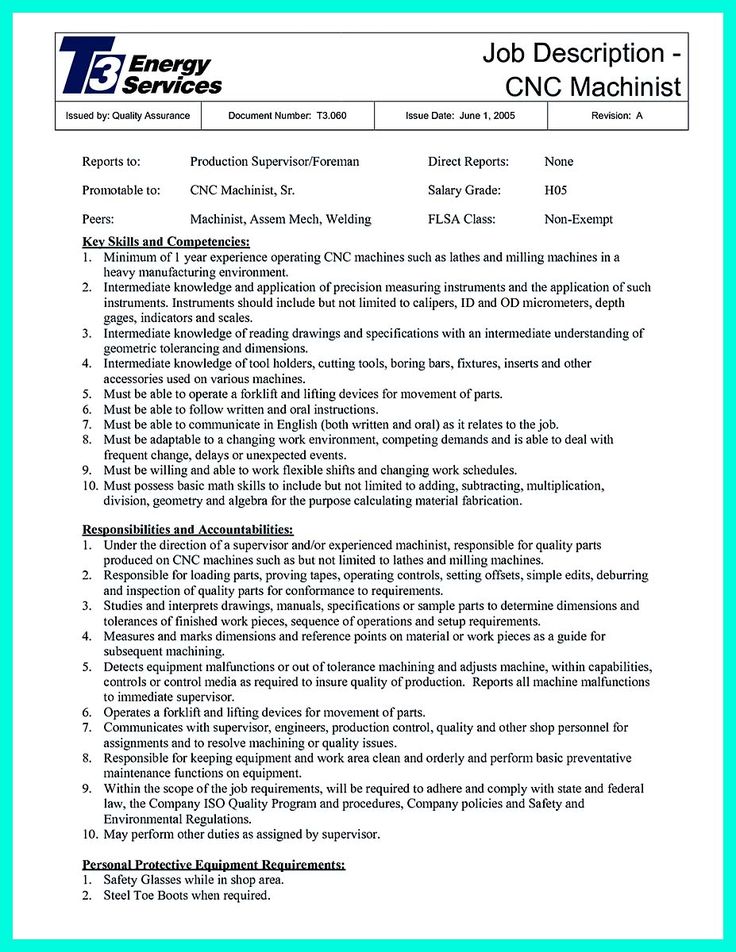

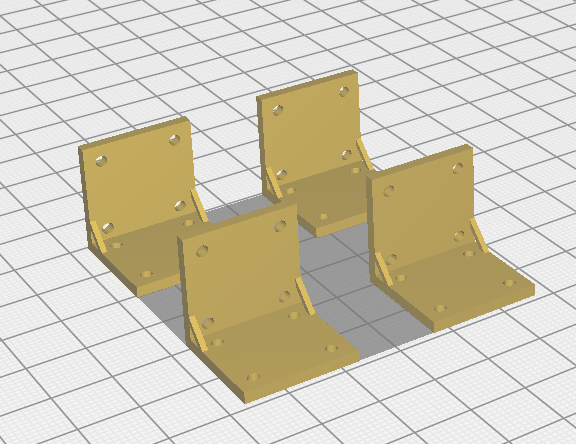

3D printed brackets

Bracket best 3D printing models・Cults

Stamp holder

€4.90

Child safetygate bracket

€0.54

PS4 Controller Wall Hook Mount

Free

MPSM Rewire Connectors

Free

Extrusion-Mount Accessory Shoe

Free

USB and SD card holder

€0.50

design bracket/shelf support

€1

Arduino Nano Pci slot for ambilight

€0.50

Bracket Collection One

Free

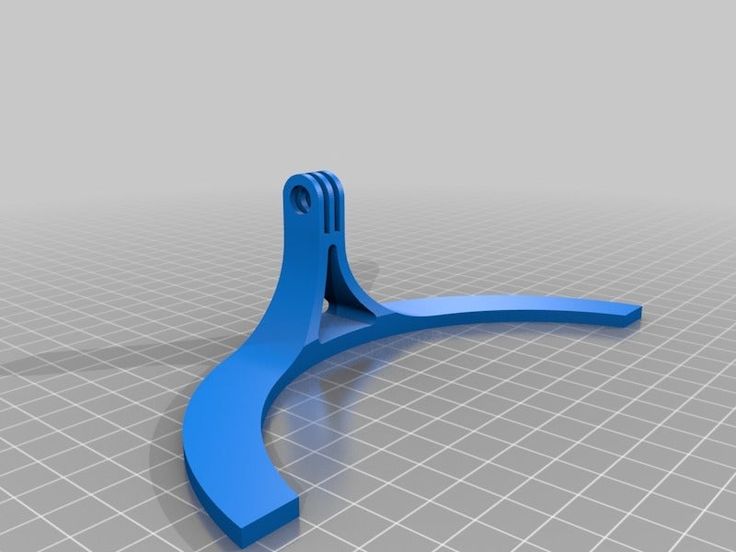

GoPro Hot Shoe Mount

Free

Filament Spool Storage Bracket 3/4 EMT

€2. 76

Rivet Shelf Joint

Free

Parametric detachable bin with modular, parametric mounting system

Free

Tablet wall mount

€2.49

Traxxas Maxx standard size servo holder

€3.50

Jeep doors off mirror extension for 7mm shank mirrors and 8mm bolt

Free

Whiteboard/Frame Mounting Brackets

Free

Multiplug Bracket

Free

Traxxas Sledge Spoiler Bracket Stable Flexible Bracket

€2.95

Tonneau Clamp Bracket

Free

Modified Mounting Bracket for Raspberry Pi 4B housing for Miuzei 800x480 4" Touchscreen for CR-6 SE

Free

License Plate Date (Fusion 360)

Free

Rear shelf holder FIAT Scudo 2014

€4. 61

61

Support for helmet zanella logo

€0.59

Ikea omlopp mounting bracket

Free

3 fold tealight holder

€0.50

Blue Yeti Pop Filter Mount

€2.07

shelf / Wall bracket 90 deg

Free

Selfie stick bracket / Soporte para celular Selfie stick

Free

FHW: You're a Star (body tassels)

Free

Etienne van Wyk

€1

GoPro Mount (RIG) (Action Camera Handle)

€5

Babyliss FX3 Hair Clipper Blade Adapter Bracket

€10.18

iSpring Filter Mount

Free

HDR 50 Revolver Mount Bracket

€2. 49

49

Insta 360Go2 Actioncam Mount for Tinyhawk 2 Freestyle FPV Drone

€9.95

Filament Bracket for Ikea Mosslanda shelf

Free

20mm Extrusion Corner Bracket

Free

Rode nt usb holder ring

€1.99

Ender 3 direct drive mount

€0.65

corner bracket

€1.25

Shelf Bracket

€1.47

Amazon Basics USB Extension Holder

Free

Step Stool Hanging Bracket

Free

Shelf Angle 150 mm

Free

ENDER 3 S1, S1 PRO, REINFORCED BRACKET Z AXIS MOTOR

Free

Royal Pot

€3

shelf Bracket for Ikea Furniture

€2. 06

06

The Best 3D Printed Brackets Service

Are you in the search to find 3D Printed brackets with an outstandingly efficient and top-notch quality?

Here is DEK, a company that specializes in providing you with 3D printed brackets with all of the great characteristics you are looking for at reasonable prices.

21+ Years

Manufacturing experience

72M+ Parts

We had finished

2300+ Clients

Over the world

99.9%

Satisfaction

Highly Accurate and Precise 3D Printed Brackets

Are you eager to be trusted by your customers with the help of offering highly accurate and precise 3D printed brackets so that they do not have any trouble attaching different objects?

You can get brackets with the greatest accuracy and precision because of our advanced technology and expert engineers.

Inexpensive and Superb Quality 3D Printed Brackets

DEK is a place that provides you with superb quality 3D printed brackets at a reasonably cheap price.

Because most of the clients want to get high-quality services at as little cost as possible.

So, worry no more! DEK is here to help you out in every aspect.

Take a Look at Our More Effective and Superior Quality 3D Printed Capabilities

SLA 3D Printing

SLA or Stereolithography is the first 3D printing technology ever invented. It uses ultraviolet lasers to selectively cure layers of polymer resin for the manufacturing of an object.

Moreover, the SLA is the most pocket-friendly 3D printing technology for highly accurate and smooth surface finishes of products.

SLS 3D Printing

SLS or Selective Laser Sintering has remarkable mechanical properties.

It does not only have high resolution but also has great strength and stiffness.

As far as its parts are concerned, it has a powder feeder on its top, laser scan system with heaters, recoater, build platform, printed part, and overflow bin.

MJF 3D Printing

MJF stands for Multi Jet Fusion that uses a fine-grained material that allows for a very thin layer of 80 microns.

The layer of 80 microns not only leads parts to high density and low porosity but also leads to an exceptionally smooth surface and finishing.

DLP 3D Printing

DLP stands for Digital Light Processing that is a type of vat polymerization 3D printing technology.

Vat polymerization 3D printing technology uses a liquid, photopolymer resin that solidifies under a light source.

Digital Light Processing has a build plate, resin, resin vat, and projector.

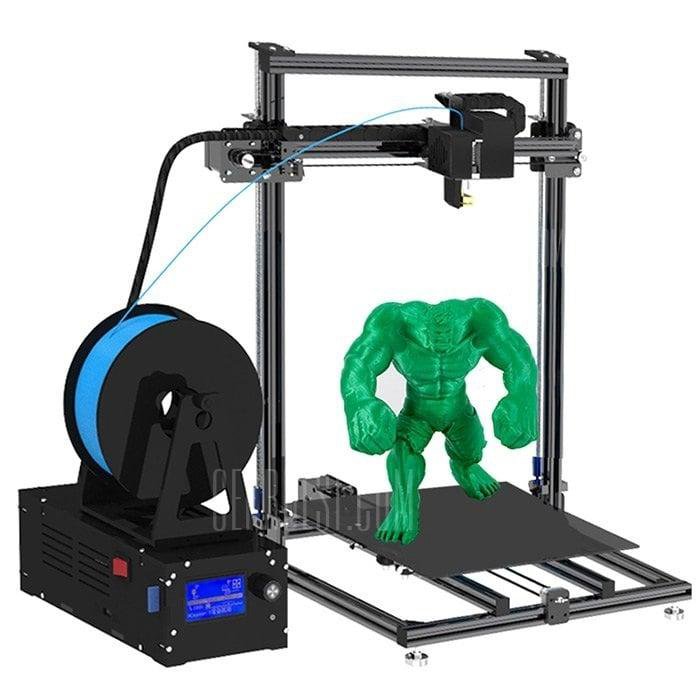

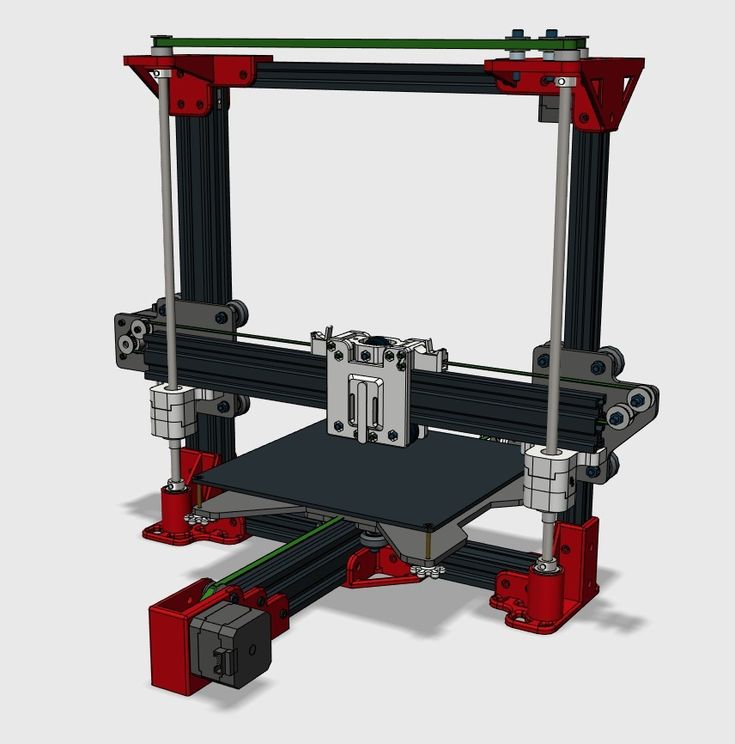

FDM 3D Printing

Fused Deposition Modeling is also known as fused filament fabrication or filament freeform fabrication.

It is a 3D printing process that uses a continuous filament of thermoplastic material.

The filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on the growing work.

Polyjet 3D Printing

A PolyJet 3D printer works like an inkjet printer. The PolyJet 3D printer jets drops of photopolymer that solidifies when exposed to ultraviolet light.

PolyJet 3D printing technology is famous for its fantabulous realism and aesthetics.

Moreover, it offers greatly precise and smooth surfaces.

SLM 3D Printing

SLM or Selective Laser Melting is one of the new assistive manufacturing technologies that appeared in the late 1980s and 1990s.

It manufactures a product by selectively melting successive layers of powder by the interaction of a laser beam.

The above process is repeated until the product is completely formed.

Recent projects we finished

Before you, we have successfully manufactured 72M+ different parts.

Why choose us?

Working with market leaders in the On-demand manufacturing industry, without the busyness and risk.

High Precision

Foremost, we'd like to mention one of the reasons why you can trust us - we offer the most precise and accurate services that have set us apart from many others.

Excellent Quality

We have maintained the excellent quality of 3D printed brackets services due to more than 21 years of experience, advanced machinery, and expert engineers.

Low Cost

DEK is a company where you can get premium-quality services at cheap prices and that is how DEK makes you feel comfortable working with us.

Quick Turnaround Time

We have made ourselves strictly prohibited to delay our services and that is why you do not have to worry about the products being late while working with us.

Business Partnership

We do not deal with you just for the sake of providing services and getting money, we assure you that working with us will inspire you to become our business partner.

24x7 Services

We feel satisfied by satisfying your wants and needs for a quick turnaround. To bring this satisfaction into reality, we work 24 hours a day and 7 days a week.

Quality is our top priority

“QUALITY COMES NOT FROM INSPECTION, BUT FROM IMPROVEMENT OF THE PRODUCTION PROCESS.

-DR. W. EDWARDS DEMING”

To DEK, Dr. Deming’s textbook remark is not a theory, but a practice we have been conducting every day. We use advanced production technologies and strict control systems to ensure high quality. More importantly, the quality-oriented attitude has been so entrenched in the mind of every single employee.

We never stop improving

“We use advanced 3D printing technologies and strict control systems to ensure high quality. More importantly, the quality-oriented attitude has been so entrenched in the mind of every single employee.”

-Austin, GM of DEK

In DEK, we never stop improving the quality of our product. This is how we differentiate ourselves from the competition and is also why we can remain on top of the game for so many years.

Will you optimize the design?

Yes, we will analyze your 3D files and make recommendations suitable for 3D printing.

Do you provide surface finishing services?

Yes, we can perform surface finishes such as sanding, polishing, and coloring on the 3D printed parts.

Do you provide parts assembly services?

Yes, after printing the parts, if necessary, we can assemble them.

How long does it take to print?

Generally within 1-3 days, depending on your requirements, such as quantity, material, surface finishing, etc.

How to pack?

The product will be wrapped with foam cotton to avoid bumps, and then placed in a reinforced 5-layer corrugated box.

How to transport to our company?

For small-sized goods, we will deliver them directly to you via DHL, FedEx, UPS, TNT. It usually takes 3-7 days.

It's our honor to be their best partner

Being a client of DEK, I have been supplied all of the 3D Printed products with satisfaction from every angle of the business.

DEK has provided me with the orders in time and I don’t have words to describe the quality of products they manufacture.

Theo Y.

I have had an awesome experience while working with DEK for its precision, accuracy, and greatness in the quality of 3D printing they have provided us. It is DEK because of whom our business is taking off day by day. I’m truly grateful for their great efforts in providing premium-quality services.

Theodore L.

Free 3D file Prusa i3 Printer Mounting Brackets・3D Print Design for Download・Cults

Credit Card, Loyalty Card, ID Card Holder Box

Free

1.25" Sony Minolta A-Mount Eyepiece Adapter

Free

Eyepiece Adapter for Sony E-Mount 1.25" Telescope

Free

Solar eclipse photography filter holder for Baader AstroSolar filter, fits 85mm lens diameter

Free

Camera lens focusing aid (for precise focusing)

Free

Knurled screw knobs

Free

QHY PoleMaster flat base with M6 screw hole

Free

Side Mount 120mm Fan to 100mm Flat Profile Duct

Free

The best files for 3D printers in the Tools category

Hanging Tool Organizer

Free

ShredderCard Herb Grinder by 420ThreeD

Free

Miter Box

Free

Multi-Color Micro-Tool Set Holder

Free

Milwaukee Charger mount (PEGBOARD REMIX)

Free

Bottle opener

Free

CUTTER FOR PLASTIC BOTTLES

3,50 €

Heart Helicopter V3

Free

Bestsellers in the Tools category

telephone ring holder

0,90 €

Ender 3 S1 BEST cable guide - vertical

2,50 €

DnD terrain rollers - Tiles

4. 61 €

61 €

Creality Sonic Pad Mount for Ender 3 S1 Pro

1.29 €

Tool holder for 3D printer V3.0

1.01 €

PET-Machine, make your own plastic bottle filament at home!

50€ -70% 15 €

PRECISION CALIPER 3D PRINT DIY

3,10 €

UNIVERSAL BED LEVELING INDICATOR FOR VERY ALL PRINTERS

2,31 €

ENDER 3 S1, S1 PRO, SPRITE, HOT END DUCT 4020 OR 5015 FAN, NON-OFFSET Y PROBE, ABL BETA 9 ADAPTER0004

€2.24 -18% 1.84 €

ENDER 3 S1, S1 PRO, SPRITE, V3 AIR DUCT FAN 5015, ACCELEROMETER, LED strip

€2. -18% 2.16 €  64

64

Chill Buddy 9 lighter case0004

0.91 €

PRECISE DIAL INDICATOR 3D PRINT DIY

1,90 €

well designed: Hemera fan duct

2.50 €

ENDER 3 S1/S1 PRO, 2020 ALU PROFILE, REEL SEAT AND DEPORTED COIL

€2.09 -18% 1.71€

Business card embossing system

3 €

Display holder FLSUN v400

9.99 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people , so support us in keeping the activity going and making future designs of is very easy. Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via Ko-Fi here 💜.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Aircraft 3D printing: An engineer's story Boeing

Each Boeing 787 passenger aircraft has about 30 3D printed parts. Combined, Boeing Commercial Airplanes (jet airliners and business jets) contain 25,000 printed parts. And military aircraft F-15 and F / A-18 - about 40,000. Most of the components are components of air ducts, but there are engine parts and parts of the interior of the cabins.

Boeing spokesman Bernardo Malfitano spoke at the EAA AirVenture Oshkosh Aviation Enthusiast Forum and talked about how 3D printing is being used in the aircraft industry today.

Mechanic, test engineer, aircraft builder and pilot

Bernardo Malfitano has been with Boeing since 2007. In his career, he was engaged in the repair and maintenance of the air fleet, analyzed the wear and tear of aircraft. Now he is involved in the development of new aircraft.

According to the expert, all popular 3D printing methods are now used in the aerospace industry: laser stereolithography (SLA), deposition method (FDM), selective laser sintering (SLS) and direct metal deposition (DMD). Unlike traditional techniques, in which the cost of a part depends on the circulation (the higher it is, the lower the price for each spare part), 3D printed products cost the same: it doesn’t matter if you ordered 10 or 1000 pieces. Therefore, it is advantageous to use this technology for small circulations.

Where are printed parts on airplanes?

Air ducts are the part of the aircraft where 3D printed parts are most widely used today. In modern aircraft, circulating air maintains a comfortable temperature for a person and a safe pressure. 3D printed air duct connections are used in the Boeing 787, F/A-18 and F-35 fighter jets, and Bell 429 helicopters.

In modern aircraft, circulating air maintains a comfortable temperature for a person and a safe pressure. 3D printed air duct connections are used in the Boeing 787, F/A-18 and F-35 fighter jets, and Bell 429 helicopters.

There are also 3D printed parts in the systems that propel the aircraft. As a rule, these are metal products made by laser sintering or metal deposition. So, in the Boeing 777, the compressor is connected to the temperature sensor using a 3D-printed adapter. And in the F-15K Slam Eagle military aircraft, casings for turbines were made using volumetric printing. This reduced the cost of the part from $34,000 to $2,550 and halved its production time.

Interior details . Shelves, brackets and various fixtures in passenger aircraft cabins are often printed in plastic. For example, the popular Boeing A350 has over 500 of these parts on board.

Small parts. End caps, parts of seats and instrument cases - all this can also be made using the 3D printing method. In the Boeing A300 passenger ship, brackets and seat belt buckles for crew seats are produced in this way.

In the Boeing A300 passenger ship, brackets and seat belt buckles for crew seats are produced in this way.

Advantages of 3D printing for aircraft construction

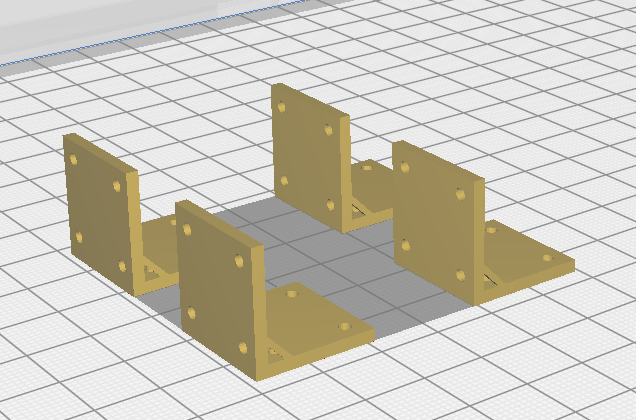

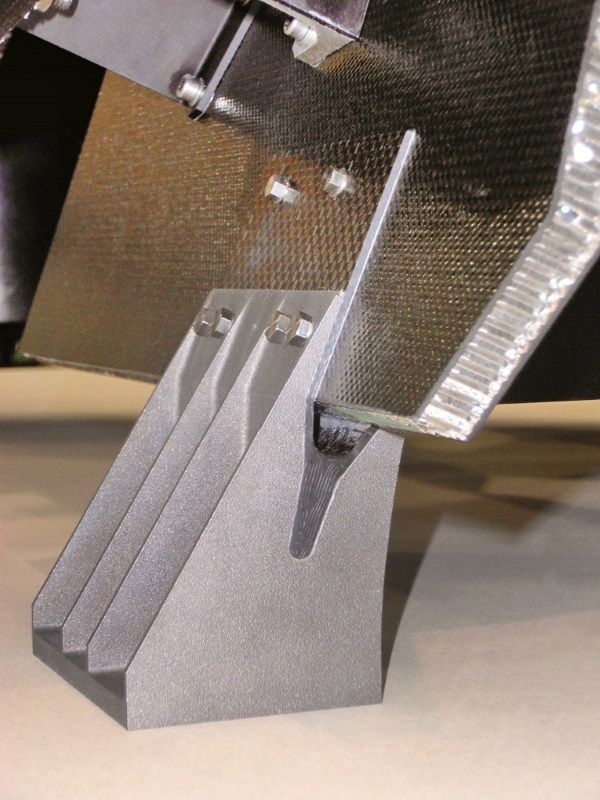

Additive technologies attract aircraft designers not only because they are economical. They make it possible to optimize the shape at the model stage and significantly reduce the weight of the product. So, by replacing the cast metal bracket with a plastic one printed on a 3D printer, the designers managed to reduce its weight from 918 grams to 326. Of course, there is more than one bracket on the plane, so the total gain in weight is several kilograms. For passenger aircraft, lightening the design means reducing fuel consumption, which reduces not only the costs of the airline, but also environmental damage.

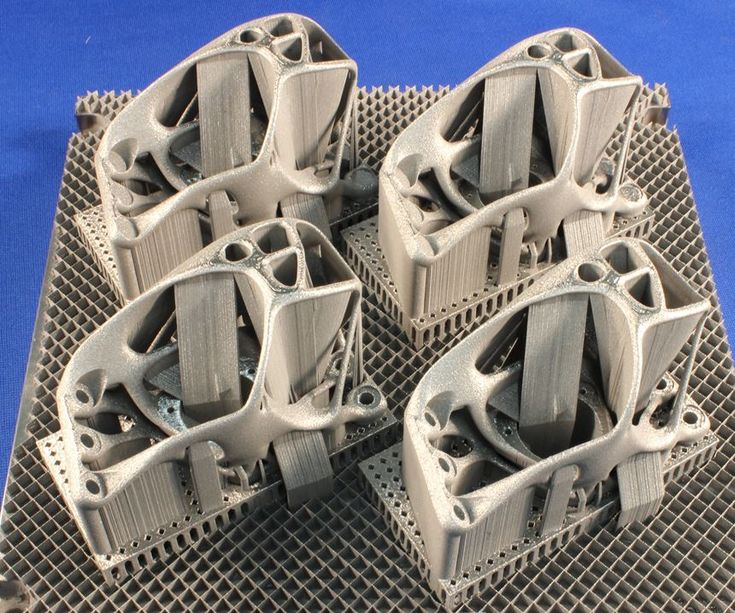

Parts with mesh and honeycomb structure are lighter than monolithic ones, but at the same time they do not lose strength. Each new sample introduced in the aircraft industry undergoes multi-stage tests, especially if it is a functional part.

Is it possible to print the entire aircraft?

If additive technologies are so good for 3D printing, is it possible to print an entire airplane? Bernardo Malfitano is sure that now it is impossible.

Today, 3D printing is successfully used to make drone bodies and working models of aircraft. At the Berlin Air Show in 2016, visitors saw the Airbus Thor, a remote-controlled aircraft about 2 meters long. All of its parts were 3D printed.

But to create the hulls of large aircraft - passenger liners, cargo planes, fighter jets - modern 3D printing technologies are not reliable enough.

Malfitano explained that the US has statutory manufacturing standards. The aircraft industry is governed by 14 CFR Part 25 (“Airworthiness Standards: Transport Category Aircraft”). It says that the structure of the materials must be strong, and the details must be reliable, which must be confirmed by certain tests. Meanwhile, testing parts created by 3D printing often reveals defects and inhomogeneities.