3D print switch

Switch best 3D printer models・Cults

25$ ON TELEGRAM: @GAS_SELL | GLOCK AUTO SEAR

€160

25$ ON TELEGRAM: @GAS_SELL | GLOCK AUTO SEAR

€150

25$ ON TELEGRAM: @GAS_SELL | Invisible switch

€160

25$ ON TELEGRAM: @GAS_SELL | Invisible switch

€160

Box for switch games

Free

Support Nintendo Switch Lite

Free

Switch drawer

Free

Mr Fusion Keychain, keychain Mr Fusion, Back to the future, Back to the future

€0.87

40$ ON TELEGRAM: @GAS_SELL | Invisible switch

€160

25$ ON TELEGRAM: @GAS_SELL | GLOCK AUTO SEAR

€200

20$ ON TELEGRAM: @GAS_SELL | AR-15 Auto Sear

€160

25$ ON TELEGRAM: @GAS_SELL | GLOCK AUTO SEAR

€160

25$ ON TELEGRAM: @GAS_SELL | GLOCK frame

€160

25$ ON TELEGRAM: @GAS_SELL | Invisible switch

€160

25$ ON TELEGRAM: @GAS_SELL | Invisible switch

€160

40$ ON TELEGRAM: @GAS_SELL | Invisible switch

€160

25$ ON TELEGRAM: @GAS_SELL | Invisible switch

€160

25$ ON TELEGRAM: @GAS_SELL | GLOCK AUTO SEAR

€160

Koco cute Sonic Frontiers

€3

Light Plate for Kossel Mini printer - LED Strip lights

Free

Peach crown switch dock

Free

Support switch games pokemon version

€1. 88

Complete collection of 26 Pokémon Pokeballs

€15 -30% €10.50

Rack Netgear switch GS108

€1.50

Robland X310 Ignition switch pin

Free

Switchcade Pac-Man

€10.50

Decoration cat for switch / Cat decoration for switch

€1

Light Switch 3D Model

€8.14

CALL OF DUTY: MODERN WARFARE II (RGB) 🎅

€0.50

Nintendo Switch Harry Potter game box

€2.50

Knob

Free

Light Switch Covers

€4. 79

79

Time Switch Delorean Back to the future, Back to the future

€23.26

NINTENDO SWITCH ARCADE BOX

€7.20

TRX4M Remote Vehicle Stand

€2.40

Range Rover Classic Rocker Switch Panel

Free

Nintendo Switch console

Free

Nintendo Switch Game Card Case

Free

Nintendo Switch Stand

€2.49

Zelda Light Switch Cover 2-Gang

€0.96

Kanto Pokedex Nintendo switch game case

€4.38

PokeDex Nintendo Switch Games Case

€3.75

SwitchCube - Switch Mayflash Charging Dock

€5. 75

75

Animal Crossing Amiibo Base

Free

Nintendo Wii custom cover [Customized cover ]

€0.75

Nintendo Switch Logo Cookie Cutter

Free

Switch Analog Stick Bracket

Free

Hinged Bistable switch

Free

These open-source, levitating keyboard switches can be 3D printed at home

0Shares

Insiders and analysts predict the 3D printing trends to watch in our latest series of articles focused on the future of 3D printing.

Riskable, a hobbyist toymaker, and 3D printing enthusiast has developed an innovative new key switch mechanism for use in PC keyboards.

Named ‘Void Switch’, the design is completely open-source and can be fabricated at home with any run-of-the-mill FFF 3D printer. The novelty of the mechanism lies in its use of magnets, which makes it levitation-based and entirely contactless. In contrast, standard mechanical keyboard switches rely on springs and metallic contact plates to determine whether or not a key has been pressed.

The novelty of the mechanism lies in its use of magnets, which makes it levitation-based and entirely contactless. In contrast, standard mechanical keyboard switches rely on springs and metallic contact plates to determine whether or not a key has been pressed.

Interestingly, the Void Switch mechanism is also fully customizable in its feel, allowing users to adjust both the tactility and return force of the keys based on personal preferences.

An assembled Void Switch. GIF via Riskable.The world of mechanical keyboards

While the average person probably doesn’t give their computing peripherals much thought, those in the PC gaming and programming communities tend to have a special affinity for kitted-out mechanical keyboards.

Unlike the compact keys found on a laptop, mechanical keys feature more depth and provide a much more satisfying feel when pressed down. You can usually tell the difference between the two from the sounds they make: mechanical keyboards often deliver a louder ‘clack’ sound.

Beyond just the RGB lighting, mechanical keyboards can be modified and customized in almost every aspect from the casing and stabilizers to the keycaps and key switches. The key switches, in particular, are what determine the tactile response of the keyboard, whether it’s a click, bump, or smooth descent all the way down.

The 3D printed Void Switch

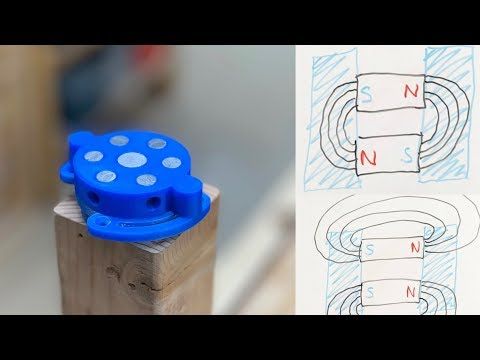

Riskable’s 3D printed Void Switch uses a Hall effect sensor to determine the pressing of the key, a type of sensor that detects the presence of a magnetic field. Each switch mechanism features three individual 4 x 2mm magnets, one central static magnet for the levitator, and two moving magnets embedded in the switch’s slider.

The two moving magnets are placed above and below the static one, and serve to maintain an equilibrium between attraction and repulsion. Specifically, the lower magnet is what provides tactility, while the upper one is what provides the repulsive force acting in the opposite direction. In a conventional key switch, a spring would be used to deliver this counter-force.

In a conventional key switch, a spring would be used to deliver this counter-force.

Furthermore, the OpenSCAD files for the mechanism are customizable, whereby the user can modify the separation of the magnets. This is what allows for full control of the tactility and the counter-force of the keys.

Riskable recommends 3D printing the Void Switches using PETG filament due to the material’s deep sound profile and comparatively low coefficient of friction, which makes key presses smoother. However, a material like PLA will also work just fine. For those that want a quieter experience, the switches can also be paired with 3D printed TPU keycaps (92A or harder). TPU is flexible enough to absorb much of the sound energy but won’t buckle or bend under the force of a finger.

The Void Switch relies on a series of magnets that push against each other to provide resistance. Image via Riskable.All of the open-source 3D files needed for the project can be downloaded on Riskable’s GitHub.

The open-source community can undeniably be a fountain of ingenuity, offering novel 3D printing applications at low costs. Earlier this month, YouTuber Akaki Kuumeri created a 3D printed adapter for the PS5 DualSense controller that enables users to play games one-handed. The add-on can be applied non-destructively to game controllers in order to allow for non-standard hand positions and make playing video games more accessible to those with physical disabilities.

Elsewhere, content creator Lucas VRTech has previously designed and 3D printed a pair of low-cost finger tracking gloves for use in virtual reality. Named LucidVR, the open-source gloves grant users the ability to precisely track their fingers without the use of dedicated VR controllers. Tallying up all of the component and filament costs, the LucidVR project cost Lucas just $22 ($11 per hand).

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows an assembled Void Switch. GIF via Riskable.

Tags Riskable Void Switch

Kubi Sertoglu

Kubi Sertoglu holds a degree in Mechanical Engineering, combining an affinity for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

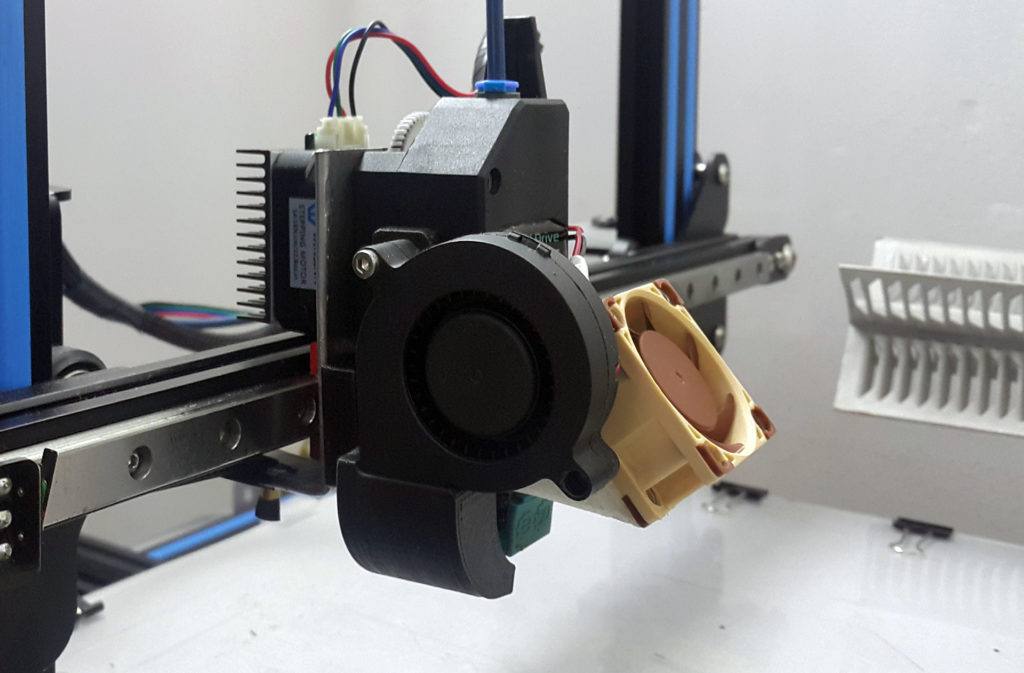

Answers to questions on endstop

Switch used to notify the controller that the printer has completed its home travel. Also known as a limit switch.

Used on all three axes to indicate to the controller that the desktop or printhead has reached the end of its home travel. This allows the controller to get a zero point as it moves, which provides a home position during printing.

There are three main types of end posts (or limit switches):

The mechanical switch is just a simple on/off device. When the table or print head is moved to the desired location, a metal lever is pressed against a switch that indicates and sends a signal to the controller.

Optical switch - This type has an optical beam which, when interrupted, sends a signal to the controller.

Proximity sensor - most commonly used on the z-axis for table alignment. When the end of the sensor approaches the table, it sends a signal to the controller before the sensor comes into contact with other parts of the printer.

- Flashforge Adventurer 3 - how to replace the x-axis stop I found a similar question on the forum, but now I need help replacing the x-axis stop. I searched for a video and did not find it yet. Can anyone help me? The printer turns on, warms up, but as soon as I ...

- How to align the kossel endpoints? My printer is kossel (delta 3d printer).

I have a probe far from the nozzle (offset -x45 y17), every time I run a G29 the result is unacceptable, distance z between points exceeds 0.5 mm,…

I have a probe far from the nozzle (offset -x45 y17), every time I run a G29 the result is unacceptable, distance z between points exceeds 0.5 mm,… - I have an old Solidoodle 2 that I bought broken at a garage sale and that I am converting to use RAMPS 1.4 with Marlin firmware. All engines are working properly, I have ...

- 3D printer affected by forced movement over limit A faulty endstop caused the printer (traditional Cartesian FDM) to try to go over the maximum axis limit from above, the noise was terrible, I don't see any damage (apparently) but I'm wondering ,…

- Ender3 V2: What stops Y? Since there is no limit switch at the Y (Y -) operator end, what stops it from moving when printing?

- Problems with Marlin 9 firmware0029 So I'm working on making a Prusa i3 MK3 clone and so far everything has been going well, but when I make changes to the firmware and re-download it, the printer doesn't seem to get it.

For example, I changed…

For example, I changed… - Ender 3 - X Axis Can't Reach True Home After a year of printing smaller models, I finally went to print something that would take up most of the build plate from left to right and realized that my nozzle was not can reach "true" X home. As you can see…

- BigTreeTech mini e3 V1.2 endstop installation I recently bought a BigTreeTech mini e3 V1.2 controller for my own 3D printer (as opposed to a pre-purchased ender 3). In doing so, I ran into a problem that the endpoints,…

- Limit switch problems on RAMPS 1.4 and a custom 3D printer running Marlin 1.1.0-rc6 So I'm trying to fix a custom 3D printer for my institute and I'm running into a problem that I can't figure out. Thus, the limit switches for the Y and Z axes…

- 3D printer endstop does not fire in Pronterface when pressed I am using Makerbot end stops connected to a RAMPS 1.4/Arduino Mega 2560 setup. I am using Marlin and Pronterface firmware.

When I send an M119 command, all six (I use max - and…

When I send an M119 command, all six (I use max - and… - Z homing problem on Ender 3 Pro with Marlin I just changed the motherboard on my Ender 3 Pro to MKS GEN_L v1.0 and flashed it Latest version of Marlin. I manually calibrated the table using the standard XY and Z auto home commands on…

- Ender 3, why only 3 limit switches? Why does Ender 3 only have 3 limit switches instead of 6? How does he deal with accidents on the other sides? Should I add them with a new motherboard?

- How to properly set house offsets and manual house definitions in Marlin? I'm using an Ender 3 and just upgraded to a Hero Me Gen 5 fan airway adapter. This caused the nozzle position to shift. I also flashed some new Marlin 2 firmware, and in…

- Y-min stay triggered I have a FLSUN i3 220x220x240 with: LCD Display Year 2004 (RepRap Discount Smart Controller) MKS-gen-L-v1.0 printer board runs Marlin 2.0 firmware…

- How do MAX endstops work? I am building my new 3D printer and I have doubts.

I use limit switches on 3 axes, but only on minimal switches. I also have three more switches that I want...

I use limit switches on 3 axes, but only on minimal switches. I also have three more switches that I want... - Stepper motor homing as extruder using E0/E1 with limit switch and end stop Note: I expanded my question as some of you mentioned that this question is not entirely clear. I'm using a RAMPS 1.4 board with an Arduino mega 2560. I need to control a stepper motor in…

- Z axis end stop not working after installing Marlin firmware I've had my Monoprice Maker Ultimate for a few months and started making updates to him. My latest change is to update the firmware to a newer version of Marlin,…

- What is this part and does it have anything to do with the fact that the z-position is broken? I recently bought my first monoprice maker select v2 3d printer. After a few print jobs, this piece fell out. I have no idea where he came from. But then I notice that...

- My homemade printer only boots when all of my endpoints fire.

Why is this? Recycling a Robin nano board for 3D printer assembly using an old computer power supply (300W), it only boots when I have no end stops at all or if I…

Why is this? Recycling a Robin nano board for 3D printer assembly using an old computer power supply (300W), it only boots when I have no end stops at all or if I… - Which endpoints are most accurate? I have seen mechanical (microswitch), optical and magnetic (magnet + hall sensor) end stops. Are there any differences in how accurately they switch in the right place? If...

- Reprogram Marlin to assign end pins to arbitrary tasks [Arduino Mega] Can someone point me to the appropriate input code for this task in the Marlin source code?

- Does moving the z-stop up affect the maximum printable height? Since moving the stop up decreases the range of the z-axis, I was wondering if this reduces the maximum printable height by the distance that the stop was moved. Or is it...

- Home E / extrude until the stopper works I'm working on something that I'll share as soon as it's done (hope it really helps someone then).

This requires the stepping mechanism to rotate the part by a certain...

This requires the stepping mechanism to rotate the part by a certain... - Tevo tarantula Z - port burnt out I burned Z - port for Z-terminus. Can I use the Z+ port? I'm using Jim Brown's Marlin Firmware. Any help in changing this is greatly appreciated. I don't know anything about the code.…

- Z-Axis TEVO Tarantula Drops Too Far After End Stop Triggered A problem with z-axis homing is giving me an ulcer. I hope someone can help with this. As usual, after the Z-stop is activated on my TEVO tarantula, the portal rises a little ...

- MKS board loses power after installing end stop I just bought MKS gen v1.3 and everything works fine except when I connect endpoints. My X end stop works great in every outlet, but when I...

- Is cutting off the lever from the Z axis switch a good idea? We all know (or should know!) that the repeatability of conventional spring-arm limit switches is crappy at best.

I'm about to build and install one of the precision regulators...

I'm about to build and install one of the precision regulators... - Z axis goes down and presses on the table while printing I am using a Prusa i3 with Marlin firmware. All components of my 3D printer are working fine. I have a problem with my z-axis, it goes down and presses against the table. I tried to adjust…

- Cannot install auto table leveling sensor in Anet A8 I tried to install an inductive automatic table leveling sensor in my Anet A8 and had a few problems. I used the wiring diagram provided by Solid...

- Connection of Sain Smart mechanical end stops to RAMPS 1.4? I have Sainsmart mechanical end stops and am building a Prusa i3 conversion. I recently made the x-axis move, but it should stop when it reaches the end, and it doesn't; in…

everything you need to know

3DPrintStory Reviews BLTouch sensor for 3D printer: everything you need to know

Automatic table calibration is a fairly common feature in desktop FDM 3D printers. However, most 3D printers with automatic table calibration use a non-contact inductive sensor, which is easy to install, operate and configure. These inductive sensors work well with metal 3D printer tables, but tables made from other common materials such as glass are virtually invisible to inductive sensors.

However, most 3D printers with automatic table calibration use a non-contact inductive sensor, which is easy to install, operate and configure. These inductive sensors work well with metal 3D printer tables, but tables made from other common materials such as glass are virtually invisible to inductive sensors.

Perhaps it is because of this lack of inductive sensors that many people hear about BLTouch sensors: if you need to use a non-metallic 3D printer slot base but need automatic calibration, these sensors are a great option. Another plus of these sensors is its high accuracy. BLTouch raw readings have one of the lowest standard deviations of any sensor type for automating 3D printer bed calibration.

In this article we will look at the BLTouch sensor, its advantages and how to use it for a 3D printer (by the way, there are many clones of BLTouch sensors, but the original design belongs to Antclabs from South Korea).

What is a BLTouch sensor?

According to Antclabs, the original manufacturer of the sensor, "BLTouch is an automatic table calibration sensor for 3D printers that can accurately measure the angle of the table surface. " This sensor works on any type of surface, be it metal, glass, wood and others.

" This sensor works on any type of surface, be it metal, glass, wood and others.

The 3D printer table tilt level sensor itself has a rather complex design. It consists of a microcontroller, a solenoid switch and a handpiece that is in direct contact with the table. The original BLTouch uses a Hall sensor for high accuracy, and this sensor, combined with the physical handpiece, allows it to be used with many types of tables.

In a sense, this sensor is equivalent to a microswitch mounted on a servo. When the tool head is lowered to "return" the nozzle in the Z-axis, the table pushes the tip slightly up, the Hall sensor is activated, and then the tool head rises.

TheBLTouch is one of the most accurate and reliable sensors out there, so it's no wonder some manufacturers like MakerGear and CraftBot use this device on their high-end 3D printers.

Now that we know exactly what we're dealing with, let's compare the BLTouch with the other two types of sensors.

Different types of sensors for automatic 3D printer table calibration

Inductive sensor

The key difference between the inductive sensor and BLTouch is that the BLTouch sensor physically touches the table during the calibration process. The inductive sensor uses currents induced by magnetic fields to detect nearby metal objects, so there is no direct physical contact with the table.

But therein lies the problem: induction sensors only work with metal tables, as they only work when they come into contact with metal. So if you are using glass, then this type of sensor will not work for you.

Microswitch (mechanical limit switch)

Don't discount the old-fashioned physical microswitch either. Compared to the BLTouch, this sensor is less accurate and possibly less reliable in the long run because the measurement is dependent on physical parts that can wear out over time.

However, these mechanical switches outperform other options when it comes to cost and ease of setup. Since mechanical switches are very simple to implement, easy to set up and cheap, they have found quite a wide application.

Since mechanical switches are very simple to implement, easy to set up and cheap, they have found quite a wide application.

Alternatives

Pinda Probe

Pina Probe is a sensor developed by Prusa Research that is an induction sensor with a thermistor to account for changes in bed temperature. The Pinda probe is specially designed for the Prusa line of 3D printers, which have special dot-mounted calibration markers on the table that help with alignment and skew correction.

This is said to be a very accurate sensor for 3D printers, and although there aren't many numbers on the internet, the reviews seem to be positive. So it is worth considering that this is a good option if your 3D printer has a metal table.

Ezabl Pro

Ezabl Pro is a capacitive sensor manufactured. It comes with a connection board that uses an optical isolator to prevent high voltage damage to the motherboard in case of connection errors.

In terms of accuracy, it can measure to one thousandth of a millimeter, which is what 3D printers need. Ezabl Pro also has useful features such as double shielding that prevents any interference from other signals.

Ezabl Pro also has useful features such as double shielding that prevents any interference from other signals.

The main disadvantage of Ezabl Pro is the cost, which is about 65 dollars. But this sensor can work with glass tables.

Piezo Sensors

Piezo Sensor uses the piezoelectric effect to sense changes in force, pressure, or strain and convert those changes into an electrical impulse. Precision Piezo is one of the few companies in the UK that makes piezo sensors for 3D printers. They have an accuracy close to 7 microns, which is pretty accurate for a 3D printer.

The advantage of the piezoelectric sensor is that a nozzle can be used as a sensing element without the need for additional components. In addition, a piezoelectric sensor can be placed on the print head or under the pressure platform. As for the price, it is in the same range as BLTouch.

BLTouch Sensor Setup Basics

Before you start modifying your 3D printer for BLTouch, you need to work out the following points.

Mounting the sensor

The BLTouch sensor must be installed as close to the print head as possible. You can find many designs available for download on the internet. If you would like to design the mounting structure yourself, be sure to read the BLTouch documentation to take into account the overall dimensions of the sensor.

Some users have experienced a problem where the nozzle hits the table on one side and prints perfectly on the other. The reason for this is that the BLTouch is mounted at an angle to the nozzle. Therefore, when designing and installing equipment, make sure that the BLTouch is mounted perfectly at right angles and aligned with the nozzle.

After installing the sensor, be sure to record the distance between the BLTouch sensor and the center of the nozzle in both the X and Y directions.

3D printer firmware configuration

To run BLTouch, you will need to change the 3D printer firmware in several places.

We used Marlin firmware version 1. 1.9 which was updated in March 2020. Enter the marlin.ino file and go to the configuration.h tab.

1.9 which was updated in March 2020. Enter the marlin.ino file and go to the configuration.h tab.

The first step is to activate the BLTouch sensor by declaring it. Remove the two slashes to uncomment the define statement:

#define BLTOUCH

The next step is to set the BLTouch offset using the X and Y distances you should have measured when you installed the sensor. Z-shifting may seem like a more complicated procedure, as the BLTouch probe protrudes below the nozzle for direct measurements. You will need to find the distance between the sensor and the end of the nozzle when the sensor is fully extended.

Also, since the probe goes below the nozzle, the offset must be negative. We recommend setting it to around -2.5 for safe first runs and then adjusting. You need to change the values of the following lines to match your numbers:

#define X_PROBE_OFFSET_FROM_EXTRUDER 30 // X offset: -left + right [nozzles] #define Y_PROBE_OFFSET_FROM_EXTRUDER 20 // Y offset: -front + back #define Z_PROBE_OFFSET_FROM_EXTRUDER -2.5 // Offset Z: -below + above

Once you're done with the offset, you'll need to choose a table alignment type. You can choose from five different compensation methods, below we will give an example using the bilinear method as it is easy to get started with.

To select the appropriate option, uncomment it by removing the slash. Please note that only one option can be left without comment. Your code should look something like this:

//#define AUTO_BED_LEVELING_3POINT //#define AUTO_BED_LEVELING_LINEAR #define AUTO_BED_LEVELING_BILINEAR //#define AUTO_BED_LEVELING_UBL //#define MESH_BED_LEVELING

You can also set the number of mesh points that you will base your calibration on. Default is 9points that form a 3-by-3 grid along the x and y axes. The number of points can be increased for more accurate results, but keep in mind that the probing time will also increase proportionally.

#if ENABLED (AUTO_BED_LEVELING_LINEAR) || ENABLED (AUTO_BED_LEVELING_BILINEAR)

// Set the number of grid points per size.

#define GRID_MAX_POINTS_X 3 #define GRID_MAX_POINTS_Y GRID_MAX_POINTS_X

Testing

After setting up the firmware, you will need to check if the BLTouch is working properly by doing a basic test. Once it's complete, you can start adjusting the Z offset. There's a great video from 3DMakerNoob that walks you through the process step by step.

Slicer setup

Be sure to add the G29 command to your Gcode right after the G28 command.

Troubleshooting

Troubleshooting

The creators of the original BlTouch at Antclabs mentioned that the original sensors come with a QR code built into the circuit board on the back. Other Chinese manufacturers, called TL Touch and 3D Touch, are also known to produce lower quality products, resulting in poorer quality. When buying online, be sure to purchase from one of the authorized resellers that are listed on the Antclabs website.

Known Issues with BLTouch Sensor

The latest version of BLTouch V3 had issues with Creality printers where it did not work properly. The Marlin firmware developers worked closely with Antclabs and determined that certain changes needed to be made to the firmware.

An excellent tutorial video on how to fix this problem was made by Teaching Tech. After making changes, many users finally solved the problem.

BLTouch Disadvantages

Although the BLTouch is an extremely accurate level sensor, it also has several disadvantages.

When using the BLTouch, it is important that there is no debris on the surface of the bed. A mechanical sensor detects the surface of the table and any damage or debris on the surface will result in inaccurate readings.

The BLTouch is also known to suffer from interference from currents in the hot end heater wires.