Plastic extruder for 3d printing

6 Best Filament Extruder Makers In 2023

- Last Updated: March 14, 2023

- Jackson O'Connell

Ever wonder how 3D printer filament is made?

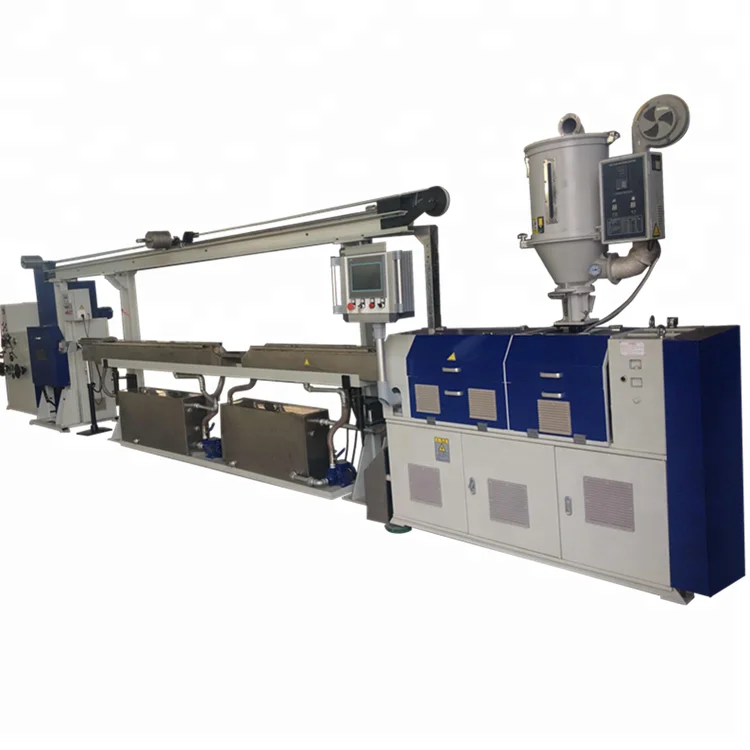

The process starts with raw plastic, which is loaded into a special machine, called a filament extruder.

Of course, a filament extruder isn’t like the one on your typical 3D printer. These filament extruders are a lot larger, and they melt plastic pellets and extrude them out as a filament strand.

While large 3D printing filament manufacturers have super expensive (and very large) filament extruders, there are consumer-grade ones that don’t cost a fortune. These filament extruders, like the Filabot EX2 or NozTek Pro, can pump out a few spools per day, significantly decreasing how much you pay to 3D print things.

Want to learn about the best filament extruders, both DIY and purchasable? Read on!

FILASTRUDER KIT (DIY)

Check Official Website

3devo Precision 350

Check Official Website

ReDeTec ProtoCycler+

Check Official Website

Table of Contents

- Best Filament Extruders At A Glance

- Filament Extruders: DIY

- 1.

Felfil Evo (High Quality Prints)

- 2. Filastruder Kit (DIY) (Best Value)

- 1.

- Filament Extruders: To Buy

- 3. Filabot EX2

- 4. 3devo Precision 350 (Best Choice)

- 5. Noztek Pro Desktop Extruder

- 6. ReDeTec ProtoCycler+ (Premium Choice)

- What is a Filament Extruder?

- How Does a Filament Extruder Work?

- What’s the Difference Between Filament Extruder and 3D Printer Extruder?

- Conclusion

Best Filament Extruders At A Glance

Filament Extruders: DIY

1. Felfil Evo (High-Quality Prints)

2. Filastruder Kit (DIY) (Best Value)

Filament Extruders: To Buy

3. Filabot EX2

4. 3devo Precision 350 (Best Choice)

5. Noztek Pro Desktop Extruder

6. ReDeTec ProtoCycler+ (Premium Choice)

Filament Extruders: DIY

First, we’ll go over the DIY options for filament extruders. These extruders don’t come pre-assembled in one piece. Instead, they’re kits that you assemble.

These extruders don’t come pre-assembled in one piece. Instead, they’re kits that you assemble.

Up first, we’ve got the Felfil Evo. This filament extruder actually comes in both a pre-assembled as well as a kit version, and both are great, but the kit is less expensive and not that difficult to build, which is why I like it more.

With an extrusion rate of 100-150 grams per hour, the Felfil Evo isn’t the fastest one around, but it’s exceptional for the price. And at this rate, you can make a little more than two 1-kilogram spools per day.

As for the quality of the filament produced, Felfil states that the filament has a tolerance of +/- 0.07 mm. That doesn’t sound very good, but it’s just the right tolerance to work on most 3D printers if you’ve got the extrusion settings right.

It’s also worth noting that the Felfil Evo kit comes in a 1.75-mm filament version as well as a 2.85-mm filament version, so you can pick the one that fits your printer’s needs.

On another note, the Evo has a maximum heating temperature of 250 °C, enough to produce PLA, ABS, HIPS, and TPU (flex) filaments. Sadly, you won’t be able to make PETG as it requires a bit more heat.

But what I love most about the Felfil Evo is that it’s not that difficult to build. Of course, you’ll need a hopper and spooling device to complete your setup, but it looks sexy and is decently reliable.

So if you want a starter filament extruder to see if making your own filament is for you, then definitely give the Evo kit a shot.

- Very cool frame design

- Easy-to-use control panel

- Can make PLA, ABS, HIPS, and other filament materials

- Some assembly required

- Very slow extrusion speed

- Not very reliable

- A high (bad) filament diameter tolerance; produced filament might jam your printer’s hot end

- Can’t make PETG filament

Check Official Website

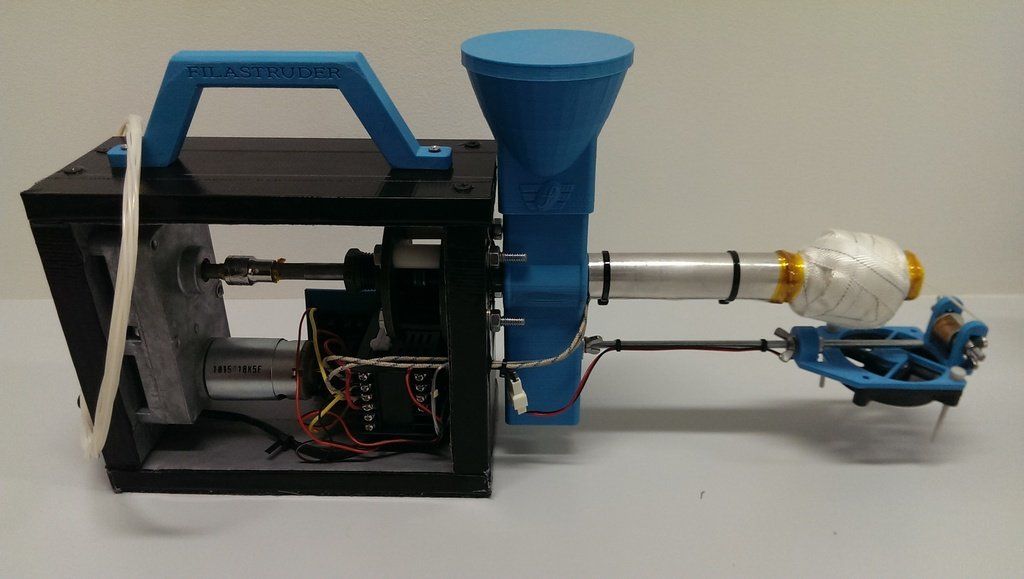

2. Filastruder Kit (DIY) (Best Value)

Filastruder Kit (DIY) (Best Value) Filastruder is a company that specializes in making their Filastruder kit, a budget-friendly extruder, as well as a few upgrades and attachments for the device.

Before we get started with the review, it’s worth mentioning that the Filastruder kit is currently out of stock with no expected restock data, but the company is working on making more. Now let’s get to it!

The Filastruder kit is easily the least expensive filament extruder on the market, costing under $500 for a fully-functional setup. And the company also sells a few attachments for the device, also at a low price, such as the Filawinder, an autonomous spooling device that goes at the end of the Filastruder, so you don’t have to manually wind filament onto spools.

Despite the low price, though, the Filastruder is one hell of a filament extruder, with a metal frame body that makes the device sturdy and visually appealing. Additionally, the 260 °C maximum temperature of the device means you can produce a wide variety of filament materials, including PLA, ABS, TPU, TPE, PMMA, and even polycarbonate.

But what’s most impressive about the Filastruder is its diameter accuracy: an impressive +/- 0.03 mm for PLA, +/- 0.02 mm for ABS and similar values for other materials. This means the filament you make with the Filastruder is literally more precise (diameter-wise) than most filaments you buy on Amazon and the like.

Sadly, the price you pay for the precision of the Filastruder Kit is the speed, as the filament extruder can only produce 1 kilogram of filament every 5 to 8 hours. Additionally, it’s known that the Filastruder is a little bit difficult to configure and isn’t too reliable compared to purchasable options.

But, with everything in mind, like the low price, precision, and potential upgrades, the Filastruder Kit is one of the best filament extruder options on the market!

- Can produce extremely precise filament

- Decently-high maximum heating temperature, so it can handle a fair amount of filament materials

- A handful of compatible attachments are available (e.

g. Filawinder)

g. Filawinder) - Some components can be 3D printed

- Very low cost; a good bang for your buck

- Currently out of stock

- Some assembly required

- Very slow extrusion speed

Check Official Website

Filament Extruders: To Buy

In the sections below, I’ll review the best filament extruders that can be purchased with no (or very minimal) assembly required.

3. Filabot EX2Our first purchasable extruder is the Filabot EX2, easily one of the most well-built extruders on this list. The first thing you’ll notice about the EX2 is its visually appealing frame, a compact, green-and-orange, all-metal chassis that makes filament extrusion look a lot sexier than it is.

The first thing you’ll notice about the EX2 is its visually appealing frame, a compact, green-and-orange, all-metal chassis that makes filament extrusion look a lot sexier than it is.

The Filabot EX2 has a maximum temperature of 329 °C, allowing it to melt a few different blends of PLA, ABS, PETG, HIPS, and even WAX. While this may sound like less material compatibility than other options, it’s worth noting that these are only the materials that will 100% work with a high level of quality. Of course, you could try making other filaments, but they might not come out as good.

On this note, Filabot has stated that the EX2 can maintain a diameter tolerance of under +/- 0.05 mm. While this isn’t perfect by any means, it’s definitely enough to work on practically any 3D printer, from an Ender 3 to an Ultimaker 3.

As for speed, the EX2 is a total beast, producing just under a kilogram in an hour. So you could make a full-years worth of filament in one 24-hour period, which is insane to think about!

My personal favorite part about the EX2, though, is the overall build quality of the machine. You can really tell that Filabot spent a lot of time making sure the design of the EX2 is perfect.

You can really tell that Filabot spent a lot of time making sure the design of the EX2 is perfect.

This is most clearly seen with the control panel on the machine, which includes a dial for the speed, temperature controller (with buttons), and switches for the main power, extruder power, and heater power. The organized and well-labeled controls make producing your filament so easy a 5-year-old could do it.

So, if you want a powerhouse of a filament extruder with a high-temperature heater, easy-to-use control panel, fast extrusion speed, and more, then the Filabot EX2 is for you. Just be ready to pay a pretty penny for these epic features.

- Well-designed, sleek, all-metal frame

- Organized and easy-to-use control panel

- Decently-high maximum heating temperature

- Super fast extrusion speed

- Pretty expensive

- A pretty bad diameter tolerance for the price

Check Official Website

Check Latest Price

4. 3devo Precision 350 (Best Choice)

3devo Precision 350 (Best Choice) 3devo is a company that specializes in making filament extruders and shredders. The Precision 350 is one of 3devo’s filament extruders, and, while on the more expensive side of the spectrum, it’s got many features that make the price worth it.

First off, the device has a maximum temperature of 350 °C, so you can use it to make PLA, ABS, PET, PETG, TPU, TPE, filaments, and more. But what’s unique about the Precision 350 is that the device has not 1, but 4 heating zones. As such, the plastic melting process is a lot more precise and controllable than on other filament extruders, hence the name of the product.

On top of high-quality cooling, the Precision 350 also features a well-designed cooling system, with two 5050-style fans placed on either side of the filament line. On top of looking really sleek, this cooling system helps produce filament more precisely.

As for the extrusion rate, 3devo didn’t provide a clear speed for the Precision 350, but it should be moderately fast given the speed of their other machines.

Lastly, it’s worth going over the frame and controls on the 3devo Precision 350. Similar to the EX2, the Precision 350 has a very appealing, all-metal frame design.

Additionally, the controls onboard the filament extruder make it super easy to configure the machine for a certain filament material. There’s also a USB port on the Precision 350 for communication via computer. 3devo also has an online interface where you can go to view extrusion data of your device.

Overall, while the Precision 350 might be expensive, it’s impossible to refute the build quality of the machine, such as the high-temperature capabilities and precise extrusion techniques.

- USB connectivity

- Four heating zones for accurate and precise plastic melting system

- Online dashboard interface

- Decently-high maximum temperature, capable of handling many materials

- High-quality cooling system

- A lot of company support (e.

g. example settings)

g. example settings) - Sleek design

- No speed provided

- Very expensive

Check Official Website

5. Noztek Pro Desktop ExtruderNoztek was one of the first companies to get involved in the consumer filament extruder business, and the Noztek Pro is an excellent machine that’s super fast.

The Noztek Pro is equipped with what the company calls their fusionX extruder, a screw mechanism that can move filament pellets through a heating (and cooling) system very fast.

How fast? How about 1 kg every 2 hours fast?

But besides its insane extrusion speed, the Noztek Pro is also a very versatile machine, with a maximum heating temperature of 600°C. This is insane for costing under $2000, and it means the Noztek Pro is capable of handling pellets of PLA, ABS, PP, PET, HDPE, and other materials.

This is insane for costing under $2000, and it means the Noztek Pro is capable of handling pellets of PLA, ABS, PP, PET, HDPE, and other materials.

It’s also worth pointing out that the Noztek Pro comes with a 0.5-kg bag of ABS pellets, so you can get right to making filament out of the box! There are also two different extruder nozzles: one for 1.75-mm filament and one for 2.85-mm filament.

Lastly, I can’t forget to talk about the overall design of the machine, which is very sleek. The red, all-metal frame gives the Noztek Pro a fair amount of durability. And the easy-to-use controls, consisting of a few knobs and buttons, make controlling the temperature and speed of the machine a breeze.

So if you’re looking for a good value filament extruder that doesn’t cost too much but has a lot of great features all packed in a well-built frame, then the Noztek Pro filament extruder is an excellent choice!

- A good bang for your buck

- Multiple nozzle sizes available

- Reliable fusionX extruder mechanism

- Easy-to-use controls

- All-metal frame

- Decently high extrusion speed

- Super high maximum heating temperature

- Can print many different filament materials

- Somewhat expensive

- Not much company support

Check Official Website

6. ReDeTec ProtoCycler+ (Premium Choice)

ReDeTec ProtoCycler+ (Premium Choice) ReDeTec is yet another popular manufacturer of filament extruder products, and the ProtoCycler+ is their flagship product. ProtoCylcer+ is an advanced filament extruder system that includes everything you need to take a failed print (or old print) and turn it into printable filament.

Yep!

On top of having a filament extruder screw and heater, the ProtoCycler+ features a built-in grinder. This mechanism turns large metal grinders to mash up plastic parts and turn them into pellets that you can run through the filament extruder system.

Additionally, the ProtoCycler+ has an automatic winding device at the end of the extruder line. This wraps the produced filament around an empty spool so you don’t have to manually do this process, which can be very annoying.

What’s super impressive about the whole setup is that the ProtoCyler+ takes up a pretty small footprint, despite there being three different mechanisms inside. And the all-metal body of the ProtoCylcer+ looks sleek, with an open-up hatch that allows you to see the internal mechanisms.

And the all-metal body of the ProtoCylcer+ looks sleek, with an open-up hatch that allows you to see the internal mechanisms.

Sadly, though, the device can only reach a heating temperature of 250 °C, which isn’t too high. But, according to the manufacturer, it’s enough to be able to make PLA, ABS, PETG, HIPS, and Nylon 12 filaments.

But the impressive speed of 1 kg every 2 hours and the spectacular diameter precision of +/- 0.05 mm certainly make up for it because this means you can make high-quality filament very fast.

- Integrated grinder (unless you choose the “Grinderless” option)

- Automatic filament winder

- Very fast extrusion

- Decent diameter tolerance for filament

- Sleek design

- Open-up hatch

- Not a very high maximum temperature

- Expensive

Check Latest Price

What is a Filament Extruder?

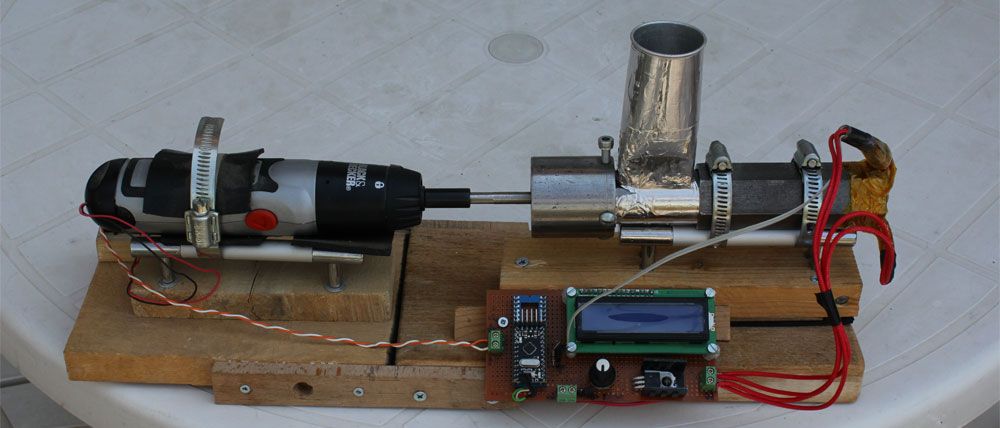

Source: Youtube diy chenA filament extruder is a device that makes 3D printable filament out of ground-up bits of plastic.

Filament extruders, which are not the same as the extruder on a 3D printer (we’ll explain more later), are most commonly used by big filament manufacturers. However, in recent years, there have been efforts to develop consumer-level filament extruders so that you can make your own filament out of plastic pellets.

And many people want to get their filament extruder because a 1-kg bag of PLA pellets is so much less expensive than a 1-kg spool of PLA filament. Moreover, on wholesale sites, like Alibaba, you can get bags of PLA pellets priced at under $3 per kilogram.

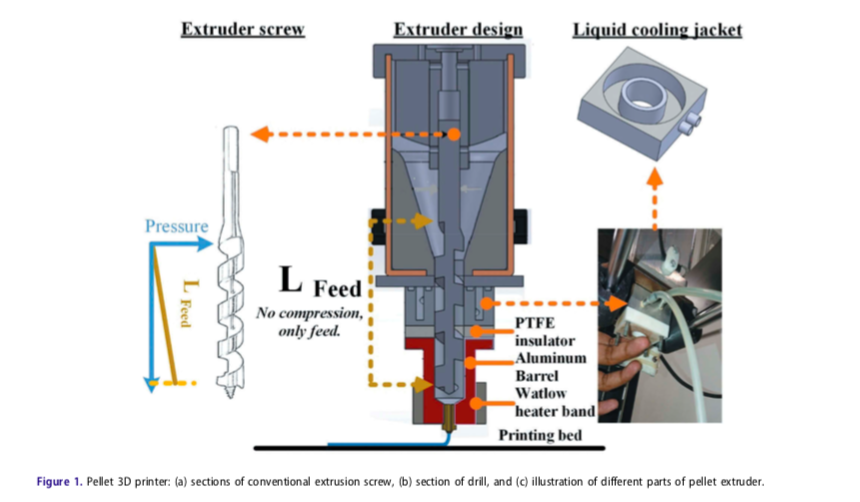

How Does a Filament Extruder Work?

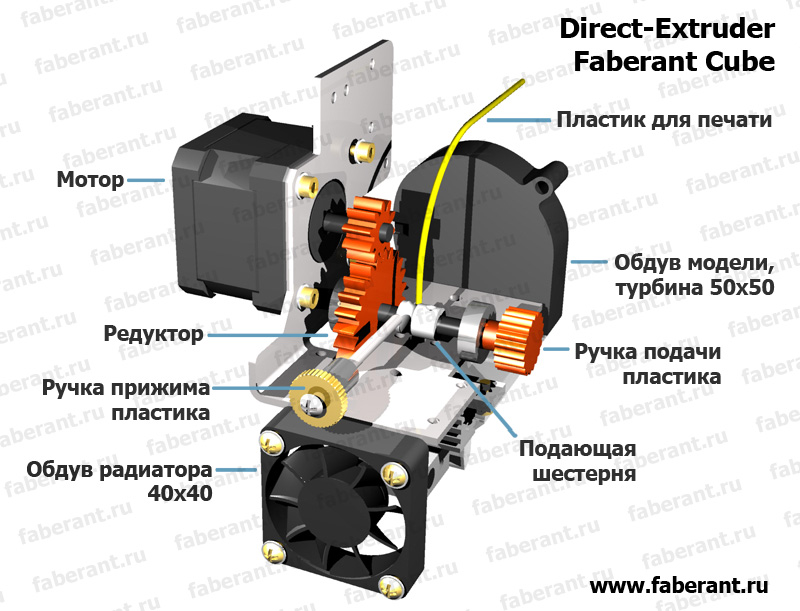

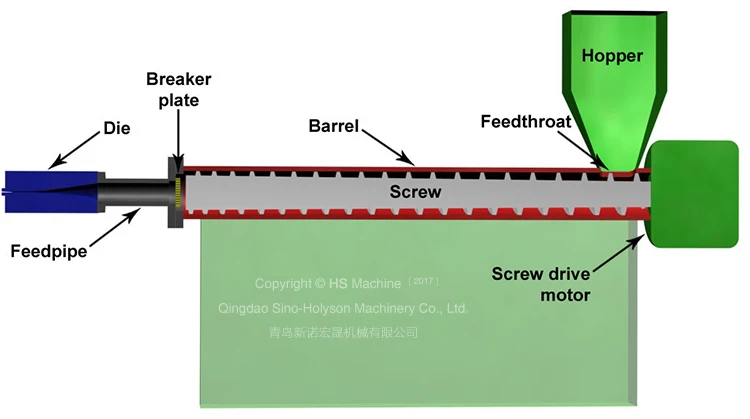

Source: Youtube CNC KitchenA filament extruder is a pretty complex system, but the easiest way to think about these machines is as an enlarged version of the hot end on a 3D printer.

The filament extrusion process starts with grinded-up plastic pellets. It’s necessary for these plastic pellets to be all of the same material and contain contaminants (e. g. metal shavings).

g. metal shavings).

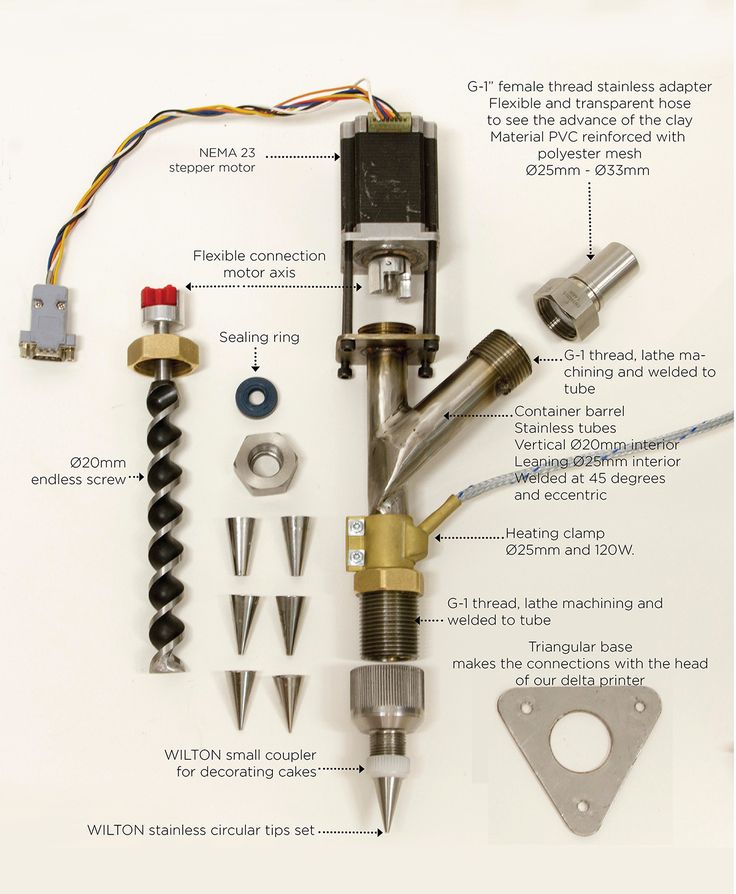

The pellets are loaded into a hopper, which feeds them into the screw of the machine. The screw is rotated by a big motor, pushing the pellets forwards at a controlled speed.

At the other end of the screw, shaft is a heater, which goes around the screw. The heater melts the plastic pellets into a molten form, similar to how a hot end melts filament.

Then, the molten plastic is pushed by the incoming melted pellets into a pipe, where a cooling mechanism usually lies. At the end of the pipe is a nozzle, where the finished filament comes out. But unlike the nozzle on a typical 3D printer, the diameter of the nozzle on a filament extruder is set to the desired filament diameter (1.75 or 2.85 mm).

And that’s it!

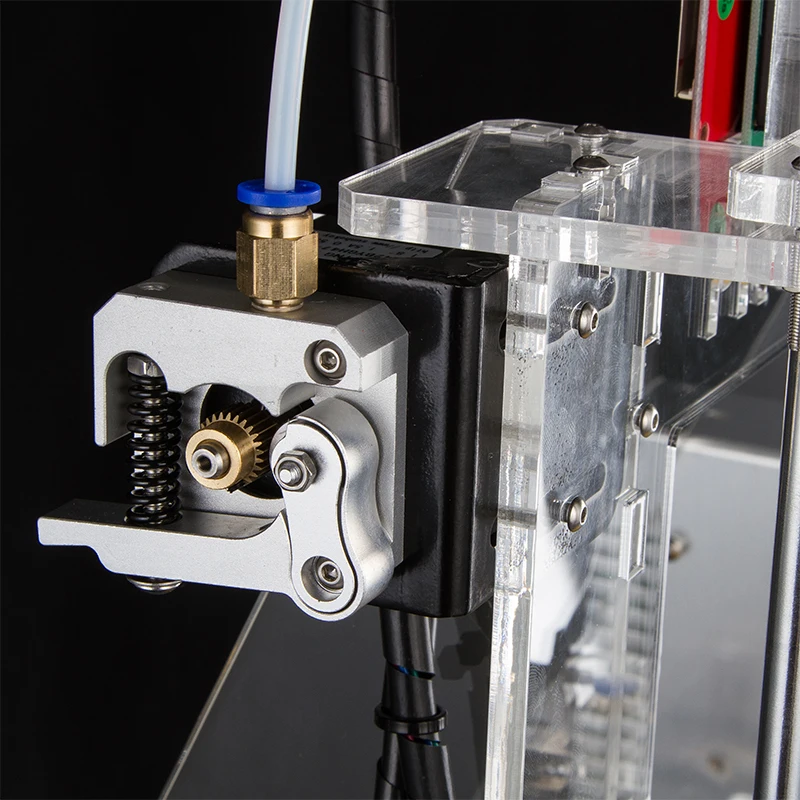

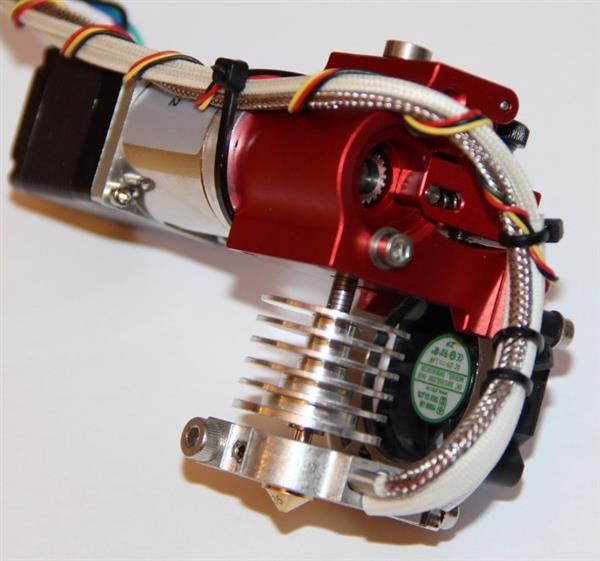

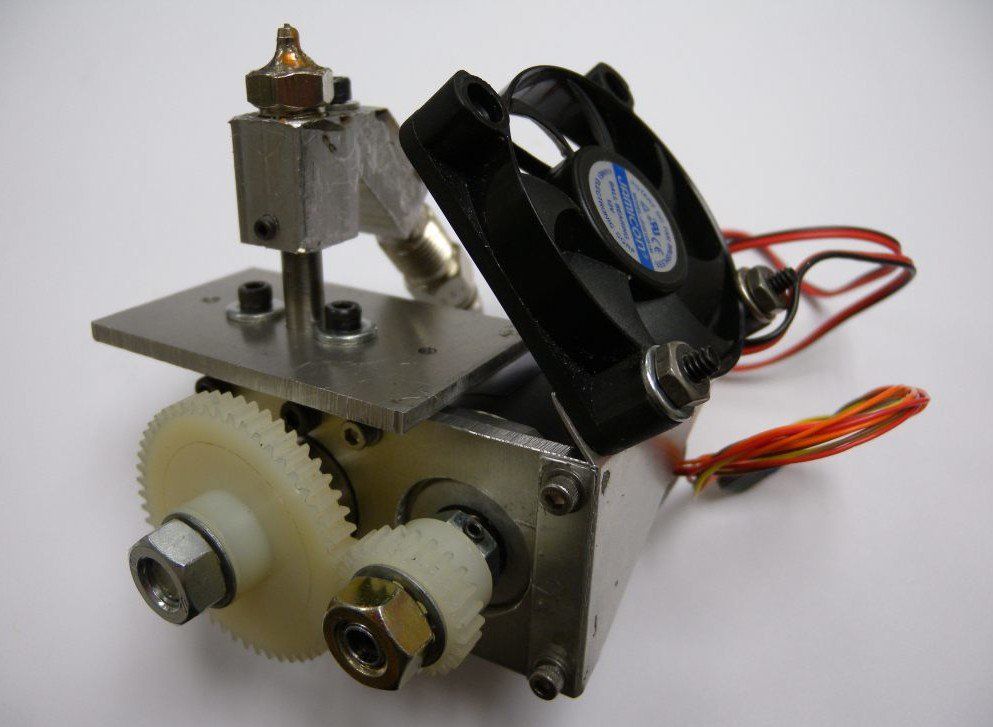

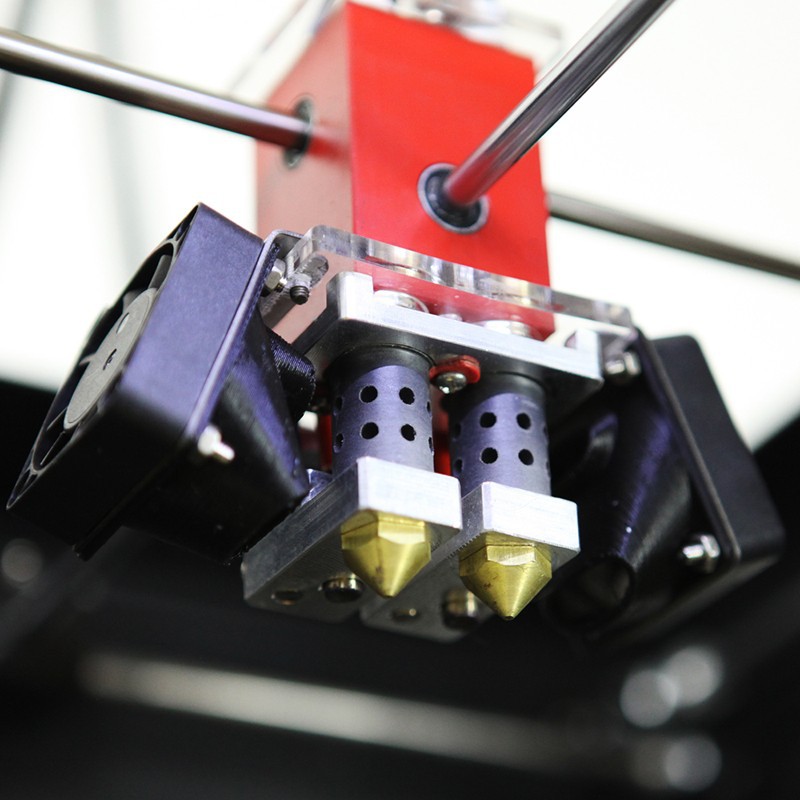

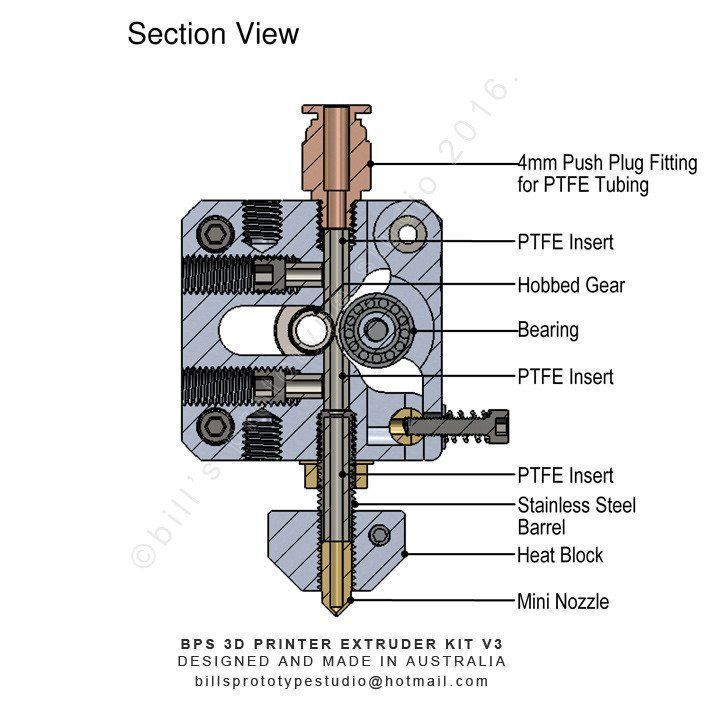

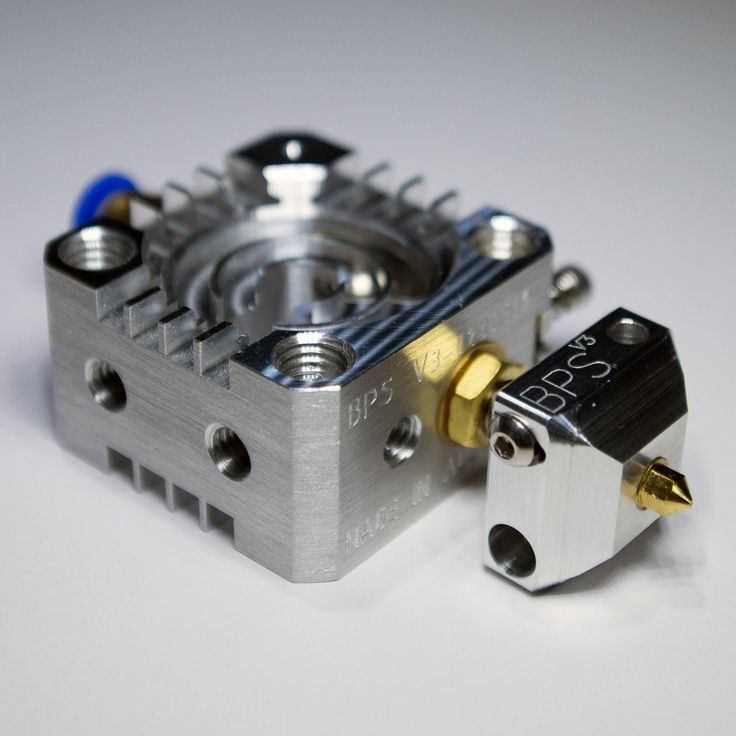

What’s the Difference Between Filament Extruder and 3D Printer Extruder?

Source: Youtube CNC KitchenA filament extruder, while similar in name, is not the same thing as the extruder on your 3D printer. Filament extruders are devices, large in size and high in price, that actually makes plastic filament.

On the other hand, 3D printer extruders, like the E3D Titan, are the assemblies on a 3D printer that push filament to the hot end where it’s melted.

Conclusion

Filament extruders make a great addition to your 3D printing setup, giving you the ability to produce filament for pennies!

If you’re looking for a good extruder, two of the best options out there are the Filabot EX2 and 3devo Precision 350. Both machines cost a pretty penny but have a well-built frame, high-quality extrusion process, wide filament compatibility, and easy-to-use controls.

And, if you want a full end-to-end system where you can take your failed prints and turn them into printable filament, the ProtoCycler+ is best. It features a high-quality extrusion system with a grinder for mashing up prints as well as a winder for wrapping the filament around a spool.

Now, if you’re on a budget, then the Filastruder kit is probably the better option for you. It has a sub-$500 price point, a decently-high temperature limit, and a very precise extrusion system.

Hope you enjoy!

3D Printer Extruders | MatterHackers

Finding the best extruder upgrade or replacement for your 3D printer can take the quality of your 3D printed parts to the next level. The extruder is responsible for how much and at what speed your 3D printer pushes filament into the hotend. MatterHackers can help you find the perfect extruder for your 3D printer to help you get the best 3D printed parts possible.

Guides & Articles

How to Succeed with Quantum Dichromatic PLA Filament

Follow this guide for tips and tricks on how to get the best results when 3D printing with Quantum Dichromatic PLA filament.

How To Succeed with LayerLock SLA Build Surfaces

Successfully achieve strong bed adhesion for Laser, DLP, and SLA resin prints using LayerLock SLA Resin 3D Printing Build Surfaces.

How To Build A Successful Makerspace

Find out the necessary components to create an effective space for your maker community.

How to Succeed When 3D Printing with Polypropylene

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

Tech Breakdown and How to Succeed: Ionic Hybrid Support Material

Supporting engineering-grade filament has been difficult without a support material dedicated to higher temperature 3D printing. Ionic aims to solve that.

How To Succeed with OBC 3D Printing Filament

From Dow Chemical, OBC combines flexible and rigid into one unique material with properties of both.

How To Succeed with LayerLock Garolite Build Surfaces

Successfully achieve strong bed adhesion for NylonX, NylonG, and standard filaments using LayerLock Garolite Build Surfaces.

How to Succeed with LayerLock Powder Coated PEI Build Plates

Powder coated PEI steel sheets are a great alternative build surface for strong bed adhesion. Here's how you can succeed using this durable build plate.

Here's how you can succeed using this durable build plate.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

How To Succeed When 3D Printing With ASA Filament

Follow this step-by-step guide to learn how to print with ASA, the perfect material for any outdoor projects.

How to Succeed when 3D Printing with Polycarbonate Filament

Follow these helpful steps to start successfully printing with this extremely tough, professional grade material.

How to Succeed with NylonX

NylonX has quickly become one of our favorite filaments for strong, durable, and ready-to-use parts. Here's an in-depth look at Nylon X, and some printing tips to get the most out of this great new material.

Portable bar extruders.

Filament manufacturing. How to make your own 3D printing consumables

Filament manufacturing. How to make your own 3D printing consumables - 1 Description

- 2 Filabot Original

- 3 Filabot Wee

- 4 Filastruder

- 5 Lyman extruder

- 6 OmniDynamics Struder

- 7 STRUdittle

- 8 Filabot Reclaimer

- 9 FilaMaker

Description

One of the limiting factors in the development of FDM printing is the relatively high cost of consumables. Although most plastics are quite affordable for an ordinary user, the difference between raw materials and finished thread is very significant - often the cost of a rod exceeds the cost of granules of the same weight by dozens of times. Thus, it is not surprising that portable, desktop devices for home production of filament from granules and plastic waste have appeared.

Extruder device

Such installations can significantly reduce the cost of printing and, of course, improve the environment. In this section, we'll take a look at some of the most well-known home rod making practices, including filament extruders and plastic waste shredders.

In this section, we'll take a look at some of the most well-known home rod making practices, including filament extruders and plastic waste shredders.

Filabot Original

The most well-known development with high performance. The device is designed to work with ABS, PLA and HIPS. Granulated plastic is used as a consumable, but plastic waste can also be used, provided that the particle size does not exceed 5 mm.

Filabot Original is the world's most famous device for home bar production.

The company offers a choice of seven colors of ABS granular dyes, allowing you to give the finished material the desired shade. Dyes are supplied in packs of 25g. One or two packs are required to paint one kilogram of ABS. For best results, the use of colorants with white ABS granules is recommended.

ABS, PLA and HIPS can also be blended with carbon fiber for stronger and more durable materials. To obtain such a composite, it is only necessary to mix plastic with carbon fiber granules and, if necessary, dye, and then load the finished mixture into a hopper.

Filabot Original has the highest performance of its kind. It takes about five hours to extrude one kilogram of bar. The temperature range during heating is 40°C-400°C, which allows you to experiment with a wide range of materials, including composites with wood filler, electrically conductive additives, etc.

Bar diameter can be 1.75mm or 3mm depending on nozzle. The extrusion speed is 250-750mm per minute depending on the diameter of the bar to be produced.

The auger rotates at 35 rpm. The power consumption of the device reaches 300W depending on the extrusion temperature. The extruder is equipped with a filter to remove contaminants just before extrusion.

The device is equipped with a durable metal case and has fairly compact dimensions, comparable to a computer system unit: 431x178x203mm.

Factory selling price: $899.

Filabot Wee

Filabot Wee is a more affordable option, not inferior to the Filabot Original

Version of the original Filabot extruder, equipped with a wooden body. This option is positioned as a budget version and is available both in assembled form and as a kit for self-assembly.

This option is positioned as a budget version and is available both in assembled form and as a kit for self-assembly.

The budget version is slightly inferior to its more expensive counterpart in terms of performance: the extrusion speed varies from 125mm to 500mm per minute. The extrusion temperature varies from 40°C to 350°C.

The device is primarily intended for the production of HIPS, ABS and PLA rod, although other materials suitable for extrusion temperatures are also possible.

Due to the use of granular dyes, a wide range of colors can be achieved - when using dyes, the use of white ABS plastic or a material with slight color shades is recommended.

The addition of granulated carbon fiber results in a higher strength end product. Carbon fiber can be used in combination with any of the calculated plastics.

The maximum power consumption is 300W. The device comes with interchangeable nozzles that allow the production of two of the most popular bar diameters: 1. 75mm and 3mm.

75mm and 3mm.

Filabot Wee dimensions are similar to Filabot Original: 431x178x203mm.

Filabot has released the Filabot Wee drawings to the public. Those wishing to build an extruder with their own hands can download the necessary files here and here.

Factory selling price: $749for an assembled extruder, or $649 for a self-assembly kit.

Filastruder

A relatively inexpensive extruder designed by two University of Florida students, Tim Elmore and Allen Haynes.

Filastruder - a relatively inexpensive but very efficient extruder

Filastruder allows you to produce one kilogram of filament in 12 hours of operation of the device, or from 150mm to 600mm per minute, depending on the diameter of the nozzle, extrusion temperature and the material used. The developers tested the extruder with ABS plastic, but they allow the use of PLA, HIPS, nylon, polyethylene and other plastics. The maximum extrusion temperature reaches 225°C.

The maximum extrusion temperature reaches 225°C.

The extruder is quite economical - the maximum power consumption is 60W with an average of 50W.

Filastruder is available with 1.75 or 3mm nozzles.

Filastruder extruder sells for $300 without hopper or $310 with printed hopper.

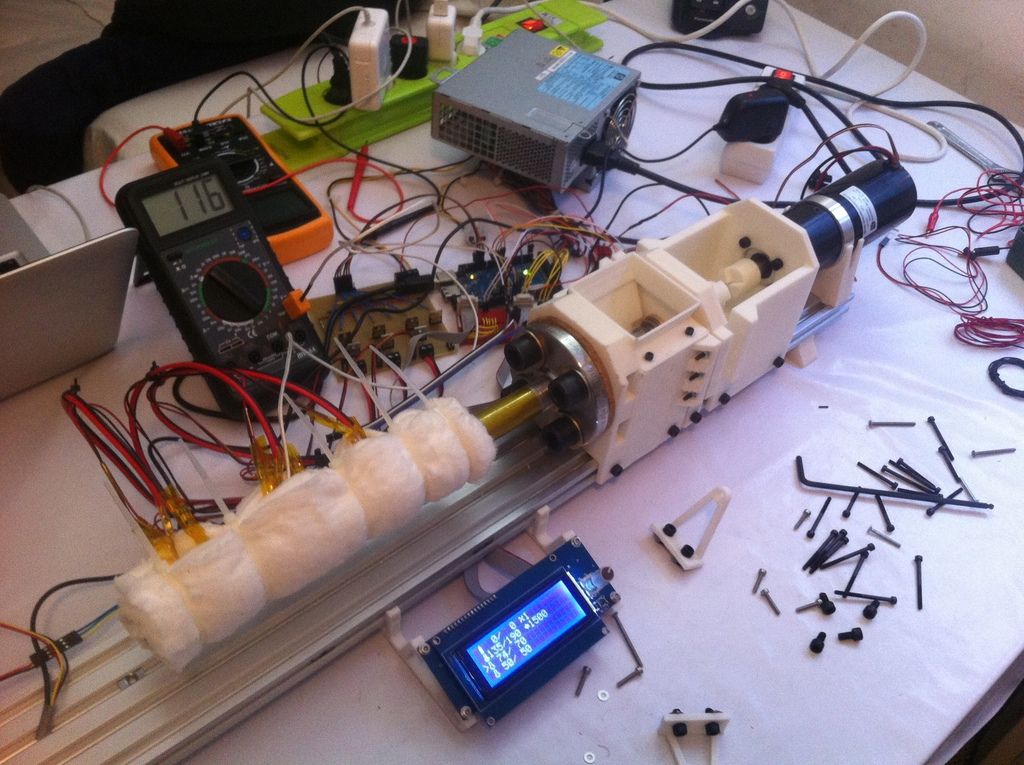

Lyman Extruder

Lyman Extruder - a pioneer of desktop filament mills

Named after the inventor, Hugh Lyman. The original development is probably the first homemade bar extruder. It was this design that won the top prize at the Desktop Factory Competition in 2013.

The design of the extruder was simplified as much as possible, which was the result of the main condition of the competition: the total cost of the components used in the design should not exceed $250.

The Lyman extruder is not commercially available and is not available at retail. The developer posted instructions for creating an extruder in the public domain. The required files can be downloaded here.

The required files can be downloaded here.

OmniDynamics Struder

OmniDynamics Struder is designed for safety and ease of use

A compact device announced on Kickstarter in May 2014. The goal of the developers is to create a portable, convenient and safe device to use.

Delivery of the first batches of the extruder is scheduled for September 2014. The retail price of the device has yet to be announced, but the Kickstarter pre-order price is £149.

Extruder designed to work with any thermoplastic used in 3D printing, including ABS, PLA, PET, HDPE, HIPS, etc. The device is equipped with a full-fledged control module with a color LCD display.

STRUdittle

STRUdittle is a promising extruder with compact dimensions and high productivity

Another interesting development that received the necessary funding on Kickstarter.

The design of the device is aimed at high compactness and good affordability while maintaining high performance.

According to the developers, the device is capable of producing up to 600mm bars per minute. The extruder is designed to work with ABS plastic. Filament diameter deviations do not exceed 0.03 mm when using a winder or 0.05 mm if the bar is simply extruded onto the floor. Customers can specify the required nozzle diameter: 1.75mm or 3mm.

Kickstarter pre-order price is $385 for extruder with winder.

Filabot Reclaimer

The Filabot Reclaimer can handle all kinds of plastic waste

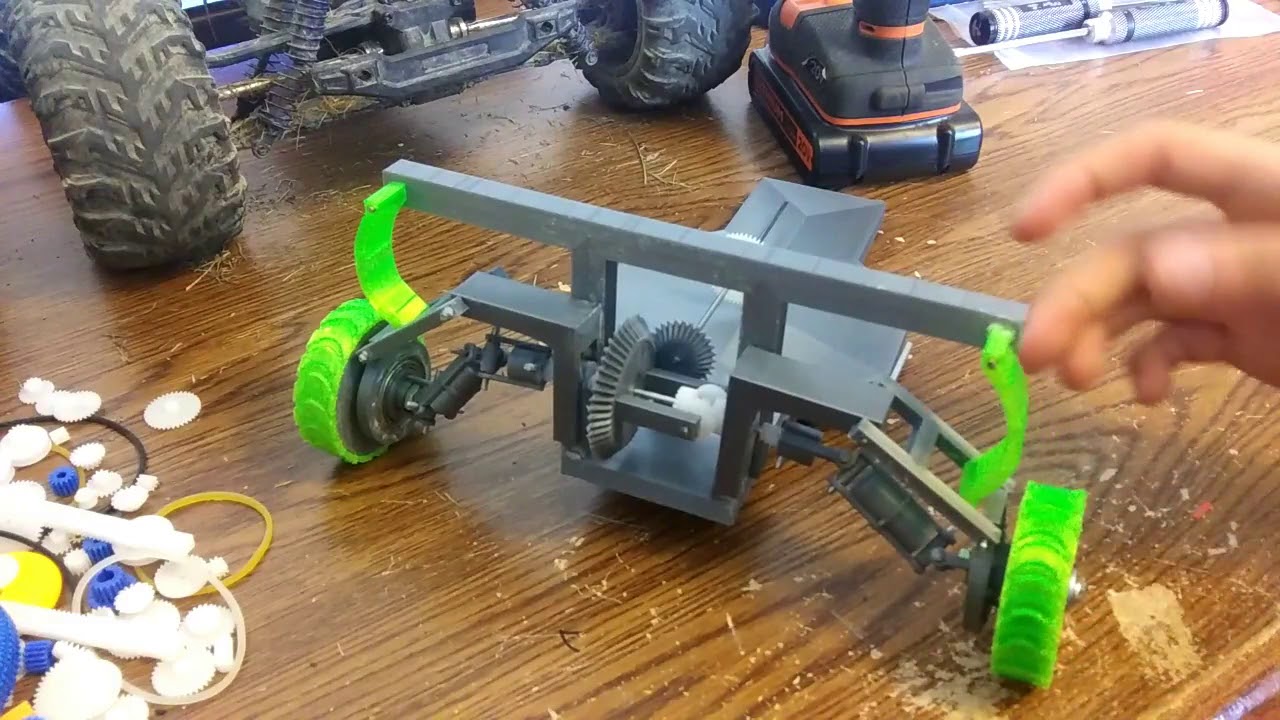

The extruders listed are designed to work with granular plastics. At the same time, FDM printers in combination with desktop extruders have great potential for recycling plastic waste into new products. Thus, to use plastic waste as consumables, a device is required that can crush plastic to obtain small particles - usually no more than 5 mm. Filabot has developed a simple yet effective shredder designed for just this purpose. The device was called the Filabot Reclaimer.

The device was called the Filabot Reclaimer.

The Filabot Reclaimer is equipped with a strong welded metal frame and hardened steel serrated rollers. The device is not equipped with an electric drive - the rollers are driven manually using a lever.

Almost any thermoplastic used in 3D printing can be used as raw material.

The Filabot Reclaimer lets you recycle bad models, 3D printed waste, and just plain old plastic items. The size of the neck and, accordingly, the processed pieces of plastic reach 50x90mm. Due to the robust metal construction of the fixture, the weight of the Filabot Reclaimer is an impressive 11kg. The installation dimensions are quite modest, reaching 255x255x380mm.

The Filabot Reclaimer retail price is $439. Despite the relatively high cost, the device quickly pays for itself, allowing, together with the extruder, to save up to 90% of the cost of the bar.

FilaMaker

FilaMaker combines crusher and extruder functionality

FilaMaker combines crusher and extruder functions in one device. The machine was demonstrated at the Maker Faire Rome in 2013 and won attention due to its high functionality, neat design and high performance.

The machine was demonstrated at the Maker Faire Rome in 2013 and won attention due to its high functionality, neat design and high performance.

The FilaMaker is capable of producing up to one meter of 3mm thread per minute. The deviation of the given diameter does not exceed 0.05 mm. Unfortunately, the selling price of the device is quite high, reaching €1,200.

Go to the main page of the Encyclopedia of 3D Printing

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

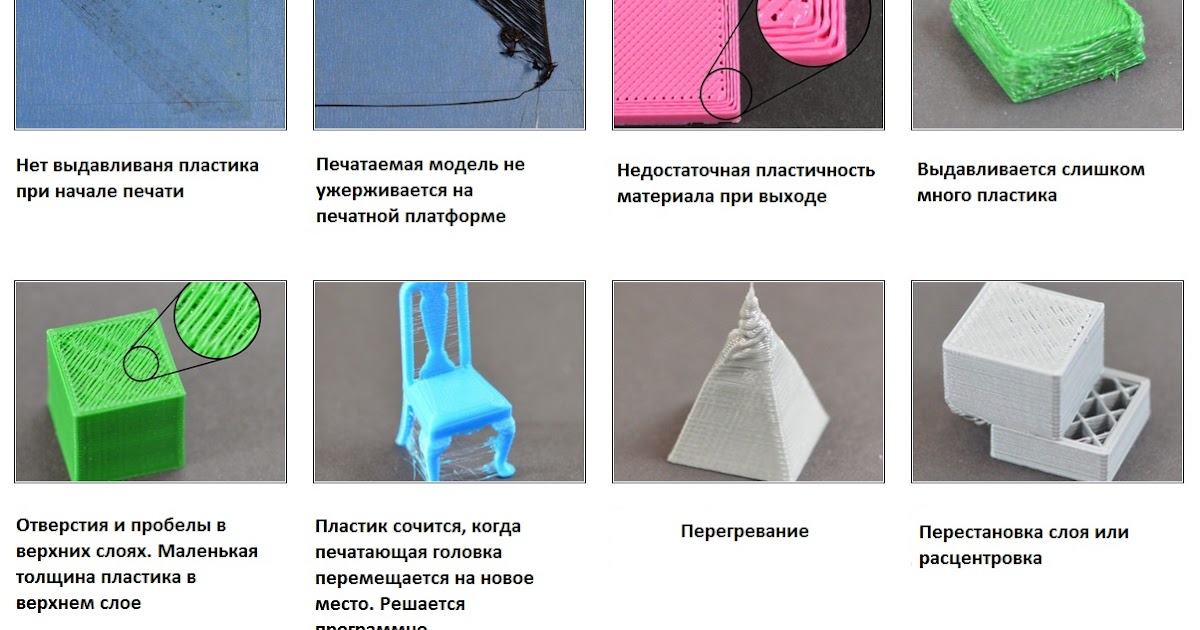

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them.

.jpg)