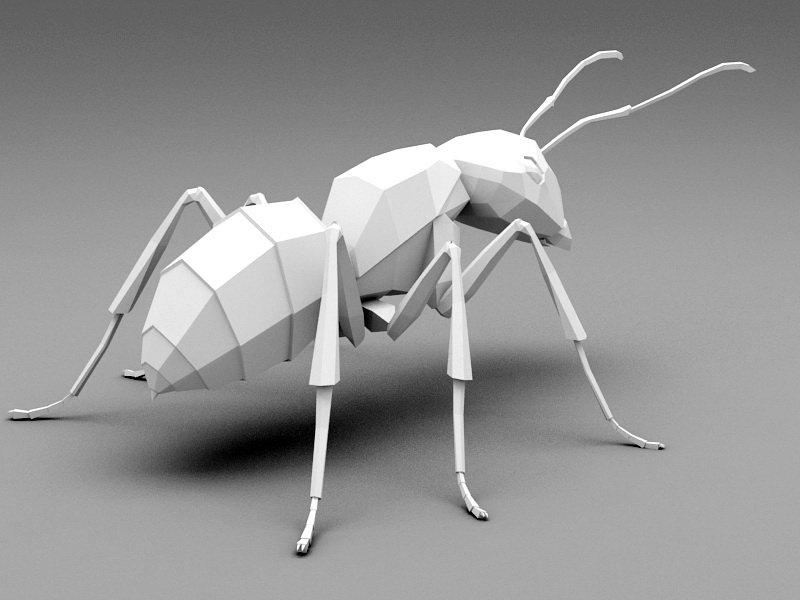

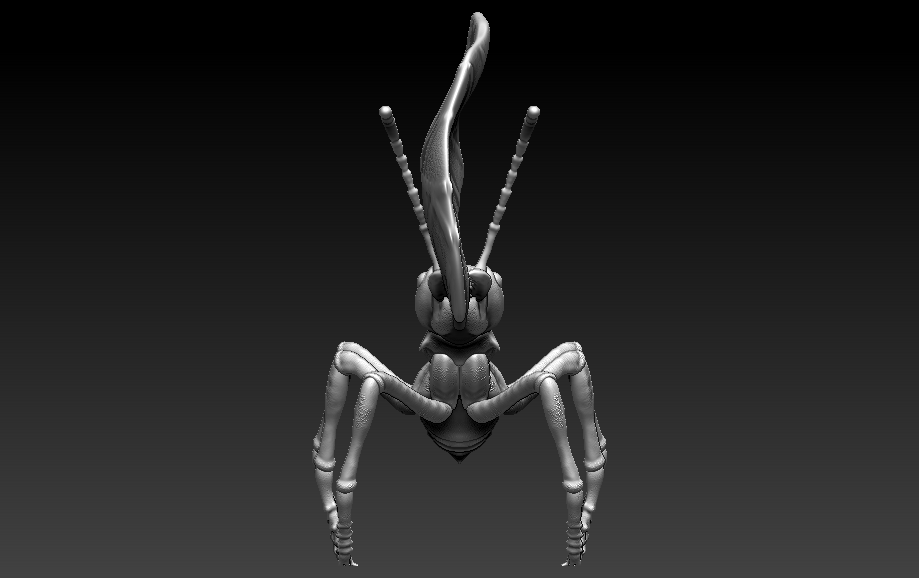

3D printed ant

Ant best 3D printer files・Cults

Avengers Assemble ! Chicken Edition meme

€0.70

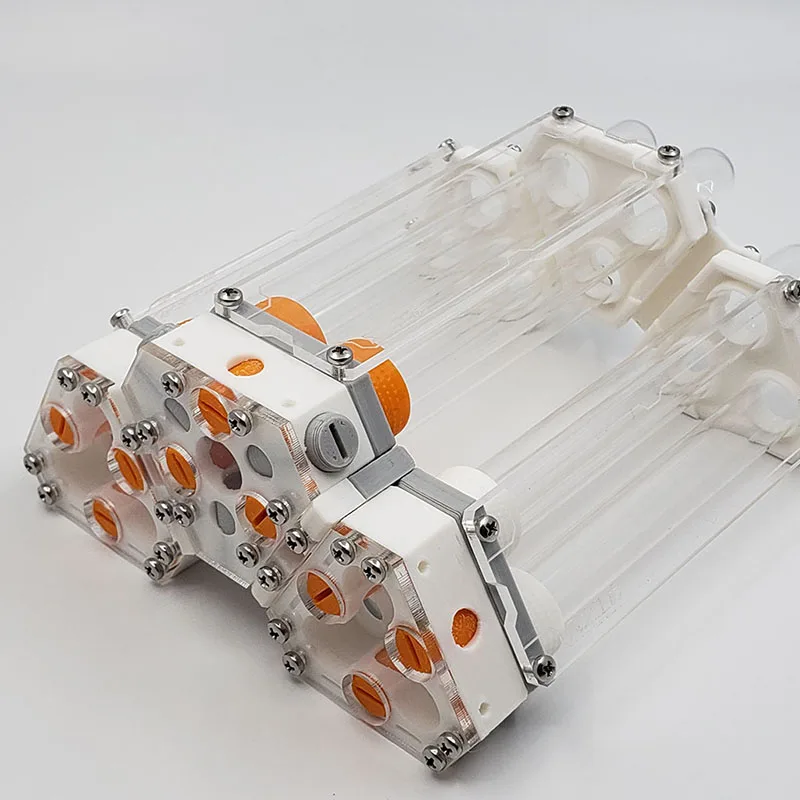

Hexxagonal ant nest

€30

Dire Pangolin

€1.86

M.O.D.O.K

Free

Hummingbird feeders Ant trap

Free

ant moat ant stopper

Free

Ant TnX

€2.79

MODOK 3D model ant man and the wasp

€10

Ant Formicarium (Supportless)

€1.25

ant farm airlock

€0.50

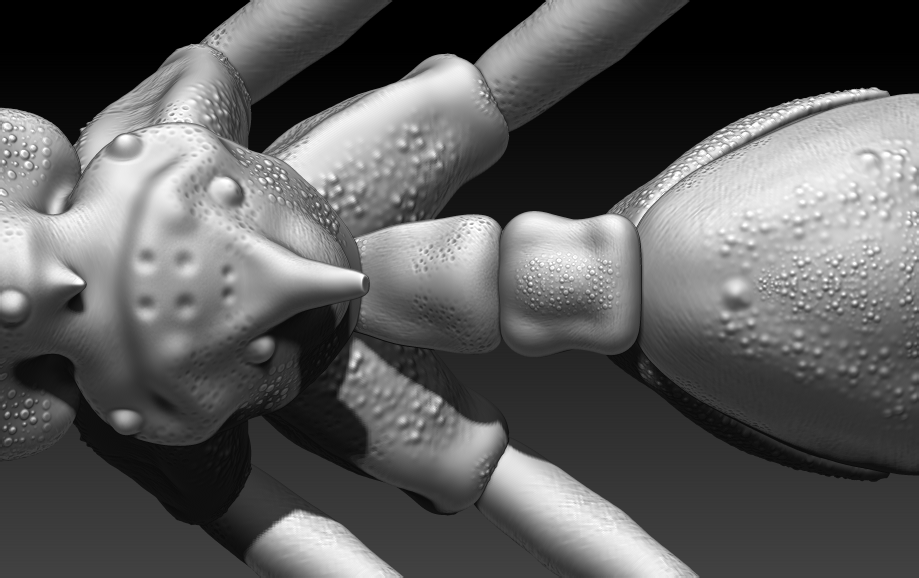

Ant 3D MODEL

€3.99

Pym particle disk Antman prop replica

€3. 50

Ant-Man Keychain and Coaster

Free

BIKE AND ANT ATOMIC ATOMICA WORLD CHAMPION BMX

€1.72

Iron-Ant // Ant-man Fusion Iron Man ( Fan Art )

€0.70

Ant Liquid feeder

Free

Space Wolf Monster

€3.26

Dragonfly Monster

€4.65

Ant Monster

€2.79

Little Formicarium

Free

Modular Formicarium Tower

€1.50

KANG The Conqueror Helmet - MARVEL COMICS 2023

€35

Ant

€2.99

Ant Formicarium

€4. 05

05

Tupolev ant-25

€2.74

ant, 3D model FTL file

€1.50

Marvel Logo

Free

Ant Queen Ring, fan art, 3dprinatble

€15

Ant Man and the Wasp: Quantumania // Keycap

€0.70

ANT-MAN

€2.09

DINORIDERS INSECT 1988 TOY 71MM FIGURE MODEL PVC EVIL WARRIOR

€3.72

Zombie ant

Free

best ant farm/formicarium for lasius ants (meets all needs)

€0.65 -7% €0.60

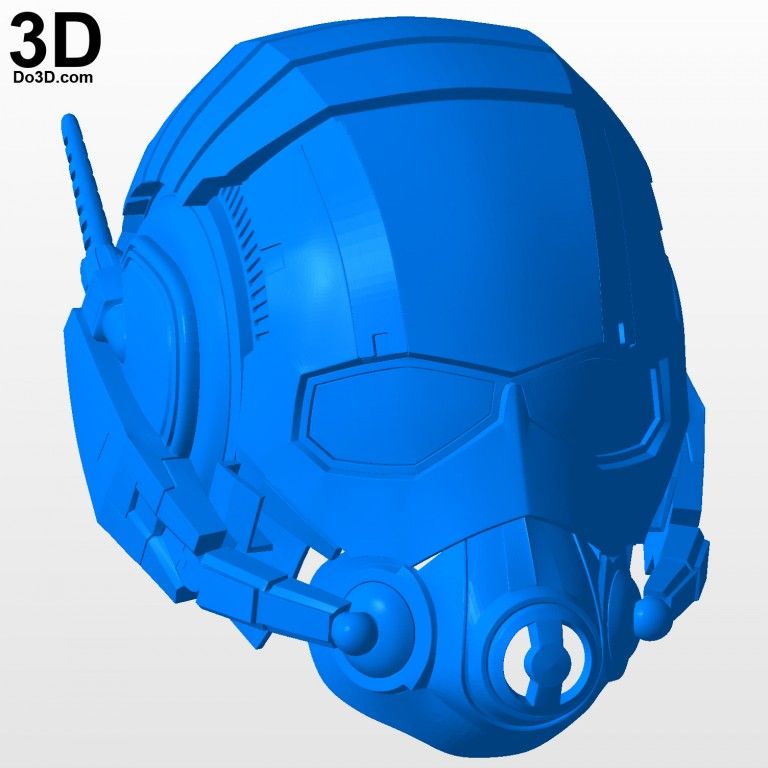

Ant-Man Helmet

€23. 25

25

Fairy bot antweight 150g flipper bot (Barqs bites)

Free

Ant, bug, insect

Free

Transformers Legacy Inferno Weapon

Free

Mini Formicarium Ant Nest

€0.50

Ant Formicarium nest

€0.50

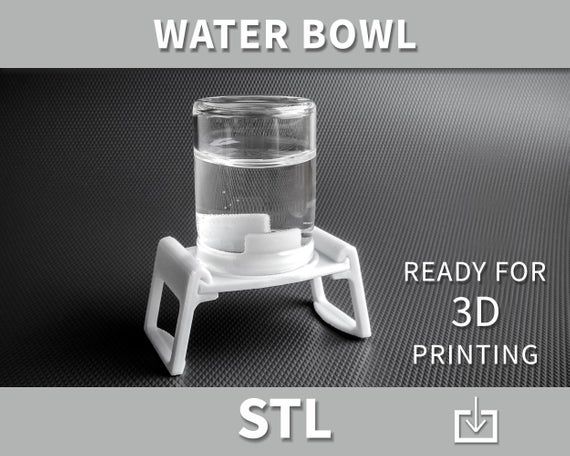

Ant drinking plate

Free

ants feeding plate

Free

Wasp Helmet - Fan Art 3D print model

€30

Antlion Halflife STL 3D print 3D print model

€9.21

Ant-stronaut Autogunners

Free

Ant V2

Free

Ant feeding tools LV2

€0. 50

50

Minifigure, Headgear Helmet with Ear Antennae

€0.50

ant flexi articulated (flexible) ant flexi articulated

€0.99

3D Printed – Ant Keeping Depot

The 3D printed nests you find below are where your ants will live. This will be their nesting area. They are individual nests that will need to be connected to an outworld. This is usually achieved with a length of vinyl tubing.

FILTER

Sort by:

FeaturedBest SellingAlphabetically, A-ZAlphabetically, Z-APrice, low to highPrice, high to lowDate, new to oldDate, old to new

Show:

91836All

Total 2 Iitem(s)

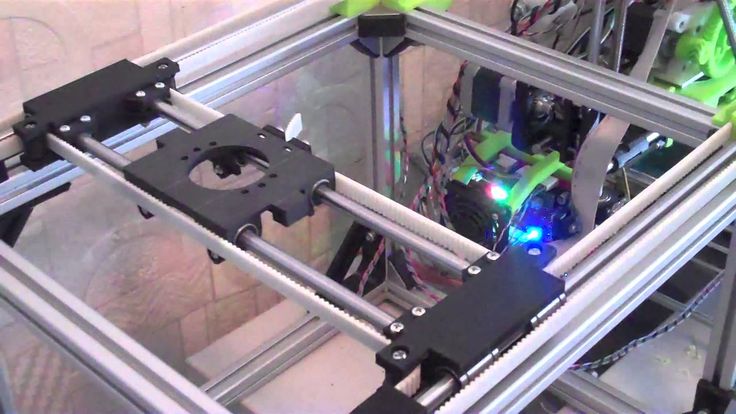

To Top17 real buildings printed on a 3D printer - The Future on vc.

ru

ru 3D printing technologies are developing extremely fast and are used in various areas of human life.

45,753 views

Recently, much attention has been paid to the printing of buildings, and printed houses are increasingly appearing in recent years in different countries of the world - in the USA, Saudi Arabia, Mexico, France, Russia, the United Arab Emirates and others. I have prepared a list of existing 3D printed buildings for 2020.

What is a 3D printer for construction.

Today's 3D construction printers differ in designs and wall construction methods. The most common printers are portal construction, two- and four-support construction, based on a manipulator arm or a circular design. The equipment allows you to create small architectural forms and elements of structures for their subsequent assembly on site, or allow you to print the entire building on the construction site. The height and dimensions of the printed building depend on the specifications of the printer being used.

How the printing process works.

The extruder extrudes a fast-hardening concrete mixture with various additives. Each subsequent layer is applied on top of the previous one, due to which a vertical structure is formed. The concrete layers below are thus compacted, thereby increasing their ability to withstand the next layers, and hence the entire weight of the structure. To strengthen the structure, it is reinforced, which can be both vertical and horizontal. The laying of the horizontal armored belt is carried out between the layers, the vertical reinforcement is installed after the composition has hardened, and then it is poured with concrete.

Advantages of 3D printing over other construction methods.

3D printer fabrication opens up great opportunities for construction and related industries. Practical application has revealed the following advantages of additive manufacturing:

- It removes the limits from the imagination of designers and architects who design buildings, as it provides opportunities that are not available with the construction methods we are used to.

- High speed of construction of buildings and structures.

- Complete process automation.

- Low power equipment.

- Significant savings compared to conventional construction methods by reducing labor and energy costs and accelerating construction time.

- The formation of waste building materials is completely eliminated.

- Minimization of human intervention in the construction process not only allows building in places inaccessible to people, but also eliminates the human factor in ordinary territories and reduces the likelihood of error.

1. June 2014. China. China's Shanghai WinSun Decoration Design Engineering Co has unveiled 3D printed houses at an industrial park in China's Jiangsu province. A total of ten houses were created, each of which cost a little more than three thousand pounds sterling. Over the next ten months, the technology improved and the company produced several different types of buildings for the exhibition, the tallest of which has five floors.

Over the next ten months, the technology improved and the company produced several different types of buildings for the exhibition, the tallest of which has five floors.

2. August 2014. USA. Andrey Rudenko's company Totalkustom printed the lock. The printing took a total of 2 months. The machine's printing speed was 50 cm in 8 hours. The main part of the castle, measuring 3m x 5m and 3.5m high, was printed as a single unit, and the towers were then printed separately.

3. July 2015. China. Chinese company Zhuoda assembled a two-story house in record time. The modular home, made up of six 3D printed modules, was assembled on site in less than 3 hours. Of course actually about 90% of the work was carried out in the company's workshops, and on the site they were only assembled into a single building.

4. September 2015. Philippines. Andrey Rudenko's Totalkustom company built apartments on the territory of a hotel in the Philippines, 10. 5 mx 12.5 m in size and 3 meters high. The building was built using local materials - sand and volcanic ash.

5 mx 12.5 m in size and 3 meters high. The building was built using local materials - sand and volcanic ash.

5. May 2016. UAE. Chinese company Shanghai WinSun Decoration Design Engineering Co printed prefabricated structures for the subsequent assembly of an office building in Dubai. The area of a one-story building is about 250 square meters. m.

6. March 2017. Russia. Apis Cor introduced the first 37 sq. m.. The printed house has an interesting shape, but as the participants themselves say: this is just to show the flexibility of printing technology, the shape of the buildings can also be the usual square. Compared to other construction 3D printers, this printer is very compact (4×1.6×1.5 m), weighs 2 tons, and can be easily transported to the construction site.

7. October 2017. Russia. In Yaroslavl, the company Spetsavia presented the first residential building in Europe and the CIS, built using construction 3D printing technology. Construction of the house began in 2015. The box of the building was printed by a portal printer piece by piece and then assembled on the foundation in one month in December 2015. In the summer of 2017, the roof was completed and the bulk of the interior finishing work was carried out.

Construction of the house began in 2015. The box of the building was printed by a portal printer piece by piece and then assembled on the foundation in one month in December 2015. In the summer of 2017, the roof was completed and the bulk of the interior finishing work was carried out.

8. March 2018. France. Yhnova presented a five-room one-story house with an area of 95 square meters. For its construction, the engineers used a large manipulator, at the end of which an extruder for polyurethane foam is fixed. While working, he applied the foam in accordance with the 3D model of the building loaded into it. After applying the foam, the builders periodically filled the erected part with concrete, and also inserted the frames of doors and windows.

9. March 2018. USA. American Company Icon built a prototype home in Texas to prove the technology's performance. The area of the building was 32 sq.m., printing was performed by a portal type 3D printer moving along rails installed on the site.

10. July 2018. Spain. Be More 3D printed a 24 m2 concrete building. For the construction, a two-support 3D printer was used, the width of which is 7 meters and the height is 5 meters.

11. September 2018. Denmark. 3D Printhuset printed a 50 square meter office in Nordhavn. The 3D printer used for printing is of the portal type and has a size of 8 x 8 x 6 meters. Print speed 2.5 meters / min. Each layer is 50-70 mm. The print material is concrete made largely from recycled tiles and sand.

12. October 2018. Italy. Company Crane Wasp using a three-bearing construction 3D printer erected a building in ten days. The house uses passive solar heating technology and natural ventilation. The composition for printing was created on the basis of waste from rice cultivation (it was 25% local soil (clay and sand), 40% straw, another 25% - from rice husks and 10% - from hydraulic lime).

November 13, 2018. Italy. Arup in collaboration with the architectural bureau CLS Architetti erected a building in 1 week with an area of 100 sq.m. The building was printed in segments with subsequent assembly at the construction site.

Italy. Arup in collaboration with the architectural bureau CLS Architetti erected a building in 1 week with an area of 100 sq.m. The building was printed in segments with subsequent assembly at the construction site.

November 14, 2018. Saudi Arabia. The Dutch company CyBe Construction has completed the construction of a building with an area of 80 sq.m. It took about a week to 3D print the necessary elements, and a little more than a day to assemble. The walls are made up of 27 printed blocks, and the parapets needed another 21 blocks to make.

15. August 2019. USA. S-Squared 3D Printers (SQ3D) showed a prototype residential building that can be built from floor to roof in just twelve hours. The house has an area of 46 m2. During the printing process, a 3D printer of a two-support design was used.

16. October 2019. UAE. Apis Cor has announced the completion of the world's largest 3D printed building. Located in Dubai, the 650 sq. meters has a building height of 95 meters and entered the Guinness Book of Records as the largest building printed directly on the construction site.

Located in Dubai, the 650 sq. meters has a building height of 95 meters and entered the Guinness Book of Records as the largest building printed directly on the construction site.

17. December 2019. Mexico. American company Icon erected two residential buildings for the non-profit organization New Story, in southeastern Mexico. The imprinted buildings have a flat roof, curved walls and an area of 46.5 square meters

As can be seen from the impressive list of completed projects, progress in the field of construction 3D printing clearly does not stand still, new techniques are constantly being introduced, various materials are being created, including from recycled raw materials, and high-tech equipment is being developed. In a short period of time, the technology has attracted the interest of a large number of enterprises that are engaged in the development of equipment, special building mixtures, libraries of structural solutions for designing buildings for 3D printing, as well as the preparation of a legislative, regulatory and regulatory framework.

I am sure that in the future the entire construction process will be able to become fully automated, without human intervention, not only when printing foundations and walls, but also when printing ceilings and roofs, automatically install utilities, doors and windows. Also, perhaps in the future we will not be limited to printing houses of 2-3 floors, but will be able to move on to multi-storey construction. All this is no longer something impossible and has ceased to sound like fantastic dreams of a high-tech future. It is only necessary to give time for the natural evolution of 3D construction technology.

Give a hand. How a 3D printer helps ATO soldiers

Victor Baklan, the founder of the White Ant 3D printing studio, told Focus why printed prostheses are better than traditional ones and what neoprostheses are

Related video

I have always been attracted to new technologies. As soon as I learned about the existence of 3D printing, I immediately caught fire. I started looking for information. But things didn't go any further. And about two years later, I came across an article that affordable 3D printers had already appeared.

I started looking for information. But things didn't go any further. And about two years later, I came across an article that affordable 3D printers had already appeared.

My wife and I just wanted to open our own business and decided: so here it is, our business idea. Our parents supported us and we bought our first Chinese 3D printer.

Victor Baklan: "To start production in order to make five analogues of finger phalanges for one prosthesis is stupid and expensive. A 3D printer can easily handle this"

First practiced 3 D - design, printed cups and looked at new technology. The name of the 3D printing studio "White Ant", by the way, was not coined by chance. The included printer reminds me of a thermite.

I came across a text saying that prostheses are printed on 3 D printers in America. We found a model of a prosthetic hand on the Internet and finalized it. Then we went to a military hospital, talked to a doctor and volunteers, and met a man who agreed to the experiment.

We found a model of a prosthetic hand on the Internet and finalized it. Then we went to a military hospital, talked to a doctor and volunteers, and met a man who agreed to the experiment.

We drew a drawing, took measurements from the fighter, adjusted the 3 D model to fit them, printed all the components and assembled the product. Of course, such a prosthesis can be made in any traditional way. It is quite simple: the hand moves by bending the mechanism at the elbow. But a 3D printer makes it possible to do this quickly (the printing process takes two days) and much cheaper. Our prosthesis weighed 660 g, while its European counterpart weighed up to 3 kg. Now we have it, but our other, improved models are used by two more people.

We are working on a new development - a neoprosthesis. They are not yet made in Ukraine, but are ordered in the USA, Germany and Great Britain. This is a robotic prosthesis with a built-in computer..jpg) It works not due to external mechanisms, but from muscle impulses, which, in turn, receive signals from the brain.

It works not due to external mechanisms, but from muscle impulses, which, in turn, receive signals from the brain.

3 D - the printer is indispensable when it comes to single items. After all, for example, to start production in order to manufacture five analogues of the phalanges of fingers for one prosthesis is stupid and expensive. A 3D printer can easily handle this, and it will be a waste-free production.

In addition to prostheses, we still make decorative items and device prototypes. Sometimes a person imagines a thing for so long, and then picks up its prototype printed on a 3D printer and realizes that he expected completely different sensations. Better or worse, it doesn't matter.

I still have the first part printed on a 3 D printer at home. This is a decorative gear. The second was a phone case, but I do not wear it, we made a mistake with the size.

.jpg)