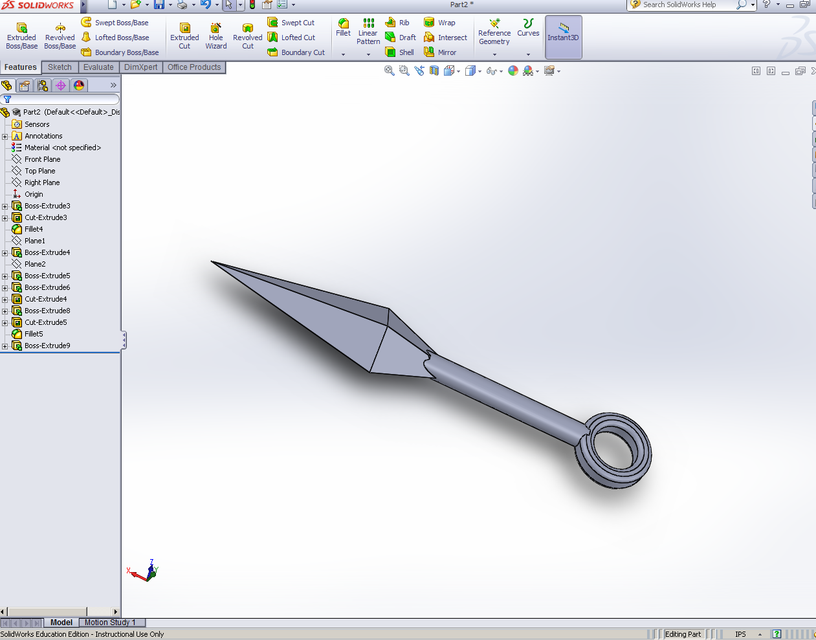

Kunai 3d print

Kunai best STL files for 3D printer・Cults

Kiriko Headgear from Overwatch 2

€3

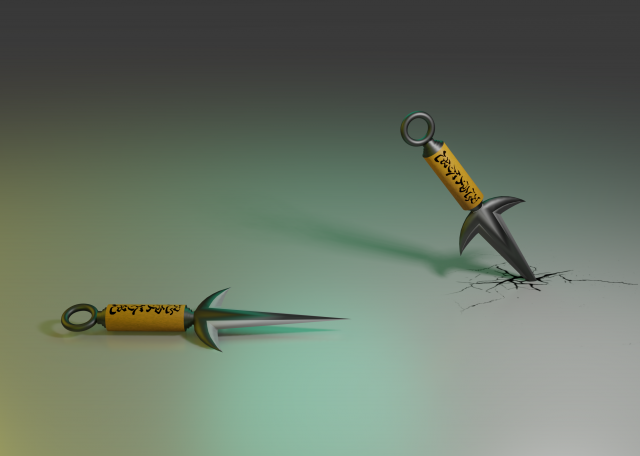

Water kunai

€4.47 -25% €3.35

Kunai camera tail mount

Free

League of Legends - Akali (Star Guardian) Kama & Kunai

€2

Goku Wall art V2

€0.60

Goku Wall art V1

€0.60

Kakashi Wall Art V2

€0.60

Overwatch Kiriko Complete Set

€3.50

KIRIKO Mask - Overwatch3

€2.33 -15% €1. 98

KUNAI KEYCHCHAIN SPINNER

€3

Kirby Ninja Figure

€3.61

Kirby Ninja

€1.81

Kakashi Wall decoration

€0.50

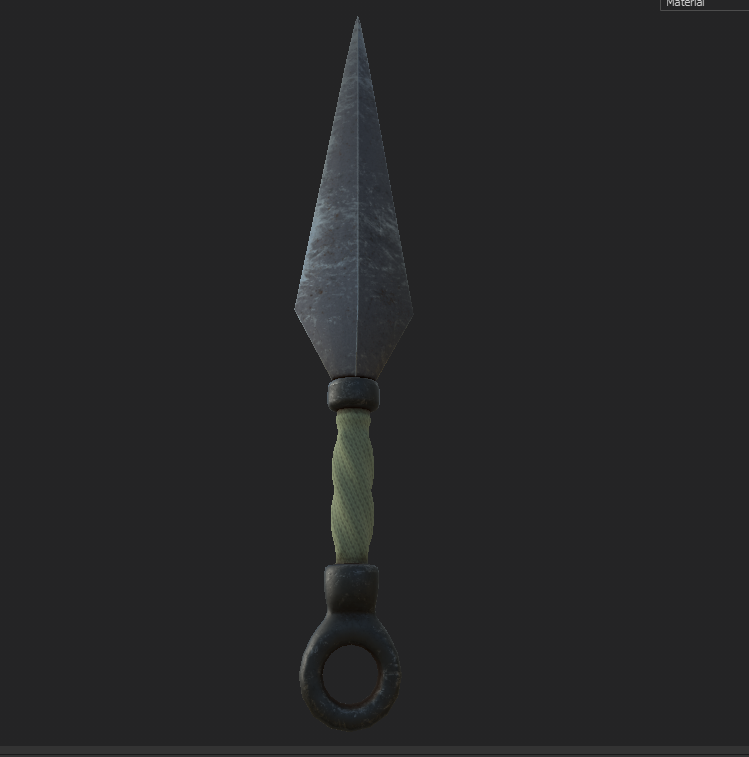

Kuni Inspired by Naruto

€5.76

Kiriko Kunai cosplay/display prop

€12

Overwach3: Kiriko Kunai

€4.31

Overwatch | Hinotori Kiriko's kunai

€14

Dragon ball Z Goku Wall art Batch 3

€0.80

Dragon ball Z Goku Wall art Batch 2

€0.80

Dragon ball z Goku Kamehameha Wall art

€0. 80

80

Kiriko's Kunai from Overwatch 2

€7.99

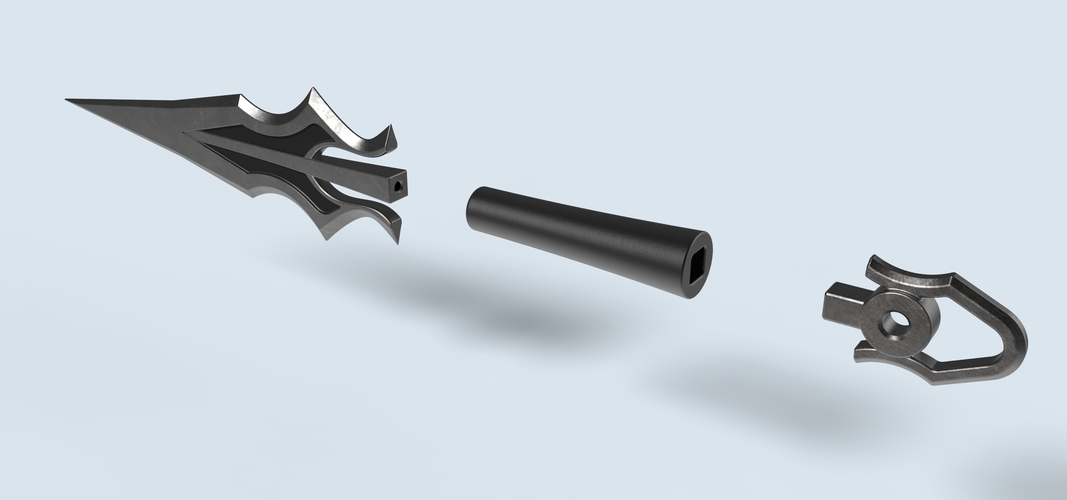

Magnetized Kunai - Minato

Free

Overwatch 2 - Kiriko Kunai

€1

Naruto Wall decoration

€0.50

Jett's Knife - Valorant

€7

Jett's Ultimate Kunai (Valorant)

Free

kunai naruto x2

€1.74

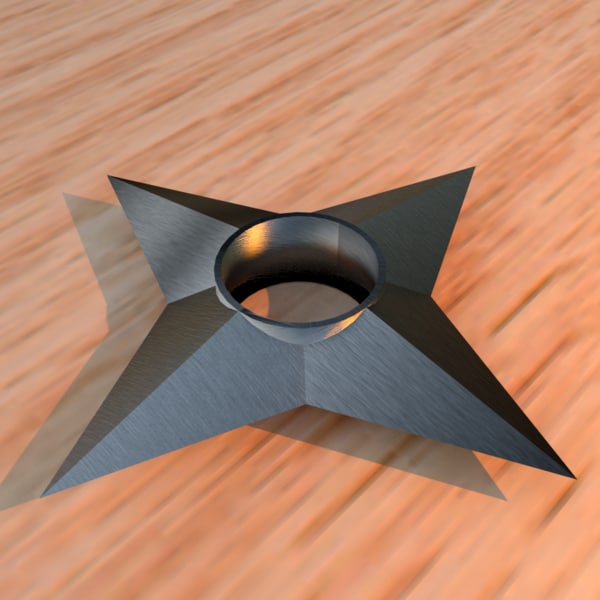

Kunai

€1

kunai

€0.59

Kiriko headpiece and kunai Overwatch 2 cosplay [3d print files]

€26.30

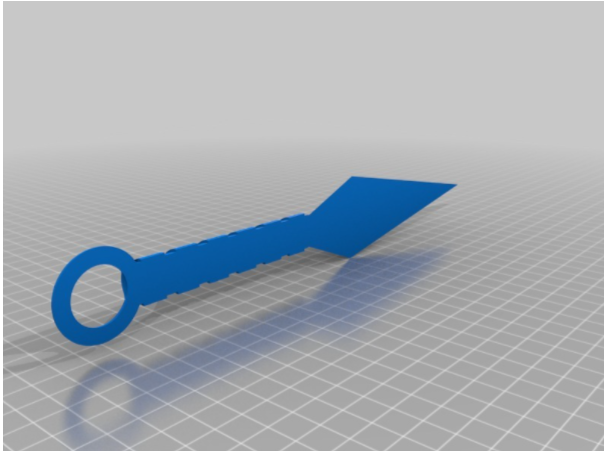

Kunai

Free

Kunai

Free

Overwatch | Kiriko Bundle - Kunai and Kitsune mask

€20

Overwatch | Kiriko's kunai

€14

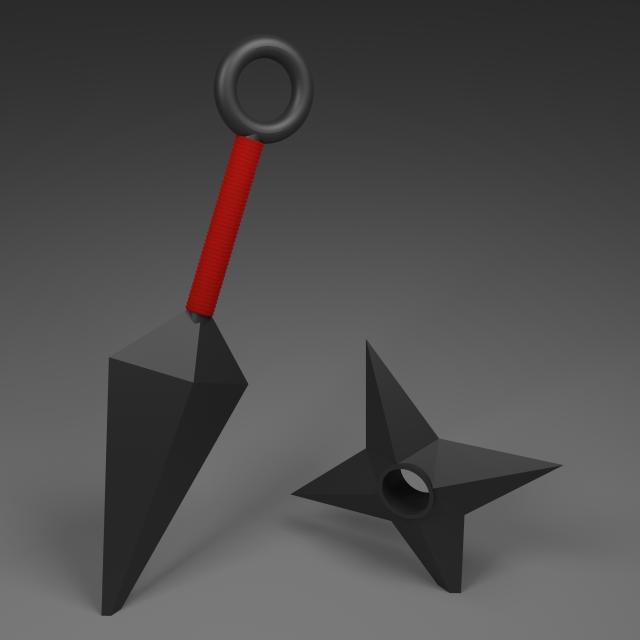

Kunai Naruto

Free

KUNAI

Free

Classic Kunai

€0. 50

50

Wraith Kunai Apex legend custom name tag

€8

Minato Kunai

€0.50

3d print ninja kunai

€1

Asuma Kunai - Naruto

Free

naruto

Free

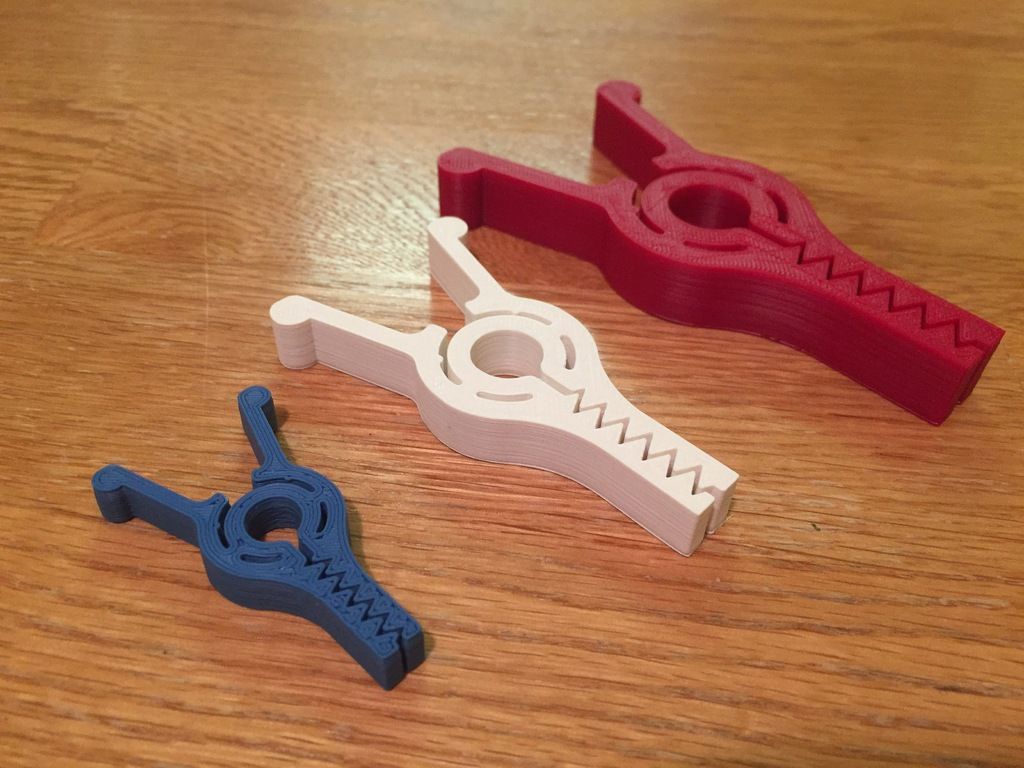

naruto kunai cookie cutter

Free

Kunai Keychain

Free

Kunai Naruto

Free

kunai with chain

€1.16

HD Jett's Kunai

€1.20

Display Base for Jett Kunai

€1.20

Kiriko Kunai display Prop STL File for 3D Printing

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Click to zoom

1,007 sales |

5 out of 5 stars €14. 28

28

Loading

VAT Included

Listed on Dec 1, 2022

9 favorites

Report this item to Etsy

Choose a reason…There’s a problem with my orderIt uses my intellectual property without permissionI don’t think it meets Etsy’s policiesChoose a reason…

The first thing you should do is contact the seller directly.

If you’ve already done that, your item hasn’t arrived, or it’s not as described, you can report that to Etsy by opening a case.

Report a problem with an order

We take intellectual property concerns very seriously, but many of these problems can be resolved directly by the parties involved. We suggest contacting the seller directly to respectfully share your concerns.

If you’d like to file an allegation of infringement, you’ll need to follow the process described in our Copyright and Intellectual Property Policy.

Review how we define handmade, vintage and supplies

See a list of prohibited items and materials

Read our mature content policy

The item for sale is…not handmade

not vintage (20+ years)

not craft supplies

prohibited or that use prohibited materials

not properly labeled as mature content

Please choose a reason

Tell us more about how this item violates our policies.Tell us more about how this item violates our policies.

All categories

Craft Supplies & Tools

STL file 3d printing ninja kunai・3D printing design to download・Cults

mini coffin for 3d printing

1 €

Kama weapon 3d print

1 €

greek sword xiphos 3d print

1 €

Flying saucer 3d print

1 €

The best files for 3D printers in the Tools category

Fishing Lure for Trout NR.

2 (one piece!)

2 (one piece!) Free

Manufacturer of PET filaments

10.26 €

Ice Tool Ax from Tomb Raider

Free

Chameleon Bookmark

Free

Dog Poop Dispenser

3.74 €

pelican 2690 LED Headlamp replace part

1,90 €

MRH Fire Starter Container

Free

Small Animal House (rats/mice/hamster)

Free

Bestsellers in the Tools category

Bit holder Spartan 4 mm Hex

1,80 €

Cut-Man - PET bottle cutter with handle!

€3. 49

49

Paint stand with scissors

5.25 €

Armadillo - flexible wire conduit

€1.70 -thirty% 1.19 €

INDICATOR FOR BETTER BED LEVELING FOR ENDER 3 V2

2.84 €

ARTEMIS -> Shop for Alligator 2 || 6.5" arrows || Repeating crossbow

6.25 €

Cooling system Minimus Hotend

€2.36 -thirty% 1.65 €

Quick print stackable parts containers / storage boxes

2.91 €

Business card embossing system

3 €

ENDER 3 S1/PRO SPRITE, V3 AIR DUCT 5015 OR 4020

€2. -twenty% 2.15 €  69

69

Fire hydrant container

1.90 €

Quick Print Paint Bottle Rack (6 sizes)

2.91 €

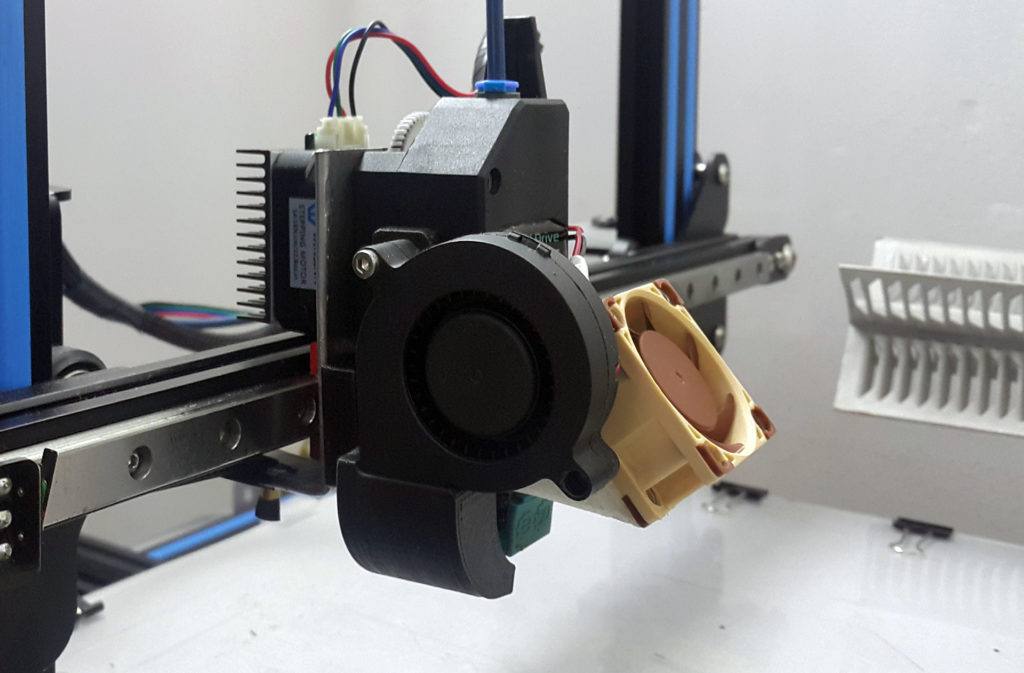

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang. CR-10, Micro Swiss direct drive and bowden compatible. Printing does not require support

1.59 €

PRECISE DIAL INDICATOR 3D PRINT DIY

1,90 €

SUPERBOX

1,50 €

PRECISION CALIPER 3D PRINT DIY

3,11 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so it is very easy to support us in maintaining activities and creating future developments of . Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

3D printers: a beautiful fairy tale of futurologists or a tool that will save Russia from sanctions0005 April 2, 2022 7:00

Our reporter went to the largest 3D workshop in the country [photo]

Komsomolskaya Pravda correspondent sat down on the steps next to the metal printer and thought about the fate of the Russian industry. Photo: Andrey ABRAMOV

I first wrote about 3D printers and additive technologies – this is how they generally call this area – in 2014. Then the country was overlaid with post-Crimean sanctions. At the state level, they headed for import substitution.

Then the country was overlaid with post-Crimean sanctions. At the state level, they headed for import substitution.

From every iron they broadcast: the era of the fourth industrial revolution, 3D printers will print whatever you want. The first suppliers of such equipment appeared in Russia. Enthusiasts told me how cunning Chinese stamp houses, cars on printers…

Everything repeats itself in the spring of 2022: factory directors, judging by the business press, are tearing their hair out and don’t know how to work without imported parts. If you are a car owner and have opened spare parts catalogs over the past month, you should have been covered in cold sweat. Deliveries of parts for foreign cars are not expected yet. All that is left can be bought at exorbitant prices.

Eight years ago we were told about life-saving technology. I myself promised readers heavenly places printed on 3D printers. It turns out that additive technologies cannot save our industry? Maybe it's the Potemkin village of futurologists. ..

..

With such mixed feelings, I went to look for answers to the largest enterprise in Russia that deals with 3D printing - "SIU System Innovation Center" . It operates on the territory of the former Moskvich automobile plant, which has now been turned into the Moskva technopolis (see "By the way").

IT DID NOT "CUT THE EXCESS", BUT GROWING THE NEW

The 3D workshop does not look like a typical plant. There is no blast furnace pouring hot metal, no conveyor running around which workers are fussing. Even boring ... Production is divided into two zones. An ordinary office, where employees clung to monitors. The second is production. There are fifty "boxes" along the walls. This is what 3D printers are. They only hum a little.

Let me remind you how this miracle works in general. Let's do without hundreds of nuances - believe me, there are enough of them in additive technologies. 3D printers are different. The simplest ones are printed with plastic. They are put in the shopping mall for the amusement of the public, they are bought for school classes in computer science. Such machines are filled with bobbins with plastic thread. Souvenirs and industrial components are printed on them.

They are put in the shopping mall for the amusement of the public, they are bought for school classes in computer science. Such machines are filled with bobbins with plastic thread. Souvenirs and industrial components are printed on them.

The machine heats up the material and in the molten form lays out layer by layer what the operator has programmed. First you need to draw a three-dimensional model on the computer, which the printer will embody. You can not draw, but take an object, scan it with a special device and get contours for printing.

— Traditional technologies: took the material, cut off the excess — got the part. Additive is growing layer by layer of the new, explains the executive director of SIU System Maria Borisova.

Executive director of SIU System Maria Borisova next to a printer that prints ceramics.Photo: Andrey ABRAMOV Imagine a metal cabinet three by three meters. Behind the glass, a bath of liquid polymer is a cloudy goo. A laser beam runs through it. Where he walked, the polymer hardens. Millimeter by millimeter, the outline of the future creation appears from the bath.

A laser beam runs through it. Where he walked, the polymer hardens. Millimeter by millimeter, the outline of the future creation appears from the bath.

This is what an industrial 3D printer that prints with liquid polymer looks like. Photo: Andrey ABRAMOV

- These are blanks for aligners that dentists use to correct an overbite. Each is unique, as it is printed for a specific patient, says Maria.

There are printers that work with metals. They are filled with powder - a titanium part is needed, titanium is poured, etc. Our enterprises make powders. They show me the nozzle of a jet engine. His machine printed in 30 hours. By the way, the speed of all printers is different. On the fastest products grow out of the polymer at 1 cm per minute.

There is a sand seal to make casting molds. I filled them with metal, broke the sandy shell, and the detail turned out. Or ceramics - the paste lays down in layers, a laser beam and firing in furnaces make the product hard. Not tea pairs with vases are printed here, but microelectronic components, parts for aviation and astronautics, cages - intervertebral implants.

Not tea pairs with vases are printed here, but microelectronic components, parts for aviation and astronautics, cages - intervertebral implants.

- A 3D printer can be selected for any production. It is necessary to produce something new - quickly reconfigured the equipment and began production. When the covid epidemic began, we began to print Venturi valves - this is a part for ventilators. Although they didn’t do this before, ”recalls Maria Borisova.

The printers are able to produce the entire mechanism at once. They show me the interweaving of a dozen gears that rotate like a jewelry piece. That is, you do not need to print each component separately, you can immediately mechanism. But it is naive to believe that finished products always come out of the printer. Some also need post-processing. For example, grinding.

MAN AGAINST THE PRINTER

For an hour I was taken around the shop, told about the miracle of printing. I was already thinking about going to the exit in order to sing to the readers again what a wonderful 3D aleco awaits us soon. I woke up the skeptic in myself and attacked the executive director with questions.

I woke up the skeptic in myself and attacked the executive director with questions.

— If 3D printers really can do anything, where is it in our industry?

- Technology is used, but can be used much more actively. Few people understand the possibilities of 3D printing. There is no wide range of centers in Russia, like ours, to see industrial printers in operation. We are used to thinking in stereotypes about technology. To produce something, you need to take a piece, cut off the excess and you get a part.

Customers come with orders and say: take this material and print a part. And in additive manufacturing, we need a clear technical task, we start from the properties of the final product, because changes occur in the process of printing under the influence of a laser beam.

- Here are your dentures. But when I come to dentistry, they sell Korean or Swiss implants. You show me printed auto parts, while Lada Vesta, meanwhile, is half assembled from imported parts. Why, with the limitless possibilities of 3D printing, can't we move our industry on this track?

Why, with the limitless possibilities of 3D printing, can't we move our industry on this track?

— We need high-quality equipment, software, suitable materials and trained personnel. If one of the components is missing or saved on it, the result will be far from ideal.

Europe is moving away from manual labor and towards automation. It's an investment, but it pays off. In Russia, the approach is different: we will put a better person, and in other areas we will save. Industrialists come to us and ask the question: where do you have ten employees around each machine? We explain: one is enough. But this is not accepted…

The black and green box on the right is the Russian Hercules printer. Photo: Andrey ABRAMOV

— Conveyor principle: at each section, the workman picks up the product, adds it, and passes it on to the next one.

— It's different here. We produce more than 20 thousand different parts per month, and not so many people work for us (we look at the office area, there are hardly ten people there - ed. ). There is a designer and a topological optimization specialist who will develop 3D models of products, taking into account material savings and speeding up printing speed. There is a print operator and his assistant who will prepare the printer, start it up, control the print and, if necessary, post-process the product. There are engineers who control the process and maintain the operation of the equipment.

). There is a designer and a topological optimization specialist who will develop 3D models of products, taking into account material savings and speeding up printing speed. There is a print operator and his assistant who will prepare the printer, start it up, control the print and, if necessary, post-process the product. There are engineers who control the process and maintain the operation of the equipment.

— What about the personnel?

— Universities and colleges have training programs for 3D printing engineers and 3D printer operators. We are involved in the development of training standards.

RUSSIA DOES NOT LIKE TO SHARE

— Let's dream: tomorrow our factories will be banned from buying equipment, except for 3D printers. They give subsidies for the purchase of equipment, train specialists. At this rate, in how many years will we print our Boeing?

- We can print a car, it's more difficult with an airplane. Aviation has a very long certification process to keep everything safe. There are companies in the world that are very actively using 3D technologies. For example, Elon Musk's rockets (American billionaire engineer, founder of the private space company SpaceX - ed.). In world practice, dozens of metal or polymer industrial 3D printers are purchased at once in order to expand production.

Aviation has a very long certification process to keep everything safe. There are companies in the world that are very actively using 3D technologies. For example, Elon Musk's rockets (American billionaire engineer, founder of the private space company SpaceX - ed.). In world practice, dozens of metal or polymer industrial 3D printers are purchased at once in order to expand production.

This is a jet engine nozzle surrounded by other "pieces of iron" that were also printed. Photo: Andrey ABRAMOV

In Russia, a factory often takes one printer and tries to integrate it into the production chain. Employees contact us. We all show, explain, tell. After a while, we can get an answer: the team is not ready to try. The manufacturing process is built in such a way that the 3D printer does not fit very well. You need to change something, educate people, change their habits ...

Or a factory comes to us with a desire to buy equipment. Sets a condition: print the part, we'll see if it works for a month, then we buy it. Then they say: let it work for another six months, more and more ... As a result, all the other parts failed, ours is still standing, and the company changed its mind about buying. Or decides to take another printer, which does not guarantee the result.

Then they say: let it work for another six months, more and more ... As a result, all the other parts failed, ours is still standing, and the company changed its mind about buying. Or decides to take another printer, which does not guarantee the result.

At the same time, there are industries in Russia that are actively introducing 3D technologies. But we are not used to sharing our developments. And additive technologies are about promotion. We have signed a non-disclosure agreement with all customers. So we would publish great news every day. Others would see and be inspired.

So far, it turns out that those who competently use 3D printers are one step ahead of the rest, but they don't always say why.

— Do we produce our own printers?

- 3D printers were invented in the USA. There are European manufacturers. Some of them have now temporarily suspended deliveries. But we think things will get better. Domestic producers are reaching a very good level. We test their developments and, if we are sure of the quality, we start using them.

We test their developments and, if we are sure of the quality, we start using them.

The blue light that illuminates the bust of Ilyich is the projection of the scanner. He creates a virtual 3D model of the part so that it can then be printed. Photo: Andrey ABRAMOV

— If you disassemble our printer, what is the probability of finding parts that are not made in Russia?

- There is a possibility. There was no task that all equipment should be made only from domestic parts. But in the future, I think it is realistic to create such a printer.

— And yet, do we urgently need to switch to additive technologies in order to save the industry?

- A 3D printer, when used correctly, allows you to create a product that you could only dream of before. If you're stamping or casting simple shapes, you might want to leave things as they are. But to improve the part, move on to the production of more technically complex components, start producing new things in a short time - only 3D printing can handle this.

Maria Borisova is holding a 3D-printed robot arm nearby. Photo: Andrey ABRAMOV

BTW

"Innovation Center SIU System" is based in the SEZ "Technopolis Moscow". There are ample opportunities for industrial cooperation with local residents. In the SEZ "Technopolis Moscow" there is a whole cluster of enterprises engaged in the production of composites and nanomaterials. In addition to it, about 200 companies from the metropolitan SEZ have united into clusters of microelectronics and optics, medical devices and biopharmaceuticals, information and communication technologies, energy-efficient and high-tech industries.

Read also

Age category of the site 18+

Online publication (website) registered by Roskomnadzor, certificate El No. FS77-80505 dated March 15, 2021

I.O. EDITOR-IN-CHIEF OF THE SITE - KANSKY VICTOR FYODOROVICH.

THE AUTHOR OF THE MODERN VERSION OF THE EDITION IS SUNGORKIN VLADIMIR NIKOLAEVICH.