3D printed lightning link

▷ ar15 lightning link 3d models 【 STLFinder 】

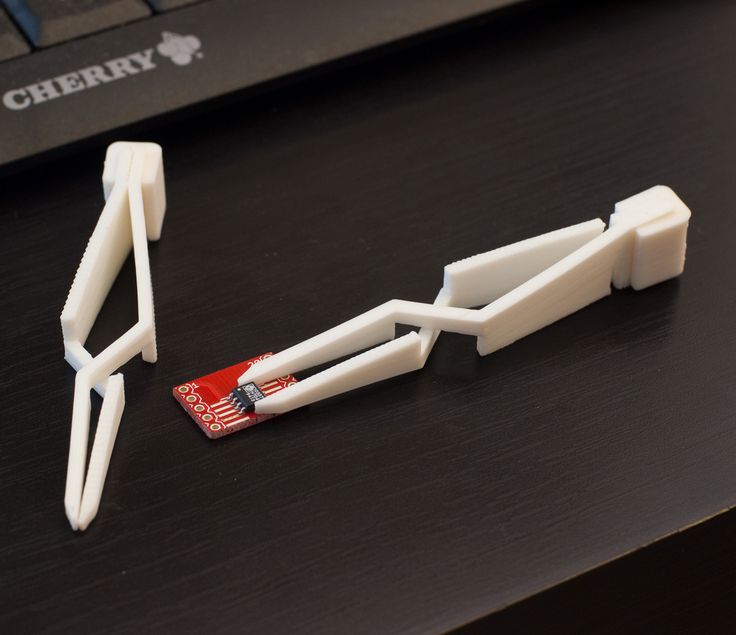

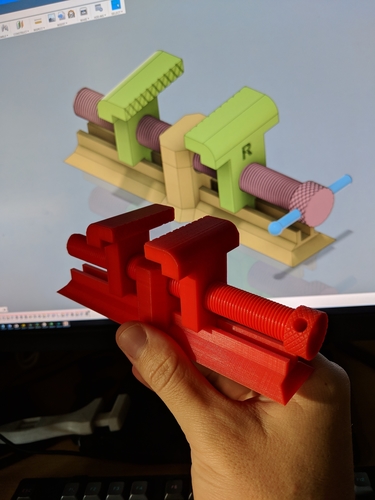

Salted Earth AR15 Receiver Link

grabcad

This receiver link allows you to hinge open and lock your AR15 upper for cleaning while the rifle is supported in a cleaning stand. The prototype was 3D printed in PLA with a 90% infill. Cost to print is about $0.20 Because your friends at Salted...

ar15

grabcad

ar15

AR15 Full Auto Link

cults3d

Files you receive with the purchase: -2 Machining Blueprints -2 STL 3D printable files

AR15

grabcad

AR15 built from picked up parts

Ar15

sketchfab

Game ready model of a AR15 assault rifle complete with animaitons.

Lightning Link

thingiverse

**Educational purposes only**

Lightning Link

thingiverse

If you know what this is for, then you might want to make this one out of metal. I've included the solidworks files. ...Do with it what you will.

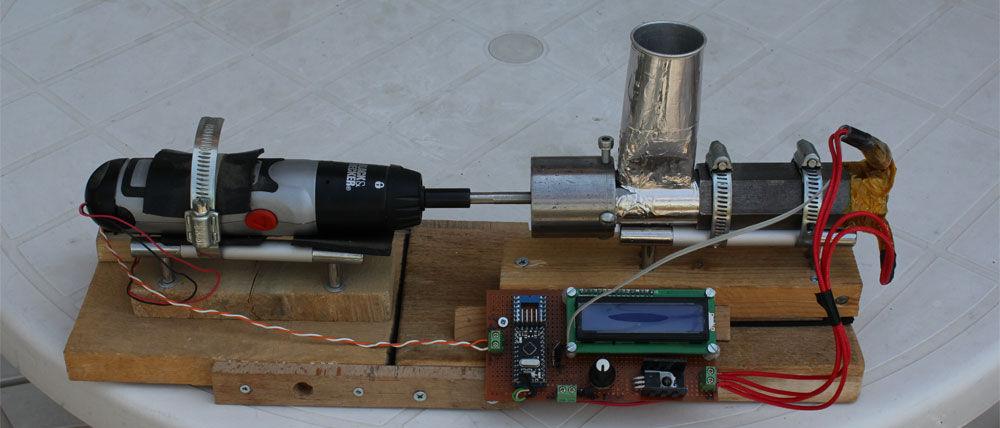

AR15 Upper/lower link (for cleaning)

thingiverse

I saw a thing like this one time, but never find it when I needed it, so I re-designed it.

Helps (with or without the retaining pin in place) to keep upper and lower at a certain angle while cleaning or maintaining. ...

I printed it on the side to...

...

I printed it on the side to...

ar15 grip

cults3d

custom skeletonized ar15 grip

Lego AR15

thingiverse

3D printable lego AR15.

link

grabcad

link

link

grabcad

link

Link

grabcad

Link

link

grabcad

link

link

grabcad

link

AR15_bowl

thingiverse

bowl with AR15 grip. ...nice

...nice

LINK

grabcad

HYDRAULICK LINK

link

grabcad

304 link

Ar15

sketchfab

AR-15 — American semi-automatic rifle chambered for 5.56×45 mm.

AR15

sketchfab

No description provided.

ar15

grabcad

triger mechanism

Ar15

sketchfab

No description provided.

AR15

grabcad

AI2013 PRO

AR15

sketchfab

Assault Rifle

AR15

cults3d

AR15

sketchfab

No description provided.

AR15

sketchfab

This gun is for sale at http://chamferzone. com/3d-shop/ (Textures for Unity, CryEngine and UE4 included) Hi! I’m Tim – Senior 3D Artist at Ubisoft Toronto, previosly 3D Artist at Crytek. Titles I worked on include Far Cry 4, the Crysis series,...

com/3d-shop/ (Textures for Unity, CryEngine and UE4 included) Hi! I’m Tim – Senior 3D Artist at Ubisoft Toronto, previosly 3D Artist at Crytek. Titles I worked on include Far Cry 4, the Crysis series,...

link

thingiverse

Its a link

Link

grabcad

Front susp link

Link

grabcad

5 mm Fork link

▷ lightning link 3d models 【 STLFinder 】

Lightning Link

thingiverse

**Educational purposes only**

Lightning Link

thingiverse

If you know what this is for, then you might want to make this one out of metal. I've included the solidworks files. ...Do with it what you will.

I've included the solidworks files. ...Do with it what you will.

link

grabcad

link

link

grabcad

link

Link

grabcad

Link

link

grabcad

link

link

grabcad

link

link

grabcad

304 link

LINK

grabcad

HYDRAULICK LINK

Link

grabcad

Front susp link

Link

sketchfab

Low poly Link.

Link

grabcad

A simple link part.

link

thingiverse

Its a link

Link

grabcad

5 mm Fork link

Link

sketchfab

Link from Legend of Zelda.

Link

grabcad

Forest Link for CAT 924

Link

grabcad

Model of link for static analysis

Link

sketchfab

Link from “The Legend of Zelda”

Link

sketchfab

Low polly link model Maya #Link #The Legend Of Zelda #Homework

link

cults3d

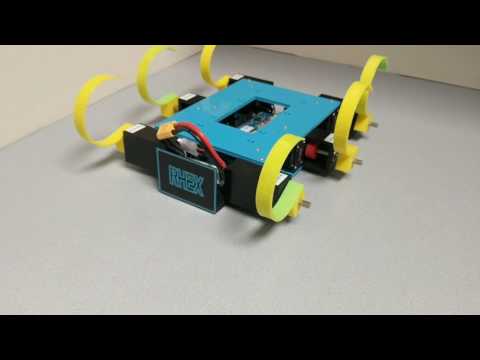

"link" is battens connector! . ..You can create furniture with link! Custom-made shelve, table, scenography! Batten section : 27x27mm link VIDEO : https://www.youtube.com/watch?v=7hSxW8hlWGE

..You can create furniture with link! Custom-made shelve, table, scenography! Batten section : 27x27mm link VIDEO : https://www.youtube.com/watch?v=7hSxW8hlWGE

Link

grabcad

Bottom bracke and chainstay link for fs frame

Link

grabcad

A request to draw this mechanical link was on a website.If you download, please Like :)

Link

sketchfab

Child Link de Ocarina of Time pero con un estilo mas parecido al de Twilight Princess.

Link

cults3d

Link from Zelda Ocarina of time, with Deku shield and Kokiri sword.

Link

pinshape

Link, l'estocade prophétique. ... inspiré par windwaker, voici chibi Link qui s’apprête a fendre Ganondorf en 2 et a restaurer la paix dans le royaume et accessoirement a sauver une fois de plus princesse Zelda.

link

thingiverse

... Batten section : 27x27mm link VIDEO : https://www.youtube.com/watch?v=7hSxW8hlWGE 3D PRINTING SETTINGS layer height : 0.3mm wall thickness : 1.6mm top/bottom thickness : 1.0mm infill density : 20% Model available directly with anti-warping support.

Link

thingiverse

Link in Breath of the Wild. I'd appreciate if you join the community on Patreon!

... http://www.patreon.com/color3d

I'd appreciate if you join the community on Patreon!

... http://www.patreon.com/color3d

Link

pinshape

It's Link made it the style of Pixlpit's animations with the sword, shield, and Majora's mask from the game series.

Link

thingiverse

Es una version de Link que me encontre y estaba muy pequeña y tenia demasiados errores, la modifique y aqui esta :) Dimensiones: z: 100 mm y: 75.3 mm x: 114.71 mm

Link

thingiverse

Modified Camera Grip to be a Link if required for extension. This was useful when i did a Microswiss Dual Extruder upgrade as the fan shroud was in the way of the camera mount.

...

Is for the Design by 3DDoodle:...

This was useful when i did a Microswiss Dual Extruder upgrade as the fan shroud was in the way of the camera mount.

...

Is for the Design by 3DDoodle:...

news about world and Russian cinema

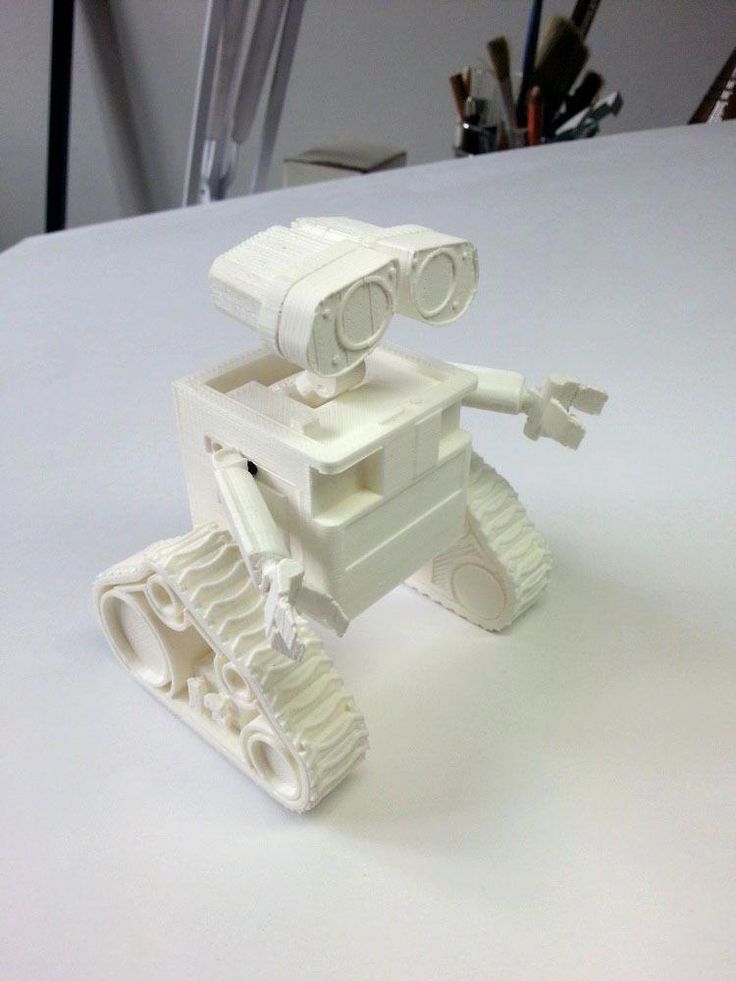

Everyone seems to know about the films of the Laika studio. These are animated pictures created with the help of puppets, stop-motion animation and translations. But today, to create these old-school puppet cartoons, computer graphics are also used, only very stylized. Below are fun facts about the making of the new Lost Link animated film.

The studio uses all the latest achievements of new technologies to create its tapes. For example, the studio's previous film is Kubo. The Legend of the Samurai” was even nominated for an Oscar in the Visual Effects category.

● The artists of Lost Link were inspired by the Victorian designs seen on the fine wallpaper and fabrics of the time. These ornaments are found throughout the film, and can be seen in the masonry of tiled roofs and even in the crowns of trees.

● Characters and objects in the film have unique and highly stylized designs. All these stylized forms and images are united by the rule of "three equal parts". For example, Sir Lionel's long legs are two thirds of his height. The eyes of Nessie the monster are located in the upper third of her head. This rule allows you to maintain consistency and maintain a common style in the depiction of different cultures and continents, which abound in this film.

● Another source of inspiration was photographs from National Geographic magazine, which brought the spirit of amazing discovery and adventure into the homes of its readers. This unique, even somewhat oversaturated color is emphasized in the painting (the only exception is the Optimat Club, which is stuck in a highly characteristic black and white scale, reflecting the worldview of its members).

Dolls

● Stop motion puppets are usually made in 1/5 or 1/6 scale of their actual counterparts. This allows them to have an internal frame strong enough to withstand a two-year filming period, and external parts large enough to work comfortably with a cinematic camera and lighting.

This allows them to have an internal frame strong enough to withstand a two-year filming period, and external parts large enough to work comfortably with a cinematic camera and lighting.

● All Lost Link dolls were made approximately 20% smaller than the previous Laika films. This scaling made it possible to make the scenery smaller, and Mr. Link to become the largest character in the film, while maintaining a height of 40 centimeters that was quite comfortable for animators.

● The elephant and horse dolls were made using a special technique where muscles are formed from foam, rubber and plastic, mounted on a rigid skeleton and covered with silicone skin, which is then hand-dyed.

● Each dolls was equipped with a unique electronic system that allowed the animators to remotely provide specified progressive movements.

Elephant:

● The first doll to be made with elastic and baggy skin not glued to the carbon fiber body panels.

● Weight: Approx. 16 kg.

● Equipped with a special foot for open cavity effects to create the illusion of mass. It has 100% independent nails.

● The inner frame is equipped with a gear in the neck area for lifting the head.

● Movement is by means of a spring on the gas actuator.

● The elephant saddle or palanquin in which Sir Lionel and Adeline traveled was mounted on a two-axle motorized platform to give the illusion of swaying while riding the elephant.

● Only one elephant doll was made for the filming of the film.

Horse:

Thanks to this, the animators were able to reproduce the effect of weight transfer from one side to the other, which is typical for horse gait.

Mr. Link:

● The heaviest protagonist ever created for a Laika film.

● In the scene where Mr. Link pulls up his pants while jumping, the desired zipper effect was achieved by swapping puppets between shots.

● The shot of the slouchy pants was created using a specially made mannequin, which is a three times enlarged fifth point of Mr. Link. Special mechanisms provided the expansion necessary for the fabric to part along the seam, and the tuft of wool jumped out.

● For filming Mr. Link's mouth, 6 progressive control units were used to move the tongue, separate mechanisms to pull the skin off the cheeks and another system of mechanisms to open and close the jaw. The entire mouth was made separately in 5 to 1 scale. Stagecoach:

● Has been decorated with 180 independent controllable tassels.

● Reclining seats have been manufactured to provide six axes of movement for each doll.

● Seats, curtains and the carriage itself were driven by forty independent, programmable and remotely controlled motors.

Train car:

● Since the characters are walking down the central aisle in the scene, the scenery has no floor. Instead, the entire set was suspended and moved along rails, depending on the needs of the animators.

Train:

● On the outside, the train was a real-life train on rails, driven by a motorized winch. It ran too smoothly on the rails, so I had to stick rust-painted tape on them to make the wheels bounce over these bumps, creating a more authentic movement.

Ship:

● The ship set was too big and heavy to move, so the camera and all surrounding lights were motorized to rotate around the ship and give the illusion of movement.

● The smallest camera tripod head ever used at Laika Studio was created for this set. She allowed the camera to be mounted on a long pole and then pushed down the long corridor of the ship to film the chase scene.

Mr. Link:

● Mr. Link Charming and friendly. Inside, it is a bundle of metal parts, including a mechanical belly drive, a breathing simulator, squeezing and stretching devices, worm gears, and gear racks with gears.

● Mr Link was made using several techniques. Most of his body was realized by attaching elements of perforated foam latex to metal reinforcement (almost like muscles). Then, like skin or hide, sheets of molded silicone coated with fur were fixed all over the surface of his body.

● Since Mr. Linka required the highest degree of movements, they were required to be the same ashly "petals of wool" made of urethane, which were applied to his neck in layers, similar to how feathers grow on the neck of birds. When Link turns or lowers his head, these layers slide over each other rather than curl and bulge as they would with a single sheet of molded silicone.

Linka required the highest degree of movements, they were required to be the same ashly "petals of wool" made of urethane, which were applied to his neck in layers, similar to how feathers grow on the neck of birds. When Link turns or lowers his head, these layers slide over each other rather than curl and bulge as they would with a single sheet of molded silicone.

● Once the wool has been applied, the meticulous and highly artistic dyeing work begins to give Mr. Link's hide depth and highlight the individual strands.

● Mr. Link's checkered suit is a nod to the then-Northeast style of dress, and a tribute to the history of the weaving industry, namely WhiteStag and Pendleton, which were founded in Oregon during that period . 9

and hand-drawn details.

Sir Lionel Frost:

● The search for the right pattern for Sir Lionel's houndstooth tweed suit began by working closely with a professional weaver to determine the size, shape and tones of the intertwining elements that created the pattern.

● However, fine ornamentation or parallel lines placed too close together can cause optical distortion on the screen, which is a visual disturbance that occurs when using digital cameras. Through extensive experimentation, the costume designer found hues that didn't stand out too much on screen, and a pattern shape that conveyed the feel of a tweed suit, but consisted of interlocking stars rather than houndstooth.

Adeline Fortnite:

The image of this woman of the era of world revolutions was inspired by the illustrations of girls by the hand of the artist Charles Gibson of the late 19th and early 20th century.

● Adelina's hairstyle consists of more than six hundred meters of multi -colored silk threads, which were then manually stylized and laid to comply with the images of the girls Charles Gibson, drawn by ink on paper.

● Another characteristic of the Gibson Girl was the S-shaped corset, which replaced the physically restrictive corsets of the Victorian era. This corset emphasized the curves of the female body, which was considered unacceptable in the Victorian era. Adeline quickly embraced this new fashion style.

This corset emphasized the curves of the female body, which was considered unacceptable in the Victorian era. Adeline quickly embraced this new fashion style.

Sets:

● More than 110 sets and 65 locations are used in the film.

● The bagpipe was made using a special latex balloon that was inflated and deflated using a pump.

● The ice bridge collapse scene involved 64 individual pieces of ice that could be controlled independently.

● The train was the largest props created for the Lost link.

● The reins, harness and saddle of the horse were made of real leather, which was specially treated to make it much thinner, bringing it into line with the required scale. Many of the books in Sir Lionel's office are leather-bound, made in accordance with all the canons using authentic technologies.

Animation:

● Stop-motion puppetry is the manipulation of physical objects in small intervals between individually captured frames to obtain the effect of independent movement. In practice, the animator moves an object, takes a photo, moves an object, takes a photo, and so on.

● Laika studio animators take the maximum number of photographs taken in classical cinematography - 24 frames per second. This means that for every second, the animator creates 24 unique poses. Studio Laika is probably the only stop-motion animation studio in the world that strictly adheres to this format. The films of Laika Studio are as close to natural style as possible, which requires the highest technique of working with the 24 frames per second format.

● Laika artists made scenery and requisite on different scale to be able to remove dolls with different prospects. Miniature replicas of the film's characters, less than five centimeters tall, were also made, allowing the animators to capture extreme wide-angle shots for the scene in the Himalayas.

Miniature replicas of the film's characters, less than five centimeters tall, were also made, allowing the animators to capture extreme wide-angle shots for the scene in the Himalayas.

Making dolls:

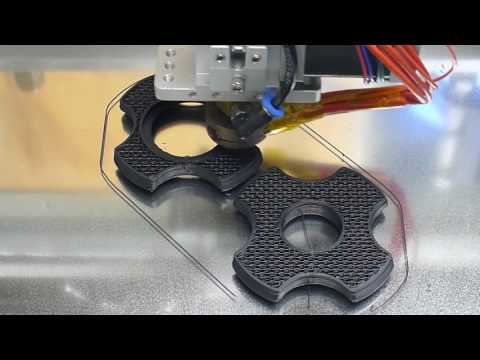

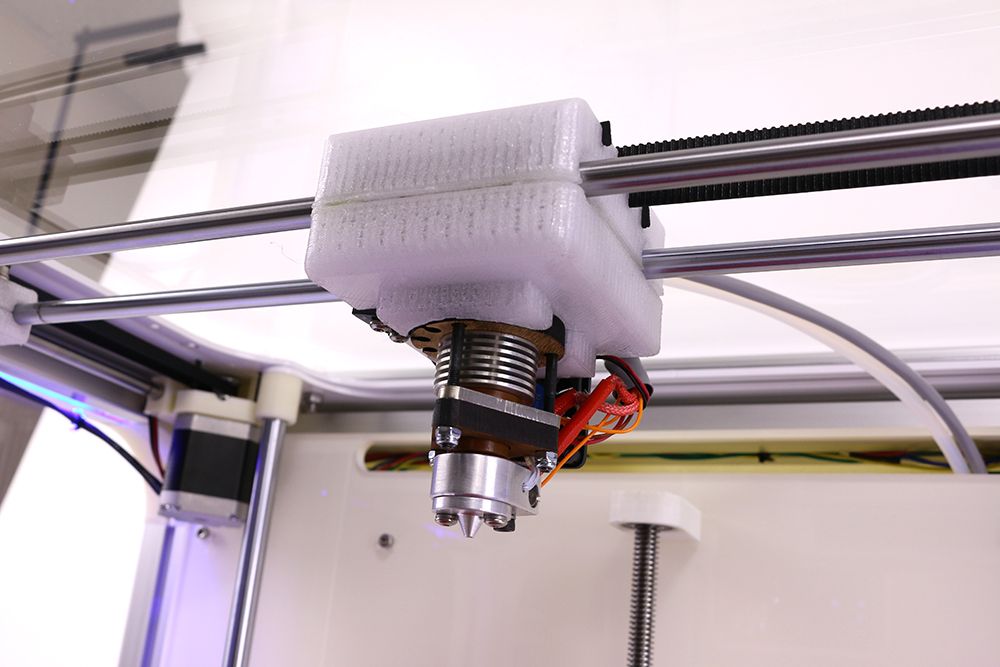

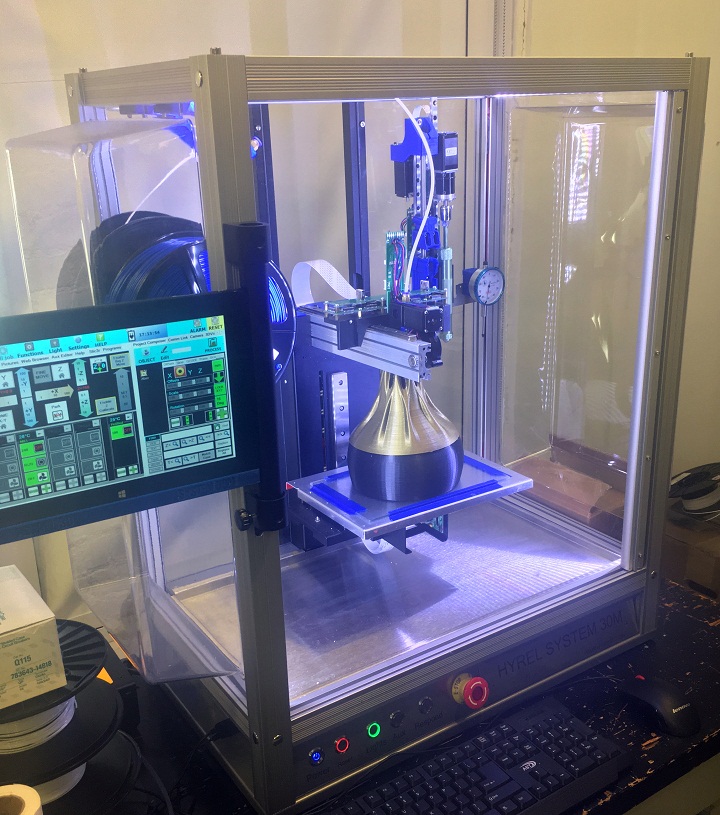

● Almost a year before the filming of Lost Link began, Laika Studio began testing a completely new color 3D printing technology on the Stratasys J750 printer. They've been using Stratasys color 3D printers since filming their second film, Paranorman, or How to Train Your Zombies?, but this new technology has revolutionized it, delivering unprecedented precision and detail.

9000 9000

● Laika studio is considered a leader in the use of quick creation technology (or 3D-printing) animation, and won an Academy Award in the Science and Technology category in 2016 for innovation in this area.

● "Lost Link" is the first film by Laika Studios to use 3D printed resin full color interchangeable faces on ALL dolls.

● Lost Link is Laika's first film to 3D print unique facial expressions for each character in each frame of the film. Past paintings have used "face kits" with interchangeable facial expressions that have been reused multiple times in the painting.

● 5 3D printers in the 3D Printing Department were often running 24 hours a day, producing around 2,000 faces per week.

● In total, the 3D printing department printed over 106,000 faces for Lost Link.

▪ Approximately 39,000 (37%) faces of Sir Lionel ▪ Approximately 27,000 (26%) faces of Mr. Link ▪ Approximately 13,000 (12%) of Adeline's faces

VFX:

● Of the 1486 VFX shots in Lost Link, only 446 were done in 2D. 465 frames required graphical expansion of the sets, 460 required graphic special effects, and 325 required computer animation.

465 frames required graphical expansion of the sets, 460 required graphic special effects, and 325 required computer animation.

● The visual effects team created 531 visual effects and 182 CG characters for LKA's Lost Link, a record for an LKA film. For comparison, in the movie "Kubo. The legend of the samurai» 249 usesgraphic elements and 77 computer characters.

● More than 1,000 off-camera parts were removed by the visual effects team.

● More than 400 graphic elements are used in the film's opening scene featuring the Loch Ness monster model. On average, over 100 physical and graphic elements were applied in a single shot of water to achieve the final image.

● Each plankton simulation in Loch Ness uses over 2 million particles.

● One simulation of a crashing storm wave contained the maximum number of voxels (3D pixels) that Katana could handle, namely 3 BILLION.

● The visual effects department used over a petabyte of data on Lost Link, and a petabyte is a million gigabytes.

● The Lost Link movie took 112 million hours of rendering data - that's 12,785 YEARS of rendering on a single core.

● The computer model of the ice bridge consisted of 37,000 parts, 20,000,000 polygons, and occupied 4.7GB of memory when fully loaded.

production features and example parts

3D basics

Aerospace

Automotive

Medicine

Experts recommend

Author: Viktor Naumov

Author: Viktor Naumov

Classification and groups of titanium alloys | Application of Ti6Al4V in additive manufacturing | Bugatti optimizes Bolide hypercar with bionic design and titanium 3D printing | Bracket for aircraft has become one third lighter | Thanks to the titanium prosthesis, the patient was able to return to normal life

Among the materials used in metal 3D printing, titanium and its alloys, especially Ti6Al4V, occupy a special place. Titanium is a metal that exists in nature in the form of oxides. The most common are rutile (TiO2) and ilmenite (FeTiO3). Pure titanium is produced by the Kroll method.

Titanium is a metal that exists in nature in the form of oxides. The most common are rutile (TiO2) and ilmenite (FeTiO3). Pure titanium is produced by the Kroll method.

Without going into details, the process is as follows. First, titanium tetrachloride (TiCl4) is obtained by chlorination in the presence of carbon monoxide at 1000 °C. After that, using magnesium or sodium, carbon monoxide is removed in an inert atmosphere at 800–850 °C. The result is pure titanium. Absolutely pure titanium is difficult to obtain due to its high reactivity, so samples with a purity of 99.9% are accepted for it on the market. For this reason, titanium is mainly used in the form of an alloy with other elements.

Read more about additive manufacturing projects for Bugatti cars in the article

The main physical and chemical properties of this metal are high mechanical strength, low density and high corrosion resistance. For this reason, titanium and its alloys are attractive materials for various industries, including the aviation industry and medicine. The only significant disadvantage of titanium is its high cost. Due to the properties of its alloys, this material has great potential for the production of parts and elements in an additive way.

For this reason, titanium and its alloys are attractive materials for various industries, including the aviation industry and medicine. The only significant disadvantage of titanium is its high cost. Due to the properties of its alloys, this material has great potential for the production of parts and elements in an additive way.

Can 3D printing help you optimize production in your organization? Order free consultation iQB Technologies experts!

Classification and groups of titanium alloys

Depending on the microstructure and phase composition, titanium alloys are divided into three groups: α, α + β, and β. What is microstructure and phase? Microstructure - the structure of the material, distinguishable under an optical or electron microscope. It can be used to determine the size, shape and orientation of individual crystals and granules that make up the material. It also largely determines its physicochemical properties. A phase, on the contrary, is a section of a material with the same physical and chemical properties. Each phase differs from the others in its microstructure and/or composition. Both of these characteristics depend on the rate at which the material cools from a liquid to a solid state, as well as on the application of heat treatment.

A phase, on the contrary, is a section of a material with the same physical and chemical properties. Each phase differs from the others in its microstructure and/or composition. Both of these characteristics depend on the rate at which the material cools from a liquid to a solid state, as well as on the application of heat treatment.

Alloys are divided into groups depending on the elements included in their composition in addition to titanium. In alloys of the α group, α-stabilizers (aluminum, carbon, oxygen, nitrogen) predominate. Compared to other titanium alloys, these alloys have relatively low mechanical properties and high corrosion resistance. The most widely used of this group are Ti3Al2.5V and Ti5Al2.5V.

Group β alloys were developed to improve the mechanical properties of the material. They include β-stabilizers (iron, molybdenum, vanadium). These alloys include, among others, Ti10.2.3, Ti555.3 and Ti17.

Finally, there are alloys of the α + β group. They are the best studied and contain stabilizers of both groups, resulting in a mixed microstructure and a good set of properties. The most widely used Ti6Al4V. Due to the optimal ratio between mechanical strength, ductility, fatigue resistance and crack resistance, its share is 56% of the entire titanium alloy market. Depending on the group, the alloys market is divided in the following proportions: 26% (α), 4% (β) and 70% (α + β).

They are the best studied and contain stabilizers of both groups, resulting in a mixed microstructure and a good set of properties. The most widely used Ti6Al4V. Due to the optimal ratio between mechanical strength, ductility, fatigue resistance and crack resistance, its share is 56% of the entire titanium alloy market. Depending on the group, the alloys market is divided in the following proportions: 26% (α), 4% (β) and 70% (α + β).

On the left is the equiaxed microstructure of the Ti6Al4V alloy (without heat treatment). On the right is a diagram of the phase composition of the Ti6Al4V alloy © 3dnatives.com

iQB Technologies Experts Recommend Article: Metal 3D Printing: Short Answers to Big Questions

Application of Ti6Al4V in additive manufacturing

Taking the market as a whole, Ti6Al4V alloy is the most widely used in 3D printing because of its high strength, low density, high corrosion resistance, and high biocompatibility. This set of properties makes it a valuable material in industries such as automotive, aerospace, medicine and biomedicine, dentistry, chemicals, defense and other areas.

Before starting 3D printing using Ti6Al4V, the alloy must be powdered. This is done using two main technologies: plasma and gas atomization.

Plasma atomization is used to produce highly pure metal powder (Ti6Al4V). The alloy in the form of a rod is fed into the atomizer tank and melted under the influence of the plasma torch. As it falls, the molten metal solidifies into spherical particles.

© 3dnatives.com

The most commonly used technology is gas atomization. The molten material is fed into the nozzle and atomized with an inert gas (argon or nitrogen). In the gas flow, the molten material solidifies and disintegrates into spherical particles, which accumulate at the bottom of the chamber.

See also: Russian manufacturer of SLM machines dispels myths about technology

The choice of technology for the production of metal powder (in this case, Ti6Al4V) is extremely important. The particle size and properties of the powder depend on it, which, in turn, determines the characteristics of the final product. There are three industrial Ti6Al4V alloys on the market today:

There are three industrial Ti6Al4V alloys on the market today:

-

TC4 conforming to GB/T 3620.1-2017;

-

Ti6Al4V class 5;

-

Ti6Al4V Grade 23 conforming to ASTM B348-13.

They differ from each other in particle size, which limits the minimum thickness of the printed layer. Most often, 3D printing using Ti6Al4V is carried out using DMLS or SLM technology. The choice of technology depends on the type of part and the desired characteristics.

Source: 3dnatives.com

Bugatti optimizes Bolide hypercar with bionic design and 3D printed titanium

© bugatti.com

Luxury car manufacturer Bugatti has been using additive technologies for years. New advances in 3D printing have been applied to the development of the Bolide hypercar, unveiled in October 2020. Bolide is equipped with an eight-liter W16 engine, weighs only 1240 kg and is capable of accelerating to more than 500 km/h.

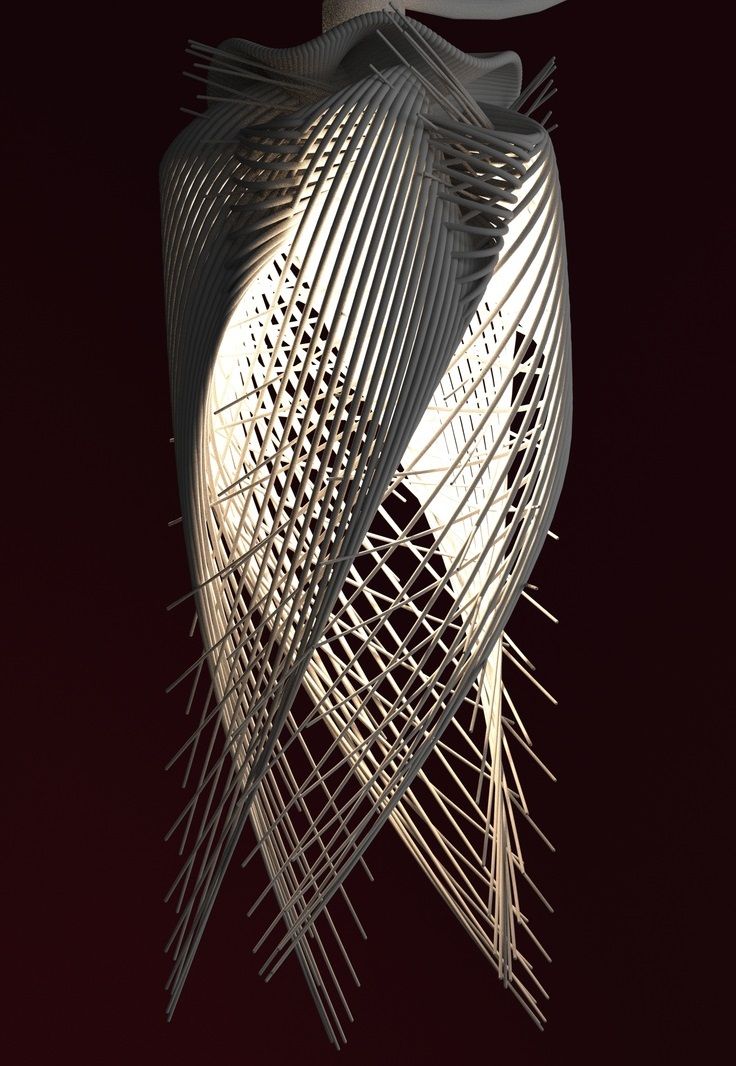

Inspired by bone structure, the design team 3D-printed automotive components with a hollow structure with thin walls (up to 0.4 mm) and small ramifications. The use of bionic design has made it possible to give the parts exceptional rigidity and at the same time significantly reduce their weight.

Of the additively produced components for the Bugatti Bolide, the push rods stand out. Despite their light weight - only 100 g - they can withstand pressures up to 3.5 tons.

Another printed detail that Bugatti is particularly proud of is the hypercar's titanium rear fender mounting bracket. Weighing 600g, the bracket is capable of withstanding an aerodynamic downforce of up to 800kg, with a hollow design and a wall thickness of 0.7mm.

Bolide titanium rear fender mounting bracket © bugatti.com

Bugatti previously created a titanium brake caliper for the Chiron hypercar, the first to be 3D printed and the largest in automotive history. The 3D printing was done on a powerful 4-laser SLM 500 machine. The titanium caliper is about 40% lighter and at the same time stronger than the original aluminum part.

The 3D printing was done on a powerful 4-laser SLM 500 machine. The titanium caliper is about 40% lighter and at the same time stronger than the original aluminum part.

Read more in the article: Bugatti did the impossible in 45 hours with a 3D printer

Bracket for the aircraft has become one third lighter

The S-bracket is an aircraft lift actuator element printed from Ti6AI4V on an SLM 280 machine by ASCO Industries. Its elegant shape is the result of strict space requirements and high stresses on the seating surfaces. The original project involved the manufacture of a high-strength stainless steel bracket and complex machining.

S-shaped bracket - an element of the actuator of the aircraft lift system

The product design has been redesigned for additive manufacturing through topological optimization. Its goal was to minimize the mass while maintaining the necessary strength to withstand the aerodynamic loads specified in the project.

Results of application of selective laser melting:

-

31% weight reduction and overall assembly time reduction;

-

combining three parts into one;

-

decrease in the material utilization factor from 17 to 1.5;

-

significant reduction in machining time.

The result of the topological optimization of the bracket

Read more in the article: How to reduce the weight of an aircraft structural element by a third

Thanks to the titanium prosthesis, the patient was able to return to normal life

The biocompatibility of titanium alloys (such as Ti6Al4V ELI) makes them ideal for 3D printing prosthetic bones of the maxillofacial region, intervertebral discs, clavicles, knees, shoulder blades, hips, and various implants. In dentistry, these materials are used for the manufacture of one-piece implants, as well as metal bases for crowns and bridges made of titanium, cobalt-chromium and other alloys.

An 81-year-old patient suffered from a type 3B acetabular defect according to the Paprosky classification. Previous revision reconstructions in this patient had failed due to calyx loosening and displacement to the posterior cranial region.

For the operation, an aMace hip joint prosthesis was designed, individually made on a 3D printer in accordance with the defect. Thanks to this, the prosthesis helped to achieve the desired degree of recovery and fixation.

aMace custom prosthesis used for surgery

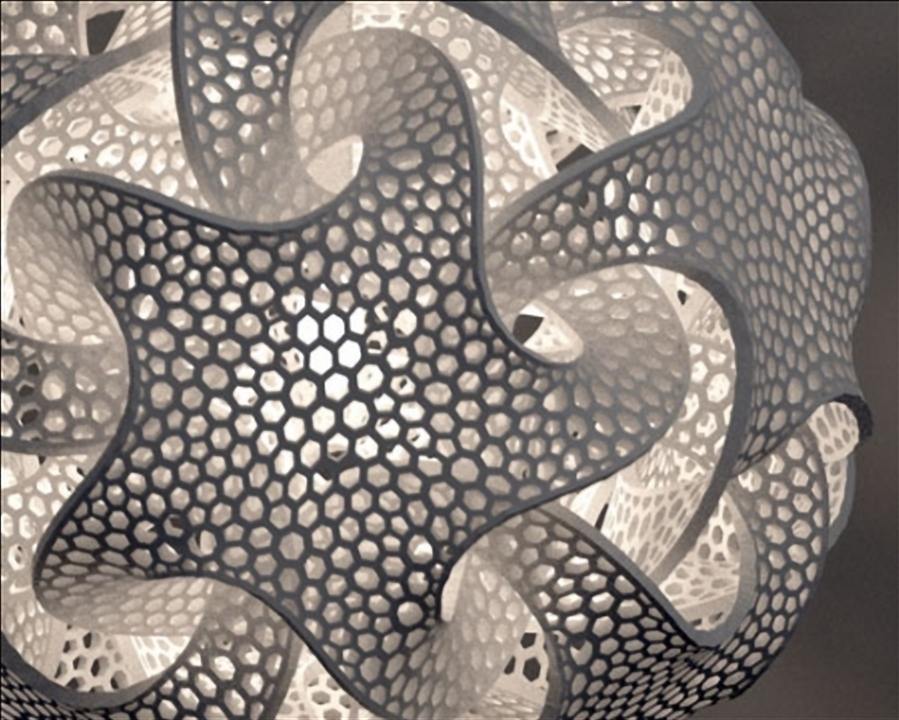

The aMace prosthesis (developed by Materialize) allows you to take into account all the medical features of the patient and the complex mechanical requirements for this important moving part of the human body. The complex porous structure of the back of the product, which allows for bone ingrowth, is a feature that can be easily reproduced using 3D printing.

The prosthesis helped to restore the center of rotation to the desired location and orientation, and also provided sufficient support despite the limited amount of bone material (especially in the posterior cranial region).