3D printed semi automatic gun

The 3D-printed semi-automatic rifle is now a reality.

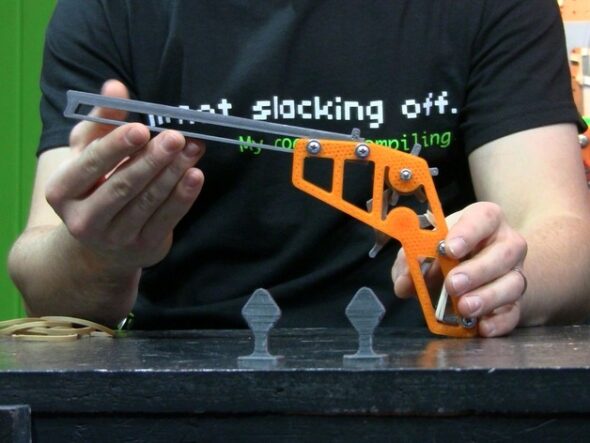

The FGC-9 is a 100 percent homemade semi-automatic rifle. CTRLPew/YouTubeOn Jan. 1, Chase Tkach—chair of the Orleans County, New York, Libertarian Party, also known as porn actor Molly Smash—uploaded two fast-flashing, dubstep-tuned theatrical trailers to their Pornhub channel. The videos were promoting cheap, untraceable, 3D-printed, plastic, DIY, semi-automatic guns. That’s because Tkach likes guns, specifically unregulated ones. And homemade guns are so hot right now.

People have been making 3D-printed guns at home since 2013. They used to be pretty low-tech, capable of one shot before busting. But they’ve come a long way in the past few years. Now you can print untraceable AR-15s, AKMs, semi-automatic pistols, and more—no serial number, no registration, no background check. Up until recently, however, the best you could do with a semi-automatic rifle like the AR-15 was 3D-print the lower receiver (the core part that’s regulated as a firearm). Users still had to buy real magazines, triggers, and barrels to complete the kit and build a working gun. That’s easy to do if you live in America, where most people can purchase gun parts (minus the receiver) online. But it’s a problem if you live in a country with strict gun control like Germany, where most people can’t easily purchase the necessary parts.

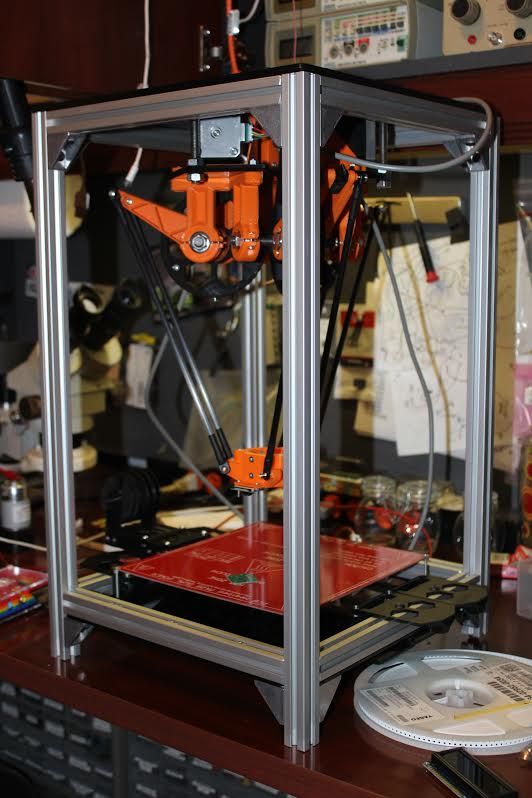

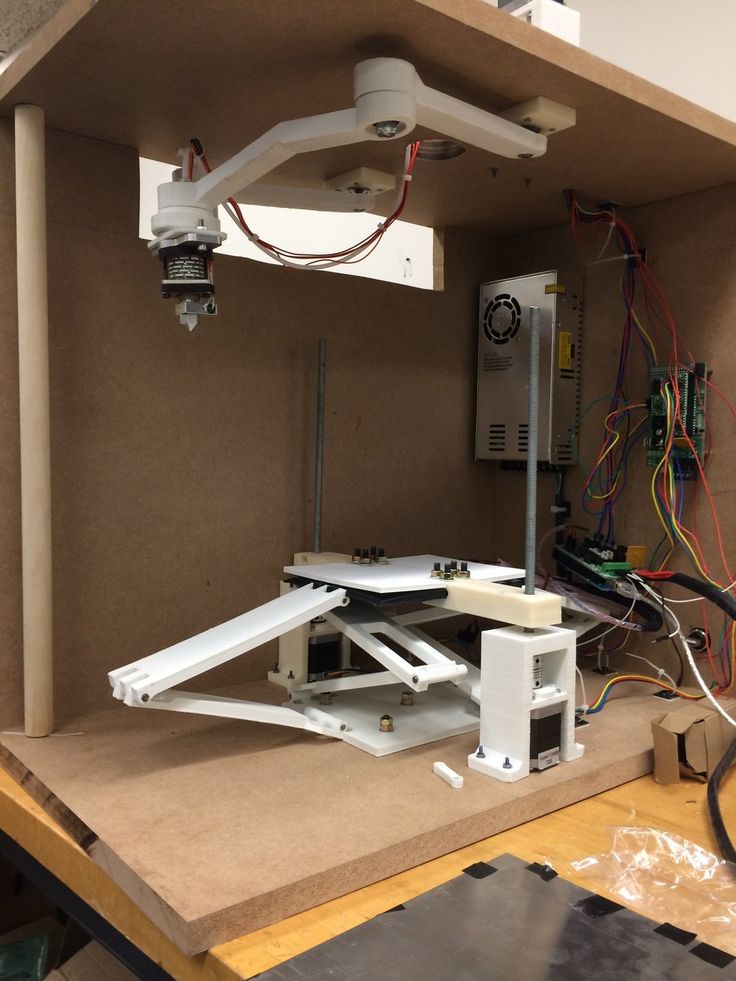

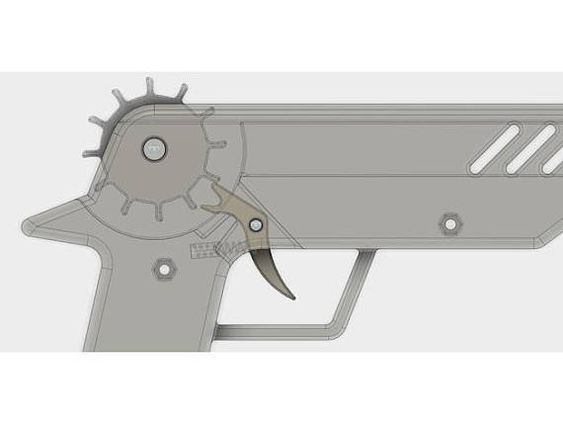

All that changed in March, when 3D-printing and firearm enthusiasts publicly released the design for a 100 percent homemade semi-automatic rifle that not only shoots 9 mm ammo exceptionally well but is durable enough to withstand thousands of rounds. They called it the FGC-9, which stands for “fuck gun control 9 mm. ” Most of the gun is 3D-printed, while the rest includes inconspicuous parts available at hardware stores. The files include detailed instructions to help anyone—even if they don’t have technical knowledge—build their own. They explain which 3D printer to buy, how to cast DIY ammo at home, and how to modify a metal tube in your bedroom to turn it into a gun barrel. The metal means the gun can’t sneak past metal detectors, but it also means there are no consequences for owning one in the U.S. 3D-printed guns are legal, as long as they can be picked up by a metal detector.

” Most of the gun is 3D-printed, while the rest includes inconspicuous parts available at hardware stores. The files include detailed instructions to help anyone—even if they don’t have technical knowledge—build their own. They explain which 3D printer to buy, how to cast DIY ammo at home, and how to modify a metal tube in your bedroom to turn it into a gun barrel. The metal means the gun can’t sneak past metal detectors, but it also means there are no consequences for owning one in the U.S. 3D-printed guns are legal, as long as they can be picked up by a metal detector.

If you already have a 3D printer (the recommended one is about $250) and basic hand tools, it costs about $100 for the rest of the tools to build the barrel, then about $100 in supplies for each gun after that. For reference, a Smith & Wesson M&P15 Sport (a popular midtier AR-15-style rifle) starts at about $750 off the shelf. A technically inclined builder could make an FGC-9 in less than a week. Someone with no experience could possibly learn everything they need and build it in a couple of weeks.

A technically inclined builder could make an FGC-9 in less than a week. Someone with no experience could possibly learn everything they need and build it in a couple of weeks.

The videos Tkach uploaded to Pornhub were cut by Alex Holladay, who has been producing content for Deterrence Dispensed, a big group chat administered by a few design collaborators including the designers of the FGC-9—an anonymous European who goes by JStark or Jacob and an American using the moniker Ivan the Troll. Jacob was the driving force behind the development of the FGC-9 and was featured in British journalist Jake Hanrahan’s short documentary Plastic Defence. Ivan, who designed the barrel and magazine for the FGC-9, is sometimes called the spokesperson of Deterrence Dispensed and has been interviewed about his gun designs in Wired and the New Republic. They are active figures in the user-made firearm subreddit, though not without pushback from the platform: Ivan has been suspended from Reddit several times and says he has lost count of how many profiles he has gone through, though he thinks it’s more than 10. He was also suspended from Twitter in 2019 after Sen. Robert Menendez of New Jersey, an opponent of the free distribution of 3D-printable-gun blueprints, wrote a letter to Twitter urging the platform to ban Ivan. He has since returned under a new handle.

He was also suspended from Twitter in 2019 after Sen. Robert Menendez of New Jersey, an opponent of the free distribution of 3D-printable-gun blueprints, wrote a letter to Twitter urging the platform to ban Ivan. He has since returned under a new handle.

I was able to verify Ivan’s actual identity and reach him for a phone call. He did not want his real name used because he says he has received death threats on social media and doesn’t want those reaching his family, so I will continue to refer to him by the pseudonym Ivan.

He’s 23 years old, graduated from college in 2020 with a degree in computer science, and lives with his parents in Southern Illinois. From the front, their house looks like any unassuming gray suburban home. Out back, his family has about 50 acres of fields and woods, where Ivan has a shooting range; inside, he has an entire room dedicated to designing and printing guns. He grew up in a gun-friendly Midwestern family and was introduced to 3D printing in a high school class.

He grew up in a gun-friendly Midwestern family and was introduced to 3D printing in a high school class.

He didn’t have gunsmithing in mind when he bought his first printer. He drives a 30-year-old car and wanted to make plastic parts to spruce up the interior trim. The gun printing started a few years later, when he read online about people printing AR-15 lower receivers. It took him about five tries to get one to turn out right, and it lasted him more than 2,000 rounds. That inspired him to pursue 3D-printable-gun development to push the technology forward. He jumped into what he calls the “social media boom” of 2018, by which he means 2018 was the year 3D-printed guns broke out of niche circles and grew a sizable following online. It was when the infamous 3D-printed gun designer and now registered sex offender Cody Wilson of Defense Distributed (to which the name Deterrence Dispensed is a cheeky tribute) settled his lawsuit against the U. S. government affirming arguments that 3D-printable-gun files could be sharable as free speech without regulation.

S. government affirming arguments that 3D-printable-gun files could be sharable as free speech without regulation.

Ivan says his first time communicating with Jacob was on Reddit and Twitter, where they ran in the same crowds of homemade gun designers. Jacob recruited Ivan to teach him computer-aided drafting software so he could design what would ultimately become the FGC-9. Since then, they’ve worked together on a few builds, but Ivan says they still don’t know each other’s real identities.

Up until mid-January, Deterrence Dispensed operated on the encrypted chat platform Keybase—recently acquired by Zoom—where it grew to almost 27,000 members, though Ivan says only a few thousand were actively participating. At the beginning of the year, Keybase informed Ivan that the group would be shut down. In an email to me, a Keybase spokesperson said Keybase’s Acceptable Use Policy was updated following Zoom’s acquisition, and the company determined Deterrence Dispensed was no longer in compliance. The policy prohibits content involving weapons and instructions on making weapons. On Jan. 20, the Keybase group was locked, and Deterrence Dispensed moved to a new self-hosted chat platform. But Ivan says they were prepared for the move—they knew that Keybase was changing its policy—most of the active users have joined the new chat, and participation is continuing uninhibited.

In an email to me, a Keybase spokesperson said Keybase’s Acceptable Use Policy was updated following Zoom’s acquisition, and the company determined Deterrence Dispensed was no longer in compliance. The policy prohibits content involving weapons and instructions on making weapons. On Jan. 20, the Keybase group was locked, and Deterrence Dispensed moved to a new self-hosted chat platform. But Ivan says they were prepared for the move—they knew that Keybase was changing its policy—most of the active users have joined the new chat, and participation is continuing uninhibited.

The goal of the chat is to build a collaborative community of designers and enthusiasts not only to advance home gunsmithing methods but also to get these guns into the hands of anyone who wants one. Ivan says the goal isn’t to make sure everyone has a gun but rather to make sure everyone has the technical capability to decide to have a gun. He is a proponent of gun freedom and believes citizens should have arms to defend and fight against tyranny. Ivan says the group has a romantic fantasy that their designs will reach oppressed groups, like Uighurs, who are facing genocide in China. But the designs are also favored by far-right extremists in the U.S., including those in the Boogaloo movement, who may want untraceable firearms to evade law enforcement, according to Wired.

He is a proponent of gun freedom and believes citizens should have arms to defend and fight against tyranny. Ivan says the group has a romantic fantasy that their designs will reach oppressed groups, like Uighurs, who are facing genocide in China. But the designs are also favored by far-right extremists in the U.S., including those in the Boogaloo movement, who may want untraceable firearms to evade law enforcement, according to Wired.

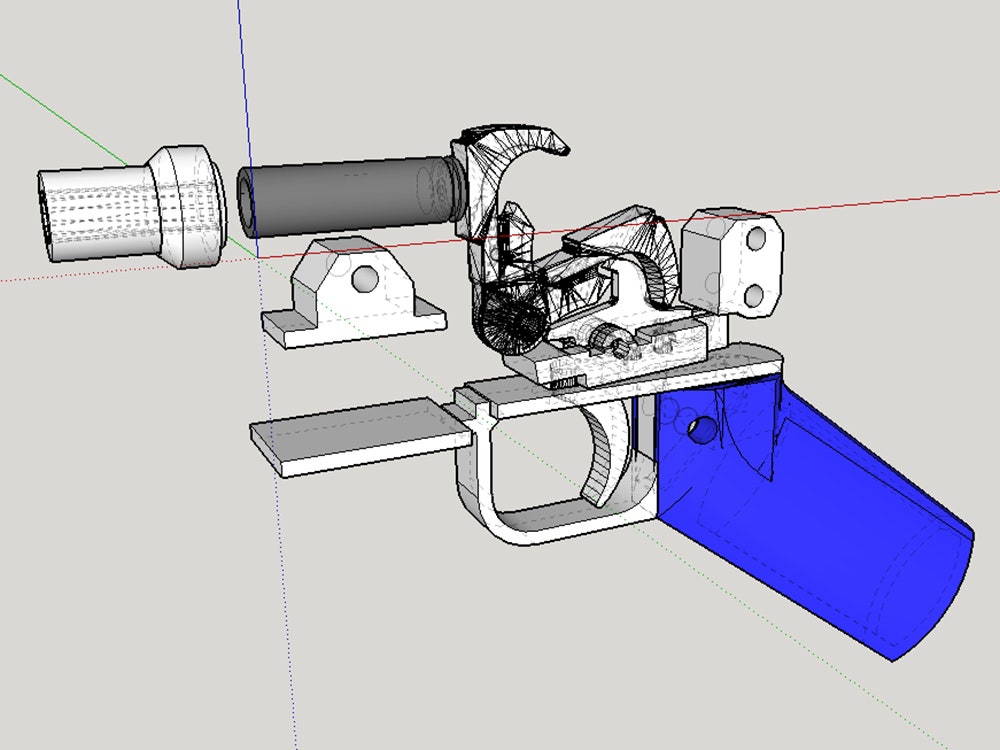

The release of the FGC-9, a major milestone for the Deterrence Dispensed coalition, was an improvement on a model called the AP-9 by an anonymous designer who goes by Derwood. The AP-9 uses a Glock barrel and magazine. But Ivan built a 3D-printed version of the magazine that uses a coiled metal spring. And he designed a homemade barrel by carving spiral grooves—the rifling that makes the bullet spin—inside a metal tube using electrochemical machining, which may sound complicated, but it’s a relatively simple DIY solution to etch steel using saltwater, electricity, and copper wire twisted around a 3D-printed mandrel. Deterrence Dispensed has a full tutorial (which I am not going to link to). The hardware has been converted to metric, to make it buildable outside the U.S.

Deterrence Dispensed has a full tutorial (which I am not going to link to). The hardware has been converted to metric, to make it buildable outside the U.S.

Ivan tells me the FGC-9 is the easiest, cheapest, most accessible, and reliable semi-automatic DIY firearm that he is aware of. It shows that it’s possible to build highly effective semi-automatic rifles with common tools. It certainly takes more work than going to Cabela’s to buy a gun in the U.S., but it’s easy enough that anyone who wants a gun and has the motivation to learn can build one at home while thousands of people online guide them through the process. It’s hard to imagine stopping it, short of banning 3D printers or metal pipes. Even regulating the distribution of the designs wouldn’t do much. The designs are distributed using a blockchain, so there’s no central server to take down. And the FGC-9 designs have already been viewed more than 44,000 times just on the original site they were uploaded to—they have been replicated elsewhere, for who knows how many people.

And the FGC-9 designs have already been viewed more than 44,000 times just on the original site they were uploaded to—they have been replicated elsewhere, for who knows how many people.

It’s a volatile time for gun owners in America. On Feb. 14, the third anniversary of the Parkland school shooting, President Joe Biden called on Congress to pass stricter gun control, including a ban on assault weapons. The future of firearms in the U.S. may be one where assault weapons can only be obtained by purchasing them on the black market or building them at home. The latter is now a viable option.

- My Son Will Never Have Several of His Adult Teeth. Here’s the Most Frustrating Part.

- I Helped Pioneer Weird Twitter. I Have a Plan for Elon Musk.

- Twitter May Be Poised to Become a Hellscape Just in Time for the Midterms

- The Case That Elon Musk Knows Exactly What He’s Doing at Twitter

There’s an ethical question that comes up in writing this story—whether I’m giving Deterrence Dispensed a platform, potentially leading more people to a dangerous movement. But Ivan and his team already have a huge platform, making critical coverage ever more important. The hype is spreading, and not just on Pornhub and Reddit. The FGC-9 has been discussed on neo-Nazi forums on the dark web. Deterrence Dispensed has been featured in gun podcasts. And users on TikTok are teaching one another how to build rifles at home with some videos reaching millions of views. It’s happening, whether or not journalists like me cover it—and because it’s happening, people need to know about it.

“There is no sign of things stopping. Projects are only getting more ambitious,” Ivan says. The group is currently working on a second-generation FGC-9. Ivan says it will make the barrel and bolt manufacturing easier, and improves the ergonomics and appearance of the gun. It’s close to ready, they just need to finish documentation and a few minor details. They expect to release the designs to the public in the next few months.

Ivan says it will make the barrel and bolt manufacturing easier, and improves the ergonomics and appearance of the gun. It’s close to ready, they just need to finish documentation and a few minor details. They expect to release the designs to the public in the next few months.

Future Tense is a partnership of Slate, New America, and Arizona State University that examines emerging technologies, public policy, and society.

- Crime

- Gun Control

- Guns

Teenager With Fully-Functional 3D Printed Gun Arrested in Australia

3D printing news News Australian Police Arrested a Teenager With a Fully Functioning 3D Printed Gun

Published on June 14, 2022 by Clemens M.

During the house raid of an 18-year-old suspect in Western Australia, Police officers from the Drug and Firearm Squad secured a number of illegal firearms, including a 3D printed semi-automatic gun. The 4kg gun is able to fire 15 lethal 9mm rounds and is considered to be fully-functional. The inclusion of select metal parts have enabled this, as often 3D printed guns fall apart quickly after use due to the use of polymers.

Only recently, the European Police Office (Europol), expressed concerns about the increasing amount of 3D printed weapons that have been seized in Europe over the last few years, resulting in a conference held in Den Haag, the Netherlands, at which professionals and experts discussed the problem. Now, after the United States and Europe have already been forced to deal with the increasing danger, it seems like the threat of 3D-printed firearms has found its way down under.

The deadly weapon looks like a plastic toy (photo credits: PerthNow)

According to various Australian news outlets, the Australian Police executed a search warrant on the 3rd of June in Bayside, Western Australia, the officers were surprised to find a fully functional, semi-automatic firearm, allegedly produced in a suburban home. The gun, which has the appearance of a regular harmless plastic toy, turned out to be a dangerous assault weapon with the ability to shoot 9mm caliber rounds, the same caliber used by the armed police. “It’s deeply concerning that this man was able to manufacture this firearm at home with a 3D printer and readily available materials” Detective Senior Sgt. Blair Smith said in a statement. “That is a semi-automatic 9mm assault rifle in essence.”

The gun, which has the appearance of a regular harmless plastic toy, turned out to be a dangerous assault weapon with the ability to shoot 9mm caliber rounds, the same caliber used by the armed police. “It’s deeply concerning that this man was able to manufacture this firearm at home with a 3D printer and readily available materials” Detective Senior Sgt. Blair Smith said in a statement. “That is a semi-automatic 9mm assault rifle in essence.”

Australia’s Tough Gun Laws

Although the police had found similar 3D printed gun parts in the past, the firearm found in Bayside is the first fully functioning gun of its kind, made from easily available materials. Besides the 3D-printed body of the weapon, the gun featured a 3D-printed magazine as well. For the trigger and mechanical parts of the gun, metal parts were added.

Australia has a very strict policy when it comes to the illegal possession and use of fire weapons. In November last year, the Government of Western Australia proposed a strict update of its gun laws. In an attempt to prevent the possible threat of an increasing number of 3D printed firearms, the newly proposed amendments included making the illegal manufacturing of plastic 3D firearms a serious felony, which may result in prison sentences up to 14 years and fines of up to $75,000.

In an attempt to prevent the possible threat of an increasing number of 3D printed firearms, the newly proposed amendments included making the illegal manufacturing of plastic 3D firearms a serious felony, which may result in prison sentences up to 14 years and fines of up to $75,000.

Detective Senior Sgt. Blair Smith and the 3D printed gun (photo credits: WA Police)

The exact details of how the firearm was constructed and which technologies were used are yet unknown and haven’t been revealed by the Police, as well as any further information about the alleged manufacturer of the gun. Given its appearance, it is highly likely that the manufacturer used a regular desktop 3D printer and acquired the models for the gun on the internet, as it had been in similar cases around the world. As a result of the discovery of the 3D-printed semi-automatic, the Australian police now even launched a special task force that targets people who try to manufacture firearms at home.

The 18-year-old alleged gun manufacturer has been charged with several offenses, including the unlicensed manufacturing and possession of a prohibited weapon, and is facing time in jail. After noting that this is the first time that a fully operational 3D printed firearm had been seen in Western Australia, Det-Sen Sgt Smith concluded, “These types of firearms are unregulated, unlicensed and have no place in our community. Our team or the drug and firearms squad will remain relentless in identifying these people using all available data to us locating them and you will be prosecuted with serious firearm offences.”

After noting that this is the first time that a fully operational 3D printed firearm had been seen in Western Australia, Det-Sen Sgt Smith concluded, “These types of firearms are unregulated, unlicensed and have no place in our community. Our team or the drug and firearms squad will remain relentless in identifying these people using all available data to us locating them and you will be prosecuted with serious firearm offences.”

What do you think of the police’s discovery of this fully functional 3D printed gun in Australia? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

is it possible to print pneumatic and firearms

Is it possible to make a gun on a 3D printer and is it legal?

Today's 3D printers offer enormous possibilities. They can print products of almost any complexity. Until quite recently, it was difficult to even imagine that a plastic weapon could shoot. However, it is already possible to make a pistol on a 3D printer, which, although not reliable, fires live ammunition.

They can print products of almost any complexity. Until quite recently, it was difficult to even imagine that a plastic weapon could shoot. However, it is already possible to make a pistol on a 3D printer, which, although not reliable, fires live ammunition.

Can firearms be 3D printed?

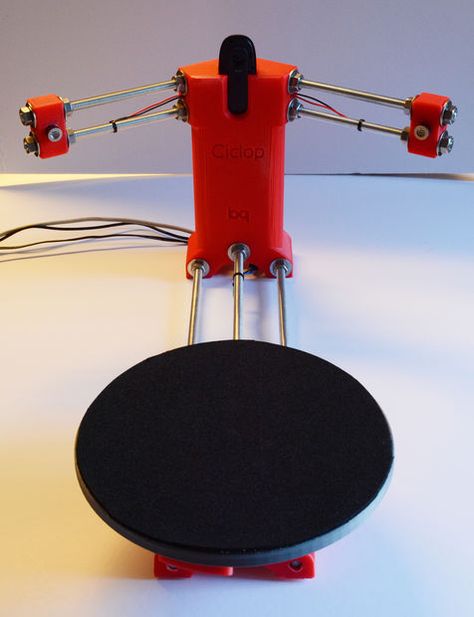

Back in 2013, a young American gun fighter proved that plastic guns could be 3D printed. He was the first in the world to make a pistol in this way, in which only the striker was made separately from metal. All other parts were printed on an FDM printer.

Today's 3D printers are capable of printing any CAD model, and these models of firearms have been available for over 10 years. If in previous years their printing required professional skills, now almost any user can master them. With a 3D printer and a finished model, it became quite possible to print a gun. Another thing is that such "creativity" is punishable by the laws of most countries.

The evolution of 3D printed weapons

Despite all the prohibitions and restrictions, the evolution of 3D printed firearms is moving at a great speed. The beginning was laid by the single-shot plastic pistol Liberator by American K. Wilson, which appeared in 2013. It had a simple design and was chambered for 380 ACP. Already after 10-12 shots, this weapon became unusable. However, the very possibility of printing firearms served as an impetus for the development of the idea. The author of the first pistol himself founded the Defense Distributed company, which began to actively improve the technology.

The beginning was laid by the single-shot plastic pistol Liberator by American K. Wilson, which appeared in 2013. It had a simple design and was chambered for 380 ACP. Already after 10-12 shots, this weapon became unusable. However, the very possibility of printing firearms served as an impetus for the development of the idea. The author of the first pistol himself founded the Defense Distributed company, which began to actively improve the technology.

One of the ways to increase the durability of weapons was to increase the number of their barrels. At the beginning of 2014, the Japanese Y. Imura makes a 38 caliber Zig Zag pistol. He was able to fire up to 6 shots non-stop. The author of the weapon was recognized as a criminal and convicted.

The next step was the production of a six-shot revolver by J. Patrick in 2015. The PM522 Washbear has been shown in action on YouTube. The weapon was noticeably safer for the shooter compared to previous versions, but still allowed to fire only a few dozen rounds.

The first semi-automatic pistol for a 9 mm bullet appeared in 2016 under the name Shuty-MP1. It was developed by a handicraft gunsmith who hid under the pseudonym Derwood. It wasn't exactly a plastic weapon. The author used some metal parts from factory pistols - a barrel, a firing pin, a bolt and several springs. This made it possible to ensure a rate of fire of more than 46 rounds / min. However, when changing the store, the plastic case had to be cooled. In 2017, the same master proposed an improved model - Shuty AP-9.

The main contribution to the development of 3D printed weapons technology was made by Defense Distributed, which united a group of like-minded activists. First, these enthusiasts won legal proceedings in the United States and obtained permission to 3D-print weapons, which greatly expanded their capabilities. Secondly, they were able to set up a professional business with product testing and quality control. As a result, in 2018–19 they developed numerous models of a variety of firearms - from pistols to carbines. They posted over 30 files for printing original gun parts. Most of them were plastic, and the metal parts were not made from purchased, ready-made elements, but from simple metal profiles (tubes, strips, etc.), which are sold in ordinary hardware stores. This made it possible to exclude the use of parts patented by gunsmiths.

They posted over 30 files for printing original gun parts. Most of them were plastic, and the metal parts were not made from purchased, ready-made elements, but from simple metal profiles (tubes, strips, etc.), which are sold in ordinary hardware stores. This made it possible to exclude the use of parts patented by gunsmiths.

At the moment, the semi-automatic carbine FGC-9, developed on the basis of the Shuty AP-9, has become the pinnacle of "creativity" of Defense Distributed. At the same time, there is not a single factory part in it. The barrel for the 9 mm cartridge is made of steel pipe using electrochemical processing.

Where can I get drawings and what should I look for?

Gun manufacturing bans make it much harder to get blueprints and models of guns for 3D printing. The right to free placement of information was achieved only by Defense Distributed. Their website provides free access to drawings, models and technologies. Other information can be found on the Internet, but they are usually illegal.

When choosing a model, pay attention to the following information:

- material used;

- cartridge for which the model is designed;

- number of cartridges in the magazine, rate of fire;

- operating time before failure.

It is important to clarify which metal parts will need to be purchased separately, in addition to plastic for printing on a printer.

What does the law say in different countries?

The only country where firearms can be 3D printed is the United States. Gun Control Act 19 is in effect here68, giving Americans the right to make weapons, but only for personal use. Only one limitation is put forward: it must be determined by metal detectors, that is, it must have a metal element. In virtually all other countries, homemade manufacture and repair of weapons for any purpose is prohibited by law. In Russia, printing it on a 3D printer falls under the Criminal Code of the Russian Federation and is punishable by imprisonment.

Should we be afraid of plastic weapons?

The question of how dangerous a weapon printed on a printer is becoming increasingly important. Despite all the prohibitions, it is extremely difficult to control the spread of technology around the world. The availability of 3D printers and the increase in their functionality make it possible to master the production of plastic guns at home. How dangerous is such a weapon?

Most experts agree that currently printed weapons are more of an interesting toy. It is quite expensive and is designed to carry out only a few dozen shots. Moreover, such pistols are quite dangerous for the shooter himself with live ammunition, because they can explode in their hands.

However, the danger cannot be underestimated. It is easier and cheaper for a "serious" criminal to buy illegal military weapons than to make them on a printer. At the same time, there may be "enthusiasts" who, for their own interest, can make a pistol and try it out in action. Such inadequate people represent an undoubted danger. In addition, the temptation is great for terrorists. Metal detectors do not detect a plastic gun, which means that it is easier to carry it, for example, on an airplane.

Such inadequate people represent an undoubted danger. In addition, the temptation is great for terrorists. Metal detectors do not detect a plastic gun, which means that it is easier to carry it, for example, on an airplane.

Important! Plastic weapons have a very small resource. At the same time, sometimes just one shot is enough to kill a person.

3D printed firearms have the following advantages:

- the ability to make military weapons at home;

- light weight;

- availability of materials;

- Ability to copy famous weapon models.

Always remember that there are significant disadvantages:

- illegal production;

- high cost of weapons;

- very small resource and limited rate of fire;

- danger to the shooter himself.

Currently, plastic weapons have more disadvantages than advantages, and most importantly, you can get a real prison term for making them.

Prospects for printing weapons

The potential for 3D printing of firearms is far from exhausted. The expansion of equipment capabilities and the development of innovative materials indicate that in the near future such weapons may approach military weapons in terms of characteristics. In the future - a significant increase in the resource and the provision of automatic firing.

Significantly increases the reliability of printed pistols and carbines SLS technology using metal powder. Such weapons already differ little from the factory metal models. While it is very expensive, which significantly limits the application. However, over time, the material will become cheaper, which means it will become more affordable.

Printing firearms on a 3D printer has become a reality. Despite its extremely low performance and reliability, interest is growing in it. Experts predict that the printing of weapons will become widespread, and it is impossible to stop such production. There comes a time when measures should be taken at the legislative level to establish effective control over this process.

There comes a time when measures should be taken at the legislative level to establish effective control over this process.

- March 21, 2021

- 3801

Get expert advice

3D printer gun | Weapons printed on a 3D printer

With the help of 3D printing, you can make not only harmless souvenirs and trinkets. People did not limit themselves to the necessary mechanisms and things. Legislators were seriously worried, because enterprising designers and inquisitive minds tried to print weapons. And not just a model for cosplay, but a real one, capable of firing live ammunition. But most importantly, they succeeded! Therefore, it was necessary to introduce restrictions at the legislative level for the safety of people.

Weapons were printed not only by professional devices capable of metal printing. And quite ordinary ones, printing using FDM technology. At the same time, it was possible to print not only prototypes of existing weapon models, but also to develop completely unique models.

And quite ordinary ones, printing using FDM technology. At the same time, it was possible to print not only prototypes of existing weapon models, but also to develop completely unique models.

3D printed weapons - analogues

The most well-known variants of weapons analogues printed in whole or in part are:

- Сolt M1911 from Solid Сoncepts

- Replica of the grizzly .22 hunting rifle, made of plastic by a Canadian with the pseudonym "Matthew"

- Horns for AK 47 and AR-15 - Feinstein from Defense Distributed

- Parts for AK-47

Concept3d printable Solt M1911 printer. For this, an alloy of chromium, nickel and molybdenum called Inconel 625 was used. 2000 shots can be fired from this weapon. In this case, the number of misfires will be minimal.

A grizzly .22 plastic hunting rifle capable of firing 14 rounds, after which its barrel becomes unusable. The weapon was built through trial and error on a Stratasys Dimension 1200e.

Other legally restricted options are hybrid systems of existing firearms.

New Designs

Many have gone further and have not tried to print existing models of weapons, but have tried to create new unique models. The most famous among them are:

- Liberator and Lulz Liberator

- Shutu-MP1

- Reprringer Pepperbox

The very first additive pistol was the Liberator. This iconic weapon appeared in 2013. It is completely printed on a Stratasys Dimension SST 3D printer, and its cost is about $10. The drawings of this device were freely available. The disadvantages of this weapon were that it gave a lot of misfires, and was only capable of one shot. The shortcomings have been eliminated in the improved Lulz Liberator model. This plastic pistol is capable of firing up to 8 shots. Now the drawings are removed from the public domain.