3D printed exo suit

▷ exoskeleton suit 3d models 【 STLFinder 】

3D Printed Exoskeleton (Exo-Suit V3.5)

thingiverse

Exo-Suit V3.5 I was inspired to complete the exoskeleton project I had started a few years ago... I ended up completely redesigning it. This version uses a lot less filament, has better mobility and is easier to make size adjustments I truly like...

$12.99OGRE Suits / Combat Exoskeletons

myminifactory

Obvious Giant Robot Exoskeleton Suits x3. Presupported and unsupported.

3x Bodies with modular arms. 2x Machine gun arm. 2x Fist arm. 2x Maul arm. ...2x shield arm

Avatar AMP suit Exoskeleton Robot Low-poly 3D model

cgtrader

Avatar AMP suit (Exoskeleton Robot) This model is animatable.User-friendly Rigging Controllers. Well functioning. Beginner friendly rigging controllers. The shape of the bullet chain of the machine gun can be controlled by five empty objects. There...

AMP Suit Avatar Exoskeleton 3D model 3D model

cgtrader

AMP Suit Avatar Exoskeleton 3D model. ...File Blender version 2.81 contains all textures.

Avatar AMP suit - Mecha Exoskeleton 3D model

cgtrader

This is an exact replica of the Avatar AMPsuit ( AMPLIFIED MOBILITY PLATFORM ) Topology is VFX production oriented, and it's ready to be used as a Subdivision setup render. ...

...

Exoskeleton

grabcad

Electro Active polymer actuators assisted full body exoskeleton suit with body panel lithium polymer batteries. ...2004 RCA student project.

Exoskeleton Free 3D model

cgtrader

Electro Active polymer actuators assisted full body exoskeleton suit with body panel lithium polymer batteries. 2004 RCA student project. ...

exoskeleton

grabcad

exoskeleton

Exoskeleton

grabcad

Exoskeleton

EXOSKELETON

grabcad

EXOSKELETON MODEL

exoskeleton

grabcad

exoskeleton to lift weight

exoskeleton

grabcad

exoskeleton from russia

Exoskeleton

grabcad

Powered Exoskeleton for paralyzed peoples

Exoskeleton

grabcad

Exoskeleton for carrying heavy loads

Exoskeleton

grabcad

This is a model for an exoskeleton

Exoskeleton

grabcad

Back frame of upper limb exoskeleton

Exoskeleton

grabcad

Design of significant joint motion for an upper body exoskeleton.

Exoskeleton

thingiverse

https://www.youtube.com/watch?v=gCGeEIigAoM Exoskeleton for less hand fatigue.

exoskeleton

grabcad

my iron man suit

Exoskeleton

grabcad

• Developed kinematic and dynamic equations for a 5-link payload carrying bot.• Performed static & transient analysis (taking a varying load from 500 N -1000 N) after multiple iterations of the design along with motor selection with sufficient...

Exoskeleton

grabcad

This is a simplified design for a part of an ergonomic exo suit , I hope I can take my part from the mission, everyone can live full life, even if there is no other way, and we need to create mechanical limbs.

3D Printed Exoskeleton Arms

pinshape

I feel that this model brings us one step closer to Matt Damon's exoskeleton suit from Elysium. All of the parts were printed on my Up Plus 2 which has a build area of 14cm x 15cm x 15cm. Please note : This is only a digital download (STL file)...

3D Printed Exoskeleton Legs & Feet - STL Files

pinshape

I feel that this model brings us one step closer to Matt Damon's exoskeleton suit from Elysium. All of the parts were printed on my Up Plus Box & Wombot Exilis which have build areas of 255cm x 205cm x 205cm (Up Plus Box) & 250cm x 250cm x. ..

..

3D Printed Exoskeleton Legs & Feet - STL Files

cults3d

I feel that this model brings us one step closer to Matt Damon's exoskeleton suit from Elysium. All of the parts were printed on my Up Plus Box & Wombot Exilis which have build areas of 255cm x 205cm x 205cm (Up Plus Box) & 250cm x 250cm x 320cm...

3D Printed Exoskeleton Feet - STL Files

cults3d

I feel that this model brings us one step closer to Matt Damon's exoskeleton suit from Elysium. All of the parts were printed on my Up Plus Box which has a build area of 255cm x 205cm x 205cm Instruction Manual: Exoskeleton. ..

..

3D Printed Exoskeleton Feet - STL Files

pinshape

I feel that this model brings us one step closer to Matt Damon's exoskeleton suit from Elysium. All of the parts were printed on my Up Plus Box which has a build area of 255cm x 205cm x 205cm Instruction Manual: Exoskeleton Feet:...

3D Printed Exoskeleton Arms 3D print model

cgtrader

I feel that this model brings us one step closer to Matt Damon's exoskeleton suit from Elysium.All of the parts were printed on my Up Plus 2 which has a build area of 14cm x 15cm x 15cm.For the latest 3D printed exoskeleton updates visit. ..

..

Knee Exoskeleton

grabcad

Knee Exoskeleton

Exoskeleton-II

grabcad

Exoskeleton-ll

exoskeleton model

grabcad

exoskeleton model

Alex Czech’s Sci-Fi 3D Printed Exoskeleton Continues to Grow—Download to Don Legs & Feet Now Too! - 3DPrint.com

The 3D printed exoskeleton arms and hands.

While many projects are indeed one-hit wonders, innovations with a clear beginning and end, we see some that just keep building upon brilliant momentum—with one continual step after another. Clearly, that’s the case with a 3D printed exoskeleton that just continues to grow, thanks to the creative spirit of one Alex Czech, an Aussie designer who was inspired after seeing Matt Damon’s character decked out in sci-fi gear as he took on a very difficult mission in Elysium. Not just making this design for himself, he’s ready for you to suit up too. And all it takes is one look at the images to see that anyone would feel pretty powerful wearing this sturdy getup.

Clearly, that’s the case with a 3D printed exoskeleton that just continues to grow, thanks to the creative spirit of one Alex Czech, an Aussie designer who was inspired after seeing Matt Damon’s character decked out in sci-fi gear as he took on a very difficult mission in Elysium. Not just making this design for himself, he’s ready for you to suit up too. And all it takes is one look at the images to see that anyone would feel pretty powerful wearing this sturdy getup.

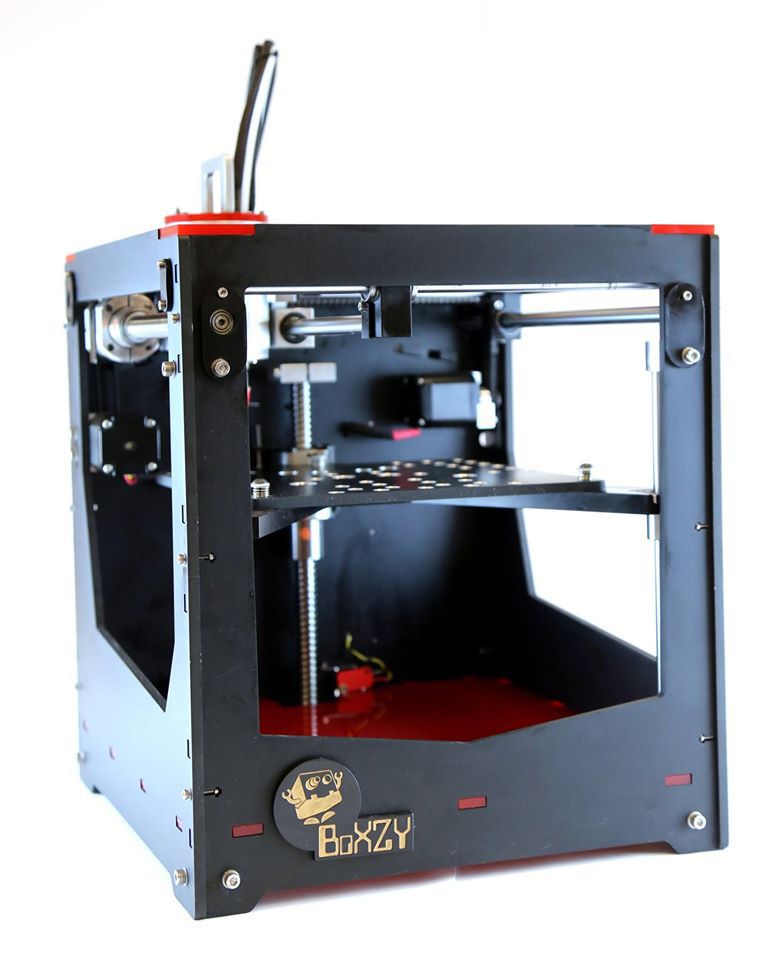

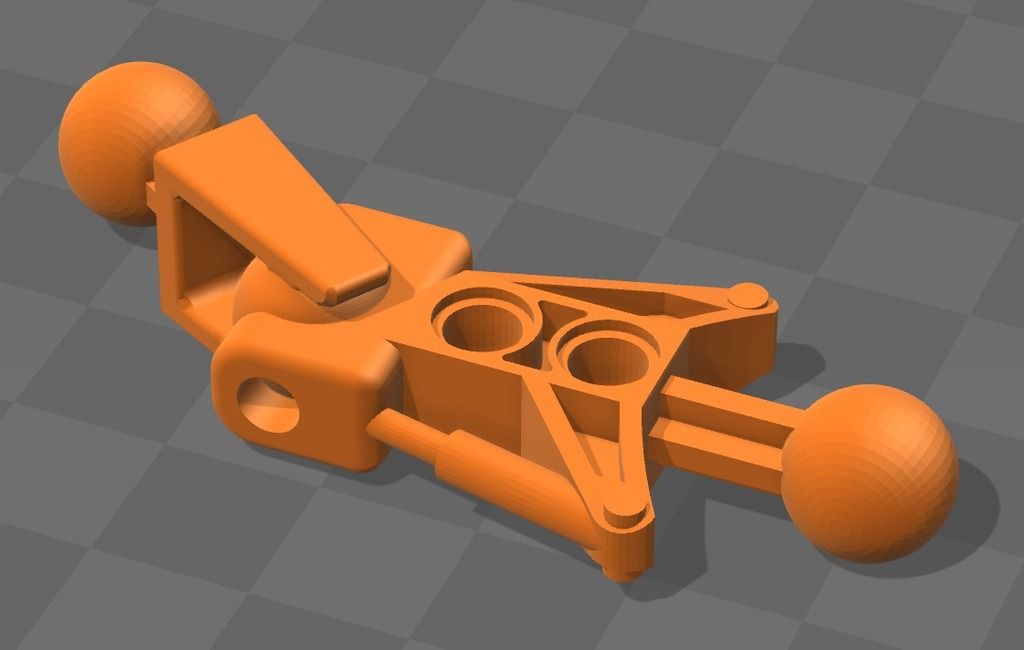

Beginning with the idea of making 3D printed universal joints, Czech ended up going so far as to make an impressive 3D printed exoskeleton hand, consisting of 13 fabricated parts produced on his Up Plus 2 3D printer with a 14 x 15 x 15 cm build area. Indicating that his plans included a full suit, Czech has continued to make progress from a fully 3D printed arm to now, an entire 3D printed exoskeleton for the legs and feet.

And while we’ve reported on numerous 3D printed medical devices from robotic prosthetic arms to 3D printed orthotics, Czech’s creation is meant purely for fun, most likely appealing to the ever growing cosplay community, but we’d venture to say that the design beckons for nearly anyone to try it on. First, you’ll need to download the files from Cults, where they are available for $21.00.

First, you’ll need to download the files from Cults, where they are available for $21.00.

Czech printed all of these parts, again, on his Up Plus, but also used the Australian manufactured Wombot Exilis, which offers a build area of 10″ x 10″ x 13″. He reports too that the exoskeleton parts are quite comfy to wear—and the future may hold robotics as the ‘suit’ design continues to expand.

“What you are downloading is the result of countless hours of test printing to give you the most freedom of movement whilst still feeling strong and solid,” says Czech. “I feel that this model brings us one step closer to Matt Damon’s exoskeleton suit from Elysium.”

Once you’ve purchased and downloaded the files, you’ll want to check out free access to the instruction manuals for 3D printing and assembly of both the exoskeleton legs and exoskeleton feet. There, Czech explains that the print is meant to be made with ABS 3D printing filament.

For the legs, you will need to purchase on the following extra supplies:

- (16) Metal screws – (Sheet metal self-tapper pan screws 8G x 15mm)

- Super glue

- (4) Buckles (print from Thingiverse or use old buckles)

- (1) Old belt

- (4) Some black plastic — Consolidated Alloys 500um Black Poly Dampcourse

And for the feet:

- (8) Metal screws – (Sheet metal self-tapper pan screws 8G x 15mm)

- (12) Metal screws – (Sheet metal self-tapper pan screws 8G x 40mm)

- Super glue

- (4) Buckles – Print from Thingiverse or use old buckles

- (2) Some black plastic — Consolidated Alloys 500um Black Poly Dampcourse

From guiding you through the 3D printing process to assembling the pieces with both instructions and accompanying visuals, Czech makes the process of creating your own exoskeleton fairly simple. He offers tips and shows you how he built out his own design in terms of some of the trickier assembly steps.

He offers tips and shows you how he built out his own design in terms of some of the trickier assembly steps.

This is definitely a challenging project, but the instructions truly are as step-by-step as you’ll ever find. If sci-fi cosplay is one of your interests, this should you be a project you enjoy completing—and showing off—as well as forging ahead fearlessly to 2154 to battle evil robots and save all those poor people living in the ruins of earth. Be safe, and report back to us on your progress, please!

To follow Alex Czech and check out some of his other designs, take a look here. Is this something you might consider downloading and printing? Let’s talk about it further over in the 3D Printed Exoskeleton Legs & Feet forum over at 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printed cosplay • 3d printed exoskeleton • 3D printed science fiction wear • alex czech • cults • exoskeleton • matt damon • thingiverse • UP Plus 2 3D printer • Wombot Exilis 3D printer

Please enable JavaScript to view the comments powered by Disqus.

3D printed robotic exoskeleton

We talked about modern medical exoskeletons in the column “Why does a soft robot need a high IQ to work as a physical therapist?”. But the actually produced ReWalk prosthesis described there is an expensive and not very convenient machine, and when a flexible prosthesis goes into series and how much it will cost, it’s hard to say. We also described an extremely cheap prosthetic arm, which was printed for ten dollars on a 3D printer for an American boy, Leon McCarthy. Well, now both technologies - complex electro-mechanical exoskeletons and cheap and fast 3D printing - are coming together.

This was announced in a very symbolic setting, at a conference held by the Singularity University in Budapest. It was there that the hybrid exoskeleton was presented - a robotic suit created with the widespread use of 3D printing technologies. It was created by a specialized robotics firm, Ekso Bionics Holdings, Inc. in collaboration with 3D Systems, a leading 3D printing company.

So, the main culprit of the event is the Californian Ekso Bionics. You can guess about the specialization by its very name, which comes from the English exoskeleton - “robotic external skeleton”. This company was created in 2005 and initially focused on military needs. The image of Robert Heinlein's Starship Troopers combat suits, combined with the habit of Pentagon strategists to send their GIs to mountainous areas, inspired engineers to create an exoskeleton for army needs.

An early version of the robotic exoskeleton that Ekso Bionics worked on with the University of California and Army megacontractor Lockheed Martin was named HULC. This is a twenty-two-kilogram hybrid of an easel backpack made of aviation aluminum alloys and titanium with hydraulically controlled prostheses, which were controlled by a processor located in the same backpack. The battery, which had enough energy for three hours, made it possible to carry loads of up to ninety kilograms over very rough terrain.

But then Ekso Bionics discovered a larger and more profitable market - medical services. You can kill a person once, but heal - for a lifetime! And despite the rise in the active and passive safety of modern cars, people regularly find themselves confined to wheelchairs as a result of road accidents. And no one canceled paralysis as a result of diseases. And the ethical component - the desire to help people return to an active life - cannot be written off either.

And in 2010, a company then called Berkeley Bionics introduced a device more useful than the army non-terminator, called the Exoskeleton Lower Extremity Gait System (eLEGS). It was also an external skeleton, a movable prosthesis with a hydraulic drive and a digital control system, allowing people with paralysis or severe injuries of the lower extremities to regain the ability to walk.

The novelty immediately "received excellent press", Time magazine included it in the list of the fifty best inventions of 2010, and according to Wired in the list of ten outstanding gadgets - 2010, it was second only to the iPad. That is, the computer engineering community immediately appreciated the device, but the medical authorities turned out to be much more conservative. The permission of the American FDA for the use of eLEGS in hospitals and rehabilitation centers was issued only in 2012, at the same time, medical European bureaucrats awarded it the CE marking, allowing it to enter the EU market.

That is, the computer engineering community immediately appreciated the device, but the medical authorities turned out to be much more conservative. The permission of the American FDA for the use of eLEGS in hospitals and rehabilitation centers was issued only in 2012, at the same time, medical European bureaucrats awarded it the CE marking, allowing it to enter the EU market.

Today, these exoskeletons are undergoing quite intensive clinical trials; they are available on the market, including for individual buyers, at a price of about $ 100 thousand. The device, renamed Ekso, weighs 20 kg, is suitable for users up to 100 kg in weight and up to 195 cm tall, is capable of allowing them to move at speed for six hours up to 3.2 km / h in a straight line, sit down and get up, independently leave the wheelchair and return to it.

Ekso Bionics, which managed to change its name to the current one, did not waste time in vain and developed more advanced versions of the exoskeleton, using materials that are lighter and stronger than titanium and aluminum - like carbon fiber - and more advanced batteries. True, the prices of such devices were already mentioned at around $140,000, which is expensive even for the United States, where the victim of an accident has a real chance for solid insurance payments, and prohibitively expensive for less prosperous countries.

True, the prices of such devices were already mentioned at around $140,000, which is expensive even for the United States, where the victim of an accident has a real chance for solid insurance payments, and prohibitively expensive for less prosperous countries.

And mass production of medical exoskeletons - unlike tablets, in the company with which they came, if not to the world, then to the pages of Wired - cannot be. The device is high-tech and complex. How can one resolve the contradiction between the limited amounts that the disabled, the poor, can pay for a vital device, its complexity and low serialization? And this is where 3D printing comes to the rescue with its possibilities for customization, the production of individual products using mass technologies.

And it comes in such a way that even the purely business newspaper The Wall Street Journal considered it necessary to reflect it. Amanda Boxtel, who was paralyzed in 1992 after a ski injury in Aspen, Colorado, presented a hybrid exoskeleton at the Budapest conference of the Singularity University. This device was assembled from 3D printed custom parts created by 3D Systems designers from multiple 3D scans of Amanda's thigh, lower leg and spine.

This device was assembled from 3D printed custom parts created by 3D Systems designers from multiple 3D scans of Amanda's thigh, lower leg and spine.

This solves several problems at once. A copy of the prosthesis, although produced using mass-scale 3D printing technologies, turns out to be customized, adjusted to the anthropological parameters of a particular user. The widespread use of 3D-printed parts will simplify and reduce the cost of exoskeleton operation. The fact is that this device is designed for intensive wear, accompanied by no less intense wear of parts. And being able to print the necessary replacement, if not at home, then at the service center, is very useful!

And mass-produced 3D printers using mass-produced consumables for 3D printing can fundamentally reduce the cost of these necessary devices. Let's remember the boy Leon McCarthy, who had no traditional left hand prosthesis even in well-fed America, and who acquired a new quality of life thanks to the simplest device made by three-dimensional printing. And how many such people live on the planet and in poorer countries...

And how many such people live on the planet and in poorer countries...

Ekso Bionics is one of the five start-ups that have changed medical technology forever, according to Medical Device & Diagonostic Industry Magazine. Indeed, the specificity of living organisms is such that each of us, although arranged in general in the same way, is individual, formed by a purely specific development of this organism. And now it has been demonstrated that it is possible to satisfy the individual needs of a particular organism using mass-produced 3D printing technology (3D scanning is also an easily automated process). So it was not in vain that the hybrid exoskeleton was presented by the University of the Singularity!

How 3D printing is changing the medical industry

3D technology is slowly becoming one of the main tools in the medical industry. For example, scientists at Stanford University in 2014 created a unique exoskeleton for the correction of scoliosis, and three years later, employees at Northwestern University Chicago developed an artificial ovary that allows complete restoration of reproductive function.

In domestic practice, 3D printing is still used fragmentarily, but interest in promising technology is growing every year. Together with 3dVISION specialists, we will tell you how else 3D technologies can help in the treatment of diseases.

Safe surgery

Previously, future surgeons were trained according to the following principle: they looked at the progress of the operation, performed the same one on their own, then trained another specialist. 3D technologies make it possible to hone surgical skills not on living people, but on the most accurate copies of organs printed on a 3D printer. This brings as close as possible to real working conditions and reduces the risk of making mistakes during serious operations such as removal of a brain tumor or congenital diaphragmatic hernia.

Donor organs

3D printed donor organs have been around for several years. So, in 2013, at Wake Forest University, scientists printed a three-dimensional bladder based on cultured cells taken from the original organ. The created prototype was placed in an incubator, and when the time came, it was transplanted into the patient's body.

The created prototype was placed in an incubator, and when the time came, it was transplanted into the patient's body.

It is not yet possible to print any organ for effective transplantation, but medicine is close to it. This is confirmed by Israeli scientists who printed the world's first three-dimensional heart. It is still very small, but already able to fully perform all its functions.

Learn more about 3D printing

Dentures

3D printers allow you to create bridges, as well as crowns, implants and other dental structures almost instantly. It is enough to scan the oral cavity and print the desired three-dimensional model, taking into account all the anatomical nuances of the jaw structure. Whereas previously a patient required at least five visits before a suitable prosthesis was made, now there is no need to regularly visit the clinic to try on an impression and a provisional prosthesis – everything can be done in one go.

Bone reconstruction

Additive manufacturing opens up new possibilities for bone reconstruction. For example, in 2014, a Dutch woman had her skull replaced with a 3D-printed plastic implant. To create a three-dimensional model of new bones, the doctors needed only tomographic images of the patient. Moreover, scientists at the University of New South Wales have recently developed a ceramic ink using living cells for a 3D printer that, at room temperature, can print material with a structure similar to bone tissue.

For example, in 2014, a Dutch woman had her skull replaced with a 3D-printed plastic implant. To create a three-dimensional model of new bones, the doctors needed only tomographic images of the patient. Moreover, scientists at the University of New South Wales have recently developed a ceramic ink using living cells for a 3D printer that, at room temperature, can print material with a structure similar to bone tissue.

Custom medicines

3D printing is also beginning to be actively used to create medicines. Aprecia Pharmaceuticals' Spritam tablet, which helps control epileptic seizures, was the first drug to be printed and approved by the US Food and Drug Administration (FDA). According to Mohamed Albed Alnan, lecturer in pharmacy at the University of Central Lancashire, 3D printing will allow the creation of medicines according to an individual prescription, exactly following the desired dosage.

Buy 3D printing equipment

You can buy a 3D printer and all the necessary accessories to work with it in the 3DVision store.

-kupit-v-soin-store.ru-3.png)