3D printed homes arizona

Leading US Homebuilder Century Communities Starts Selling 3D Printed Homes in Arizona - 3DPrint.com

Century Communities, one of the top 10 homebuilders in the US, announced that it is now selling homes with walls built using additive construction (AC) methods. The company has made the homes, which comprise a community in Casa Grande, AZ called ‘Mountain View Estates’, available for purchase through its website.

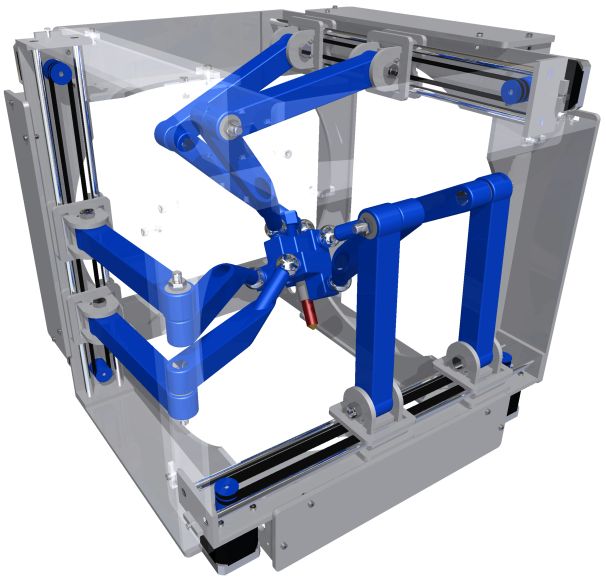

Century Communities is selling the homes through its Century Complete brand, which is marketed for its affordability and ease of purchase. The company worked with Diamond Age 3D, a Phoenix-based startup that combines robotic arms with a gantry-based AC platform, to build the homes. Around the same time that the partnership was originally announced, in March, 2022, Diamond Age also received $50 million in a Series A financing round.

Image courtesy of Century CommunitiesImage courtesy of Diamond Age 3DIn a press release announcing the homes with 3D printed walls at Mountain View Estates, the president of Century Complete, Greg Huff, commented, “…[This new technology showcases] the traditional aesthetic that our buyers love but with industry-leading concrete printed walls designed for durability, energy-efficiency, and noise reduction.

…[This project] further expands on our mission to provide affordable new homes that keep the dream of homeownership within reach.” Genji Nakata, the executive VP of National Operations at Century Communities, added, “This is a significant breakthrough not just for Century Complete but also for the housing industry and homebuyers looking for cutting-edge construction at an affordable price.”

The homes at Mountain View Estates were built according three different single-story floor plans, and start in the upper $200,000 range. According to Diamond Age, the homes can be built in 30 days, and reduce the manual labor required for construction by over 50 percent.

https://youtu.be/t5ky1vfW_vM

Although this isn’t “the first” community of homes built with AC — nor does Century Communities make that claim — it is certainly one of the largest such communities to hit the market so far, especially in terms of projects delivered by companies that build on-site rather than those that rely on a prefab business model. The most obvious competitor to Century Communities/Diamond Age is the collaboration between homebuilding giant Lennar Corporation and Austin-based ICON. The latter is currently working on Wolf Ranch, a community of 100 homes in Texas, unfazed by a Black Friday fire that destroyed ICON’s headquarters.

The most obvious competitor to Century Communities/Diamond Age is the collaboration between homebuilding giant Lennar Corporation and Austin-based ICON. The latter is currently working on Wolf Ranch, a community of 100 homes in Texas, unfazed by a Black Friday fire that destroyed ICON’s headquarters.

Just as it did in 2022, the AC market segment continues to send signals that it is the dark horse in the additive manufacturing (AM) space. As the number of finished projects such as this one, or ICON’s, increase, the more that regulatory regimes are likely to respond favorably to AC processes: as Montana did last year, when its state government gave broad regulatory approval to concrete printed walls.

The notable detail here, as with multiple other developments last year, is that construction giants seem to be embracing AC, not fleeing from it. The volatility of the construction and real estate markets suggest that the adoption of AC methods should only accelerate from here, if only as a means to stabilize building costs.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printed homes • 3d printed walls • additive construction • Arizona • Century Communities • community • diamond age • robotic arm 3d printer

Please enable JavaScript to view the comments powered by Disqus.

3D printing and foam: Arizona organizations make homes more sustainable

Kenneth Skinner’s house sits on a hillside in north Phoenix on July 1, 2022. The home is constructed with expanded polystyrene foam and Sabscrete, a concrete mix developed by Strata International Group.

roy Hill,Cronkite News

Amid global climate change and a chronic shortage of affordable housing, local construction companies and nonprofits are taking innovative steps to make homes more energy efficient and environmentally sustainable.

Strata International Group, headquartered in Phoenix, has made a name by building homes out of foam and concrete, and Habitat for Humanity of Central Arizona has successfully 3D printed a home for a Tempe family – the first structure printed in Arizona.

These energy-efficient and affordable materials and techniques arrive at an opportune time. A 2018 study by the National Low Income Housing Coalition reported a shortage of more than 7.2 million rental homes for low-income renters, and a 2019 report by the International Energy Agency and the U.N. Environment Programme found that the construction industry accounts for 39% of energy-related carbon emissions.

The foam home

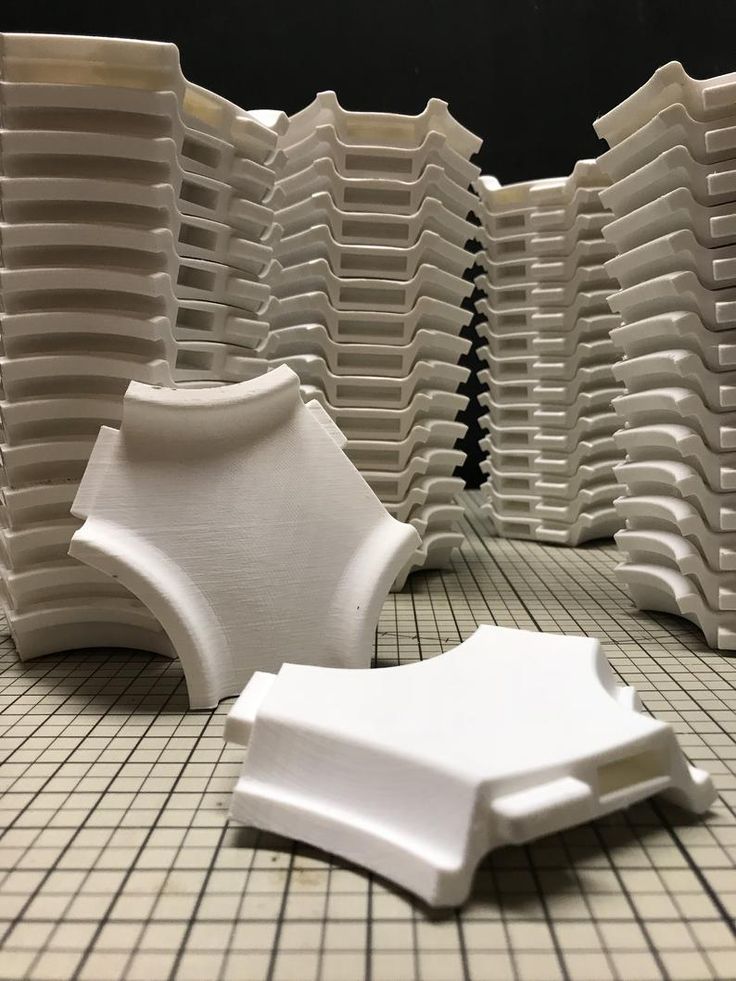

To form the structure of a house, Strata uses a system it calls SABS, which utilizes an expanded polystyrene foam similar to Styrofoam. The foam is shaped, the shapes are bonded together into walls, ceilings and floors, then coated inside and out with a layer of the company’s special concrete mix, called Sabscrete. It holds everything together, protects the foam from impact, weather and fire, and allows the surface to be painted and textured. No lumber or steel is used.

“These houses are built to last 300, 400, 500 years,” said Amir Saebi, executive operations manager at Strata, adding that the foam acts as insulation – meaning less energy is required to cool or heat homes.![]() That benefits both homeowners and the environment.

That benefits both homeowners and the environment.

Contractor Kenneth Skinner, who’s using SABS to build his personal home in north Phoenix, expects the solar panels he’s installing on the roof to meet all his energy needs because of the insulating foam.

Because SABS doesn’t use lumber, it’s a big cost saving at a time of supply chain issues and inflation.

“It was going to cost me somewhere between $35,000 to $40,000 more … because of the lumber prices,” Skinner said. “So that’s right when I got introduced (to) Strata, and so I saved that money.”

Skinner is constructing his home with only a few workers; Saebi said some builds can have as few as three workers, given that construction is less intensive because workers only have to move large slabs of foam and Sabscrete mix.

But it’s not entirely eco-friendly, as Saebi acknowledged. Expanded polystyrene foam is made from petroleum waste products, he said, but that impact is offset because the homes are expected to last centuries – far longer than contemporary homes made of wood.

The printed house

Habitat for Humanity took another approach to affordable, sustainable homes: a giant 3D printer.

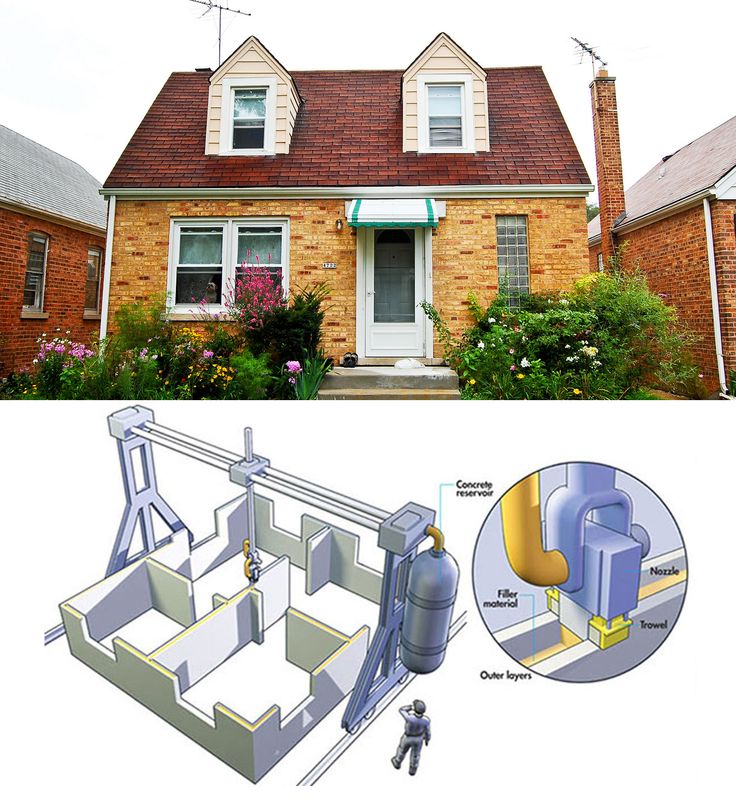

The equipment applies thin layers of concrete, one over the other, until a full wall or frame is erected, then workers pack insulation in the space between the wall layers. Once the exterior and interior walls are complete, the floors, ceilings, and installations are completed using traditional building techniques. Habitat for Humanity estimates that 70% to 80% of the 1,738-square-foot, three-bedroom house was printed.

It’s the first 3D-printed home the nonprofit has built – and the first in Arizona – and the idea came from two ASU graduates in sustainability. Habitat officials say they can’t calculate an exact cost for the project because most materials were donated, but they hope to use this technology to build more at lower costs.

3D printed houses are more energy efficient than traditional houses because concrete and the solidly packed insulation sustain internal temperatures.

“We’ve heard from the family (who lives in the home) that the AC doesn’t really come on much,” said Dusty Parsons, the chief marketing officer for Habitat for Humanity. “When it does, it’s only on for a few minutes, the house … stays very, very cool because it’s a solid double wall of concrete with foam insulation.”

The printer, made by the German company Peri and donated by them for use in this project, is supported by metal pillars and moved around the site on sliders controlled by computer.

Cronkite News reporter Jessica Herrera contributed to this story.

What it's like to live in a 3D printed house

This year's South by Southwest (SXSW) festival had the usual line-up of bands and films, but the agenda was different , a more relevant topic. “We need to find new ways to protect ourselves,” says Jason Ballard, co-founder and CEO of Icon, an Austin-based construction startup. "The houses and buildings of our future must be very different from those of today. " For Icon and other innovators in the construction industry, the solution lies not in optimizing human labor or materials, but in building with robots.

" For Icon and other innovators in the construction industry, the solution lies not in optimizing human labor or materials, but in building with robots.

Ballard and his company envision a future in which all our housing needs will be 3D printed using advanced technology. "It's time for the built environment to join the digital automated robotic revolution that has benefited so many other industries," says Ballard.

Icon unveiled the world's first 3D printed house at SXSW four years ago. This house was designed as a prototype for affordable housing and was later converted into several tiny residential villages that the company helped build. This year, Icon presented their latest achievement, House Zero.

Modeled after a ranch-style residence by Lake Flato Architects, the model home is arguably the most advanced formal 3D printed living design expression to date. Its undulating, textured concrete walls alternate with floor-to-ceiling windows where they are topped by a traditional flat wooden roof. "It's important to make intentionally provocative houses like House Zero," says Ballard. "It's about changing people's perceptions of what modern housing can be."

"It's important to make intentionally provocative houses like House Zero," says Ballard. "It's about changing people's perceptions of what modern housing can be."

While it's good to invite people to dream, what about the promise of 3D printing to actually create and provide housing? Is this what people want or need? What is this shelter, exactly?

For a select group of global citizens who ended up in 3D printed homes, while reality may not be as glamorous as House Zero, it was nonetheless surprisingly comfortable.

“I was worried,” says Markus Shivers, a Phoenix, Arizona resident, of his first reaction to the news that he might be moving into a 3D printed house. “It looked like a nice house on the mock-ups, but my main concern was that the technology was new — I was wondering who actually knows how to operate the house if something goes wrong.”

Marcus and his wife Sean were motivated by the opportunity to stay in the Tempe area where they had lived for decades (but were quickly outbid), so they took a chance and signed up to own the house.![]() which was recently completed by Habitat for Humanity Central Arizona.

which was recently completed by Habitat for Humanity Central Arizona.

Targeting LEED Platinum, Shivers' new residence is the first 3D printed Habitat for Humanity home in the country, and the nonprofit hopes to scale the design to create other homes in Tempe and beyond. All walls of the three-bedroom home were shaped on site by portal printers using Laticrete, a composite concrete material, while the ceiling and roof were built using traditional construction methods.

Now that they've moved in, Shivers' initial hesitation has been replaced by delight. “It's so energy efficient and airtight, and the walls are so thick,” Markus says. “We rarely have to turn on the air conditioner, and when we do, we turn it off after five minutes.” Sean agrees: “Looks like a fortress, but not too enclosed. You can’t hear through the walls at all, and I like the safety and strength of the structure,” she says.

The cavernous quality of 3D printed homes has some would-be homeowners on their guard, especially when designers use the organic undulations that 3D printing naturally produces (a la House Zero). In Holland, architects Houben/Van Mierlo have designed the world's first legally habitable property with 3D printed load-bearing walls that are shaped like a giant boulder with rounded walls and roof shapes. Built in 2021 by the Milestone project, the two-bedroom bungalow is currently home to Elise Lutz and Harry Dekkers, who were intrigued by its unique shape from the start.

In Holland, architects Houben/Van Mierlo have designed the world's first legally habitable property with 3D printed load-bearing walls that are shaped like a giant boulder with rounded walls and roof shapes. Built in 2021 by the Milestone project, the two-bedroom bungalow is currently home to Elise Lutz and Harry Dekkers, who were intrigued by its unique shape from the start.

“For 40 years we had a shop selling modern jewelry, so we liked to look at the design and we were interested in the shape of this building,” says Elise. "It's like a bunker, but it's cozy inside." Harry agrees, but notes that he never feels closed off. "It's very safe inside, like being in a cocoon, but when the doors are open you can see the whole house and it's a very open feeling," he says. Project Milestone is currently working on the second and third of five planned homes in Eindhoven, which are expected to be completed by the end of the year.

Los Angeles-based architect Matthew Cheney's EYRC Architects is working with Mighty Buildings to design and build a new 3D printed community in Desert Hot Springs.![]() He notes that this type of 3D printing is ideal for unlocking the full potential of 3D printing. “Organic molds have more form stability, which makes them better for 3D printing,” he explains. “However, 3D printing tends to be a hybrid of organic shapes and traditional residential architecture shapes because, for example, you can’t easily print a concrete roof.”

He notes that this type of 3D printing is ideal for unlocking the full potential of 3D printing. “Organic molds have more form stability, which makes them better for 3D printing,” he explains. “However, 3D printing tends to be a hybrid of organic shapes and traditional residential architecture shapes because, for example, you can’t easily print a concrete roof.”

As companies like Icon continue to push the boundaries of technology to combine 3D printed shapes with typical architectural elements, 3D printed home residents are finding them surprisingly convenient. Tim Shea, who moved into the Icon House in 2020 at Community First! Village, a 51-acre development designed to provide housing for the homeless in Austin, was pleased with how comfortable and inviting he found his 400-square-foot home. “There are no sharp corners in the house, and the roundness envelops,” he says. "It's warm, safe and cozy inside - like I'm being hugged by my home."

While it remains to be seen whether 3D printing can deliver on its promise of providing adequate housing for the world, for the few who currently live in 3D printed homes, the experience has been instructive. “This house is a new take on how to build and what a house can be,” says Elise Lutz, who, along with her partner Harry, just renewed their lease on their home in Eindhoven because they are so happy.

“This house is a new take on how to build and what a house can be,” says Elise Lutz, who, along with her partner Harry, just renewed their lease on their home in Eindhoven because they are so happy.

For Icon's Jason Ballard, technology has always been a means to an end that strives for the most comfortable, sustainable and dignified homes. “We now believe that 3D printed houses are the best houses,” says Ballard. “But I promise that if tomorrow we came up with a better solution, we would start doing it.”

Source: https://www.dwell.com/article/what-its-really-like-to-live-in-a-3d-printed-home-bf0fa07f0106

Can 3D printing change the residential architecture we know?

Can 3D printing change the residential architecture we know?

Dubai plans to print a quarter of its buildings using 3D construction techniques by 2025, demonstrating the potential of a fast-growing technology to redefine and push the boundaries of traditional architecture. As this technique becomes a viable solution in the fields of construction, engineering and architecture, its popularity is growing rapidly. In fact, between 2021 and 2028 alone, the global 3D construction market is expected to grow by 91%, according to a July 2021 Grand View Research report. Why such a rapid growth? In addition to being a faster alternative and lower building costs, it can also offer affordable housing solutions and provides countless design possibilities, among many other benefits. Thus, as architects must adapt to a new technological age where speed and efficiency have become key factors in design and execution processes, the growth of 3D printing shows great promise. It could even help change the design as we know it.

As this technique becomes a viable solution in the fields of construction, engineering and architecture, its popularity is growing rapidly. In fact, between 2021 and 2028 alone, the global 3D construction market is expected to grow by 91%, according to a July 2021 Grand View Research report. Why such a rapid growth? In addition to being a faster alternative and lower building costs, it can also offer affordable housing solutions and provides countless design possibilities, among many other benefits. Thus, as architects must adapt to a new technological age where speed and efficiency have become key factors in design and execution processes, the growth of 3D printing shows great promise. It could even help change the design as we know it.

Design flexibility and reduced construction time

Structural 3D printing is a new formworkless concrete molding technology, which means that precast parts and entire walls can be printed in any shape quickly and cost-effectively. Essentially, 3D shapes are created through a computer-controlled process, transforming the traditional building process and opening up many design possibilities. Unlike other traditional methods, architects can easily design custom designs with unparalleled surfaces, shapes and colors for creative, innovative and eye-catching buildings that are first and only of their kind. Almost any organic shape is possible: curved or straight walls, smooth or rough surfaces, flat or angled. There are truly no boundaries for the expression of architectural creativity.

Essentially, 3D shapes are created through a computer-controlled process, transforming the traditional building process and opening up many design possibilities. Unlike other traditional methods, architects can easily design custom designs with unparalleled surfaces, shapes and colors for creative, innovative and eye-catching buildings that are first and only of their kind. Almost any organic shape is possible: curved or straight walls, smooth or rough surfaces, flat or angled. There are truly no boundaries for the expression of architectural creativity.

In addition to this design freedom, the printing process itself is also particularly efficient. Not only does it provide a high degree of planning reliability from the start, but it also has fast printing speed and requires little coordination effort, which reduces construction costs. For example, PERI AG can now easily build an entire single-family home (otherwise built of brick or wood in months or years) in just 25 hours of net print time thanks to new technology. This opens up the possibility of architecturally innovative buildings that can come to life in less time - and at no extra cost - compared to traditional methods.

This opens up the possibility of architecturally innovative buildings that can come to life in less time - and at no extra cost - compared to traditional methods.

How does 3D printing work?

Although 3D printing of building materials is currently in its infancy, PERI, one of the world's leading suppliers of formwork and scaffolding, has been active in the market for several years. The German family company is working with Danish COBOD to improve the technology and expand into new markets. The main focus is on residential construction, but also includes the production of individual prefabricated elements.

PERI uses a machine known as COBOD BOD2, a fully developed and secure 3D construction printer that can be configured in any direction for a wide range of applications, be it walls, columns, stairs or other building elements. Each COBOD BOD2 offers many benefits, such as a gantry system suitable for remote manufacturing and on-site applications, eliminating the need for frequent repositioning and calibration. At the same time, the system includes a number of modules that can be selected for specific projects.

At the same time, the system includes a number of modules that can be selected for specific projects.

However, the printer stands out in particular for its speed compared to other machines. In addition to being the fastest construction printer on the market with a top speed of 1m/s, it is certified to allow work to be done in the print area while printing. In this way, all kinds of manual work, such as pipe installation, can be easily integrated and thus optimize the construction process.

Just last year, the first sale of a construction 3D printer proved its success. In an effort to produce a wide range of precast concrete elements and minimize planning constraints, the German company Röser GmbH placed an order with PERI as an innovative long-term investment.

Application method

Although ceilings, floor slabs and foundations are built in the traditional way, BOD2 has proven that it can successfully produce concrete walls. After transporting the printer to the construction site, the Z-axes are installed, the print head is attached to the X-axis of the steel structure, and the commercially available hopper and concrete pump are connected to BOD2. After the assembly is completed, the printing process takes place in three dimensions along 3 axes on a reliable metal frame.

After transporting the printer to the construction site, the Z-axes are installed, the print head is attached to the X-axis of the steel structure, and the commercially available hopper and concrete pump are connected to BOD2. After the assembly is completed, the printing process takes place in three dimensions along 3 axes on a reliable metal frame.

Because the printed hollow wall meets the static requirements in residential buildings, no reinforcement is required. In addition, printed double wall cavity walls can integrate insulation techniques in some way.

Residential buildings: milestones in 3D building technology

3D building technology has reached an unprecedented milestone: Germany's first fully functioning printed house has been officially opened and is now ready for the market. With the start of printing in September 2020, the two-story mansion built by PERI and designed by MENSE-KORTE ingenieure + architekten has passed all regulatory approval procedures and opened this July in Beckum, North Rhine-Westphalia. PERI printed three-layer hollow walls with an area of 80 square meters. M on each floor, which are filled with an insulating compound and provide space for elements related to water and electricity. Röser GmbH supplied the loft components as prefabricated parts, which, combined with the on-site printing process, resulted in a homogeneous unit.

The Beckum project has been awarded the German Innovation Award by the German Design Council, an annual award given to projects that demonstrate excellence in the industry through originality, implementation and efficiency.

“Beckum has three features - digital, dynamic, print-ready. With the advent of Germany's first 3D-printed residential building, the construction industry has created positive pressure: for innovative building with new technologies, for making building professions more attractive, and for modern architecture with new styles.” — Ina Scharrenbach, Minister of the Interior, Municipal Affairs, Building and Equality North Rhine-Westphalia.

![]()

In addition to positioning PERI as a pioneer in the market, the success of this unique project proves that 3D construction is viable and opens up a range of opportunities in the industry. It also paved the way for larger and more complex housing units. Exactly two months after starting work on the Beckum house, PERI began printing the largest printed residential building in Europe, this time in Wallenhausen, Bavaria. Distribution over 3 floors and 380 sqm, 4 out of 5 apartments are rented out and one of them is used as a showroom apartment. Since then, much of what was originally explored at Beckum has also been incorporated into the first residential project in Tempe, Arizona, an addition to an apartment building on Lake Constance in Germany, and the first 3D printed building in Austria, made in collaboration with STRABAG SE.

With the latest printing project in Austria, the PERI 3D printing team has successfully completed five printing projects in one year. All these are not research projects, but real houses that have gone through all the processes of approval of building codes, rented out and occupied or in which people work.

As architects around the world face periods of uncertainty, labor and housing shortages, or other industry challenges, one thing is certain: construction and planning as we know it will change dramatically in many areas . With 3D printing as a promising alternative, slow and costly planning adjustments may become a thing of the past. Its increased viability, productivity, and building process optimization may not only offer affordable housing solutions and lower rents, but may also provide a haven for disaster-stricken regions or the answer to more sustainable building. While there are still many opportunities to explore in other markets and other segments of the industry, it is clear that 3D printing in construction is not going anywhere.