3D print titanium

Titanium (Ti-6Al-4V) 3D Printing | Get Custom Metal 3D Parts Fast

Back

-

Materials

Materials by Service

Injection MoldingCNC Machining3D PrintingSheet Metal

Materials by Type

PlasticsMetalsElastomers

Related Links

Customer Supplied ResinsColors

Injection Molding Material Alternatives Guide

Struggling with thermoplastic material shortages? We created a detailed guide to resin substitutes for ABS, PC, PP, and other commonly molded thermoplastics.

Download

-

Resources

Design Tips Guides and Trend Reports Success Stories Design Aids Webinars & Trade Shows

Blog Videos FAQs Educators & Students Glossary

Industries Medical Aerospace Automotive Consumer Electronics Industrial Equipment

-

About Us

Who We Are Why Protolabs? Research and Development Cool Idea Award Partnerships Sustainability & Social Impact

Careers Investors Locations Press Procurement

Contact Us

Proto Labs, Inc.

5540 Pioneer Creek Dr.

Maple Plain, MN 55359

United StatesP: 877.479.3680

F: 763.479.2679

E: [email protected]Best-in-Class Online Quoting

After uploading your part design, you'll receive an online quote that includes manufacturing analysis to help improve part manufacturability. Within your quote, you can also adjust quantity and material and see price changes in real-time.

Learn More

Get a QuoteSign In

Titanium is a lightweight metal with high strength and excellent corrosion resistance

GET INSTANT QUOTE

Titanium (Ti6Al4V) is a workhorse alloy. Versus Ti grade 23 annealed, the mechanical properties of Ti6Al4V are comparable to wrought titanium for tensile strength, elongation, and hardness. Final parts built in Ti6Al4V receive vacuum stress relief application.

Primary Benefits

- High stiffness and strength relative to weight

- High temperature and corrosion resistance

Design Guidelines for Titanium 3D Printing

- US

- Metric

| Normal Resolution | High Resolution | |

|---|---|---|

| Max Part Size | 9. 6 in. x 9.6 in. x 13.0 in. 6 in. x 9.6 in. x 13.0 in. | 3.5 in. x 3.5 in. x 2.7 in. |

| Layer Thickness | 0.0012 in. | 0.00079 in. |

| Minimum Feature Size | 0.015 in. | 0.006 in. |

| Normal Resolution | High Resolution | |

|---|---|---|

| Max Part Size | 245mm x 245mm x 330mm | 88mm x 88mm x 70mm |

| Layer Thickness | 30 microns | 20 microns |

| Minimum Feature Size | 0.381mm | 0.153mm |

Tolerances: For well-designed parts, tolerances of ±0.003 in(0.076mm) plus ±0.001 in./in. (0.0254mm/mm) can typically be achieved. Note that tolerances may change depending on part geometry.

Titanium (Ti6Al4V) Material Properties

- US

- Metric

Applications for 3D-Printed Titanium

Due to its light weight, high strength, and excellent high temperature and corrosion resistance, titanium is often used for aerospace, industrial, and medical applications. Common uses include:

Common uses include:

- Compressor blades and discs

- Rings for jet engines

- Airframe and space capsule components

- Surgical instruments

- Medical implants

Related Resources

Blog

Titanium vs Aluminum: Workhorse Metals for Machining and 3D Printing

Light weight and strength help aluminum and titanium excel for 3D-printed and machined parts.

Read Blog

Webinar

Best Practices to Fast Track Design and Production Using Metal Additive

In our webinar co-hosted with GE Additive, industry experts take you on an in-depth journey through some common and not-so-common hurdles experienced when designing for metal 3D printing.

Watch Webinar

Design Tip

Designing for Direct Metal Laser Sintering

Direct metal laser sintering (DMLS) produces complex, durable, lightweight metal parts. Depending on the design, DMLS can be a reliable way to manufacture metal parts.

Read Design Tip

Trend Report

Prototyping and Production for Aviation, Aerospace, and Defense

Move from prototyping to production faster and more efficiently with industrial 3D printing and other advanced manufacturing technologies.

Read Trend Report

A Guide to 3D Printing With Titanium

18 June 2019

With the benefits of reduced material waste and the ability to create lightweight designs, titanium 3D printing is finding its niche in many industries.

Titanium has excellent material properties, but its high cost has historically limited its use to high-value applications in aerospace. Now that metal 3D printing is becoming increasingly recognised as a viable manufacturing method, the technology is making titanium more available to industries like medical, automotive and motorsports.

Today’s post looks at what makes titanium a good choice for 3D printing, the technologies that support the material, as well as key industrial applications.

| Sector | Properties | Applications |

|---|---|---|

| Aerospace | Corrosion resistance High strength-to-weight ratio High temperature resistance | Airframe and wing structures Smaller parts like compressor blades, rotors and other turbine engine components |

| Medical | Excellent strength Biocompatibility (non-toxic, non-allergenic) | Orthopaedic devices like spine, hip and knee implants. |

| Automotive & Motorsports | Corrosion resistance High strength-to-weight ratio High temperature resistance | Brake calipers, brackets, wheel rims, uprights. |

Think strong, light and corrosion-proof, and you have the essence of what makes titanium such a sought-after material. Titanium is known for its excellent material properties — as strong as steel but with only 60% of its density.

Titanium is known for its excellent material properties — as strong as steel but with only 60% of its density.

Titanium’s high strength-to-density ratio, good corrosion resistance and chemical resistance make it particularly desirable for high-performance industries like aerospace and defence.

Here, titanium alloys are used in applications that require lightweight parts able to retain their mechanical properties at high temperatures.

Titanium is also known for its biocompatibility, which makes it an ideal choice for medical applications, such as implants.

However, while titanium offers a range of benefits, it remains a relatively expensive material. This is because the metal is mined in relatively small quantities, and processing raw titanium remains a complex task, making the material considerably more expensive than alternative metals like steel.

Titanium can be a difficult metal to work with, particularly when it comes to machining. For one thing, titanium has a low thermal conductivity. This means that when it is machined, for example with a CNC machine, the heat generated is stored in the CNC tool – which could cause the tool to wear out quickly.

For one thing, titanium has a low thermal conductivity. This means that when it is machined, for example with a CNC machine, the heat generated is stored in the CNC tool – which could cause the tool to wear out quickly.

Additionally, since machining involves the cutting and removal of material, the process can lead to a lot of material waste being produced. Many companies are, as a result, looking for better alternatives to produce titanium parts.

Metal 3D printing is proving to be that viable alternative.

With metal 3D printing, the most commonly-used grade of titanium is the alloy, Ti6Al4V (Ti64). In addition to Ti64, it’s also possible to 3D print with pure titanium.

There are many benefits to 3D printing titanium.

For aerospace applications, using titanium to 3D print parts often helps to lower the buy-to-fly ratio. The term, which comes from the aerospace industry, refers to the correlation between the weight of the amount of material originally purchased and the weight of the finished part.

In conventional manufacturing, for example, titanium aircraft components may have a buy-to-fly ratio between 12:1 and 25:1. This means that 12-25kg of raw material is required to produce 1kg of parts. In this scenario, up to 90% of the material is machined away.

Metal 3D printing can reduce this ratio for titanium components to between 3:1 and 12:1. This is because metal 3D printers typically use only the necessary amount of material needed to create a part, generating only a little waste from support structures. For an expensive material like titanium, the cost-savings from this reduced buy-to-fly ratio can be quite significant.

Additive manufacturing can also enhance the lightweight properties of titanium thanks to topology optimisation. Using topology optimisation software, engineers set certain requirements, such as load and stiffness constraints and then let the software tool to optimise the initial design to meet those requirements. Through this optimisation, any unnecessary material is removed from the design, creating a lighter yet strong component.

Topologically optimised designs can often only be manufactured with the help of additive m manufacturing technologies. This benefit is particularly valued by the aerospace industry, where lightweight 3D-printed titanium parts can lead to weight savings and better aircraft performance.

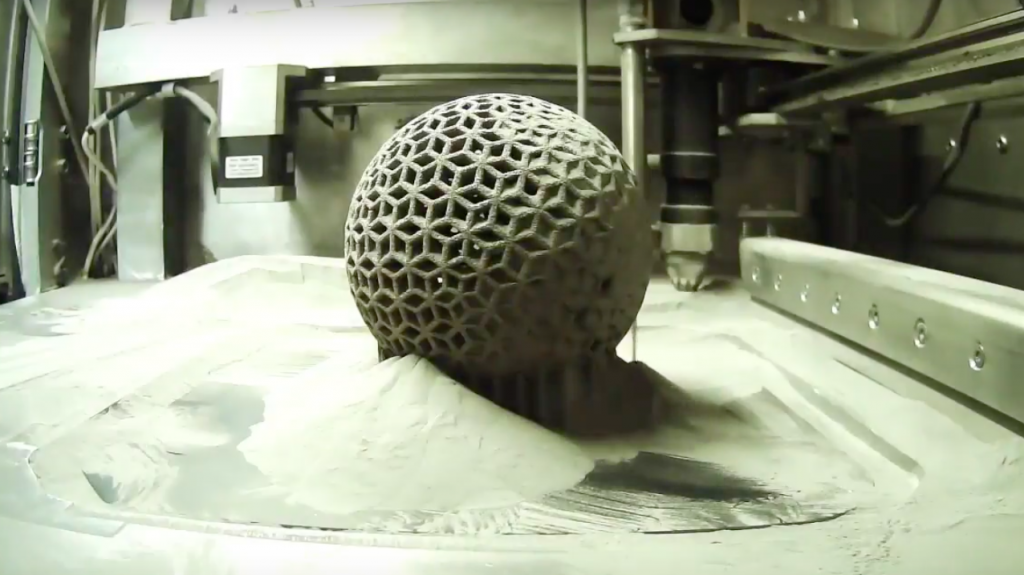

The three metal 3D printing methods most commonly used to create titanium parts are Direct Energy Deposition (DED), Electron Beam Melting (EBM) and Selective Laser Melting (SLM).

The first efforts to 3D print titanium began in 1997 at the Aeromet Corporation, which used DED technology to produce parts for the aerospace industry.

In DED, a high-intensity energy source such as a laser or a beam is used to melt the titanium powder (or wire) as it is deposited through a nozzle onto the substrate. The key benefit here is the ability to create large parts at a relatively high material deposition rate (up to 320 cc/h).

Today, there are many variations of DED technology, including Sciaky’s Electron Beam Additive Manufacturing (EBAM) and Wire Arc Additive Manufacturing (WAAM).

Swedish company, Arcam, has been developing its EBM technology to enable titanium 3D-printed implants and aerospace components. In EBM, an electron beam is applied to a layer of metal powder, melting and fusing it with the previous layer.

EBM is considered to be more accurate than DED, and suitable for smaller, complex parts. Notably, the EBM process takes place in a vacuum and at a high temperature. This results in minimal residual stresses in 3D-printed parts, which also means the parts don’t require subsequent heat treatment.

In 2013, Arcam released two AM machines, Arcam Q10 and Arcam Q20, targeting the orthopaedic implant and aerospace industries respectively. The Arcam Q20 is particularly designed to work with the Ti6Al4V alloy.

Arcam has also released the Arcam Spectra H 3D printer, which is capable of printing new crack-prone titanium alloys such as titanium aluminide.

Like EBM, SLM is a powder bed fusion process, although it uses a laser beam instead of an electron beam to melt and fuse the layers of metal powder. The thickness of one layer in the SLM process can be as thin as 20 microns, making this technology much more accurate when compared to DED and EBM.

Aerospace dominates the key applications of titanium 3D printing. That said, other industries like medical, motorsports, chemical and marine are also starting to investigate the technology to produce titanium components.

For aerospace companies, 3D printing titanium helps to reduce the weight of highly-loaded structures, making it extremely suitable for jet engines, gas turbines and many airframe components.

Many of the biggest aerospace companies are incorporating 3D-printed titanium parts into their aircraft.

Liebherr-Aerospace & Transportation SAS

For example, aerospace supplier, Liebherr-Aerospace & Transportation SAS, started the serial production of 3D-printed titanium nose landing gear brackets for the Airbus A350 XWB earlier this year. These brackets will be the first Airbus parts to be produced with 3D-printed titanium.

These brackets will be the first Airbus parts to be produced with 3D-printed titanium.

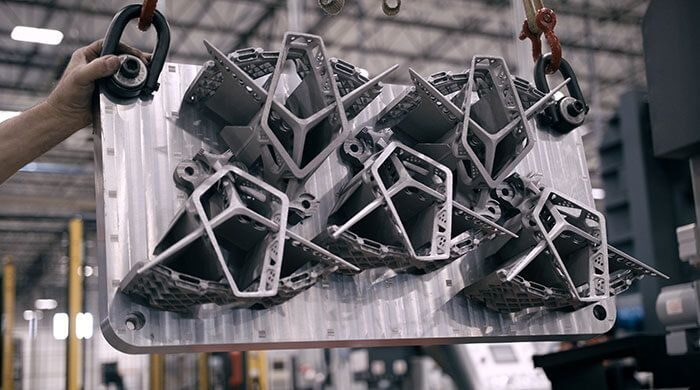

Boeing and Norsk Titanium

Boeing, too, has placed its bets on titanium 3D printing. Since 2015, Boeing has been in partnership with Norwegian metal 3D printing company, Norsk Titanium, to produce large structural titanium components for the 787 Dreamliner. In 2017, they FAA-qualified the unnamed titanium part, made with the help of Norsk’s proprietary Rapid Plasma Deposition (RPD) technology.

Norsk Titanium’s 3D-printed and machined part [Image credit: Norsk Titanium]

Based on the DED process, RDP uses titanium wire with plasma torches to print large titanium structural components. The technology is reportedly 50-100 times faster than powder-based systems and uses 25-50% less titanium than forging processes. The accelerated lead times and reduce material waste could save Boeing up to $3 million per aircraft.

Currently, titanium 3D printing is being explored largely for smaller aircraft components such as brackets and housings. In future, however, its use may expand into much larger structural components, fuelled by the savings in weight, cost and development time.

In future, however, its use may expand into much larger structural components, fuelled by the savings in weight, cost and development time.

Titanium’s non-toxicity, high strength and resistance to corrosion make it an attractive material for orthopaedic and dental implants.

When used with 3D printing, medical device manufacturers can create implants with complex, porous structures. Remarkably, these structures imitate the structure of human bones so the bone cells recognise it as a scaffold through which to grow.

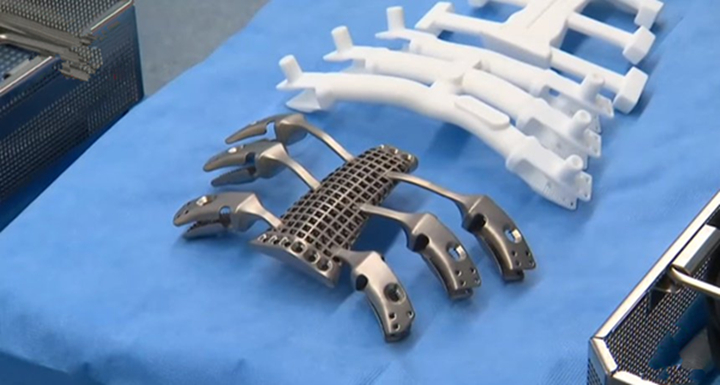

Osseus’ titanium spinal implants

Osseus’ interbody fusion device manufactured using titanium 3D printing [Image credit: Osseus]

One company developing such devices is US-based Osseus Fusion System. Its 3D-printed titanium spinal implants, called Aries-L Interbody Fusion Devices, feature a proprietary multi-axis mesh and optimised micro-surface topology, which enable bones to fuse together faster. To make such complex features possible, Osseus prints its Aries devices on an FDA-validated SLM 3D printer.

To make such complex features possible, Osseus prints its Aries devices on an FDA-validated SLM 3D printer.

The use of titanium 3D printing for orthopaedic devices, like spine, hip and knee implants, is on the rise. By 2020 medical applications of 3D-printed titanium will account for around 274,000 kg of titanium, according to a recent Smartech report. This sets a very positive outlook for titanium 3D printing in the medical industry.

Bugatti’s titanium brake caliper

[Image credit: Bugatti]

Compared to aerospace and medical, the automotive industry hasn’t been as quick to adopt titanium 3D printing. Even though the same benefits apply, the consumer automotive market is very cost conscious, which limits the use of this expensive material in most vehicles.

Currently, titanium 3D-printed parts can be found in racing cars and luxury vehicles where weight and performance are significant factors.

One of the most prominent examples of using titanium 3D printing in automotive is Bugatti’s brake caliper, developed for its Bugatti Chiron supercar.

An essential part of the braking system, the brake caliper measures 41 x 21 x 13.6 cm and was 3D printed in 45 hours using SLM technology. The finished part is said to be around 40% lighter than a machined aluminium alternative.

Last year, the company successfully tested the brake caliper, proving that it can meet extreme strength, stiffness and temperature requirements.

In addition to the brake caliper, Bugatti has used titanium 3D printing in the production of an active spoiler bracket. In partnership with Siemens, the part was optimised to reduce weight while still delivering strength, resulting in a 53% weight saving and increased rigidity.

HRE’s 3D-printed titanium wheels

US wheel rims manufacturer, HRE, is another company to benefit from titanium 3D printing. HRE’s primary goal was to reduce the amount of material wasted when producing wheel rims.

HRE’s primary goal was to reduce the amount of material wasted when producing wheel rims.

Using EBM technology, HRE 3D printed a complex-shaped wheel rim and achieved a weight reduction of 19% in the process.

With traditional production methods for this application, the material waste generated can reach up to 80%. With 3D printing, HRE says the wasted material doesn’t exceed 5%.

HRE considers the wheel rim more of a technological showcase rather than a commercial product. That said, the project offers a glimpse into what the future of wheel design and manufacturing could hold.

Titanium 3D printing and motorsports

In motorsports, titanium 3D printing plays “a critical strategic role” in producing high-performance, lighter vehicles, including racing cars.

One example comes from Oxford Brookes Formula Student team. In partnership with the UK’s Manufacturing Technology Centre (MTC), the team redesigned the uprights of the vehicle and and manufactured them using the EBM technology. Thanks to this process, the team achieved 50% in weight savings.

Thanks to this process, the team achieved 50% in weight savings.

Despite the advantages of titanium 3D printing, there are a few challenges that need to be taken into consideration.

First is the need to develop standards for using titanium with additive technologies. Some companies are already taking steps in this direction. In 2018, Boeing and Oerlikon signed a five-year partnership focused on standardising titanium 3D printing and ensuring printed components meet FAA and DoD flight requirements.

The second challenge lies in the high cost of titanium powders. For example, the cost of titanium powder optimised for 3D printing ranges from $300 to $600.

To reduce the actual material cost per kilogram of titanium, some powder producers have developed alternative powder production methods. Canadian PyroGenesis, for example, is using its NexGen™ Plasma Atomization System, which produces metal powder, including titanium, at over 25 kg/h. Higher production rates allow the company to produce titanium at competitively lower price points.

Higher production rates allow the company to produce titanium at competitively lower price points.

UK-based company, Metalysis, has developed another powder production method which could lower prices of titanium. The method employs a form of electrolysis to transform raw titanium oxide into titanium powder. The key benefits of this technology lie in its eco-friendliness and low cost compared to the traditional powder production methods.

In September 2018, Metalysis began the commercial production of titanium powders, in addition to other alloys, looking to deliver between 10 and 100 tonnes of metal powders per year.

If new titanium powder manufacturing methods are able to deliver on their potential, the average price of one kg of titanium could be reduced by 17% by 2024, according to SmarTech Analysis.

Titanium 3D printing has become a valuable technology within aerospace, medical and automotive. The key reason for this is the winning mix of titanium’s excellent properties and 3D printing’s ability to reduce waste and create complex and lightweight designs.

Going forward, as the cost of titanium lowers and more applications are discovered, titanium 3D printing will become a great manufacturing alternative for a much wider range of industries.

Custom titanium 3D printing. Sprint 3D!

Titanium is a widely used metal for 3D printing. It is also one of the most practical, being both very wear-resistant and lightweight. 3D printing with titanium is used in various industries: medical (in particular, individual prosthetics), aerospace, space, engineering and others. The only significant disadvantage of titanium is its increased reactivity in powder form. Therefore titanium printing on a 3D printer must be performed by qualified specialists and in an inert Argon gas environment.

You can already order 3D printing with titanium in our company Sprint 3D. We guarantee the quality, durability of all products, meeting deadlines and a personalized approach. All details are below.

We guarantee the quality, durability of all products, meeting deadlines and a personalized approach. All details are below.

Titanium 3D printing with Sprint 3D

3D printing with our own industrial 3D printers

The largest working area is 90x90x80 mm

First-rate material-Titan

Shipment the next day

Delivery throughout Russia and CIS countries

PROCESSIONS AY ACTION

For a long time, 3D printing technology was expensive and out of reach for most potential customers. Only in recent years has it and printing software become more accessible. And most importantly, they made it possible to print not only with plastics, but also with more durable materials.

Due to its low density and high resistance to mechanical and thermal influences, titanium has become one of the optimal materials for printing products in various industries.

Already now printing with titanium on the 3D printer allows you to print structures for aerospace, automotive, military, jewelry and many other important industries. That is, even where particularly high precision in production is important.

That is, even where particularly high precision in production is important.

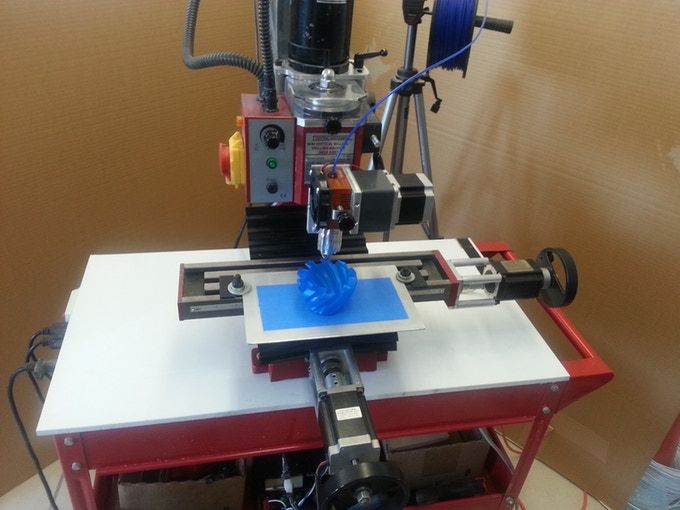

Titanium is 3D printed by classical technology as follows:

1. Metal in powder form is processed by electron beam melting. This technology allows you to create the thinnest layer - less than 0.2 mm.

2. Melting takes place in a special chamber by means of a directed action of electronic emitters.

3. In the chamber, successive layers are formed until the desired dimensions and shape of the product are achieved.

In some cases, titanium products are milled, but modern technology and software allow you to create products of high complexity without the need for post-processing. This reduces production time and makes it more cost-effective due to the lack of additional technologies.

Titanium printing on the 3D printer involves the use of additive manufacturing technology - direct laser sintering. Briefly, it can be divided into two stages:

1. A thin layer of titanium powder is fed onto the heating table.

A thin layer of titanium powder is fed onto the heating table.

2. A carbon dioxide laser fuses titanium powder particles to each other and to the previous layer.

Please note: when 3D printing with titanium, there is no traditional shine familiar to many - the details are somewhat dull and rough. However, if the characteristic titanium sheen is important to you, it can be achieved with manual processing. Polishing allows you to easily and quickly achieve the desired visual look with a bright and attractive sheen.

7

Key Features of

Titanium 3D PrintingDespite its practicality and versatility,

3D printing with titanium has some limitations, which we always warn our customers about.

- Difficulty printing products with right angles and lines. Titanium has many features, and one of them is not perfect straight lines. But smooth shapes and rounded elements look great. Plus, they are more convenient and easier to process in the future.

Therefore, most experts agree that the angles in titanium-printed objects should be at least 35 degrees.

Therefore, most experts agree that the angles in titanium-printed objects should be at least 35 degrees. - The need for product support when printing. When using DMLS technology, model support is required. The product must be firmly fixed to the base. Without this, it is impossible to achieve high printing accuracy. After the printing process is completed, the support is removed.

- There are some nuances when printing small items, as well as when reproducing depressions by engraving. For example, when printing letters from titanium. If we print titanium letters, the minimum thickness is 0.4mm, and the thickness of the recesses is about 0.15mm.

There are other features of 3D printing with titanium depending on the products to be printed. We always discuss all these aspects with the client before completing the order.

Specifications of titanium

When printing with this metal, the parameters of this metal and the requirements for products based on it must be taken into account:

- The walls of the product must be no thinner than 0.

4 mm.

4 mm. - Small parts size up to 0.25 mm.

- Printing accuracy is about 0.2%.

- Tensile strength - 1140 MPa.

- Rockwell hardness approx. 37 HRC.

- Density - 4.41 grams per cm3.

- Melting point - 1660 degrees Celsius.

If you have additional questions about 3D printing with titanium or other metals, please contact us at +7 (495) 740 51 70 or use the feedback form on the website.

You may be interested in

90,000 production features and examples of parts

Fundamentals 3D

Airlines

Medicine

Experts recommend

Author: Victor Naumov

Author

Classification and groups of titanium alloys | Application of Ti6Al4V in additive manufacturing | Bugatti optimizes Bolide hypercar with bionic design and titanium 3D printing | Bracket for aircraft has become one third lighter | Thanks to the titanium prosthesis, the patient was able to return to normal life

Among the materials used in metal 3D printing, titanium and its alloys, especially Ti6Al4V, occupy a special place. Titanium is a metal that exists in nature in the form of oxides. The most common are rutile (TiO2) and ilmenite (FeTiO3). Pure titanium is produced by the Kroll method.

Titanium is a metal that exists in nature in the form of oxides. The most common are rutile (TiO2) and ilmenite (FeTiO3). Pure titanium is produced by the Kroll method.

Without going into details, the process is as follows. First, titanium tetrachloride (TiCl4) is obtained by chlorination in the presence of carbon monoxide at 1000 °C. After that, using magnesium or sodium, carbon monoxide is removed in an inert atmosphere at 800–850 °C. The result is pure titanium. Absolutely pure titanium is difficult to obtain due to its high reactivity, therefore samples with a purity of 9 are accepted on the market for it.9.9%. For this reason, titanium is mainly used in the form of an alloy with other elements.

Read more about additive manufacturing projects for Bugatti cars in the article

The main physical and chemical properties of this metal are high mechanical strength, low density and high corrosion resistance. For this reason, titanium and its alloys are attractive materials for various industries, including the aviation industry and medicine. The only significant disadvantage of titanium is its high cost. Due to the properties of its alloys, this material has great potential for the production of parts and elements in an additive way.

For this reason, titanium and its alloys are attractive materials for various industries, including the aviation industry and medicine. The only significant disadvantage of titanium is its high cost. Due to the properties of its alloys, this material has great potential for the production of parts and elements in an additive way.

Can 3D printing help you optimize production in your organization? Order a free consultation iQB Technologies experts!

Classification and groups of titanium alloys

Depending on the microstructure and phase composition, titanium alloys are divided into three groups: α, α + β, and β. What is microstructure and phase? Microstructure - the structure of the material, distinguishable under an optical or electron microscope. It can be used to determine the size, shape and orientation of individual crystals and granules that make up the material. It also largely determines its physicochemical properties. A phase, on the contrary, is a section of a material with the same physical and chemical properties. Each phase differs from the others in its microstructure and/or composition. Both of these characteristics depend on the rate at which the material cools from a liquid to a solid state, as well as on the application of heat treatment.

A phase, on the contrary, is a section of a material with the same physical and chemical properties. Each phase differs from the others in its microstructure and/or composition. Both of these characteristics depend on the rate at which the material cools from a liquid to a solid state, as well as on the application of heat treatment.

Alloys are divided into groups depending on the elements included in their composition in addition to titanium. In alloys of the α group, α-stabilizers (aluminum, carbon, oxygen, nitrogen) predominate. Compared to other titanium alloys, these alloys have relatively low mechanical properties and high corrosion resistance. The most widely used of this group are Ti3Al2.5V and Ti5Al2.5V.

Group β alloys were developed to improve the mechanical properties of the material. They include β-stabilizers (iron, molybdenum, vanadium). These alloys include, among others, Ti10.2.3, Ti555.3 and Ti17.

Finally, there are alloys of the α + β group. They are the best studied and contain stabilizers of both groups, resulting in a mixed microstructure and a good set of properties. The most widely used Ti6Al4V. Due to the optimal ratio between mechanical strength, ductility, fatigue resistance and crack resistance, its share is 56% of the entire titanium alloy market. Depending on the group, the alloys market is divided in the following proportions: 26% (α), 4% (β) and 70% (α + β).

They are the best studied and contain stabilizers of both groups, resulting in a mixed microstructure and a good set of properties. The most widely used Ti6Al4V. Due to the optimal ratio between mechanical strength, ductility, fatigue resistance and crack resistance, its share is 56% of the entire titanium alloy market. Depending on the group, the alloys market is divided in the following proportions: 26% (α), 4% (β) and 70% (α + β).

On the left is the equiaxed microstructure of the Ti6Al4V alloy (without heat treatment). On the right is a diagram of the phase composition of the Ti6Al4V alloy © 3dnatives.com

iQB Technologies Experts Recommend Article: Metal 3D Printing: Short Answers to Big Questions

Application of Ti6Al4V in additive manufacturing

Taking the market as a whole, Ti6Al4V alloy is the most widely used in 3D printing because of its high strength, low density, high corrosion resistance, and high biocompatibility. This set of properties makes it a valuable material in industries such as automotive, aerospace, medicine and biomedicine, dentistry, chemicals, defense and other areas.

Before starting 3D printing using Ti6Al4V, the alloy must be powdered. This is done using two main technologies: plasma and gas atomization.

Plasma atomization is used to produce highly pure metal powder (Ti6Al4V). The alloy in the form of a rod is fed into the atomizer tank and melted under the influence of the plasma torch. As it falls, the molten metal solidifies into spherical particles.

© 3dnatives.com

The most commonly used technology is gas atomization. The molten material is fed into the nozzle and atomized with an inert gas (argon or nitrogen). In the gas flow, the molten material solidifies and disintegrates into spherical particles, which accumulate at the bottom of the chamber.

See also: Russian manufacturer of SLM machines dispels myths about technology

The choice of technology for the production of metal powder (in this case, Ti6Al4V) is extremely important. The particle size and properties of the powder depend on it, which, in turn, determines the characteristics of the final product. There are three industrial Ti6Al4V alloys on the market today:

There are three industrial Ti6Al4V alloys on the market today:

-

TC4 conforming to GB/T 3620.1-2017;

-

Ti6Al4V class 5;

-

Ti6Al4V Grade 23 conforming to ASTM B348-13.

They differ from each other in particle size, which limits the minimum thickness of the printed layer. Most often, 3D printing using Ti6Al4V is carried out using DMLS or SLM technology. The choice of technology depends on the type of part and the desired characteristics.

Source: 3dnatives.com

Bugatti optimizes Bolide hypercar with bionic design and 3D printed titanium

© bugatti.com

Luxury car manufacturer Bugatti has been using additive technologies for years. New advances in 3D printing have been applied to the development of the Bolide hypercar, unveiled in October 2020. Bolide is equipped with an eight-liter W16 engine, weighs only 1240 kg and is capable of accelerating to more than 500 km/h.

Inspired by bone structure, the design team 3D-printed automotive components with a hollow structure with thin walls (up to 0.4 mm) and small ramifications. The use of bionic design has made it possible to give the parts exceptional rigidity and at the same time significantly reduce their weight.

Of the additively produced components for the Bugatti Bolide, the push rods stand out. Despite their light weight - only 100 g - they can withstand pressures up to 3.5 tons.

Another printed detail that Bugatti is particularly proud of is the hypercar's titanium rear fender mounting bracket. Weighing 600g, the bracket is capable of withstanding an aerodynamic downforce of up to 800kg, with a hollow design and a wall thickness of 0.7mm.

Bolide titanium rear fender mounting bracket © bugatti.com

Bugatti previously created a titanium brake caliper for the Chiron hypercar, the first to be 3D printed and the largest in automotive history. The 3D printing was done on a powerful 4-laser SLM 500 machine. The titanium caliper is about 40% lighter and at the same time stronger than the original aluminum part.

The 3D printing was done on a powerful 4-laser SLM 500 machine. The titanium caliper is about 40% lighter and at the same time stronger than the original aluminum part.

Read more in the article: Bugatti did the impossible in 45 hours with a 3D printer

Bracket for the aircraft has become one third lighter

The S-bracket is an aircraft lift actuator element printed from Ti6AI4V on an SLM 280 machine by ASCO Industries. Its elegant shape is the result of strict space requirements and high stresses on the seating surfaces. The original project involved the manufacture of a high-strength stainless steel bracket and complex machining.

S-shaped bracket - an element of the actuator of the aircraft lift system

The product design has been redesigned for additive manufacturing through topological optimization. Its goal was to minimize the mass while maintaining the necessary strength to withstand the aerodynamic loads specified in the project.

Results of application of selective laser melting:

-

31% weight reduction and overall assembly time reduction;

-

combining three parts into one;

-

decrease in the material utilization factor from 17 to 1.5;

-

significant reduction in machining time.

The result of the topological optimization of the bracket

Read more in the article: How to reduce the weight of an aircraft structural element by a third

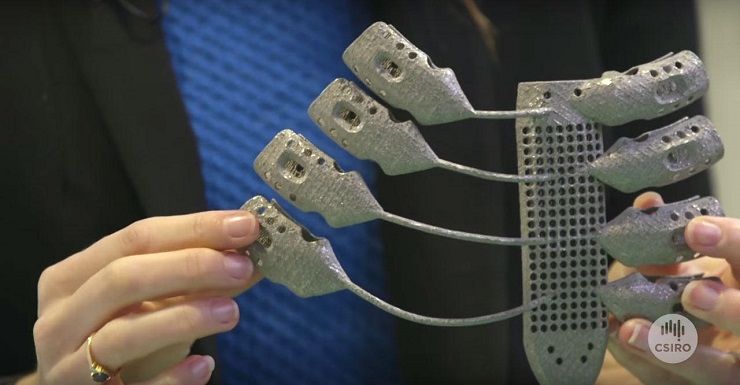

Thanks to the titanium prosthesis, the patient was able to return to normal life

The biocompatibility of titanium alloys (such as Ti6Al4V ELI) makes them ideal for 3D printing prosthetic bones of the maxillofacial region, intervertebral discs, clavicles, knees, shoulder blades, hips, and various implants. In dentistry, these materials are used for the manufacture of one-piece implants, as well as metal bases for crowns and bridges made of titanium, cobalt-chromium and other alloys.

An 81-year-old patient suffered from a type 3B acetabular defect according to the Paprosky classification. Previous revision reconstructions in this patient had failed due to calyx loosening and displacement to the posterior cranial region.

For the operation, an aMace hip joint prosthesis was designed, individually made on a 3D printer in accordance with the defect. Thanks to this, the prosthesis helped to achieve the desired degree of recovery and fixation.

aMace custom prosthesis used for surgery

The aMace prosthesis (developed by Materialize) allows you to take into account all the medical features of the patient and the complex mechanical requirements for this important moving part of the human body. The complex porous structure of the back of the product, which allows for bone ingrowth, is a feature that can be easily reproduced using 3D printing.

The prosthesis helped to restore the center of rotation to the desired location and orientation, and also provided sufficient support despite the limited amount of bone material (especially in the posterior cranial region).