition, some consider this dual extrusion printer to be a professional piece of kit at the price of more beginner-level 3D printers and its large printing volume helps users get creative.

"This printer is the best bang for your buck to create large, very high-quality prints," one happy buyer reviewed. "[It] has a very high quality, well planned/built enclosure, which you won't find in many printers at this price. It even has two filament spool holders inside the enclosure."

Specifications

Build volume: 230 x 150 x 150 mm

Print speed: “100 micron and can really go to 75 micron at slower printing speed” (as per one customer)

Resolution: 0.1-0.2mm

Filament compatibility: ABS, PVA, PLA,

BUY NOW:

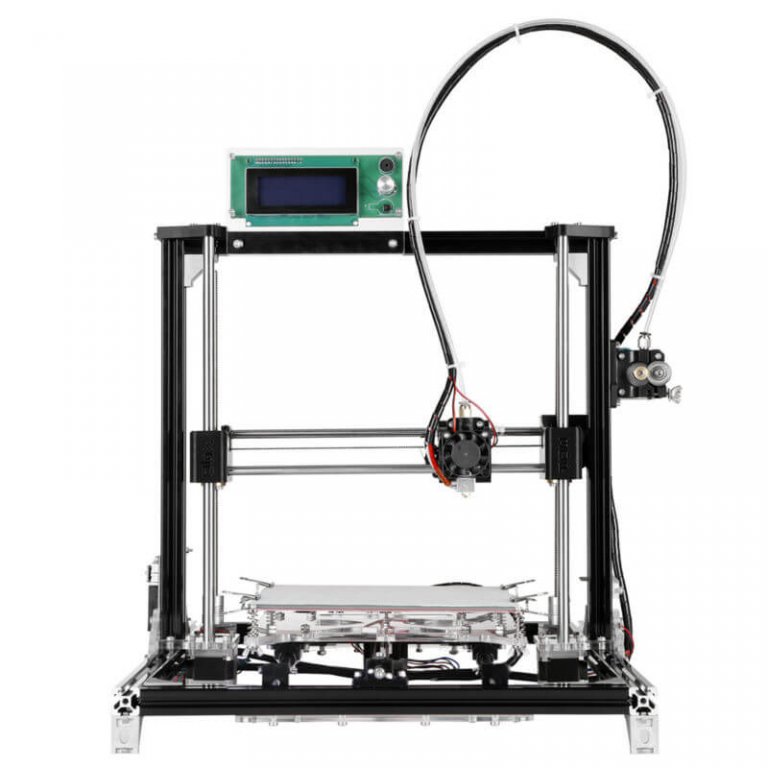

US$699, Amazon4. Best Cheap Dual Extruder 3D Printer—Sovol SV02 3D Printer

Great for beginners, this dual extrusion 3D printer from Sovol with large print volume capacity comes 95% pre-assembled so you can get to printing pretty much straight out of the box. Its full-metal body is stable and made to last, and the touch-screen is user-friendly.

Its full-metal body is stable and made to last, and the touch-screen is user-friendly.

With an impressive build volume, and the ability to print in two colors (or two types of filament), you'd be hard-pressed to find another 3D printer with the same capabilities at this price. In addition, you could buy an extra kit that will turn this thing into a laser engraving machine too if you’d like to add that something special that laser engraving can bring to your projects.

"I purchased it for the dual extrusion capability, and the large build area," wrote one buyer. "I was very impressed with the smoothness of this printer. The only sound during operation is the sound from the fans." Another happy purchaser helpfully added that the "dual extrusion is awesome, but for most prints, you will waste a lot of filament with the purge tower due to the shared hot end. It is a necessary evil."

Specifications

Build volume: 240 x 280 x 300 mm

Print precision: ±0. 1mm

1mm

Layer thickness: 0.1-0.4mm

Filament compatibility: can support material including PLA, ABS, PETG, WOOD, TPU

BUY NOW:

US$359, Amazon5. Best Professional Dual Extruder 3D Printer—Raise3D E2 3D Printer

For a professional 3D printing matching (with a price tag to match), the Raise3D is actually rather simple to use and even easier to set up. It has an auto bed leveling system and will guide you through the offset calibration system via a video.

It has an intuitive user interface with a large 7-inch touchscreen, and also many other features such as independent dual direct-drive extruders, a filament run-out sensor, resume-printing function, WiFi connectivity, and a live, built-in camera so you can monitor your prints remotely.

There's even a HEPA filter to clear any harmful and annoying fumes. It's compatible with almost any filament available. "This is my second dual-extruder printer," wrote one thrilled customer, "and compared to all of the less expensive units, the difference is night and day... Where the less expensive printers leave you feeling like the printer itself is more of a prototype, this one screams quality polished product."

"This is my second dual-extruder printer," wrote one thrilled customer, "and compared to all of the less expensive units, the difference is night and day... Where the less expensive printers leave you feeling like the printer itself is more of a prototype, this one screams quality polished product."

Specifications

Build volume: 11.6 x 9.4 x 9.4 inches

Minimum layer height: 20 microns (0.02 – 0.25 mm)

Precision: 0.78125, 0.78125, 0.078125 micron

Filament compatibility: practically all of them (PLA, ABS, HIPS, PC, TPU, TPE, Nylon, PETG, ASA, PP, PVA, glass fiber infused, carbon fiber infused, metal fill, wood fill)

BUY NOW:

US$3,499, Amazon6. Best Quiet Dual Extrusion Machine—JG AURORA Artist-D Pro IDEX 3D Printer

With super quiet functioning so that you can leave it printing all night if needed without waking up the whole household, the Artist-D Pro 3D printer by JG AURORA has an IDEX system, an ejectable nozzle for easy replacement, changes, and maintenance, and an industrial-grade linear rail for smooth and practically friction-free precision.

It provides the option to change to an optical limit switch, and, as a step up from the Artist-D, has a color touch screen. There are power-resume and filament runout detector functions and duplicate as well as mirror printing options.

One customer with a lot of experience in 3D printing with industrial printers felt that this printer is “the best desktop printer I have ever purchased,” and added, “it has features that my more expensive desktop printers do not have… It has been printing since it showed up at my door, well-needed production parts.”

Specifications

Build volume: 300 x 300 x 340mm build plate

Precision: up to 0.001 mm

Filament compatibility: PLA, TPU, PETG, PVA

BUY NOW:

US$599, AmazonThe BIBO 3D Printer (US$579, Amazon) is a great foray into the world of dual extruding, but for something a bit more economical, the price-performance ratio of the Sovol SV02 3D printer (US$359, Amazon) is impressive too.

We hope our review of the best dual Extruder 3D printers has been helpful and you found the best dual extrusion printer for your needs to get creative and print objects in multiple colors, shapes, and sizes, and perhaps even add laser engraving to the mix too. For more 3D printers and other 3D printing suppliers, including 3D printer filaments suppliers, additive manufacturing suppliers, 3D photographic printing services, and 3D sand printing additive manufacturing, consult our additional guides, or visit the Thomas Supplier Discovery Platform.

Other 3D Printing Articles- The Best 3D Printers under $300

- The Best 3D Printers under $200

- The Best 3D Printer Under $1000

- The Best 3D Printer Under $500

- Top 3D Printing Services Companies in the USA

- Origins of 3D Printing and Additive Manufacturing

- Overview of 3D Printing Technologies

- Top 3D Printing Manufacturers and Suppliers (Publicly Traded and Privately-Owned)

- Top Suppliers of Additive Manufacturing Consulting Services

Other Best Product Articles

- The Best Cordless Impact Wrenches

- The Best Portable Generators

- The Best Portable Band Saws

- The Best Electric Space Heaters

- The Best Mini Milling Machine

- The Best Attic Ladders

- The Best Air Purifiers for Smoke

- The Best Circuit Breaker Locator

- The Best Engine Hoists and Accessories

- The Best Drywall Lifts

- The Best Whole-House Generators

- The Best Home Automation Systems

- The Best Quietest Portable Generators

- The Best Uninterruptible Power Supply Systems

- The Best Commercial Patio Heaters

- The Best Electric Bikes

- The Best Electric Pressure Washers

- The Best Keyless Door Locks

- The Best Electric Lawnmowers

- The Best Electric Hand Warmers

More from Custom Manufacturing & Fabricating

The 9 Best Dual Extruder 3D Printers for Multi Material Printing – Clever Creations

Dual-extruder 3D printers are an excellent solution for multi-color and multi-material 3D printing. You don’t need to swap out filaments for a color change or limit yourself to printing with only a single material at a time. In a dual extrusion printing process, you get two entirely separate extruders for printing with multiple filaments.

If you decide to buy a dual extruder 3D printer, you’ll encounter terms like IDEX system, dual print-head system, and more. It can get quickly confusing to select the right printer for your needs, and you might end up getting one that is not the best fit for you.

In this article, we’ve created a list of the best dual extruder 3D printers that are available for you to buy right now and sorted them into different categories to make your buying decision a little bit easier.

Read on to understand more about these machines and how to choose the best dual extruder 3D printer for your needs.

| Dual Extruder 3D Printer | Category | Type | Price (~) | Best Offer |

|---|---|---|---|---|

| Sovol SV02 | Best under $500 | Single hot end | $359 | Sovol3D |

| Flashforge Dreamer | Best under $500 | Dual hot end | $449 | Flashforge |

| TENLOG TL-D3 Pro | Best under $1000 | IDEX | $699 | Amazon |

| Flashforge Creator Pro 2 | Best under $1000 | IDEX | $649 | Flashforge |

| QIDI Tech i-Fast | Best prosumer | Dual hot end | $2299 | Amazon |

| Ultimaker S3 | Best prosumer | Dual hot end | $4725 | MatterHackers |

| BCN3D Sigma D25 | Best professional | IDEX | $3995 | MatterHackers |

| Raise3D Pro 3 | Best professional | Dual hot end | $5249 | MatterHackers |

| Ultimaker S5 | Best professional | Dual hot end | $6355 | MatterHackers |

What is a Dual Extruder 3D Printer?

A dual extruder 3D printer is a machine that has two extruders, as the name suggests. These extruders can be used to print with different colors or different materials simultaneously. This way, you don’t have to swap out filaments every time you want to change the color of your print.

These extruders can be used to print with different colors or different materials simultaneously. This way, you don’t have to swap out filaments every time you want to change the color of your print.

You can also use dual extruders to print with multiple materials at the same time, for example, printing with both ABS and TPU filaments in a single 3D print. This opens up a lot of possibilities for interesting prints that wouldn’t be possible with a single extruder printer.

In this article, we’ve covered three types of different dual extrusion 3D printers: Single hot end setup, Dual hot end extrusion, and Independent Dual Extruder system (IDEX).

The single hot end setup is the least complex. It gives you the benefits of dual extrusion 3D printers without actually having a second print head or a complex motion system.

The dual hot end setup incorporates a second print head next to your primary hot end, and both hot ends move together. You can assign different materials for each hot end, effectively giving you the capabilities of printing with two 3D printers, albeit on a single print bed.

You can assign different materials for each hot end, effectively giving you the capabilities of printing with two 3D printers, albeit on a single print bed.

One of the best and the most practical applications of dual extruders is the IDEX style of 3D printer. These printers have two independent print heads that can be controlled and moved separately. This gives you a lot of control over the printing process and opens up a lot of possibilities for complex prints.

What is the Benefit of a Dual Extruder 3D Printer?

A dual extruder 3D printer triumphs over the regular single extruder 3D printer in many ways. You do not need to swap out any filaments mid-print for any color changes, leading to a faster print speed.

You can print with multiple materials simultaneously with a dual extruder printer. You can use one print head to print the outer shell of the model, while the secondary hot end will print the infill with a more robust material. Similarly, you can use filaments with different colors to print a colorful model.

IDEX printers give you the added benefits of printing modes. You can print multiple objects simultaneously with the duplication mode and print a mirrored version of your design with the mirror print mode. It leads to increased productivity and is useful for 3D printing larger batches of objects.

The last and probably one of the most popular benefits of dual extruder 3D printers is their ability to print soluble supports. You can use PVA or HIPS filament in your secondary extruder to print water dissolvable supports. It gives you the freedom to print complex objects and significantly saves post-processing time, as it takes away the need to remove supports manually.

The Best Dual Extruder 3D Printers

Sovol SV02

Best under $500

Check Price

AmazonSovol3D

The Sovol SV02 is an excellent budget dual extruder 3D printer. It features a Y-shaped, two-in, one-out single print head. It is a clever way to carry out multi-filament printing without adding too many extra 3D printer costs.

The SV02 has a decent printing volume and a dual Z-axis design for better printing accuracy. Its textured glass bed helps with first-layer adhesion and makes the removal of prints easier.

Its mainboard features TMC 2208 stepper drivers for a silent 3D printing process. You also have the option to install a BLTouch auto-leveling sensor as an upgrade, taking away the need for manual bed leveling.

Additionally, you can buy a mixing hot end that lets you mix two different colors simultaneously. This feature gives a lot of room for fun experimentation and creative 3D prints.

The SV02 is an excellent fit for schools to print colorful educational models and for beginners and amateurs users who want to experiment with dual extruder 3D printing without breaking the bank.

Standout Features

- 2-in-1-out hot end

- Optional color mixing

- Dual Z-axis

Technical Details | |

|---|---|

| Build volume | 280 x 240 x 300 mm |

| Dual extrusion setup | Single hot end |

| Max hot end temperature | 260°C |

| Bed leveling | Manual |

| Connectivity | SD Card or Data Cable |

| Compatible materials | PLA, TPU, HIPS, ABS, PETG, WOOD |

What We Like

- Lightweight hot end

- Silent 3D printing

- Can mix two colors

Could Be Better

- Inconsistent print quality

- Occasional filament jams

Find Sovol SV02 at

AmazonSovol3D

Flashforge Dreamer

Best under $500

Check Price

AmazonFlashforgeMatterHackers

The Flashforge Dreamer is one of the most popular dual extruder 3D printers in the market that comes with some elegant features for easy multi-material 3D printing. It comes fully assembled, and you can get started with 3D printing on it within 30 minutes of unboxing the printer.

It comes fully assembled, and you can get started with 3D printing on it within 30 minutes of unboxing the printer.

With the Dreamer, you get two print heads with a direct-drive setup that can help you print a wide variety of materials with ease. The fully enclosed design prevents any harmful 3D printer fumes from leaving the printer and aids considerably with printing ABS. It includes an aluminum heated print bed for a more even heat distribution on the print surface.

The dual extruder design does result in a slight reduction in the build volume of the 3D printer, however, and you get a relatively small print area for the price. Some users also find the bundled FlashPrint slicing software limiting in terms of features.

Nonetheless, considering that the Dreamer is primarily aimed towards beginners, it does an excellent job in the user convenience and accessibility department. It is a good choice for educational institutes and amateur 3D printer users who want a plug-n-play solution for their multi-color and multi-material printing needs.

Standout Features

- Fully enclosed print chamber

- Aluminum build plate

- Wi-Fi connectivity

Technical Details | |

|---|---|

| Build volume | 230 x 150 x 140 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 240°C |

| Bed leveling | Assisted Manual |

| Connectivity | USB cable, SD card, Wi-Fi |

| Compatible materials | PLA, TPU 95A, ABS, PETG |

What We Like

- Stable printing area

- Beginner-friendly

- Plug-n-play functionality

Could Be Better

- Small build volume

Find Flashforge Dreamer at

AmazonFlashforgeMatterHackers

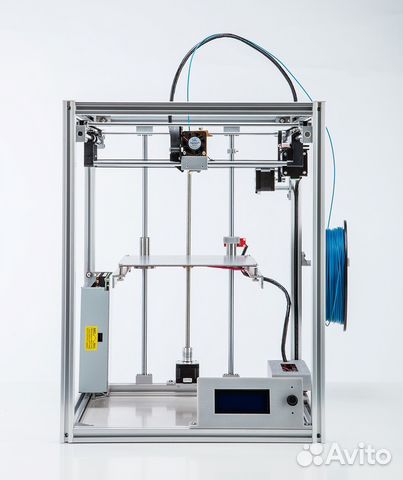

TENLOG TL-D3 Pro

Best under $1000

Check Price

Amazon

The Tenlog TL-D3 Pro is a rare dual extruder 3D printer to feature an IDEX system under $1000. It has two independent extrusion systems that move independently and let you print in mirroring print modes and duplicating modes.

It has two independent extrusion systems that move independently and let you print in mirroring print modes and duplicating modes.

You get a linear rail precision guide on the X-axis to support the IDEX system and a sturdy metal frame to deliver accurate printing quality. The tempered glass heated print bed gives excellent bed adhesion, and the silent motherboard with TMC 2208 and TMC 2225 stepper drivers delivers a quiet 3D printing experience.

The Tenlog TL-D3 Pro is a great dual extruder 3D printer that provides a unique mix of features at an affordable price. If you’re someone who has the need for batch 3D printing in a semi-professional setup, or you want an IDEX 3D printer on a budget, the TL-D3 Pro is a solid option.

Standout Features

- Multiple printing modes

- X-axis linear rail

- IDEX system

Technical Details | |

|---|---|

| Build volume | 300 x 300 x 350 mm |

| Dual extrusion setup | IDEX |

| Max hot end temperature | 300°C |

| Bed leveling | Manual |

| Connectivity | SD card, USB 2. 0 0 |

| Compatible materials | TPU, PVA, PLA, ABS, HIPS, WOOD, PETG, FLEXIBLE |

What We Like

- Easy to assemble

- Silent 3D printing

- Wide material compatibility

Could Be Better

- Open-frame design

Find TENLOG TL-D3 Pro at

Amazon

Flashforge Creator Pro 2

Best under $1000

Check Price

AmazonFlashforgeGeekbuyingAliExpress

While the aforementioned Flashforge Dreamer is suited for beginners and amateur users, the Flashforge Creator Pro 2 is aimed more towards the professional user base. The Creator Pro 2 is a fully enclosed 3D printer with a similar level of user convenience, but now with an upgraded independent dual extruder (IDEX) system.

The Flashforge Creator Pro 2 has multiple printing modes that let you print mirrored designs, duplicate your models for faster 3D printing, and even print with soluble support materials for complex and intricate 3D designs. The heated print bed and the enclosed design further expand the material compatibility of the printer, letting you print with PLA, ABS, HIPS, and PVA.

The heated print bed and the enclosed design further expand the material compatibility of the printer, letting you print with PLA, ABS, HIPS, and PVA.

The Flashforge Creator Pro 2 is a superb dual extruder 3D printer for industry professionals and hobbyists alike. You get a robust build quality, an IDEX system, ease of use, and excellent printing, all for a relatively low cost. In our book, it’s the best dual extruder 3D printer under $1000

Standout Features

- Fully enclosed design

- Residue scraping

- Easy to use touchscreen

Technical Details | |

|---|---|

| Build volume | 200 x 148 x 150 mm |

| Dual extrusion setup | IDEX |

| Max hot end temperature | 240°C |

| Bed leveling | Manual |

| Connectivity | SD Card |

| Compatible materials | PLA, ABS, PVA, PETG |

What We Like

- Affordable IDEX printer

- Excellent print quality

- Great support team

Could Be Better

- Small printing volume

- Lacks air filters

Find Flashforge Creator Pro 2 at

AmazonFlashforgeGeekbuyingAliExpress

QIDI Tech i-Fast

Best prosumer

Check Price

AmazonGeekbuying3DPrintersBay

The QIDI Tech i-Fast is not for the masses and is instead more positioned as a premium 3D printer for prosumers. For almost $2300, you get a printer that comes with many high-end features and a large build volume (uncommon in dual-extruder 3d printers) to accommodate a wide variety of 3D designs.

For almost $2300, you get a printer that comes with many high-end features and a large build volume (uncommon in dual-extruder 3d printers) to accommodate a wide variety of 3D designs.

Its heated print chamber measures 330 x 250 x 320 mm and is fully enclosed. For better printing with high-end materials like Nylon, Polycarbonate, and PolyPropylene, it can be heated up to 60°C. The motion system is fully supported with high-quality precision linear rails, and it has a dual Z-axis setup for increased accuracy.

The QIDI Tech i-Fast is a feature-packed dual extruder 3D printer for professional use case scenarios and printing high-end prototypes. Despite its high price, it still offers excellent value compared to similar printers in this price range. If you’re planning on adding an industrial machine to your workflow, the i-Fast is likely to be a perfect choice for your prototyping needs.

Standout Features

- Heated build chamber

- Extra all metal print-heads

- Large build volume

Technical Details | |

|---|---|

| Build volume | 330 x 250 x 320 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 300 °C |

| Bed leveling | Manual |

| Connectivity | Wi-Fi, USB and SD Card |

| Compatible materials | PLA, Nylon, TPU, PETG, ABS, PC, Wood, CF |

What We Like

- Quiet 3D printing

- Prints ABS very well

- Retractable hot ends

Could Be Better

- Manual bed leveling

- Limited firmware support

Find QIDI Tech i-Fast at

AmazonGeekbuying3DPrintersBay

Ultimaker S3

Best prosumer

Check Price

MatterHackers

The Ultimaker S3 is feature-packed and one of the best dual extruder 3D printers by Ultimaker. It is for professional users who want a high-quality, compact printer that consistently delivers excellent print quality.

It is for professional users who want a high-quality, compact printer that consistently delivers excellent print quality.

With the Ultimaker S3, you get a modest build volume of 230 x 190 x 200 mm. This is enough for most typical 3D prints but can be a limitation if your needs involve creating larger multi-color or multi-material objects.

The dual extruders on the Ultimaker S3 have swappable print cores that let you print with advanced materials if you need to. Over 200 materials are tried and tested on the S3, making it one of the most compatible dual extruder printers in terms of filaments.

Additional features include a 4.3-inch touchscreen with an easy-to-use UI, an onboard camera for remote monitoring, and an automatic bed leveling system to give you perfect bed adhesion and first layers every time.

The Ultimaker S3 is a premium 3D printer, and at a price point of over $4000, it is undoubtedly not for primary hobby purposes. The features it provides and the materials it supports are more geared towards industrial prototyping and end-component solutions for industries. If you’re someone who fits in that bracket, the S3 is a good choice for your 3D printing needs.

If you’re someone who fits in that bracket, the S3 is a good choice for your 3D printing needs.

Standout Features

- Swappable print cores

- Onboard camera

- Automatic bed leveling

Technical Details | |

|---|---|

| Build volume | 230 x 190 x 200 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 280 °C |

| Bed leveling | Automatic |

| Connectivity | Wi-Fi, Ethernet, USB |

| Compatible materials | PLA, ABS, PETG, NylonX, TPU, PVA, PP, PC |

What We Like

- Excellent print quality

- Professional software support

- Wide material compatibility

Could Be Better

- Limited build volume

- Expensive replacement parts

Find Ultimaker S3 at

MatterHackers

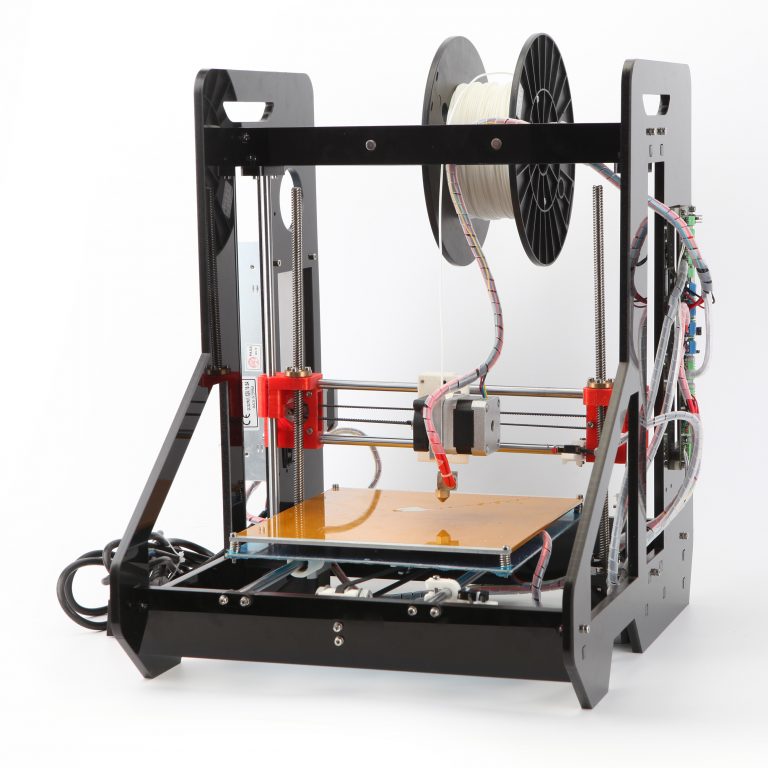

BCN3D Sigma D25

Best professional

Check Price

MatterHackers

Improving on the R17 and R19 Sigma’s series of independent dual extruder (IDEX) 3D printers, BCN3D’s new Sigma D25 is a professional-grade 3D printer that comes in a new light gray color and with a desktop-sized footprint. It features an independent extruder system, letting you print with multiple print modes and enhance your productivity.

It features an independent extruder system, letting you print with multiple print modes and enhance your productivity.

The Sigma D25 includes stainless steel, precision linear rails on the X-axis, and a robust Z-axis designed for durability and maximum print accuracy. For better bed adhesion, its new aluminum heated build plate comes with a silicon thermal pad to evenly heat its area.

It also includes a new set of custom-made E3D hot ends coupled with Bondtech extruders that support a wide variety of materials and deliver a consistent 3D printing performance. The filament spools are neatly tucked within the printer frame itself, protecting them from any external debris and giving the printer a clean look.

BCN3D Sigma D25 aims to deliver the highest dual extrusion 3D printing in a clean-looking, easy-to-use package. The large build volume, IDEX system, and interface make it suitable for batch printing, print farms, and educational purposes.

Standout Features

- IDEX setup

- Built-in filament holders

- Large build volume

Technical Details | |

|---|---|

| Build volume | 420 x 300 x 200 mm |

| Dual extrusion setup | IDEX |

| Max hot end temperature | 300°C |

| Bed leveling | Manual |

| Connectivity | SD card, Wifi, Ethernet |

| Compatible materials | PLA, PVA, PET-G, TPU, PP, PA |

What We Like

- Easy to use interface

- Great build quality

Could Be Better

- Manual bed leveling

- Limited Z-height

Find BCN3D Sigma D25 at

MatterHackers

Raise3D Pro 3

Best professional

Check Price

MatterHackers

The Raise3D Pro 3 is one of the flagship 3D printers by the Raise3D team. It builds upon the previous generation of the Pro 2 series of industrial 3D printers. Its improvements lie with its new dual extruder setup, interchangeable hot end, and airflow system to give you great 3D printing results every time.

It builds upon the previous generation of the Pro 2 series of industrial 3D printers. Its improvements lie with its new dual extruder setup, interchangeable hot end, and airflow system to give you great 3D printing results every time.

The Pro 3 comes with a large build volume of 300 x 300 x 300mm. That volume is fully enclosed to isolate the print area from the external environment. Additionally, it includes a HEPA filtration system to keep away potantially unhealthy 3D printer fumes.

Its automatic bed leveling minimizes the calibration time required, resulting in improved productivity. The built-in ‘EVE intelligent assistant’, too, is a unique feature with the Pro 3 designed to locate and resolve any issues and give helpful feedback to the user.

The Raise 3D Pro 3 is for professional users who need a robust, large-sized 3D printer that lets you execute multi-material 3D printing on an industrial scale. You can use it to carry out batch 3D printing with advanced materials and end-use components without hassles.

Standout Features

- Airflow manager

- Interchangeable hot ends

- EVE Smart assistant

Technical Details | |

|---|---|

| Build volume | 300 x 300 x 300 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 300°C |

| Bed leveling | Automatic |

| Connectivity | Wi-Fi, LAN, USB port |

| Compatible materials | PLA, ABS, HIPS, PC, TPU, TPE, PETG, ASA, PP, PVA, Nylon |

What We Like

- Professional build quality

- High repeatability

- Auto bed leveling

- Large filament compatibility

Could Be Better

- Large investment

Find Raise3D Pro 3 at

MatterHackers

Ultimaker S5

Best professional

Check Price

AmazonMatterHackers

The Ultimaker S5 is the bigger brother of the Ultimaker S3, but with a larger build volume to utilize the benefits of dual extrusion 3D printing fully. It is similar to the S3 in many aspects, but the additional upgrades and add-ons make it an automated industrial-level 3D printer.

It is similar to the S3 in many aspects, but the additional upgrades and add-ons make it an automated industrial-level 3D printer.

The S5’s large build volume of 330 x 240 x 300 mm is suitable for big-sized objects, and it can be fully enclosed with an optional air management system to maintain a stable temperature in the printing area. This makes it more suitable as a Nylon 3D printer or to work with other high-temperature filaments.

To expand this 3D printer further, you can add a material station that takes up to six materials and automatically choose the required material for the current print without any user intervention.

The swappable print cores, retracting nozzles, and automatic bed leveling are the same as the S3, delivering a predictable and high-quality 3D printing experience each time.

The Ultimaker S5 is an excellent printer for industrial environments and can be upgraded to fulfill even more complex needs. It is our top pick for the best dual extruder 3D printer for professionals.

Standout Features

- Large build volume

- Additional upgrades

- Swappable print cores

Technical Details | |

|---|---|

| Build volume | 330 x 240 x 300 mm |

| Dual extrusion setup | Dual hot end |

| Max hot end temperature | 280°C |

| Bed leveling | Automatic |

| Connectivity | Wi-Fi, Ethernet, USB |

| Compatible materials | PLA, ABS, PETG, NylonX, TPU, PVA, PP, PC |

What We Like

- Wide material compatibility

- Premium components

- Reliable

Could Be Better

- Pricy upgrades

Find Ultimaker S5 at

AmazonMatterHackers

What to Look For When Buying a Dual Extruder 3D Printer

Dual extruder type

When you consider buying a dual extruder 3D printer, you’ll come across technologies such as the IDEX system, double hot ends, and a single Y-shaped hot end.

The IDEX system lets you simultaneously 3D print with two independently driven extruders and a hot end setup.The advantages of an IDEX system are the multiple printing modes that you get with it. You get to duplicate and mirror your models, effectively resulting in increased productivity.

If you look at the single hot end setup, you’ll notice that the hot end is much lighter, and you do not lose any printing area to a second print head. The downside, though, is that this setup is more likely to run into issues, as a single print head is used for multiple materials at a single time.

The most common and relatively more accessible dual extrusion system is double hot ends. You get two individual hot-ends and extruders, and each hot end can be configured to print a single material with maximum efficiency. However, two hot ends next to each other occupy extra space, cost more, and do not increase productivity like the IDEX system.

If you want a printer for maximum productivity and are looking to run it into print farms or to run multiple batches of prints, the best dual extruder 3D printer for you is an IDEX one. In contrast, the dual hot end setup is more suitable for conventional dual extrusion 3D printing, where you do not need to print many parts.

In contrast, the dual hot end setup is more suitable for conventional dual extrusion 3D printing, where you do not need to print many parts.

Printing modes

While the single nozzle and the dual hot ends styles let you print with multiple materials and soluble supports, printing modes are truly available only on the IDEX style of dual extruder 3D printers.

There are four printing modes that come with dual extruder 3D printers – Mirror, duplication, soluble supports, and multi-material mode. The mirror mode lets you print symmetrical mirrored objects, and you can print the part and its inverse simultaneously. For example, shoes, gloves, and other things come in a couple but are symmetrically opposite.

Another helpful model is the duplication mode, which helps carry out batch prints. In duplication mode, both the hot ends repeat the same movements and produce identical copies of the original design. It drastically improves your productivity rates and is suitable for print farms.

The soluble supports and the multi-material modes are similar and not just available in the best dual extruder 3D printers; any dual extruder printer can do them. While the primary nozzle is used for the main filament, you can use the secondary nozzle with either soluble supports or a differently colored material.

Print Volume

The dual extruder design reduces the printing volume of any 3D printer due to the extra space the secondary extruder takes up. This results in a smaller printing volume on the Y-axis in dual extruder printers compared to a single extruder setup.

When you use print modes, too, you’ll realize that the print area is reduced considerably due to the second extruder’s size in mirror mode. Hence, in the case of dual extruder printing, it becomes more crucial to look at the actual printing volume that you’ll get.

If you need a bigger print size, you should look at the Raise3D Pro 3, Ultimaker S5, and the BCN3D Sigma D25. These printers come with a large print volume that gives you more freedom to take full advantage of their dual extrusion capabilities.

Print Speed

Even with the addition of a second hot end on the motion system, the printing speeds of dual extruder 3D printers are relatively unaffected. Powerful stepper motors and a rigid frame can compensate for the added weight of the hot end.

Almost all of the 3D printers in this list can comfortably print at around 60-100 mm/s of printing speeds, while travel speeds go up to 200 mm/s. These speeds give you a good balance between print quality and lead times.

If you consider the other benefits of dual extruder 3D printers, you’ll realize that the printing modes lead to a considerable increase in overall productivity. The ability to print with two print heads simultaneously easily triumphs the faster printing speeds of any other 3D printer.

Filament Compatibility

Ensuring that your 3D printer is compatible with many filaments is one of the primary things you need to consider while buying any 3D printer. More so with dual extruder 3D printers due to their second print head.

The second print head is helpful for printing soluble supports. If you’re getting a dual extruder printer specifically for printing with soluble filaments such as PVA and HIPS, you should check whether or not it is compatible with these materials.

Every printer in this list is equipped to print with these materials. And some of the dual extruder 3D printers like the Ultimaker S3, S5, Raise3D Pro 3 go beyond and let you swap your print heads for printing with specific materials, thus increasing their material compatibility.

Enclosure

A 3D printer enclosure plays a crucial role with dual extruder 3D printers. The isolated printing area on enclosed 3D printers lets you print with tricky materials such as ABS filament and keeps 3D printing fumes within the printer body itself.

Aside from the Sovol SV02 and the Tenlog TL-D3, all other dual extruder 3D printers come with at least a partially enclosed design. And with the Creator Pro 2, you get the benefits of both; you can choose to keep the printer open on the top while printing with PLA and fully enclose it when you want to print with ABS.

The Ultimaker S5 goes a step beyond its airflow management system, however, the QIDI Tech i-Fast is the only dual extruder 3D printer on the list with an actively heated build chamber. This ensures that you get the best print quality and that the printer is compatible with a wide variety of materials.

Warranty

Warranty is often an overlooked factor when buying dual extruder 3D printers. You need to carefully evaluate the warranty conditions and everything that is covered within it. Some manufacturers offer a warranty on specific components for a short while, while the best dual extruder 3D printers tend to get comprehensive coverage of any manufacturing defect in the printer.

In this list, all the dual extruder 3D printers have at least a 12 months warranty period that covers any manufacturing defect from the company’s end.

FAQ

Are dual extruder printers faster?

Even the best dual extruder 3D printers are not necessarily faster than any other 3D printer. However, the dual extrusion process leads to an overall increase in productivity due to the ability to print multiple copies at the same time.

However, the dual extrusion process leads to an overall increase in productivity due to the ability to print multiple copies at the same time.

Can dual extruder printers print with soluble filaments?

Yes, all of the dual extruder 3D printers in this list are capable of printing with soluble filaments.

How many extruders can a 3D printer have?

Most 3D printers have a limit of two extruders. However, depending on the electronics capabilities and general hardware setup, some 3D printers can have up to four or five extruders.

What is the advantage of a dual extruder printer?

The dual extruder setup allows for printing with multiple materials, which leads to an increase in productivity. Additionally, dual extruder printers are compatible with a wider range of filaments.

Do dual extruder printers have an enclosed build area?

No, dual extruder printers do not necessarily have an enclosed build area as it is not necessary for their operation. However, some dual extruder printers do come with a partially or fully enclosed design.

However, some dual extruder printers do come with a partially or fully enclosed design.

Can you 3D print multiple objects at once?

Yes, dual extruder 3D printers can print multiple objects at once provided that they have the necessary build volume. However, the print quality may not be as good as if you were to print them one at a time.

What is the average price of a dual extruder 3D printer?

Dual extruder 3D printers generally cost more than single extruder 3D printers. However, the price difference is not as significant as it used to be and there are a number of excellent dual extruder 3D printers in the market at a wide range of prices.

You can find a good one, like the Flashforge Creator Pro 2, for around $650. The best dual extruder 3D printers, however, cost multiple thousands of dollars.

How do you print multiple filaments?

To print multiple filaments, you need to have a dual extruder 3D printer with two extruders. The filaments are then loaded into the extruders and the printer will print with both filaments simultaneously.

Conclusion

Dual extruder 3D printers let you print with multiple materials simultaneously, and that too with ease. Especially with the IDEX style of printers and the multi-material capabilities, you get the added benefits of various printing modes that increase your overall productivity and are great for the batch style of prints.

From the list, the best dual extruder 3D printer that stands out on the top is the Flashforge Creator Pro 2. It gives you the benefits of the IDEX system, is fully enclosed, and has broad material compatibility while still being affordable and accessible for professionals and hobbyists alike. Its only downside is a relatively small print volume.

If print area is your main criteria, you should consider the QIDI Tech i-Fast and the BCN3D Sigma D25 for their large print chambers in decent footprint size. These are professional dual extruder 3D printers with advanced features, excellent print quality, and great for industrial prototyping needs.

Let us know your thoughts on the list, and if you have anything else to add, feel free to comment below.

3D printing for "dummies" or "what is a 3D printer?"

- 1 3D printing term

- 2 3D printing methods

- 2.1 Extrusion printing

- 2.2 Melting, sintering or gluing

- 2.3 Stereolithography

- 2.4 Lamination

- 3 Fused Deposition Printing (FDM)

- 3.1 Consumables

- 3.2 Extruder

- 3.3 Working platform

- 3.4 Positioners

- 3.5 Control

- 3.6 Varieties of FDM printers

- 4 Laser stereolithography (SLA)

- 4.1 Lasers and projectors

- 4.2 Cuvette and resin

- 4.3 Types of stereolithographic printers

3D printing term

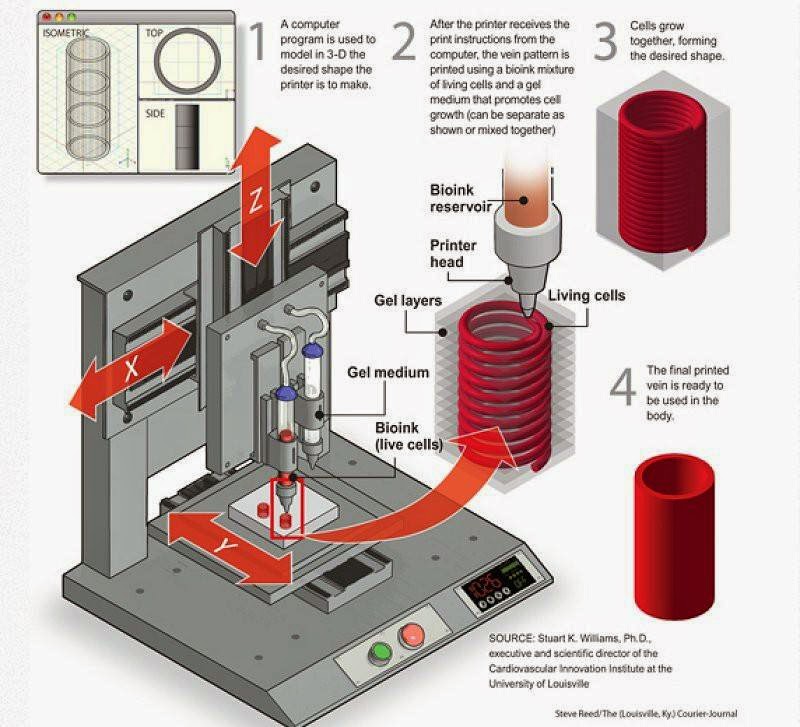

The term 3D printing has several synonyms, one of which quite briefly and accurately characterizes the essence of the process - "additive manufacturing", that is, production by adding material. The term was not coined by chance, because this is the main difference between multiple 3D printing technologies and the usual methods of industrial production, which in turn received the name "subtractive technologies", that is, "subtractive". If during milling, grinding, cutting and other similar procedures, excess material is removed from the workpiece, then in the case of additive manufacturing, material is gradually added until a solid model is obtained.

The term was not coined by chance, because this is the main difference between multiple 3D printing technologies and the usual methods of industrial production, which in turn received the name "subtractive technologies", that is, "subtractive". If during milling, grinding, cutting and other similar procedures, excess material is removed from the workpiece, then in the case of additive manufacturing, material is gradually added until a solid model is obtained.

Soon 3D printing will even be tested on the International Space Station

Strictly speaking, many traditional methods could be classified as "additive" in the broad sense of the word - for example, casting or riveting. However, it should be borne in mind that in these cases, either the consumption of materials is required for the manufacture of specific tools used in the production of specific parts (as in the case of casting), or the whole process is reduced to joining ready-made parts (welding, riveting, etc. ). In order for the technology to be classified as “3D printing”, the final product must be built from raw materials, not blanks, and the formation of objects must be arbitrary - that is, without the use of forms. The latter means that additive manufacturing requires a software component. Roughly speaking, additive manufacturing requires computer control so that the shape of final products can be determined by building digital models. It was this factor that delayed the widespread adoption of 3D printing until the moment when numerical control and 3D design became widely available and highly productive.

). In order for the technology to be classified as “3D printing”, the final product must be built from raw materials, not blanks, and the formation of objects must be arbitrary - that is, without the use of forms. The latter means that additive manufacturing requires a software component. Roughly speaking, additive manufacturing requires computer control so that the shape of final products can be determined by building digital models. It was this factor that delayed the widespread adoption of 3D printing until the moment when numerical control and 3D design became widely available and highly productive.

3D printing techniques

3D printing technologies are numerous, and there are even more names for them due to patent restrictions. However, you can try to divide technologies into main areas:

Extrusion printing

This includes methods such as deposition deposition (FDM) and multi-jet printing (MJM). This method is based on the extrusion (extrusion) of consumables with the sequential formation of the finished product. As a rule, consumables consist of thermoplastics or composite materials based on them.

This method is based on the extrusion (extrusion) of consumables with the sequential formation of the finished product. As a rule, consumables consist of thermoplastics or composite materials based on them.

Melting, sintering or bonding

This approach is based on bonding powdered material together. Formation is done in different ways. The simplest is gluing, as is the case with 3D inkjet printing (3DP). Such printers deposit thin layers of powder onto the build platform, which are then selectively bonded with a binder. Powders can be made up of virtually any material that can be ground to a powder—plastic, wood, metal.

This model of James Bond's Aston Martin was successfully printed on Voxeljet's SLS printer and blown up just as successfully during the filming of Skyfall instead of the expensive original

sintering (SLS and DMLS) and smelting (SLM), which allow you to create all-metal parts. As with 3D inkjet printing, these devices apply thin layers of powder, but the material is not glued together, but sintered or melted using a laser. Laser sintering (SLS) is used to work with both plastic and metal powders, although metal pellets usually have a more fusible shell, and after printing they are additionally sintered in special ovens. DMLS is a variant of SLS installations with more powerful lasers that allow sintering metal powders directly without additives. SLM printers provide not just sintering of particles, but their complete melting, which allows you to create monolithic models that do not suffer from the relative fragility caused by the porosity of the structure. As a rule, printers for working with metal powders are equipped with vacuum working chambers, or they replace air with inert gases. Such a complication of the design is caused by the need to work with metals and alloys subject to oxidation - for example, with titanium.

Laser sintering (SLS) is used to work with both plastic and metal powders, although metal pellets usually have a more fusible shell, and after printing they are additionally sintered in special ovens. DMLS is a variant of SLS installations with more powerful lasers that allow sintering metal powders directly without additives. SLM printers provide not just sintering of particles, but their complete melting, which allows you to create monolithic models that do not suffer from the relative fragility caused by the porosity of the structure. As a rule, printers for working with metal powders are equipped with vacuum working chambers, or they replace air with inert gases. Such a complication of the design is caused by the need to work with metals and alloys subject to oxidation - for example, with titanium.

Stereolithography

How an SLA printer works

Stereolithography printers use special liquid materials called "photopolymer resins". The term "photopolymerization" refers to the ability of a material to harden when exposed to light. As a rule, such materials react to ultraviolet irradiation.

The term "photopolymerization" refers to the ability of a material to harden when exposed to light. As a rule, such materials react to ultraviolet irradiation.

Resin is poured into a special container with a movable platform, which is installed in a position near the surface of the liquid. The layer of resin covering the platform corresponds to one layer of the digital model. Then a thin layer of resin is processed by a laser beam, hardening at the points of contact. At the end of illumination, the platform together with the finished layer is immersed to the thickness of the next layer, and illumination is performed again.

Lamination

Laminating (LOM) 3D printers workflow

Some 3D printers build models using sheet materials - paper, foil, plastic film.

Layers of material are glued on top of each other and cut to the contours of the digital model using a laser or a blade.

These machines are well suited for prototyping and can use very cheap consumables, including regular office paper. However, the complexity and noise of these printers, coupled with the limitations of the models they produce, limit their popularity.

However, the complexity and noise of these printers, coupled with the limitations of the models they produce, limit their popularity.

Fused Deposition Modeling (FDM) and Laser Stereolithography (SLA) are the most popular 3D printing methods used in the home and office.

Let's take a closer look at these technologies.

Fused Deposition Printing (FDM)

FDM is perhaps the simplest and most affordable 3D construction method, which makes it very popular.

High demand for FDM printers is driving device and consumable prices down rapidly, along with technology advances towards ease of use and improved reliability.

Consumables

ABS filament spool and finished model

FDM printers are designed to print with thermoplastics, which are usually supplied as thin filaments wound on spools. The range of "clean" plastics is very wide. One of the most popular materials is polylactide or "PLA plastic". This material is made from corn or sugar cane, which makes it non-toxic and environmentally friendly, but makes it relatively short-lived. ABS plastic, on the other hand, is very durable and wear-resistant, although it is susceptible to direct sunlight and can release small amounts of harmful fumes when heated. Many plastic items that we use on a daily basis are made from this material: housings for household appliances, plumbing fixtures, plastic cards, toys, etc.

This material is made from corn or sugar cane, which makes it non-toxic and environmentally friendly, but makes it relatively short-lived. ABS plastic, on the other hand, is very durable and wear-resistant, although it is susceptible to direct sunlight and can release small amounts of harmful fumes when heated. Many plastic items that we use on a daily basis are made from this material: housings for household appliances, plumbing fixtures, plastic cards, toys, etc.

In addition to PLA and ABS, printing is possible with nylon, polycarbonate, polyethylene and many other thermoplastics that are widely used in modern industry. More exotic materials are also possible, such as polyvinyl alcohol, known as "PVA plastic". This material dissolves in water, which makes it very useful for printing complex geometric patterns. But more on that below.

Model made from Laywoo-D3. Changing the extrusion temperature allows you to achieve different shades and simulate annual rings

It is not necessary to print with homogeneous plastics. It is also possible to use composite materials imitating wood, metals, stone. Such materials use all the same thermoplastics, but with impurities of non-plastic materials.

It is also possible to use composite materials imitating wood, metals, stone. Such materials use all the same thermoplastics, but with impurities of non-plastic materials.

So, Laywoo-D3 consists partly of natural wood dust, which allows you to print "wooden" products, including furniture.

The material called BronzeFill is filled with real bronze, and models made from it can be ground and polished, achieving a high similarity to products made from pure bronze.

One has only to remember that thermoplastics serve as a binding element in composite materials - they determine the thresholds of strength, thermal stability and other physical and chemical properties of finished models.

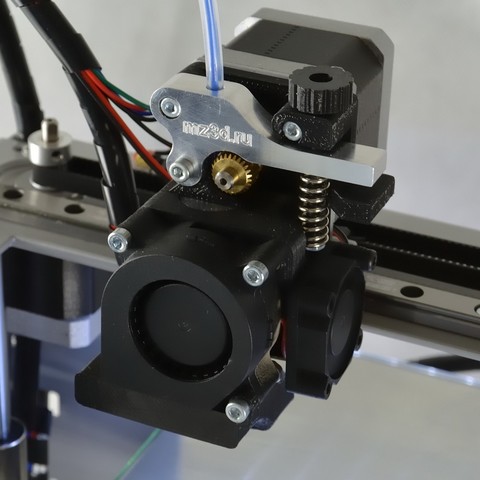

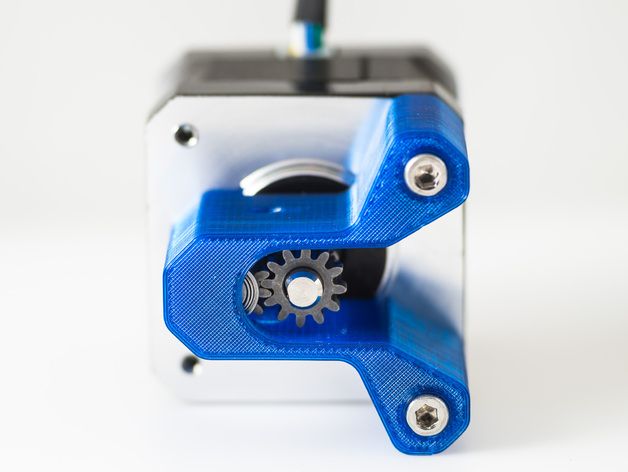

Extruder

Extruder - FDM print head. Strictly speaking, this is not entirely true, because the head consists of several parts, of which only the feed mechanism is directly "extruder". However, by tradition, the term "extruder" is commonly used as a synonym for the entire print assembly.

FDM extruder general design

The extruder is designed for melting and applying thermoplastic thread. The first component is the thread feed mechanism, which consists of rollers and gears driven by an electric motor. The mechanism feeds the thread into a special heated metal tube with a small diameter nozzle, called a "hot end" or simply a "nozzle". The same mechanism is used to remove the thread if a change of material is needed.

The hot end is used to heat and melt the thread fed by the puller. As a rule, nozzles are made from brass or aluminum, although more heat-resistant, but also more expensive materials can be used. For printing with the most popular plastics, a brass nozzle is quite enough. The “nozzle” itself is attached to the end of the tube with a threaded connection and can be replaced with a new one in case of wear or if a change in diameter is necessary. The nozzle diameter determines the thickness of the molten filament and, as a result, affects the print resolution. The heating of the hot end is controlled by a thermistor. Temperature control is very important, because when the material is overheated, pyrolysis can occur, that is, the decomposition of plastic, which contributes both to the loss of the properties of the material itself and to clogging of the nozzle.

The heating of the hot end is controlled by a thermistor. Temperature control is very important, because when the material is overheated, pyrolysis can occur, that is, the decomposition of plastic, which contributes both to the loss of the properties of the material itself and to clogging of the nozzle.

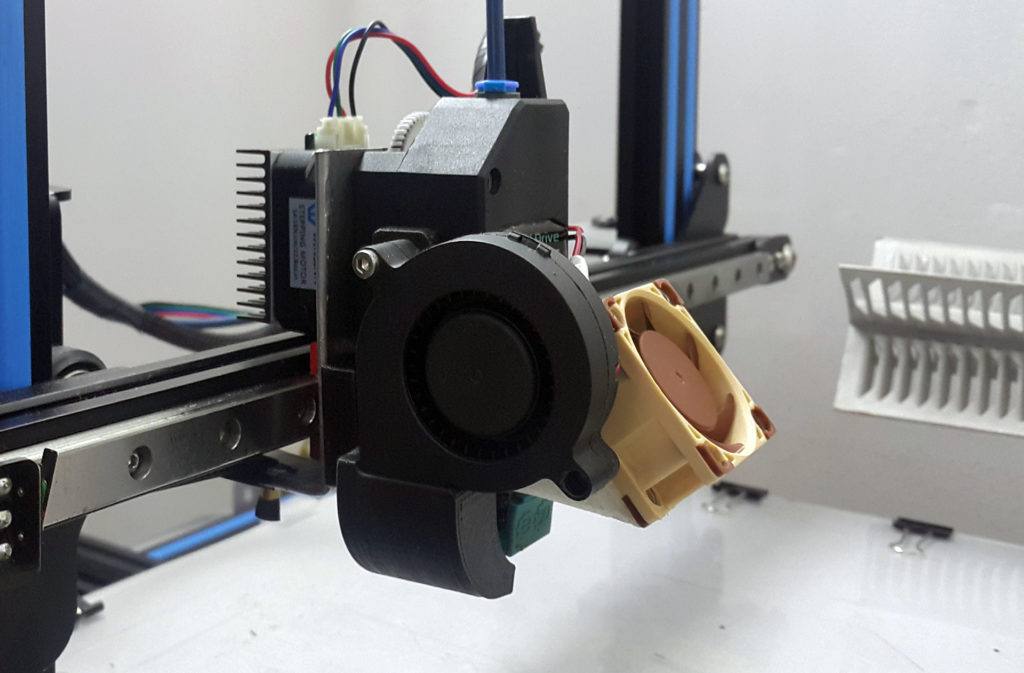

PrintBox3D One FDM Printer Extruder

To prevent the filament from melting too early, the top of the hot end is cooled by heatsinks and fans. This point is of great importance, since thermoplastics that pass the glass transition temperature significantly expand in volume and increase the friction of the material with the walls of the hot end. If the length of such a section is too long, the pulling mechanism may not have enough strength to push the thread.

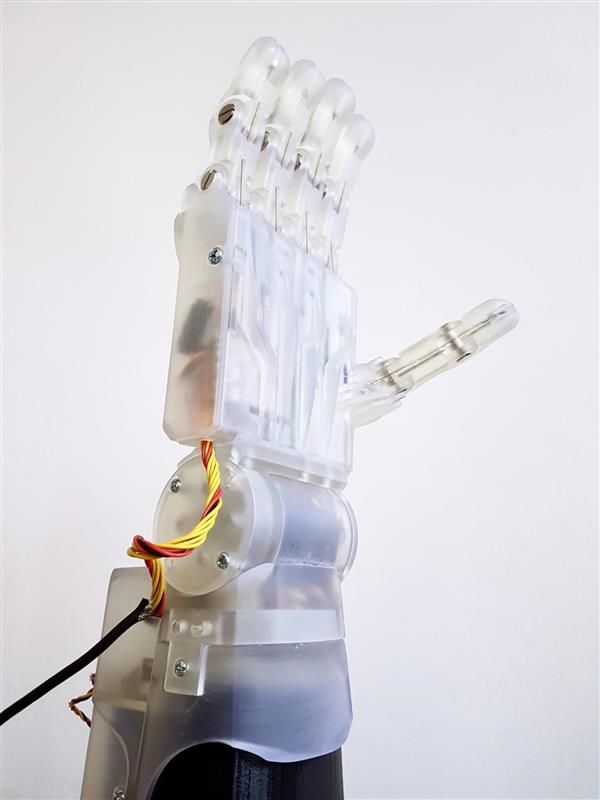

The number of extruders may vary depending on the purpose of the 3D printer. The simplest options use a single print head. The dual extruder greatly expands the capabilities of the device, allowing you to print one model in two different colors, as well as using different materials. The last point is important when building complex models with overhanging structural elements: FDM printers cannot print “over the air”, since the applied layers require support. In the case of hinged elements, temporary support structures have to be printed, which are removed after printing is completed. The removal process is fraught with damage to the model itself and requires accuracy. In addition, if the model has a complex structure with internal cavities that are difficult to access, building conventional supports may not be practical due to the difficulty in removing excess material.

The last point is important when building complex models with overhanging structural elements: FDM printers cannot print “over the air”, since the applied layers require support. In the case of hinged elements, temporary support structures have to be printed, which are removed after printing is completed. The removal process is fraught with damage to the model itself and requires accuracy. In addition, if the model has a complex structure with internal cavities that are difficult to access, building conventional supports may not be practical due to the difficulty in removing excess material.

Finished model with PVA supports (white) before and after washing

In such cases, the same water-soluble polyvinyl alcohol (PVA) comes in handy. Using a dual extruder, you can build a model from waterproof thermoplastic using PVA to create supports.

After printing, PVA can be simply dissolved in water and a complex product of perfect quality can be obtained.

Some FDM printers can use three or even four extruders.

Working platform

Heated platform covered with removable glass work table

Models are built on a special platform, often equipped with heating elements. Preheating is required for a wide range of plastics, including the popular ABS, which are subject to a high degree of shrinkage when cooled. The rapid loss of volume by cold coats compared to freshly applied material can lead to model distortion or delamination. The heating of the platform makes it possible to significantly equalize the temperature gradient between the upper and lower layers.

Heating is not recommended for some materials. A typical example is PLA plastic, which requires a fairly long time to harden. Heating PLA can lead to deformation of the lower layers under the weight of the upper ones. When working with PLA, measures are usually taken not to heat up, but to cool the model. Such printers have characteristic open cases and additional fans blowing fresh layers of the model.

Such printers have characteristic open cases and additional fans blowing fresh layers of the model.

Calibration screw for work platform covered with blue masking tape

The platform needs to be calibrated before printing to ensure that the nozzle does not hit the applied layers and move too far causing air-to-air printing resulting in plastic vermicelli. The calibration process can be either manual or automatic. In manual mode, calibration is performed by positioning the nozzle at different points on the platform and adjusting the platform inclination using the support screws to achieve the optimal distance between the surface and the nozzle.

As a rule, platforms are equipped with an additional element - a removable table. This design simplifies the cleaning of the working surface and facilitates the removal of the finished model. Stages are made from various materials, including aluminum, acrylic, glass, etc. The choice of material for the manufacture of the stage depends on the presence of heating and consumables for which the printer is optimized.

For a better adhesion of the first layer of the model to the surface of the table, additional tools are often used, including polyimide film, glue and even hairspray! But the most popular tool is inexpensive, but effective masking tape. Some manufacturers make perforated tables that hold the model well but are difficult to clean. In general, the expediency of applying additional funds to the table depends on the consumable material and the material of the table itself.

Positioning mechanisms

Scheme of operation of positioning mechanisms

Of course, the print head must move relative to the working platform, and unlike conventional office printers, positioning must be carried out not in two, but in three planes, including height adjustment.

Positioning pattern may vary. The simplest and most common option involves mounting the print head on perpendicular guides driven by stepper motors and providing positioning along the X and Y axes.

Vertical positioning is carried out by moving the working platform.

On the other hand, it is possible to move the extruder in one plane and the platforms in two.

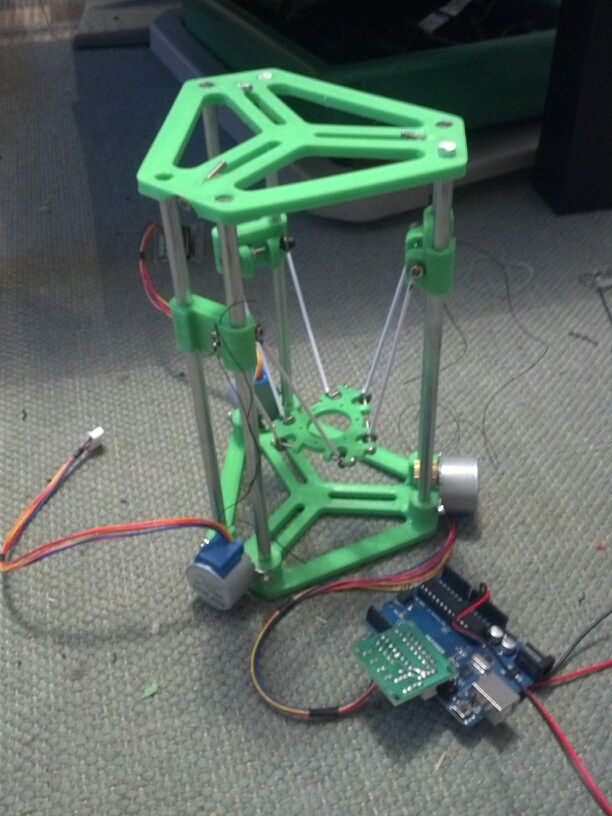

SeemeCNC ORION Delta Printer

One option that is gaining popularity is the delta coordinate system.

Such devices are called "delta robots" in the industry.

In delta printers, the print head is suspended on three manipulators, each of which moves along a vertical rail.

The synchronous symmetrical movement of the manipulators allows you to change the height of the extruder above the platform, and the asymmetric movement causes the head to move in the horizontal plane.

A variant of this system is the reverse delta design, where the extruder is fixed to the ceiling of the working chamber, and the platform moves on three support arms.

Delta printers have a cylindrical build area, and their design makes it easy to increase the height of the working area with minimal design changes by extending the rails.

In the end, everything depends on the decision of the designers, but the fundamental principle does not change.

Control

Typical Arduino-based controller with add-on modules

The operation of the FDM printer, including nozzle and platform temperature, filament feed rate, and stepper motors for positioning the extruder, is controlled by fairly simple electronic controllers. Most controllers are based on the Arduino platform, which has an open architecture.

The programming language used by the printers is called G-code (G-Code) and consists of a list of commands executed in turn by the 3D printer systems. G-code is compiled by programs called "slicers" - standard 3D printer software that combines some of the features of graphics editors with the ability to set print options through a graphical interface. The choice of slicer depends on the printer model. RepRap printers use open source slicers such as Skeinforge, Replicator G and Repetier-Host. Some companies make printers that require proprietary software.

Some companies make printers that require proprietary software.

Program code for printing is generated using slicers

As an example, we can mention Cube printers from 3D Systems. There are companies that offer proprietary software but allow third-party software, as is the case with the latest generation of MakerBot 3D printers.

Slicers are not intended for 3D design per se. This task is done with CAD editors and requires some 3D design skills. Although beginners should not despair: digital models of a wide variety of designs are offered on many sites, often even for free. Finally, some companies and individuals offer 3D design services for custom printing.

Finally, 3D printers can be used in conjunction with 3D scanners to automate the process of digitizing objects. Many of these devices are designed specifically to work with 3D printers. Notable examples include the 3D Systems Sense handheld scanner and the MakerBot Digitizer handheld desktop scanner.

MakerBot Replicator 5th Generation FDM Printer with built-in control module on the top of the frame

The user interface of a 3D printer can consist of a simple USB port for connecting to a personal computer. In such cases, the device is actually controlled by the slicer.

The disadvantage of this simplification is a rather high probability of printing failure when the computer freezes or slows down.

A more advanced option includes an internal memory or memory card interface to make the process standalone.

These models are equipped with control modules that allow you to adjust many print parameters (such as print speed or extrusion temperature). The module may include a small LCD display or even a mini-tablet.

Varieties of FDM printers

Professional Stratasys Fortus 360mc FDM printer that allows printing with nylon

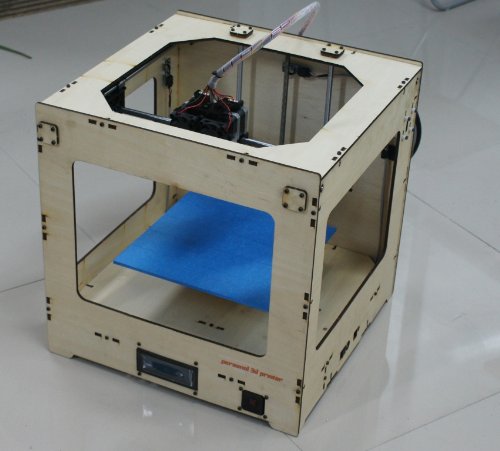

FDM printers are very, very diverse, ranging from the simplest homemade RepRap printers to industrial installations capable of printing large-sized objects.

Stratasys, founded by Scott Crump, the inventor of FDM technology, is a leader in the production of industrial installations.

You can build the simplest FDM printers yourself. Such devices are called RepRap, where "Rep" indicates the possibility of "replication", that is, self-reproduction.

RepRap printers can be used to print custom built plastic parts.

Controller, rails, belts, motors and other components can be easily purchased separately.

Of course, assembling such a device on your own requires serious technical and even engineering skills.

Some manufacturers make it easy by selling DIY kits, but these kits still require a good understanding of the technology. RepRap Printers

And, despite their "homemade nature", RepRap printers are quite capable of producing models with quality at the level of expensive branded counterparts.

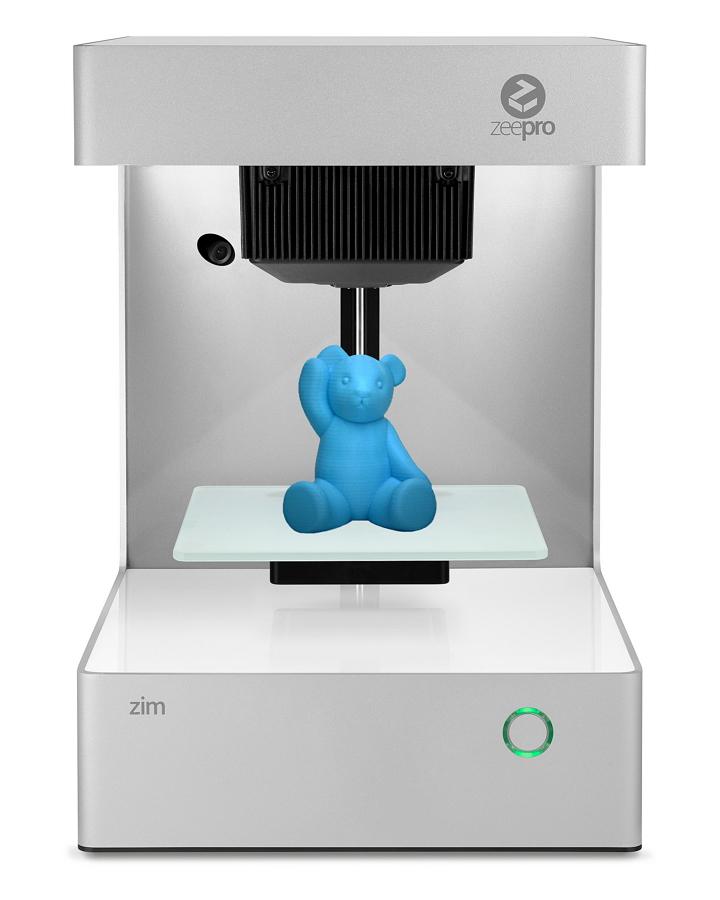

Ordinary users who do not want to delve into the intricacies of the process, but require only a convenient device for household use, can purchase a ready-made FDM printer.

Many companies are focusing on the development of the consumer market segment, offering 3D printers for sale that are ready to print “right out of the box” and do not require serious computer skills.

3D Systems Cube consumer 3D printer

The most famous example of a consumer 3D printer is the 3D Systems Cube.

While it doesn't boast a huge build area, ultra-fast print speeds, or superb build quality, it's easy to use, affordable, and safe: This printer has received the necessary certification to be used even by children.

Mankati FDM printer demonstration: http://youtu.be/51rypJIK4y0

Laser Stereolithography (SLA)

Stereolithographic 3D printers are widely used in dental prosthetics

Stereolithographic printers are the second most popular and widespread after FDM printers.

These units deliver exceptional print quality.

The resolution of some SLA printers is measured in a matter of microns - it is not surprising that these devices quickly won the love of jewelers and dentists.

The software side of laser stereolithography is almost identical to FDM printing, so we will not repeat ourselves and will only touch on the distinctive features of the technology.

Lasers and projectors

Projector illumination of a photopolymer model using Kudo3D Titan DLP printer as an example

The cost of stereolithography printers is rapidly declining due to growing competition due to high demand and the use of new technologies that reduce the cost of construction.

Although the technology is generically referred to as "laser" stereolithography, most recent developments use UV LED projectors for the most part.

Projectors are cheaper and more reliable than lasers, do not require the use of delicate mirrors to deflect the laser beam, and have higher performance. The latter is explained by the fact that the contour of the whole layer is illuminated as a whole, and not sequentially, point by point, as is the case with laser options. This variant of the technology is called projection stereolithography, "DLP-SLA" or simply "DLP". However, both options are currently common - both laser and projector versions.

This variant of the technology is called projection stereolithography, "DLP-SLA" or simply "DLP". However, both options are currently common - both laser and projector versions.

Cuvette and resin

Photopolymer resin is poured into a cuvette

A photopolymer resin that looks like epoxy is used as consumables for stereolithographic printers. Resins can have a variety of characteristics, but they all share one key feature for 3D printing applications: these materials harden when exposed to ultraviolet light. Hence, in fact, the name "photopolymer".

When polymerized, resins can have a wide variety of physical characteristics. Some resins are like rubber, others are hard plastics like ABS. You can choose different colors and degrees of transparency. The main disadvantage of resins and SLA printing in general is the cost of consumables, which significantly exceeds the cost of thermoplastics.

On the other hand, stereolithography printers are mainly used by jewelers and dentists who do not need to build large parts but appreciate the savings from fast and accurate prototyping. Thus, SLA printers and consumables pay for themselves very quickly.

Thus, SLA printers and consumables pay for themselves very quickly.

Example of a model printed on a laser stereolithographic 3D printer

Resin is poured into a cuvette, which can be equipped with a lowering platform. In this case, the printer uses a leveling device to flatten the thin layer of resin covering the platform just prior to irradiation. As the model is being made, the platform, together with the finished layers, is “embedded” in the resin. Upon completion of printing, the model is removed from the cuvette, treated with a special solution to remove liquid resin residues and placed in an ultraviolet oven, where the final illumination of the model is performed.

Some SLA and DLP printers work in an "inverted" scheme: the model is not immersed in the consumable, but "pulled" out of it, while the laser or projector is placed under the cuvette, and not above it. This approach eliminates the need to level the surface after each exposure, but requires the use of a cuvette made of a material transparent to ultraviolet light, such as quartz glass.

The accuracy of stereolithographic printers is extremely high. For comparison, the standard for vertical resolution for FDM printers is considered to be 100 microns, and some variants of SLA printers allow you to apply layers as thin as 15 microns. But this is not the limit. The problem, rather, is not so much in the accuracy of lasers, but in the speed of the process: the higher the resolution, the lower the print speed. The use of digital projectors allows you to significantly speed up the process, because each layer is illuminated entirely. As a result, some DLP printer manufacturers claim to be able to print with a vertical resolution of one micron!

Video from CES 2013 showing Formlabs Form1 stereolithography 3D printer in action: http://youtu.be/IjaUasw64VE

Stereolithography Printer Options

Formlabs Form1 Desktop Stereolithography Printer