3D printed aerospike

AMCM ups the Game in 3D Printed Rockets with World’s Biggest Aerospike Engine - 3DPrint.com

The leader in powder bed fusion printers, EOS and its sister company AMCM are stepping up their efforts to advance 3D printed space propulsion. Just last week, the company announced a partnership with Munich and Singapore-based software startup Hyperganic to accelerate innovation in space propulsion engineering. By integrating Hyperganic’s AI-powered algorithmic engineering software platform with EOS’ digital, high-end additive manufacturing solutions, the trio plans to revolutionize the field of space propulsion, which still uses very conservative designs.

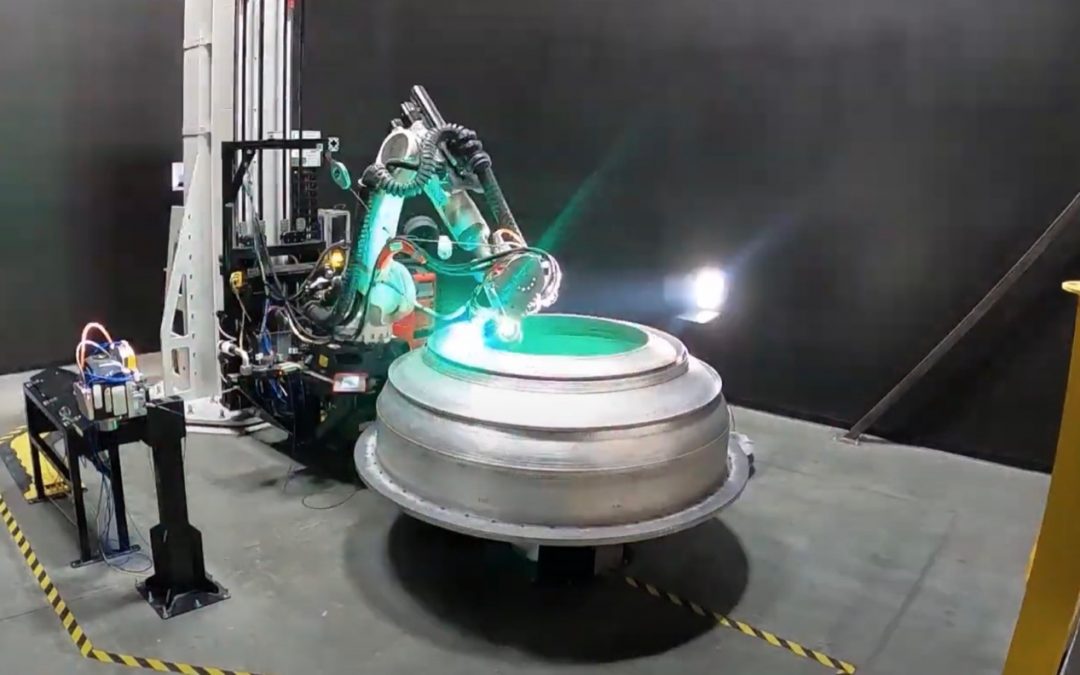

As the first product in this collaboration, AMCM completed printing the world’s largest aerospike rocket engine on May 11, 2022, which was engineered using Hyperganic’s upcoming algorithmic engineering platform called Core. Set for release to a limited number of applicants on June 15, 2022, Hyperganic Core empowers designers to build 3D printing applications using advanced software algorithms without even a single piece of manual CAD.

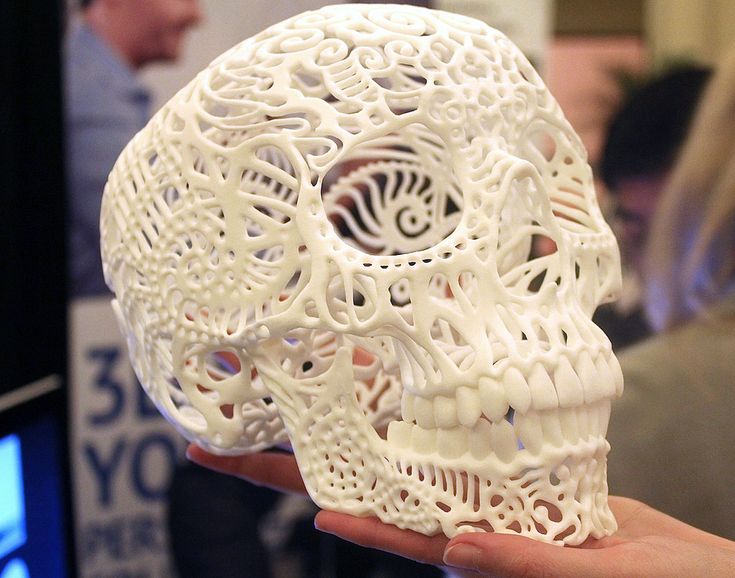

The result is what Hyperganic CEO and Co-Founder Lin Kayser described as “the most complex AM part ever produced.” In fact, according to the long-time entrepreneur, the novel part broke all conventional workflows. The aerospike engine was automatically reengineered for production on an AMCM M 4K large scale, high productivity system for demanding AM applications, using EOS CopperAlloy CuCrZr. Standing at 80 cm tall, the engine demonstrates what’s possible when the power of software algorithms is combined with advanced AM systems.

Algorithmically engineered aerospike rocket engine printed in copper at AMCM. Image courtesy of AMCM/EOS/Hyperganic.Both the private and public space sectors have turned to 3D printing technologies to advance rocket engine manufacturing throughout the last decade. From NASA to industry giants like Aerojet Rocketdyne and new startups like Launcher, many are traveling the AM road to develop and industrialize advanced 3D printed propulsion systems. So, why is this new engine so important to the space industry?

This technical innovation is supposed to make rocket engines more efficient than standard propulsion systems. For decades, the aerospike engine has been considered a promising solution. Even NASA tested the concept extensively on the ground and hoped to incorporate it into the Space Shuttle program, but due to budget constraints, the orbiter ended up being equipped with tried-and-tested bell-shaped nozzles instead. However, now that this technology can be built and engineered thanks to new advanced manufacturing techniques and AM’s design freedom, we are starting to hear more about aerospike rocket engines.

For decades, the aerospike engine has been considered a promising solution. Even NASA tested the concept extensively on the ground and hoped to incorporate it into the Space Shuttle program, but due to budget constraints, the orbiter ended up being equipped with tried-and-tested bell-shaped nozzles instead. However, now that this technology can be built and engineered thanks to new advanced manufacturing techniques and AM’s design freedom, we are starting to hear more about aerospike rocket engines.

Unlike the standard bell-nozzle rocket engine, the aerospike engine nozzle looks like a spike and has significant advantages over traditional designs. Kayser points out that it is “altitude compensating” and “does away with the heavy nozzle extension, with a spike in the middle instead.” Additionally, it is easily up to 20% more efficient than bell nozzle engines, which is a dramatic improvement in the field of rocketry where even fractions of percentage points are worth pursuing, says Kayser.

“The challenge was always cooling the spike in the middle of the extremely hot exhaust gas. With Additive Manufacturing, we can finally produce these kinds of objects, and a few startups have been successful in initial designs. The problem now is to create a reliably working engine that can power a spaceship. This requires many iterations — and iterations in CAD are prohibitively complicated, especially for complex designs. This is where Hyperganic Core and Algorithmic Engineering come into play,” explained the CEO.

Kayser refers to initial designs of 3D printed aerospike engines done by Spanish startup Pangea Aerospace, done in collaboration with the German Aerospace Center (DLR) and industrial AM expert firm Aenium. Developed in 2021, Pangea aimed to test several aerospike engine designs that engineers believe can improve rocket engine efficiency by up to 15%. DLR carried out the first hot-run tests of this innovative engine, demonstrating the success of the new technology. Now EOS, AMCM, and Hyperganic hope to take aerospike engines one step forward.

Now EOS, AMCM, and Hyperganic hope to take aerospike engines one step forward.

For the task, Hyperganic Strategic Engineering Lead Josefine Lissner created a completely algorithmic model for various aerospike designs. Within minutes, the team claims they can create almost any engine design imaginable, including injector heads, advanced heat transfer systems, and complex combustion chamber geometries with different thrust levels and sizes.

Selected from the many hundreds of designs, the first aerospike engine design was produced by Hyperganic in mere days. Then it was printed in one job on an EOS M 400-4 with zero supports, thanks to the newly launched EOS NickelAlloy IN718 process. After EOS had its first Inconel aerospike engine, it was automatically reengineered for production on the substantially larger AMCM M 4K system in copper. Dubbed by the companies as “the world’s largest 3D printed aerospike rocket engine,” this final copper engine was built from the ground up using Lissner’s Hyperganic Core algorithms.

The actual parts can be seen live at the upcoming RAPID + TCT event on May 17 through 19 in Detroit and at the Space Tech Expo USA in Long Beach, California, October 6 through 8.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3D printed engine nozzles • 3D printed propulsion • 3d printed rocket engine • aerospike rocket engine • AMCM • AMCM M4K • copper aerospike engine • eos • EOS M 400 • Hyperganic • Hyperganic core

Please enable JavaScript to view the comments powered by Disqus.

World’s Largest Printed Aerospike Engine Unveiled

Traditional rockets are incredibly inefficient for a number of reasons, not least due to the fact that they are mostly disposable.

But reusability aside, another reason that rockets are inefficient is the fixed geometry of the bell nozzle.

Efficient rocket thrust is dependent on the exhaust gas going in the correct direction (opposite to direction of travel, ideally).

A bell shaped rocket nozzle (also called a convergent/divergent, or “con-di” nozzle) shapes the exhaust gasses so they flow out in more or less a straight vector. But as it exits the nozzle, the flow encounters the atmosphere, which also shapes the flow.

Aerospike engine (Image credit: Hyperganic)At low altitudes, the ambient pressure is enough to tame the flow into a straight path. However, once the altitude increases and the ambient pressure decreases, the pressure affects the flow less and hence the exhaust “expands” as it exits the nozzle. This results in a loss of thrust as the altitude changes, because a con-di nozzle is optimized for lower altitudes.

Of course, it would be lovely to have some kind of morphing nozzle that varies its geometry as the altitude changes, but such a device would carry a huge mass penalty, which is not good for rockets. Some rockets use a nozzle extension to offer some compensation, however this also carries a huge mass penalty.

Another solution is to use an aerospike engine, as seen in the picture above. The aerospike engine, due to its operating principles, performs optimally across a range of altitudes and can increase efficiency significantly.

The aerospike engine, due to its operating principles, performs optimally across a range of altitudes and can increase efficiency significantly.

On an aerospike engine, rather than having the exhaust flow pushed against the nozzle wall where it will expand outwards as it leaves the nozzle at higher altitudes, the flow is pushed inward against the nozzle spike, and so expansion problems are eliminated.

These engines have existed in conceptual form or as test items for decades, but the problem has been with the cooling requirements for the middle spike. Additive manufacturing is now enabling the cooling channels to be manufactured with relative ease.

Hyperganic has not only made the world’s largest printed aerospike (measuring 80cm tall) but they have done so without any manual CAD inputs at all.

Apparently their algorithmic design software will churn out aerospike designs all day long based on a few inputs, and will generate complex designs that cover all aspects of the engine including spike geometry, cooling channel paths and injector parameters.

This is pretty handy, because as anyone who has attempted to design a rocket engine can confirm, most of these parameters are dynamically linked in some way, so changing one thing totally screws with everything else. Hence a parametric approach is preferred, and an AI assisted or algorithmic approach is even better for iteration.

The Hyperganic aerospike is printed in what appears to be copper, or maybe even mixed metals, as we have seen before.

So the big question remains…

Does it actually work?

Printing fancy looking motors is one thing, but the proof as always is in the pudding.

The pudding in this case will be full motor tests, and we await these results eagerly!

3D Printed Rocket Engine / Sudo Null IT News Ocelot

3D printers

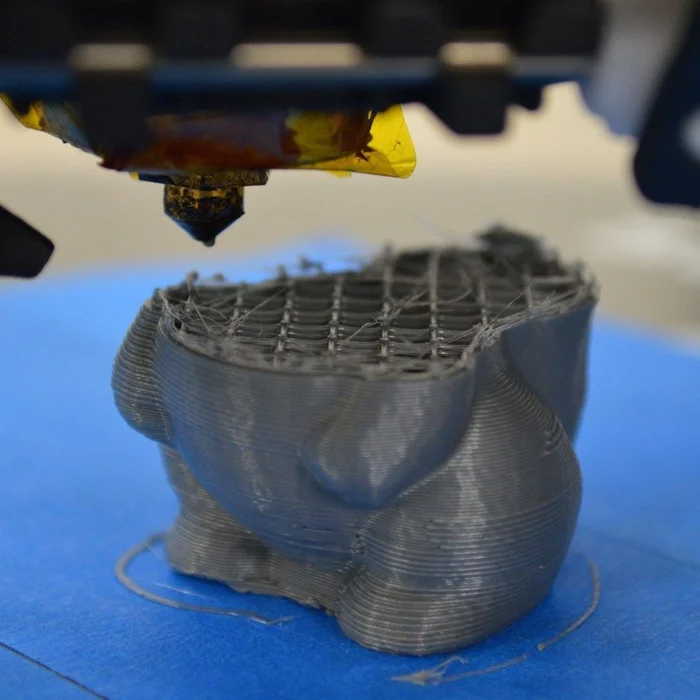

3D printing technologies are steadily developing and finding more and more diverse applications. If initially 3D printers were only suitable for creating layouts and prototypes, now it is quite possible to print functional parts right away.

If initially 3D printers were only suitable for creating layouts and prototypes, now it is quite possible to print functional parts right away.

Here's a fresh example of the serious possibilities of 3D printing: a friend with the nickname RocketMoonlighter demonstrated a 3D printed liquid rocket engine (LRE).

In amateur rocket science, solid propellant rocket engines are mainly used. The main reason for this is the simplicity of the design. At the same time, liquid engines, which allow achieving better performance, are not available to a simple amateur, as they are much more complicated and require special equipment for manufacturing.

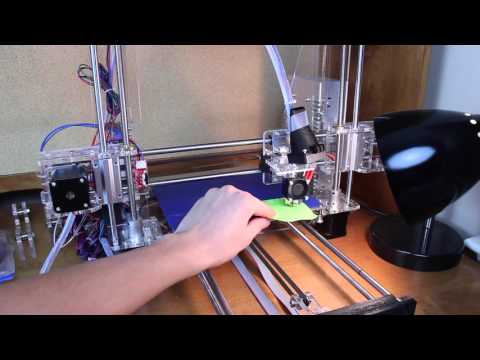

3D printers are just perfect for the production of non-standard parts with a complex internal structure. But is there a 3D printable material that can withstand the heat and pressure inside a rocket engine? There is a technology of direct laser sintering (Direct metal laser sintering), which allows you to print directly from metal powder, and the finished model almost does not differ in strength from a solid piece of metal. nine0005

nine0005

The heart of the engine, the combustion chamber, is laser printed from stainless steel. Naturally, this is still unrealistic at home, so an order was made from one of the companies involved in industrial 3D printing. The cost of the order amounted to several thousand dollars.

Specifications

- Fuel - propane, oxidizer - nitrogen oxide (I) N 2 O.

- Estimated thrust - 5 kgf.

- The pressure in the combustion chamber is 8.5 atm. nine0027

- Ignition - automotive spark plug.

- Cooling - regenerative, cooling agent - oxidizer.

Several engine test videos:

Sources

rocketmoonlighting.blogspot.com/2011/03/what-its-all-about.html -

author blog www.rocketmoonlighting.com/projects/printed-chamber -

specifications www.youtube.com/user/RocketMooonlighter - YouTube channel

UPD:

At the request of Nickel3000, I added a video of the DMLS printing process itself. There are not a missile engine, but also stainless steel details:

There are not a missile engine, but also stainless steel details:

Tags:

- 3D-repairing

- DMLS

- missile engine

- Do not repeat this

Total votes 67: ↑67 and ↓0 +67

Views127K

Comments 90

Dmitry Yakhontov @Ocelot nine0005

Circuit engineer

Comments Comments 90

3D print engine (5 best models for 3D printing)

3DPrintStory 3D printing process How to 3D Print an Engine (Top 5 Models for 3D Printing) nine0005

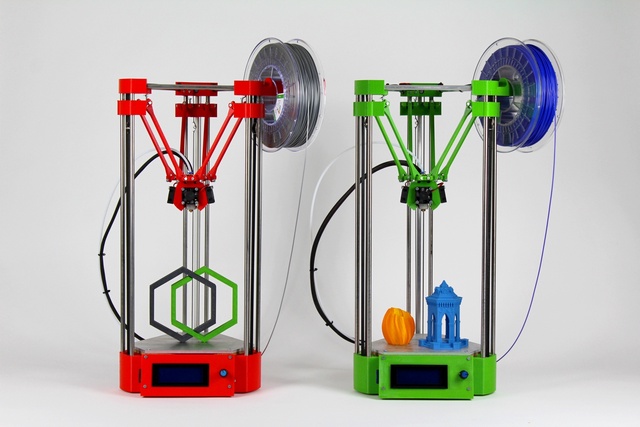

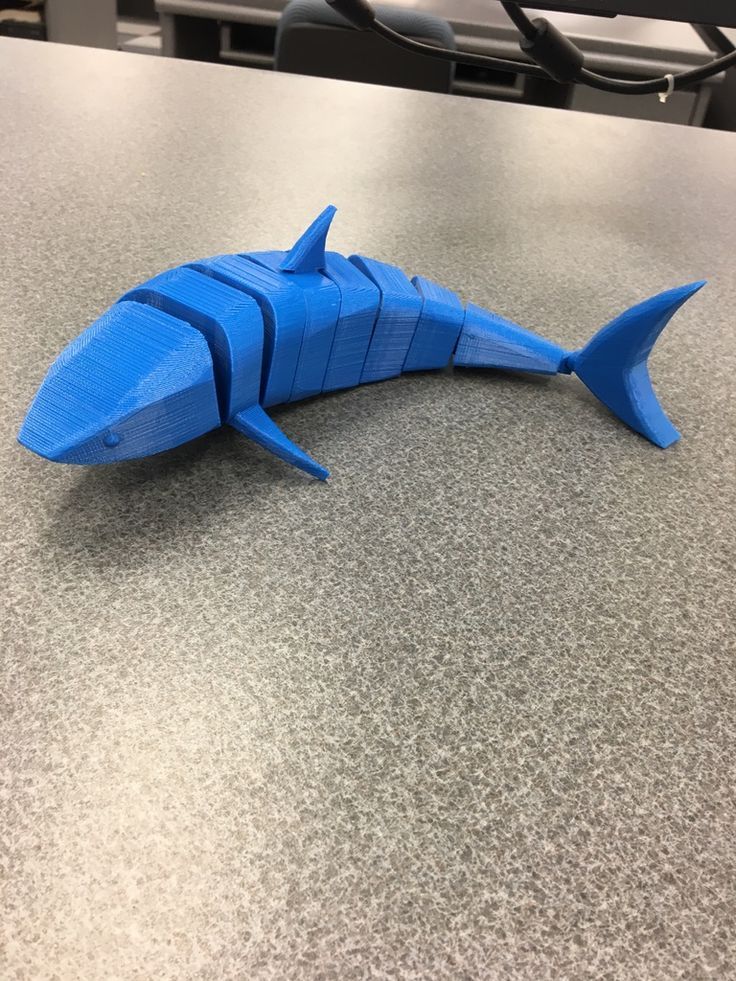

3D printing at home has come a long way. To date, there are a huge number of 3D printers in various price ranges, there are plenty to choose from. And as there are more and more happy owners of 3D printers, the community is growing, there is a huge number of 3D models that people share. But the static figures downloaded from Thingiverse are gradually getting bored and I want new challenges and experiments. Well, you've come to the right place. How about printing a running electric motor? nine0005

To date, there are a huge number of 3D printers in various price ranges, there are plenty to choose from. And as there are more and more happy owners of 3D printers, the community is growing, there is a huge number of 3D models that people share. But the static figures downloaded from Thingiverse are gradually getting bored and I want new challenges and experiments. Well, you've come to the right place. How about printing a running electric motor? nine0005

If you are interested, then welcome to the rest of the article, as here we have collected for you the best options for engine designs that you can print on your 3D printer.

Brushless motor

Designed and built by Christophe Laimar, this motor has impressive power. The 3D printed motor uses a 3D printed rotor and stator and delivers 600W of power with an efficiency of 80%. The complexity of 3D printing rightly allows it to be used as a demonstration of technical prowess as well as knowledge of 3D printing. nine0005

nine0005

Where to find : You can download the part files from the developer's website for a fairly small $10 license fee. Also included is an approved list of 3D printing hardware and engine components.

How to make : Christoph provides very detailed information on how to print and assemble this impressive brushless motor project. You can find the full instructions for 3D printing and assembling this model on Instructables. nine0005

In the video below you can see how this engine works.

Simple DC Motor

This motor is astonishingly simple: it was designed for training purposes by user Thingiverse for MakerEd Challenge 2.0.

Where to find : Thingiverse has all the parts you need to 3D print this DC motor. In addition, there are detailed instructions for assembling the model, as well as materials with examples of its use. nine0005

nine0005

How to make : Follow instructions on Thingiverse where the author recommends printing at a high resolution of 0.1mm. In addition, it provides a complete list of required parts for a complete build so that even before starting this project, you can be fully prepared and armed with everything you need.

A short video showing the operation of this 3D printed motor is shown below.

Mendocino small solar motor

As stated by the creator, "The Mendocino engine is a solar-powered electric motor with magnetic levitation." Watching a video of his work will definitely make you wonder how interesting this design really is. The assembled model is practically a work of art, with a stylish floating design.

Where to find : This unusual engine model can be found on Thingiverse.

How to make : The author used a 0. 5 mm nozzle with a layer height of 0.2 mm for the stator components. Detailed instructions are also provided on the Thingiverse page. nine0005

5 mm nozzle with a layer height of 0.2 mm for the stator components. Detailed instructions are also provided on the Thingiverse page. nine0005

Tesla Turbine

Originally designed and manufactured by Portuguese manufacturer and engineer Integza. This 3D printed engine is based on a Tesla turbine. It is propelled by the use of high-pressure air, acting in a vortex through thin, 3D printed plates. The original design used a few 3D printed components, but the current second iteration is almost entirely 3D printed.0005

Where to find : The author has posted 3D printing files and instructions on her Thingiverse page.

How to make : unfortunately the author does not offer any technical documentation. But the author has a video where he reveals some background of this project, and also describes the build process.

Spring Motor

Designed and printed by Greg Zumwalt, this powerful 3D printed spring motor demonstrates the unique properties of PLA plastic. And it's especially impressive that Greg has created many other models based on the lessons learned in this project. nine0005

Where to find : Greg Zumwalt has posted all of his part files on MyMiniFactory.

How to make : Greg has posted instructions on MyMiniFactory that explains in detail how to print and assemble each of the parts. The most important tip is to print with 100% coverage. In addition, he recommends using light machine oil for lubrication.

Here are just a few options to make your 3D printed projects even more colorful and impressive. As you can see, 3D printing is about more than just static miniatures. Implement at least a couple of the above projects, and your knowledge in the field of 3D printing (and not only) will expand significantly.