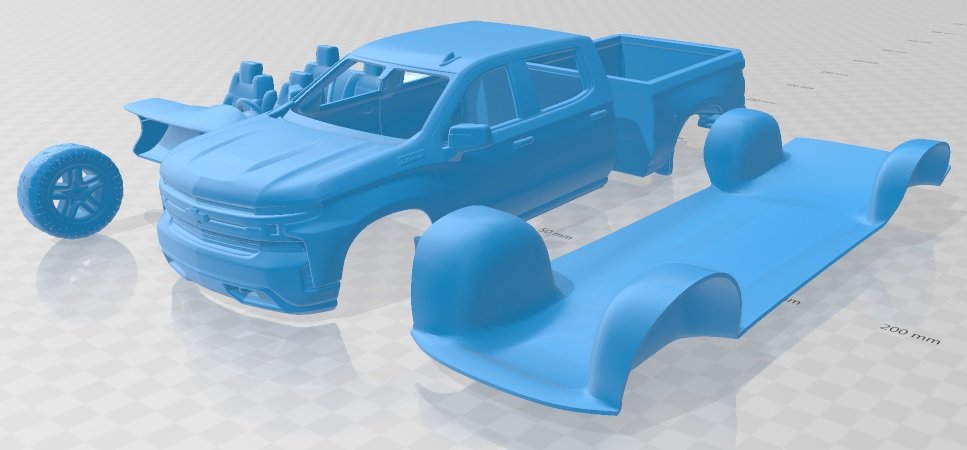

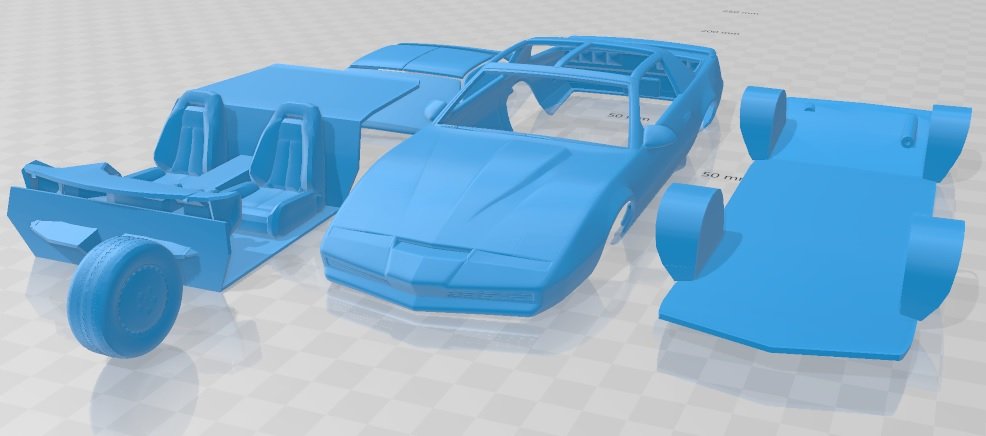

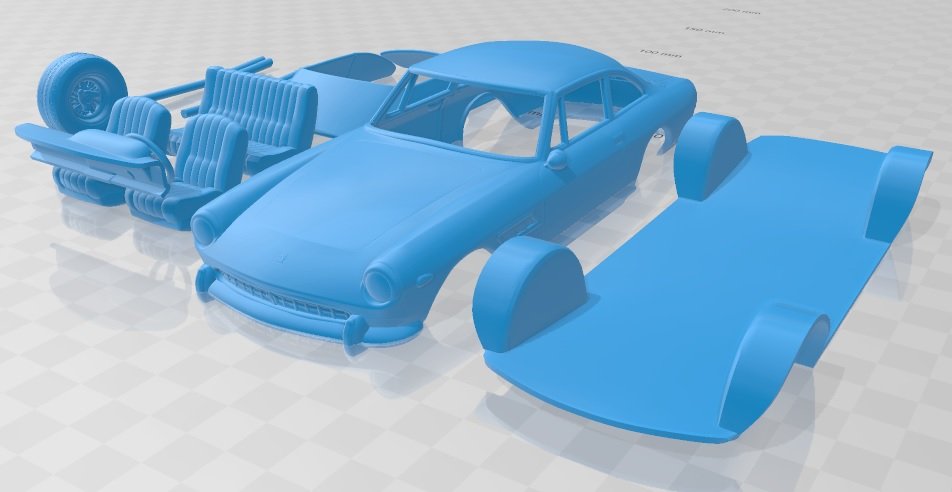

3D printed car for sale

3d Printed Car - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

The 10 Most Exciting 3D Printed Cars & Supercars 2023

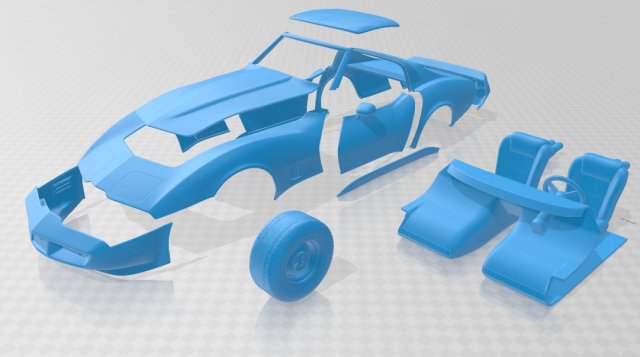

Cars are made from thousands of parts, including some that are incredibly intricate and difficult to make. Enter 3D printers — especially metal 3D printers — that can create these 3D printed car parts on-demand, quickly, accurately, and can create lighter parts that use less petrol.

Experts predict that the 3D printed car market will grow to a $5.3bn industry by 2023, increasing to $12.4bn in 2028. 3D printed cars are predicted to have an impact throughout the automotive industry, ranging from parts — classic car parts, and for new cars — low cost prototypes, tools, and more.

- We have also written a feature story into the uses of 3D printed car parts

- Additionally, we have a feature story into 3D printing in the automotive industry

Advantages of 3D printed cars

How long until a 3D printed car cracks the mainstream car market?

3D printed cars are not far away at all from being regularly seen on city streets. Finished, working prototypes have been around since 2014, and 3D printed buses have been active on an American university for the last three years.

That being said, a fully 3D printed car is yet to hit the city streets. Though small numbers of 3D printed car parts are commonplace, the closest completely 3D printed car to getting a wide release, the LSEV, is yet to announce a concrete release date.

Therefore, we created our ranking of the exciting 3D printed car designs, prototypes and models to showcase the upcoming 3D printed car revolution.

1 – Divergent3D Blade – Awesome 3D Printed Supercar

- Top speed: around 200mph

- 0-60mph time: 2.5 seconds

- Weight: 619kg

Divergent3D are an ambitious and exciting company who have developed the Blade 3D printed supercar, made from carbon fiber tubes and 3D printed aluminium rods.

The company’s ethos is to test how alternative and innovative new ways of manufacturing can bring down costs and make more lightweight yet beautiful cars. The result is the Blade, a 3D printed supercar capable of 200 mph, and equipped with 629 horsepower. The car looks tremendous and will undoubtedly be in-demand by those for whom the likely steep price is no barrier.

Despite not receiving a wide release yet, Divergent founder Kevin Czinger has since released images of a personal project, the Czinger 21C, which is even more extraordinary than the Blade. Capable of a claimed 268mph and with a 1233 bhp engine, the 21C would be one of the fastest cars of all time.

Divergent have recently had to shed a third of their staff due to the COVID-19 pandemic, but we hope they can succeed and release the first 3D printed supercar for the world to enjoy.

Divergent3D’s Blade 3D printed supercar is stunning, and goes fast, too!2 – EDAG Light Cocoon

- Top speed: around 155mph

- Price: estimated $100,000

Unveiled at the Geneva Motor Show in 2015, the EDAG Light Cocoon is a fantastic example of how 3D printed cars can be lightweight but still retain their strength.

Created mostly using Selective Laser Melting, similar to Direct Metal Laser Sintering, though also involving FDM and Stereolithography, EDAG plan to fully finish and release the car in around 2025. This may sound far away, but EDAG are merely working on a realistic timescale for the amount of innovation and work that is required to build a fully 3D printed car of that power. Even so, this is a project that most definitely excites us.

This may sound far away, but EDAG are merely working on a realistic timescale for the amount of innovation and work that is required to build a fully 3D printed car of that power. Even so, this is a project that most definitely excites us.

3 – Nanyang Venture 8

- Top speed: 37mph

Created by a group of students and staff at Nanyang Technological University in Singapore, the Nanyang Venture 8 3D printed car contains over 150 3D printed parts.

Mostly made from ABS material, the team elected to use 3D printing for the car’s shell, grills, door latches, and more. They used an FDM 3D printer to create these parts.

Able to reach speeds of up to 37mph, what’s most interesting about the team behind the NV 8 is that they have since designed its successor, the NV 9, which is partially solar powered. This opens up the possibility of solar powered cars in the future. Both the NV 8 and NV 9 appeared in the Shell Eco-Marathon Asia.Nanyang Venture 8, pictured above, competing in Shell’s Eco-Marathon.

4 – Local Motors Strati 3D printed car

- Top speed: 40mph

- Full charge range: 100-120 miles

- Price: estimated $18,000-$30,000

Conceptualized in collaboration with Cincinnati Incorporated alongside Oak Ridge National Laboratory (ORNL) who supplied the large FDM 3D printer, Local Motors‘ Strati is claimed to be the first ever electric 3D printed car.

The Strati took 44 hours to 3D print back in 2014 – though Local Motors intend to get this down to 10 hours – showcasing it for the first time at the 2014 International Manufacturing Technology Show in Chicago. The design was credited to Italian Michele Anoe, who won $5,000 for the design.

Read more: best car design software (2D and 3D designs)

With a top speed of around 40mph (64kph) and a range of between 100-120 miles, the Strati isn’t just a shiny toy, and is on the fringes of usable for daily life. The price is estimated to be between $18,000-$30,000 with production originally planned for the end of 2015, but in 2020 there is still no official news on the Local Motors website.

What we most like about the Strati however is its environmental friendliness. The thermoplastic used by the FDM 3D printer is fully recyclable, so an old and damaged car can be stripped of this material and reused to make a new 3D printed car. Only the electrical components like the battery and motors, and suspension need to be manually assembled, which is a very exciting development.Local Motors debuting the Strati 3D printed car at IMTS 2014.

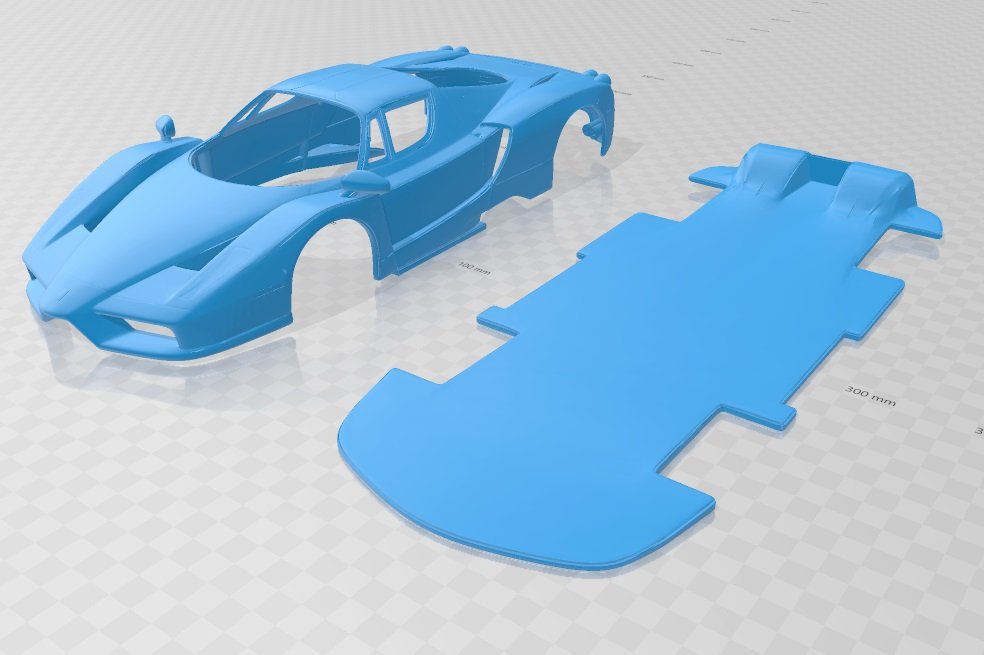

5 – LSEV

- Top speed: 43mph

- Full charge range: 90 miles

Born out of a collaboration between Hong Kong design firm XEV, and Chinese 3D printing company Polymaker, known best for making 3D printer filaments, the LSEV is an electric 3D printed car that was originally set to hit the Asian and European markets in 2019.

Affordably priced at $7,500, the LSEV is completely 3D printed except for the tires, windows, seats and chassis – both the interior and exterior are 3D printed.

As a result, the LSEV 3D printed car weighs just 450kg, and can drive for around 90 miles on a full charge at a top speed of 43mph. What’s more, the LSEV is 3D printed using fused deposition modeling, and takes just 3 days to completely print.

What’s more, the LSEV is 3D printed using fused deposition modeling, and takes just 3 days to completely print.

3D printing was chosen due to its ability to reduce investment costs by a massive 70%, as production is more efficient and less components need to be made. In fact, 3D printing reduced the number of parts needed to make the LSEV from 2,000 down to just 57!

The companies have claimed that these factors make the LSEV an attractive prospect to car buyers, with 7,000 pre-orders claimed to have been made. 3D printing in cars is shown in the LSEV to reduce costs and weight, and encourage the switch to electric cars, which are all beneficial to the environment, and therefore we highly support the increasing adoption of 3D printed cars.

However, now well into 2020 we have not seen a wide release of the LSEV. The company launched a Kickstarter at the end of last year to raise $500,000 for a new 3D printed car, but just under $100,000 was reached and it failed to reach the target. We hope to see the LSEV, or a variant of it, release soon.The innovative LSEV 3D printed car features just 57 3D printed plastic parts, down from 2,000!

We hope to see the LSEV, or a variant of it, release soon.The innovative LSEV 3D printed car features just 57 3D printed plastic parts, down from 2,000!

6 – PUV ORNL 3D printed car

- Top speed: 35mph

- Full charge tank: 35 miles

The PUV is a 3D printed car developed as part of Oak Ridge National Laboratory’s AMIE project. The project aimed to innovate how we use and store energy, with the PUV being equipped with the incredible ability to wirelessly transfer electricity to and from nearby buildings.

The PUV qualifies for our 3D printed car list as it has 3D printed body panels in order to save weight and money, made from carbon fiber-reinforced plastic. Though the PUV can only travel up to 35 miles on a full charge, the fact that it can wirelessly transmit energy makes it a fantastic innovation which we will hopefully see more of in the future.

7 – Toyota uBox

Created from a collaboration between Toyota and Clemson University’s International Center for Automotive Research, the Toyota uBox is a futuristic looking concept car with a 3D printed interior.

Though most of the functional parts of the car are made using traditional techniques, Toyota are experimenting in 3D printed car interiors with the uBox.

Their idea is that, in the future, customers will elect to customize their car’s interior, such as the door trims, dashboard or air vents. Toyota plan to service this market with 3D printed car parts, and eventually allow customers to 3D print their own car parts from home to customize their cars. This is another fantastic example of how 3D printing is being used to add value and customization in new areas.

8 – Project M

- Top speed: 156km/h

Project M is another ambitious 3D printed car project. Made by Shell, Project M is a compact car made of 93 3D printed parts that was designed to be maximally energy efficient.

As a result, whilst weighing just 550kg, Shell’s Project M 3D printed car can reach speeds of 156km/h using its powerful petrol engine. Shell elected to use 3D printing as it saved them money; they no longer had to outsource production and instead could create complex plastic parts quickly and in-house. This shows how effective 3D printing is in reducing the barriers to manufacturing.Somehow, the Project M 3D printed car manages to look both futuristic and retro at the same time.

This shows how effective 3D printing is in reducing the barriers to manufacturing.Somehow, the Project M 3D printed car manages to look both futuristic and retro at the same time.

9 – BMW S1000RR 3D printed bike

So maybe not exactly a 3D printed car, but instead a 3D printed bike, we still felt that the BMW S1000RR deserved a place on this list.

Though not completely 3D printed, this innovative bike does include a 3D printed frame and swingarm, which were 3D printed as it saved BMW money and was quicker to make.

The S1000RR follows over 10 million Euros of investment by BMW in their new 3D printing and additive manufacturing center, with the aim to make future designs lighter. Therefore, we expect to see more 3D printing in future BMW bikes and cars.Though not a car, BMW’s S1000RR is a partially 3D printed bike; the frame and swingarm are 3D printed.

10 – Olli 3D printed bus

- Top speed: 35mph

- Max carry load: 612kg

Olli is another of Local Motors’ innovative inventions in the automotive sector. Not only is Olli a futuristic and sleek-looking 3D printed bus, but it’s also autonomous, and can drive itself to wherever you want to go.

Not only is Olli a futuristic and sleek-looking 3D printed bus, but it’s also autonomous, and can drive itself to wherever you want to go.

Local Motors are striving to improve travel with Olli, which can come and pick you and your friends up if you hail it, and drop you to your destination. It’s already seeing use on university campuses such as Sacramento State. Having received masses of funding to advantage electric, autonomous cars, many clearly have high hopes for Olli, so we will have to see if more of these innovative 3D printed buses start appearing all over major cities.

Related Articles:

- Best 3D Printed Car Parts

- 3D Printed Engines To Make

- Best 3D Printed RC Planes You Can Print Today

- Best Trains To 3D Prints

5 ways 3D printing is changing the automotive industry / Sudo Null IT News

You can't buy a fully 3D printed car in a car dealership yet, but additive technologies have been used in car design for many years. Every year, especially in recent years, 3D printing is taking an increasingly important place at all stages of production. This is evidenced by the rapid growth of 3D printing market share in automotive manufacturing, which is projected to reach $2.5 billion by 2023.

Every year, especially in recent years, 3D printing is taking an increasingly important place at all stages of production. This is evidenced by the rapid growth of 3D printing market share in automotive manufacturing, which is projected to reach $2.5 billion by 2023.

For example, luxury car companies including Bentley, Porsche, BMW and Ferrari are using 3D printing to create custom car interior parts. GM, Volvo, Ford are using 3D printing to produce tooling to save money, improve designs and reduce delivery times. 3dprinting.com If the first 3D printers cost about $20,000, now you can find 3D equipment for $100. Now companies can, with the help of additive technologies, produce the necessary components directly at their own enterprises and not depend on suppliers.

With new materials, 3D printers can print high-precision, functional end parts. Additive technologies facilitate the production of custom products and increase productivity.

But this is only the beginning of the journey. Here are five key ways 3D printing is driving innovation in the automotive industry, from car design to manufacturing. Plus one bonus.

Here are five key ways 3D printing is driving innovation in the automotive industry, from car design to manufacturing. Plus one bonus.

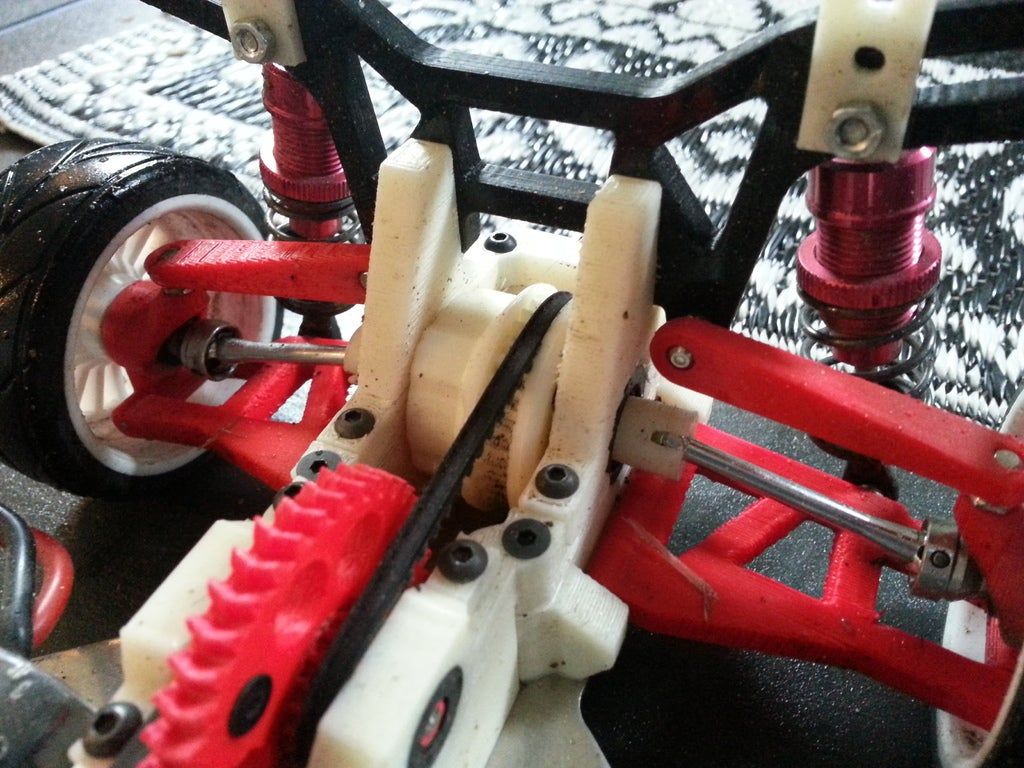

1. Changing the prototyping process

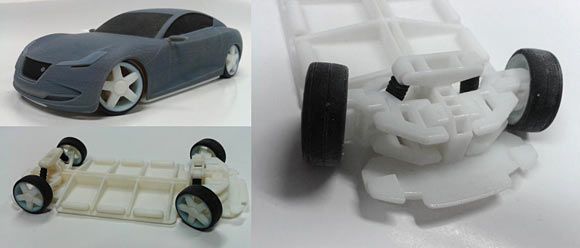

It was with the manufacture of prototypes that the use of 3D printers in the automotive industry began. 3D printed prototypes took much less time than traditional methods required.

Using Raise3D 3D printers and ideaMaker software, Crazy Grandpa Garage was able to automate the process of creating custom car parts. Production costs have been reduced by 50%, design reliability has improved significantly, and lead time has been reduced by 83%. The parts now come out very well fitted to the car.

Source: facebook.com

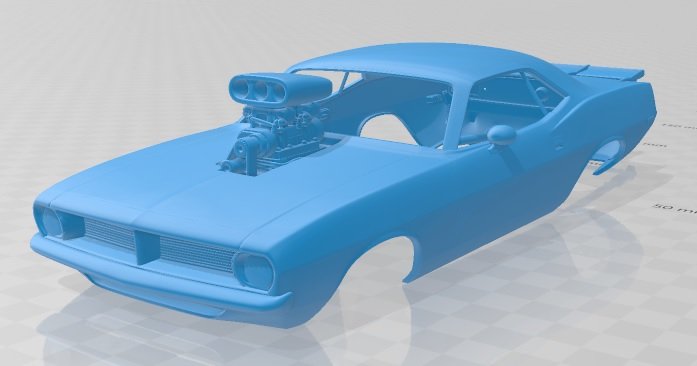

Using 3D printing, car designers can quickly prototype individual parts or assemblies, from interior detail to dashboard, or even full-size car models. Thanks to 3D prototyping, the initial idea quickly turns into a physical embodiment of the concept - a conceptual model. The concept can then be developed into full-featured, high-fidelity prototypes, and after several validation steps, mass production begins. For the automotive industry, getting through these steps quickly is vital, and the entire downtime of an automobile production line in just an hour is very costly for the company.

The concept can then be developed into full-featured, high-fidelity prototypes, and after several validation steps, mass production begins. For the automotive industry, getting through these steps quickly is vital, and the entire downtime of an automobile production line in just an hour is very costly for the company.

For example, the assembly plant of the US car manufacturer General Motors claims to have saved more than $300,000 by purchasing a 3D printer in 2016.

Ringbrothers designers and engineers are not dependent on third parties to implement laser stereolithography (SLA) in their facility. The cost is reduced, the development time is reduced. Source: formlabs.com

Hose for Eventuri BMW M4, Source: ultimaker.com

Traditional prototyping was time-consuming and costly, in part because the product went through more iterations. With 3D printing, you can create high-quality prototypes in one day and at a much lower cost. More examples.

More examples.

The Ford Fiesta ST with 3D printed parts, ext. SEMA 2016, ultimaker.com

For example, General Motors has partnered with Autodesk to produce low cost, lightweight automotive parts using 3D printers. Tools, fixtures and fittings can now be produced at a fraction of the cost, according to Autodesk. For example, a 3D printed tool used to align engine and transmission ID numbers costs less than $3 at General Motors. A traditionally produced instrument will cost $3,000. In addition, downtime due to faulty tools can be significantly reduced as new tools are produced in-house.

2. Creation of non-standard and complex parts

Daihatsu, Japan's oldest car manufacturer, launched a project in 2016 to customize its Copen model.

Source: 3dprint.com

In partnership with Stratasys, Daihatsu customers can design and order custom 3D printed panels for their front and rear bumpers with a choice of over 15 basic patterns in 10 different colors.

Source: 3dprint.com

In Europe, the BMW MINI brand also uses 3D printing to create personalized car parts. Since the beginning of 2018, MINI customers have been able to personalize various trim elements such as the dashboard, LED treadplates and illuminated bumpers, as well as choose from different colors and textures. These parts are then 3D printed using a range of technologies from DLS Carbon to SLS.

Source: formlabs.com

Volkswagen Motorsport's I.D. R Pikes Peak is designed with over 2000 3D printed test parts.

Source amfg.ai

The use of 3D printers makes it possible to experiment in the development of non-standard designs, reduces the cost of their production. Time-consuming manufacturing processes for custom-made products are becoming much shorter.

Ringbrothers uses 3D printing to create customized end pieces, such as ventilation grilles. Source: formlabs. com

com

Large companies are merging 3D printing technologies with traditional manufacturing methods. Volkswagen has recreated its iconic 1962 Microbus by replacing the petrol engine with a 120-hp electric one. The Type 20 concept electric minivan has received many improvements using 3D printed parts. These improvements include cast aluminum wheels. Even the wheel hubcaps, while looking like stamped steel, are actually printed on a Formlabs SLA 3D printer, then electroplated and polished.

Source: formlabs.com

Formlabs Form 2 3D printer SLA specifications

Bentley has used cutting-edge metal 3D printer technology to produce a grille, side vents, door handles and exhaust pipes that are much more complex than those used on current production models.

Bentley used metal 3D printing to create intricate micron precision parts. Source: formlabs.com

Source: youtube. com

com

3D printing has also made it possible to create parts that could not be made in any other way.

Bugatti's monobloc brake caliper is a prime example. For some components, Bugatti would have preferred titanium due to its high performance, but processing this metal with traditional methods is expensive and difficult. 3D printing has allowed Bugatti to produce a titanium alloy brake caliper. Due to the thin walls, the caliper turned out to be very light - almost two times lighter than forged aluminum. At the same time, the strength of the 3D-printed monoblock is superior to that of aluminum. The 3D printed titanium monoblock has a tensile strength of 1250 N/mm2. This means that a force of just over 125 kg will be applied per square millimeter of this titanium alloy without tearing the material. The new titanium caliper is 41 cm long, 21 cm wide and 13.6 cm high and weighs only 2.9kg compared to currently used aluminum, which weighs 4.9 kg.

Source: youtube. com

com

The Bugatti brake monoblock is the industry's largest functional 3D printed titanium component for a car. Source: formlabs.com

3. Tool making

Various devices help to facilitate and speed up the production and assembly processes, improve the safety of workers. Automotive factories and component suppliers use a large number of non-standard tooling that is specifically designed and optimized for end use. As a result, a lot of non-standard equipment and tools are made, which increases production costs.

This 3D protective wheel disc was purchased for 800 euros but can now be printed for just 21 euros. Tool development time has been reduced from 56 to 10 days.

Source: ultimaker.com

Delegating custom tooling and fixtures to service providers who machine parts from solid metal or plastic stock can delay production by weeks.

For example, the development and prototype of a commutator motor using traditional manufacturing methods can take up to four months and cost about half a million dollars. Thanks to 3D printing, Ford was able to develop several variants in just 4 days and 99.4% cheaper - only $3,000.

Thanks to 3D printing, Ford was able to develop several variants in just 4 days and 99.4% cheaper - only $3,000.

Source: youtube.com

Additive technologies allow you to complete the task in a few hours and significantly reduce costs compared to ordering from a third-party enterprise. Since increasing the complexity of a 3D printed model does not incur additional costs, products can be better optimized for their application. New elastic materials for 3D printing in many cases allow you to print plastic parts instead of metal or create prototypes on a 3D printer to test the tool before using it in production

Gradually, the production of 3D printed accessories and tools is becoming one of the largest applications of additive technologies.

Pankl Racing Systems uses 3D printed fixtures to fasten workpieces to a conveyor belt. Source: formlabs.com

For example, Pankl Racing Systems uses a stack of multiple Formlabs SLA 3D printers to make critical manufacturing tools. The multi-stage production of parts for transmissions on automatic lathes requires a series of fixtures and tools designed for each specific part.

The multi-stage production of parts for transmissions on automatic lathes requires a series of fixtures and tools designed for each specific part.

With the help of 3D printing, Pankl's engineers have reduced the production time for the aids by 90%, from 2-3 weeks to around 20 hours. Costs were also reduced by 80-90%, saving $150,000.

The transition to 3D printing has enabled Volkswagen Autoeuropa to cut tooling development costs by 91% and cut tooling times by 95%.

4. Troubleshooting spare parts

Spare parts have always been a problem for the automotive industry. The demand for them is either there or not, so the production of spare parts is not economically viable, and the storage of pre-fabricated replacement components is also costly. But if there are no repair parts available, difficulties arise and the main product becomes less valuable.

3D printing could solve the problem of parts in the automotive industry in many ways. The main factors are printed materials, which can match the characteristics of traditional materials used in parts and be cost-effective. There are prerequisites for this.

The main factors are printed materials, which can match the characteristics of traditional materials used in parts and be cost-effective. There are prerequisites for this.

Using computer-aided design, drawings of all parts can be stored digitally, so there is no need to store the parts themselves. The parts needed by the client can be printed on a 3D printer right in the workshop.

Even obsolete parts whose drawings have not survived can in principle be recreated by making a 3D scan of existing parts of this type and applying reverse engineering (reverse engineering). You can read more about this on our blog. Old projects can take on new life. There are many lovers of vintage cars, with the help of 3D printing it would be possible to create parts for them.

Ringbrother 3D printed the Cadillac emblem for a custom built old car. Source: formlabs.com

5. Production of standard parts

As 3D printers and materials for 3D printing become more affordable, a gradual transition to the production of mass-produced automotive parts using additive technologies is possible.

3D printing makes it possible to combine components into a single whole. Let's say there is a mechanism assembled from six or seven car parts that can be combined into one printed part. It will save time and assembly costs. With 3D printing, it is also possible to reduce the weight of the combined assembly, as a result, the car will use fuel more efficiently.

3D Systems has developed an advanced exhaust pipe for a sport bike. In the image below, you will see 20 sheet metal and hydroformed parts needed to assemble the original exhaust pipe. On the right is a monolithic exhaust pipe that does not require assembly, made using metal 3D printing.

Source designnews.com

The 3D printed tube was produced using Grade23 titanium in just 23 hours, compared to three weeks for traditional production. Design development time reduced from 6 weeks to 6 days. Additive manufacturing also eliminates the need for tooling, fixtures, multiple welding and multiple inspections.

Geometry optimization has reduced the amount of material needed for maximum productivity. All elements of the original exhaust are included in the new design and, when printed at a typical wall thickness of 0.5mm, the 3D printed exhaust is about 25% lighter than the original.

A wide range of 3D printing materials is beginning to meet the requirements of various vehicle components. Since additive methods reduce costs compared to traditional methods (such as molding and injection molding), it makes a lot of sense from a production and financial point of view to further introduce 3D printing into the production of basic parts.

Volkswagen, one of the world's largest and most innovative car manufacturers, is using an HP Metal Jet 3D printer to produce high-performance functional parts with special design requirements, such as shift knobs and mirror mounts. Volkswagen's long-term plans to work with HP include accelerating the production of mass-customized parts such as key rings and exterior nameplates.

Source: youtube.com

+1. 3D printed cars

While 3D-printed cars have yet to hit the market, some interesting designs and concepts can provide clues as to where the automotive industry might go.

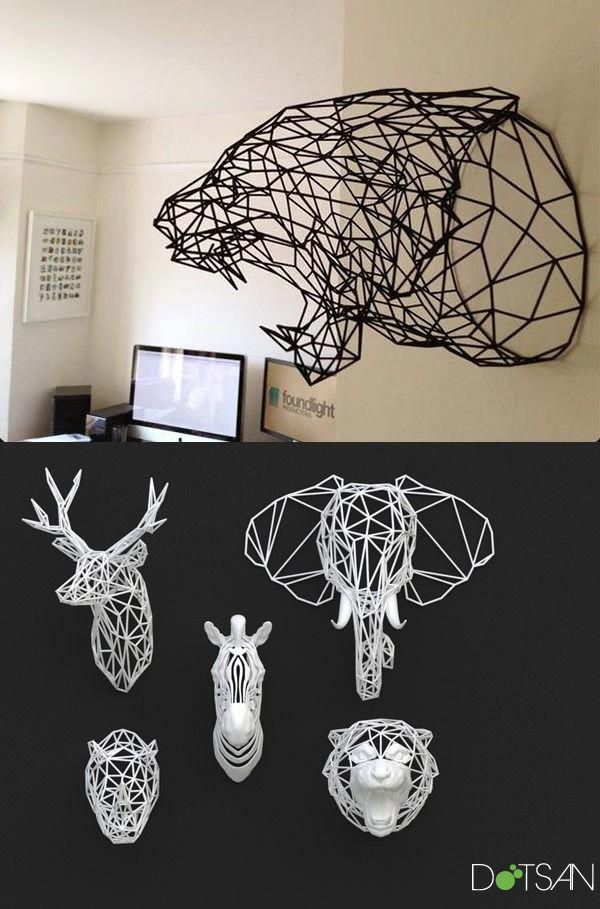

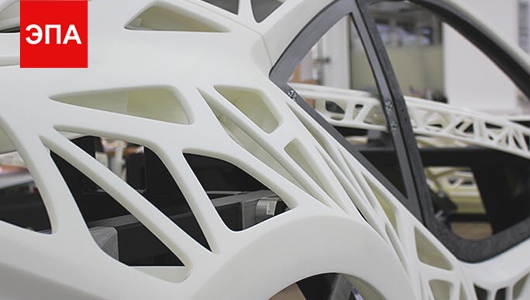

Light Cocoon . German engineering firm EDAG was clearly inspired by nature to create the 3D printed supporting structure of the Light Cocoon concept car. The frame resembles the veins of a tree leaf or its branch. Despite the fact that the design of the EDAG took less material than a conventional frame, all the strength requirements for structurally significant components are met. Outside, the case is covered with a lightweight and durable waterproof fabric.

The cover protects the EDAG Light Cocoon from bad weather and gives the car a unique personality. Source: formlabs.com

Blade . Blade ("Blade") announced as "the world's first 3D-printed supercar. " It meets supercar standards but is made from inexpensive materials: carbon fiber tubes and aluminum rods, combined with 3D printed metal parts. Blade turned out to be very light and does not take long to assemble.

" It meets supercar standards but is made from inexpensive materials: carbon fiber tubes and aluminum rods, combined with 3D printed metal parts. Blade turned out to be very light and does not take long to assemble.

The world's first 3D printed Blade supercar. Source: formlabs.com

Strati . The American company Local Motors 3D printed and assembled the Strati electric car right at the exhibition stand, in just 44 hours. Most of the components were printed - the body, seats, interior parts. A car is made up of less than 50 assemblies, far fewer than the thousands of parts that go into a traditional car. The company intends to reduce the print time to 10 hours.

The Strati from Local Motors consists of less than 50 individual parts*. Source: formlabs.com

LSEV. Developed by the Italian company XEV, the LSEV could be the first in the 3D printed electric vehicle market when it goes on sale. The 3D printed chassis, seats, windshield and all visible parts of the LSEV. Thanks to the active use of 3D printing, the number of components was reduced from 2000 to just 57, resulting in a very lightweight design. The electric car weighs only 450 kg.

Thanks to the active use of 3D printing, the number of components was reduced from 2000 to just 57, resulting in a very lightweight design. The electric car weighs only 450 kg.

The LSEV is the first 3D printed electric vehicle to hit the market in 2020. Source: formlabs.com

While most of these and many other 3D printed car projects remain at the concept stage, the extent to which 3D printing has penetrated various areas of the automotive industry is striking. In some cases, additive technologies provide new opportunities for design and production, in others they reduce production costs and save time.

See also:

3D printer and CNC race car making

3D scanning of cars in tuning and repair

5 ways 3D printing is changing the automotive industry

Photo source .com

An article from formlabs.com adapted and supplemented for you by Top 3D Shop.

You can't buy a fully 3D printed car at a car dealership yet, but additive technologies have been used in car design for many years. Every year, especially in recent years, 3D printing is taking an increasingly important place at all stages of production. This is evidenced by the rapid growth of 3D printing market share in automotive manufacturing, which is projected to reach $2.5 billion by 2023.

Every year, especially in recent years, 3D printing is taking an increasingly important place at all stages of production. This is evidenced by the rapid growth of 3D printing market share in automotive manufacturing, which is projected to reach $2.5 billion by 2023.

For example, luxury car companies including Bentley, Porsche, BMW and Ferrari are using 3D printing to create custom car interior parts. GM, Volvo, Ford are using 3D printing to produce tooling to save money, improve designs and reduce delivery times.

Source 3dprinting.com

3D printing is constantly emerging new opportunities, it is becoming more accessible. If the first 3D printers cost about $20,000, now you can find 3D equipment for $100. Now companies can, with the help of additive technologies, produce the necessary components directly at their own enterprises and not depend on suppliers.

With new materials, 3D printers can print high-precision, functional end parts. Additive technologies facilitate the production of custom products and increase productivity.

But this is only the beginning of the journey. Here are five key ways 3D printing is driving innovation in the automotive industry, from car design to manufacturing. Plus one bonus.

1. Changing the prototyping process

It was with the production of prototypes that the use of 3D printers in the automotive industry began. 3D printed prototypes took much less time than traditional methods required.

Using Raise3D 3D printers and ideaMaker software, Crazy Grandpa Garage was able to automate the process of creating custom car parts. Production costs have been reduced by 50%, design reliability has improved significantly, and lead time has been reduced by 83%. The parts now come out very well fitted to the car.

Source: facebo ok.com

Using 3D printing, car designers can quickly prototype individual parts or assemblies, from interior detail to dashboard, or even full-size car models. Thanks to 3D prototyping, the initial idea quickly turns into a physical embodiment of the concept - a conceptual model. The concept can then be developed into full-featured, high-fidelity prototypes, and after several validation steps, mass production begins. For the automotive industry, getting through these steps quickly is vital, and the entire downtime of an automobile production line in just an hour is very costly for the company.

The concept can then be developed into full-featured, high-fidelity prototypes, and after several validation steps, mass production begins. For the automotive industry, getting through these steps quickly is vital, and the entire downtime of an automobile production line in just an hour is very costly for the company.

For example, the assembly plant of the US car manufacturer General Motors claims to have saved more than $300,000 by purchasing a 3D printer in 2016.

Ringbrothers designers and engineers are not dependent on third parties to implement laser stereolithography (SLA) in their facility. The cost is reduced, the development time is reduced. Source: formlabs.com

Tailpipes for BMW M4 by Eventuri, Source: ultimaker.com

Traditional prototyping was time consuming and costly, in part because the product went through more iterations. With 3D printing, you can create high-quality prototypes in one day and at a much lower cost. More examples.

The Ford Fiesta ST with 3D printed parts, ext. SEMA 2016, ultimaker.com

For example, General Motors has partnered with Autodesk to produce low cost, lightweight automotive parts using 3D printers. Tools, fixtures and fittings can now be produced at a fraction of the cost, according to Autodesk. For example, a 3D printed tool used to align engine and transmission ID numbers costs less than $3 at General Motors. A traditionally produced instrument will cost $3,000. In addition, downtime due to faulty tools can be significantly reduced as new tools are produced in-house.

2. Creating custom and complex parts

Daihatsu, the oldest car manufacturer in Japan, launched a project in 2016 to customize its Copen model.

Source: 3dprint.com

In partnership with Stratasys, Daihatsu customers can design and order custom 3D printed panels for their front and rear bumpers, with a choice of over 15 basic patterns in 10 different colors.

Source: 3dprint.com

In Europe, the BMW MINI brand also uses 3D printing to create personalized car parts. Since the beginning of 2018, MINI customers have been able to personalize various trim elements such as the dashboard, LED treadplates and illuminated bumpers, as well as choose from different colors and textures. These parts are then 3D printed using a range of technologies from DLS Carbon to SLS.

Source: formlabs.com

Volkswagen Motorsport's I.D. R Pikes Peak is designed with over 2000 3D printed test parts.

Source amfg.ai

The use of 3D printers makes it possible to experiment in the development of non-standard designs, reduces the cost of their production. Time-consuming manufacturing processes for custom-made products are becoming much shorter.

Ringbrothers uses 3D printing to create customized end pieces such as ventilation grilles. Source: formlabs.com

Large companies are merging 3D printing technologies with traditional manufacturing methods. Volkswagen has recreated its iconic 1962 Microbus by replacing the petrol engine with a 120-hp electric one. The Type 20 concept electric minivan has received many improvements using 3D printed parts. These improvements include cast aluminum wheels. Even the wheel hubcaps, while looking like stamped steel, are actually printed on a Formlabs SLA 3D printer, then electroplated and polished.

Source: formlabs.com

Formlabs Form 2 SLA Specifications

Source: top3dshop.ru

The Bentley Speed 6 is another example. Bentley has used cutting-edge metal 3D printer technology to produce a grille, side vents, door handles and exhaust pipes that are much more complex than those used on current production models.

Bentley used metal 3D printing to create intricate micron precision parts. Source: formlabs.com

Bugatti's monoblock brake caliper is a prime example. For some components, Bugatti would have preferred titanium due to its high performance, but processing this metal with traditional methods is expensive and difficult. 3D printing has allowed Bugatti to produce a titanium alloy brake caliper. Due to the thin walls, the caliper turned out to be very light - almost two times lighter than forged aluminum. At the same time, the strength of the 3D-printed monoblock is superior to that of aluminum. The 3D printed titanium monoblock has a tensile strength of 1250 N/mm2. This means that a force of just over 125 kg will be applied per square millimeter of this titanium alloy without tearing the material. The new titanium caliper is 41 cm long, 21 cm wide and 13.6 cm high and weighs only 2.9kg compared to currently used aluminum, which weighs 4.9 kg.

The Bugatti Brake Monobloc is the industry's largest functional 3D printed titanium vehicle component. Source: formlabs.com

3. Tool and fixture making

A variety of fixtures help make manufacturing and assembly processes easier and faster, and improve worker safety. Automotive factories and component suppliers use a large number of non-standard tooling that is specifically designed and optimized for end use. As a result, a lot of non-standard equipment and tools are made, which increases production costs.

This 3D protective wheel disc was purchased for 800 euros but can now be printed for just 21 euros. Tool development time has been reduced from 56 to 10 days.

Source: ultimaker.com

Delegating custom tooling and fixtures to service providers who machine parts from solid metal or plastic stock can delay production by weeks.

For example, the development and prototype of a commutator motor using traditional manufacturing methods can take up to four months and cost about half a million dollars. Thanks to 3D printing, Ford was able to develop several variants in just 4 days and 99. 4% cheaper - only $3,000.

Additive technologies allow you to complete the task in a few hours and significantly reduce costs compared to ordering from a third-party enterprise. Since increasing the complexity of a 3D printed model does not incur additional costs, products can be better optimized for their application. New elastic materials for 3D printing in many cases allow you to print plastic parts instead of metal or create prototypes on a 3D printer to test the tool before using it in production.

Gradually, the production of 3D printed accessories and tools is becoming one of the largest applications of additive technologies.

Pankl Racing Systems uses 3D printed fixtures to fasten workpieces to a conveyor belt. Source: formlabs.com

For example, Pankl Racing Systems uses a stack of multiple Formlabs SLA 3D printers to make critical manufacturing tools. The multi-stage production of parts for transmissions on automatic lathes requires a series of fixtures and tools designed for each specific part.

With the help of 3D printing, Pankl's engineers have reduced the production time for the aids by 90%, from 2-3 weeks to around 20 hours. Costs were also reduced by 80-90%, saving $150,000.

The transition to 3D printing has enabled Volkswagen Autoeuropa to cut tooling development costs by 91% and cut tooling times by 95%.

4. Solving problems with spare parts

Spare parts have always been a problem for the automotive industry. The demand for them is either there or not, so the production of spare parts is not economically viable, and the storage of pre-fabricated replacement components is also costly. But if there are no repair parts available, difficulties arise and the main product becomes less valuable.

3D printing could solve the problem of parts in the automotive industry in many ways. The main factors are printed materials, which can match the characteristics of traditional materials used in parts and be cost-effective. There are prerequisites for this.

Using computer-aided design, drawings of all parts can be stored digitally, so there is no need to store the parts themselves. The parts needed by the client can be printed on a 3D printer right in the workshop.

Even obsolete parts whose drawings have not survived can in principle be recreated by making a 3D scan of existing parts of this type and applying reverse engineering (reverse engineering). You can read more about this on our blog. Old projects can take on new life. There are many lovers of vintage cars, with the help of 3D printing it would be possible to create parts for them.

Ringbrother 3D printed the Cadillac emblem for a custom built old car. Source: formlabs.com

5. Production of standard parts

As 3D printers and materials for 3D printing become more affordable, a gradual transition to the production of mass-produced automotive parts using additive technologies is possible.

3D printing makes it possible to combine components into a single whole. Let's say there is a mechanism assembled from six or seven car parts that can be combined into one printed part. It will save time and assembly costs. With 3D printing, it is also possible to reduce the weight of the combined assembly, as a result, the car will use fuel more efficiently.

3D Systems has developed an advanced exhaust pipe for a sport bike. In the image below, you will see 20 sheet metal and hydroformed parts needed to assemble the original exhaust pipe. On the right is a monolithic exhaust pipe that does not require assembly, made using metal 3D printing.

Source: designnews.com

3D printed tube produced using Grade23 titanium in just 23 hours, it would take three weeks for traditional production. Design development time reduced from 6 weeks to 6 days. Additive manufacturing also eliminates the need for tooling, fixtures, multiple welding and multiple inspections.

Geometry optimization has reduced the amount of material needed for maximum productivity. All elements of the original exhaust are included in the new design and, when printed at a typical wall thickness of 0.5mm, the 3D printed exhaust is about 25% lighter than the original.

A wide range of 3D printing materials is beginning to meet the requirements of various vehicle components. Since additive methods reduce costs compared to traditional methods (such as molding and injection molding), it makes a lot of sense from a production and financial point of view to further introduce 3D printing into the production of basic parts.

Volkswagen, one of the world's largest and most innovative car manufacturers, is using an HP Metal Jet 3D printer to produce high-performance functional parts with special design requirements, such as shift knobs and mirror mounts. Volkswagen's long-term plans to work with HP include accelerating the production of mass-customized parts such as key rings and exterior nameplates.

+1. 3D Printed Cars

Although complete 3D printed cars have not hit the market yet, some interesting designs and concepts are suggestive of a possible direction for the automotive industry.

Light Cocoon. German engineering firm EDAG was clearly inspired by nature to create the 3D printed supporting structure of the Light Cocoon concept car. The frame resembles the veins of a tree leaf or its branch. Despite the fact that the design of the EDAG took less material than a conventional frame, all the strength requirements for structurally significant components are met. Outside, the case is covered with a lightweight and durable waterproof fabric.

The cover protects the EDAG Light Cocoon from bad weather and gives the car a unique personality. Source: formlabs.com

Blade . Blade ("Blade") announced as "the world's first 3D-printed supercar. " It meets supercar standards but is made from inexpensive materials: carbon fiber tubes and aluminum rods, combined with 3D printed metal parts. Blade turned out to be very light and does not take long to assemble.

The world's first 3D printed Blade supercar. Source: formlabs.com

Strati . The American company Local Motors 3D printed and assembled the Strati electric car right at the exhibition stand, in just 44 hours. Most of the components were printed - the body, seats, interior parts. A car is made up of less than 50 assemblies, far fewer than the thousands of parts that go into a traditional car. The company intends to reduce the print time to 10 hours.

The Local Motors Strati consists of less than 50 individual parts*. Source: formlabs.com

LSEV . Developed by the Italian company XEV, the LSEV could be the first in the 3D printed electric vehicle market when it goes on sale. The 3D printed chassis, seats, windshield and all visible parts of the LSEV.

.jpg)