3D print shoe sole

3D Printing Shoes & Soles

Personalization has been more than just a trend for a while now. As well as offering greater comfort to their wearers, custom shoe soles open up completely new possibilities for fashion customization.

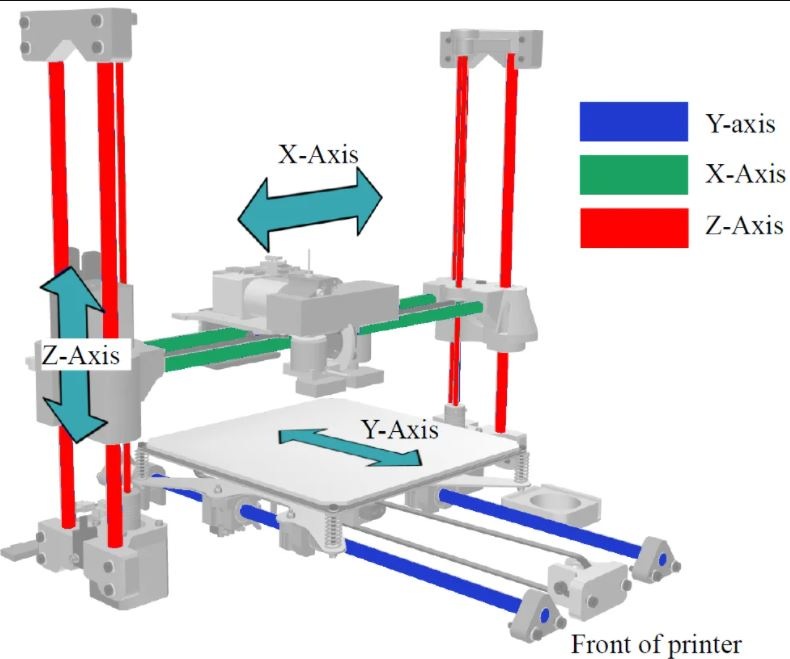

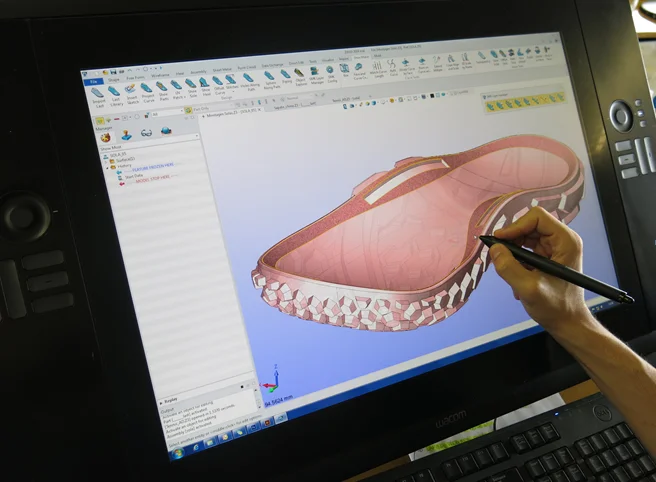

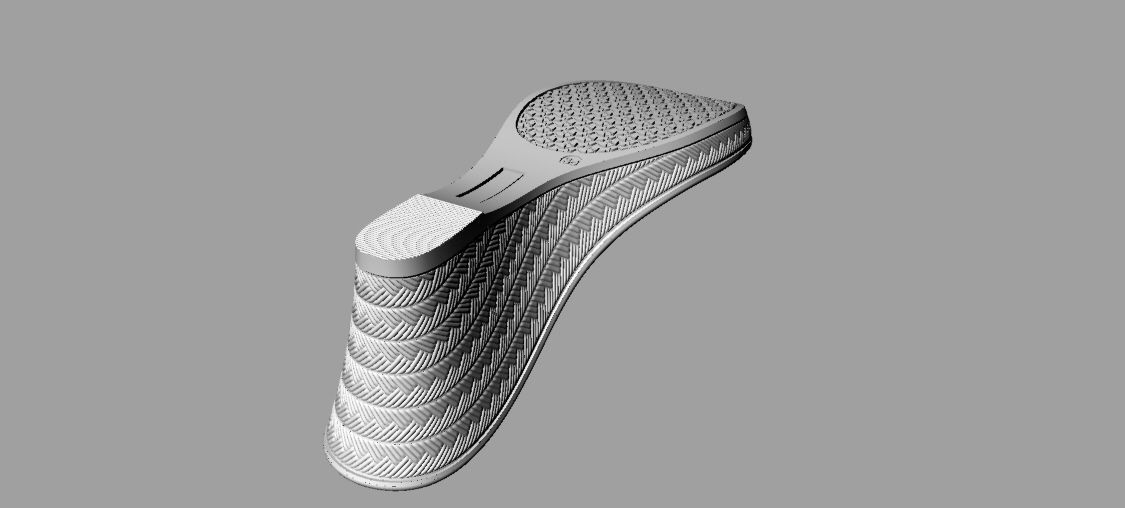

Additive manufacturing has the solution: Thanks to a fully digital process, trendy designs can be put together using scans of the sole of the foot, then transformed into custom-fitting shoe soles made from polymer materials by industrial 3D printing.

For contract manufacturers and shoemakers, the advantages are obvious. They can reliably deliver custom soles to their customers, allowing them to react quickly to new trends. At the same time, industrial 3D printing is extremely suitable for series production. It is characterized by high flexibility of material strength and structure, so that the products can be perfectly fitted to the wearer’s anatomy. The manufacturing process is also relatively cost-efficient.

3D printed shoe soles combine personal style with the demands of fashion. The manufacturing process guarantees maximum flexibility while also being cost-efficient.

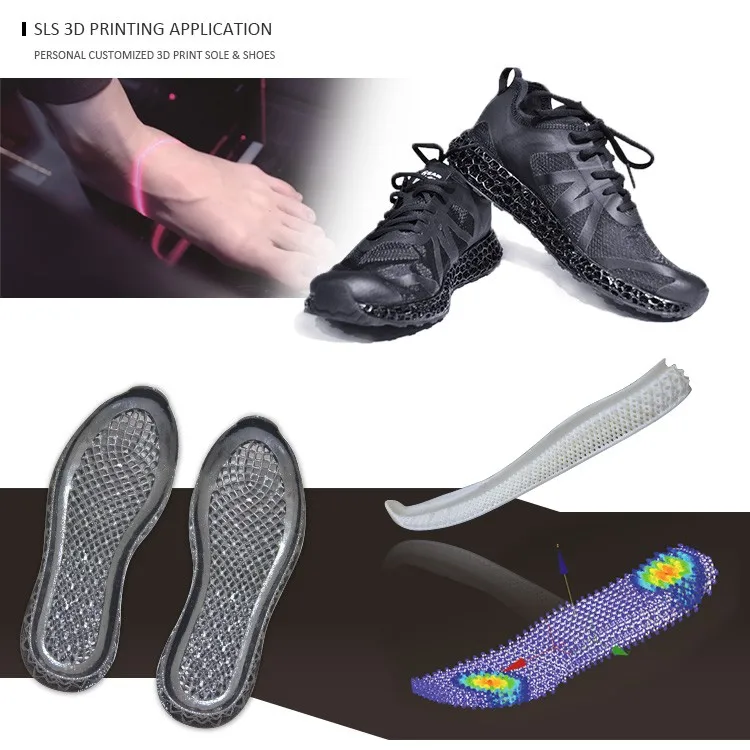

Aetrex is a global leading manufacturer of foot scanning technology, orthoses and comfort shoes. In partnership with EOS, Aetrex uses a Digital Foam approach to make custom 3D printed soles. The production and delivery of the finished product is completed very quickly. The partnership between Aetrex and EOS resulted in a complete 3D printing value chain with digital production in a mainstream format.

The path to a customized mass product

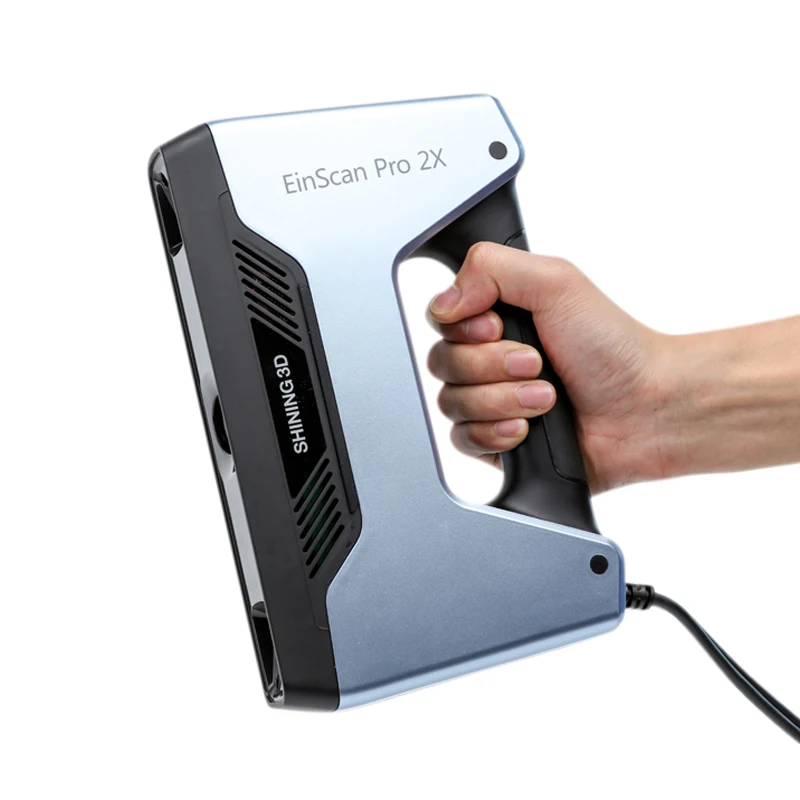

Aetrex uses customer data collected using the Albert program, an innovative foot scanning system. The captured data is then sent to the EOS 3D printer. Based on the measurements of the individual pressure point distribution, the 3D printer then creates a 3D printed insole. The result is a product that is precisely tailored to the customer’s foot.

“Mass customization” – adapting individual products to many different variants

58_time_savingsRapid availability – the sole is ready in less than 2 weeks

60_resp_peopleImproved ergonomics – the product fits better than conventionally manufactured soles

59_resp_sustainabilitySustainability – less material consumption, since any leftover material can be reused

With EOS’s industry-leading 3D printing technology, Under Armour has found a meaningful way to bring shoes to the market by creating truly amazing and high-quality products that meet the needs of our customers in ways that we never imagined. Together, our two organizations make an outstanding team.

Clay Dean | Under Armour

Success Story Kerrie Luft

Additive Manufacturing of Extravagant Shoes

The English shoe designer Kerrie Luft is placing her trust in EOS’ innovative 3D printing technology to manufacture her extraordinary footwear. She is taking advantage of the AM process on a conceptual level.

She is taking advantage of the AM process on a conceptual level.

Her Nouveau collection is based on the Art Nouveau style. Inspired by nature, Kerrie Luft has developed innovative shapes for shoes and heels made from titanium, manufactured with an EOS system.

-- loading ... --

Be inspired. Stay up to date.

Join our Monthly Newsletter Now!

3D Printed Shoes: What's Available on the Market Today?

Published on March 4, 2022 by Carlota V.

In August 2020, research firm SmarTech Analysis unveiled its second study on the 3D printing and footwear market. According to the report, this industry is expected to generate more than $8 billion in profits by 2030. And it must be said that additive manufacturing offers a number of benefits in footwear production, perhaps the most important being the ability to customize the final product. Consumers are looking for differentiation and uniqueness, and 3D technologies can meet that need. They are also able to offer custom-made products with complex designs, perfectly adapted to each individual’s morphology. Thus, thanks to 3D scanning and 3D printing, companies are imagining more efficient sneakers, futuristic shoes for high fashion or comfortable and durable soles. Yes, it should be noted that it is not always the entire shoe that is 3D printed – which is actually quite rare – but rather the upper or the sole for example. In any case, 3D printing and footwear go hand in hand, and the market certainly is showing a lot of promise! For that reason, we wanted to introduce you to a few of the most impressive 3D printed shoes currently available, whether for sports, going to the beach or just going to work.

They are also able to offer custom-made products with complex designs, perfectly adapted to each individual’s morphology. Thus, thanks to 3D scanning and 3D printing, companies are imagining more efficient sneakers, futuristic shoes for high fashion or comfortable and durable soles. Yes, it should be noted that it is not always the entire shoe that is 3D printed – which is actually quite rare – but rather the upper or the sole for example. In any case, 3D printing and footwear go hand in hand, and the market certainly is showing a lot of promise! For that reason, we wanted to introduce you to a few of the most impressive 3D printed shoes currently available, whether for sports, going to the beach or just going to work.

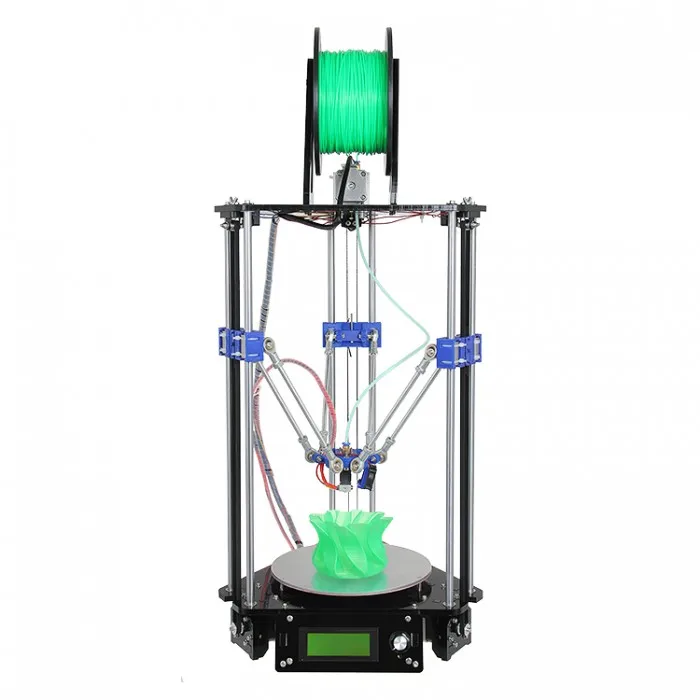

Adidas’ Range of 3D Printed Shoes

When it comes to 3D printed shoes, we would be remiss if we do not mention the offerings from famed shoe manufacturer, adidas. The company has been using 3D printing since 2017 when it entered into a partnership with Carbon to create new shoes, starting in 2018 with Futurecraft 4D 3D printed shoes, which are still being sold. Since then, they have continued to use additive manufacturing to create unique, sustainable footwear. For example, just last year the company released two new 3D printed sneakers, the 4D Fusion and the adidas 4DFWD, the latter of which was specifically created to improve athlete performance. According to the company 3D printing adds performance thanks to the lattice structure as well as adding a lot of flexibility to its activities, from reducing lead times to offering a shoe that could be completely customized at a reasonable price.

Since then, they have continued to use additive manufacturing to create unique, sustainable footwear. For example, just last year the company released two new 3D printed sneakers, the 4D Fusion and the adidas 4DFWD, the latter of which was specifically created to improve athlete performance. According to the company 3D printing adds performance thanks to the lattice structure as well as adding a lot of flexibility to its activities, from reducing lead times to offering a shoe that could be completely customized at a reasonable price.

Thanks to Carbon’s DLS technology, the adidas 4DFWD has a unique lattice midsole made of 40% bio-based material (photo credits: adidas)

Liquid Speed from Reebok

Reebok is one of the largest and most recognized companies in the footwear industry. That’s why, a few years ago, they decided to use additive manufacturing technologies to create soles for one of their athletic shoe collections. While the rest of the shoe was made using traditional methods, the Liquid Speed incorporates a maximum fit sole. Reebok partnered with chemical company BASF, who used a liquid polyurethane material. They used a programmed robot to create the successive layers, bringing the sole to life. In addition to offering better performance and durability, the Liquid Speed has a very original design.

Reebok partnered with chemical company BASF, who used a liquid polyurethane material. They used a programmed robot to create the successive layers, bringing the sole to life. In addition to offering better performance and durability, the Liquid Speed has a very original design.

The Liquid Speed’s design is original

New Balance Incorporates a 3D Midsole

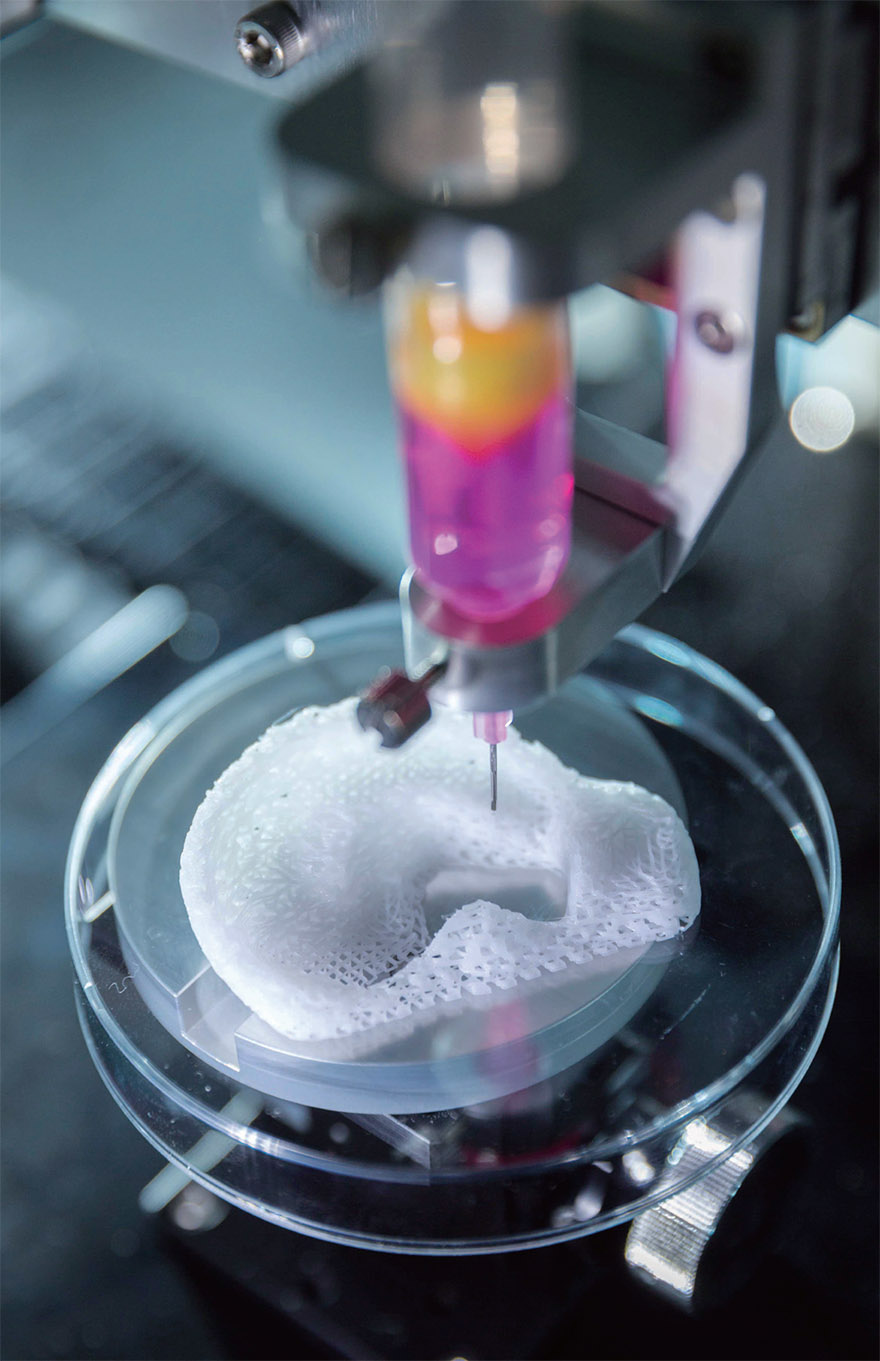

In a similar vein, New Balance has collaborated with 3D Systems to develop 3D printed midsoles. DuraForm Flex are insoles created with SLS technology from a thermoplastic elastomer material. They combine strength and flexibility and provide maximum comfort for the sports shoe. The 3D printing technology allows the production of complex structures that optimize shock absorption while making the shoe lighter. Since then, the American brand has been working with Formlabs and its stereolithography technology on the development of a Triple Cell platform to produce the FuelCell Echo.

The shoe’s midsole was 3D printed

ECCO and its customizable midsoles

ECCO is a Danish shoe manufacturer with many years of experience in the industry. In 2019, the company launched its Quant-U service aimed at customizing shoes through 3D printing. Using a 3D scanning process of the feet, it is possible to determine the orthopedic fit required for each person. With this device, ECCO designs 3D printed insoles tailored to the needs of its customers. This part is made from silicone, a material that provides stability as well as an adequate degree of cushioning. In addition, the company says the insoles are easily interchangeable and can be put in the washing machine.

In 2019, the company launched its Quant-U service aimed at customizing shoes through 3D printing. Using a 3D scanning process of the feet, it is possible to determine the orthopedic fit required for each person. With this device, ECCO designs 3D printed insoles tailored to the needs of its customers. This part is made from silicone, a material that provides stability as well as an adequate degree of cushioning. In addition, the company says the insoles are easily interchangeable and can be put in the washing machine.

Photo Credits: ECCO Quant-U

Wiivv Goes for Customization

Wiivv is a young Canadian company that specializes in the production of 3D printed soles and flip-flops, entirely adapted to the wearer’s morphology. Thanks to a Smartphone application, the user can directly scan his or her foot, send their data to the company and receive a customized solution a few weeks later. Take flip-flops for example: thanks to 3D printing, Wiivv can customize certain elements of the shoe such as the straps or the vertical strap. The objective is of course to offer more comfort to the user. The company is equipped with a machine park in San Diego and the product is made using SLS technology.

The objective is of course to offer more comfort to the user. The company is equipped with a machine park in San Diego and the product is made using SLS technology.

Wiivv’s flip-flops are fully customizable

Sustainable 3D Printed Shoes

How can you best combine fashionable footwear with a responsible environmental conscience? By using additive manufacturing! Chris Margetts, founder of The Sole Theory and fashion brand Humans Are Vain, uses recycled textiles to make his 3D printed shoes. He explains, “There is a strong demand for more sustainable products. There is no doubt that there will be consumers who want to buy this type of footwear when we launch it on the market.” He is deliberately using the fibers from clothing he once loved to turn into composite materials. This way, they can be used as material for 3D printing to create new shoes. The fibers are ground up and turned into filament for ZYYX Labs’ 3D printer.

Photo Credits: The Sole Theory

HERON01, the Fully 3D Printed Sneaker

Attention sneaker fans: the 3D printed HERON01 is sure to be a crowd-pleaser. This shoe was made entirely by additive manufacturing by the American company Heron Preston, named after its founder Heron Preston Johnson. For this model, the founder of Heron01 is particularly focused on the theme of sustainability, as no glue or toxic materials were used in the production process. It was also possible to dispense with the use of seams, which means that the shoe can be completely recycled. The scraps and waste can eventually be used to make a new product. The design idea that goes beyond traditional shoe making is also reflected in the shoe’s features: low ankle cutouts, printed scales and textures, and the bird’s foot pattern on the sole.

This shoe was made entirely by additive manufacturing by the American company Heron Preston, named after its founder Heron Preston Johnson. For this model, the founder of Heron01 is particularly focused on the theme of sustainability, as no glue or toxic materials were used in the production process. It was also possible to dispense with the use of seams, which means that the shoe can be completely recycled. The scraps and waste can eventually be used to make a new product. The design idea that goes beyond traditional shoe making is also reflected in the shoe’s features: low ankle cutouts, printed scales and textures, and the bird’s foot pattern on the sole.

The HERON01 sneaker (photo credits: HERON01)

Natives Shoes and its 3D Printed Shoes

Canadian manufacturer Native Shoes launched the Liquid Printed Natives project with the intention of developing everyday objects using advanced methods such as additive manufacturing. As part of this, the company used liquid rubber to 3D print shoes. The manufacturer says it used a 50% recycled ethylene vinyl acetate (EVA) material to achieve greater flexibility and a more rubbery appearance. What stands out about Native Shoes’ project is the speed of production, with the company explaining that 3D technologies have significantly reduced manufacturing time compared to traditional methods. They also offer consumers a high level of customization.

The manufacturer says it used a 50% recycled ethylene vinyl acetate (EVA) material to achieve greater flexibility and a more rubbery appearance. What stands out about Native Shoes’ project is the speed of production, with the company explaining that 3D technologies have significantly reduced manufacturing time compared to traditional methods. They also offer consumers a high level of customization.

The shoes would be 3D printed directly into a tray containing a reusable water-based viscous gel formula

Eco-Friendly Sandals

We continue in this trend of 3D printed sandals with the Organic collection, imagined by a young student in fashion design, Lucie Trejtnarová. In collaboration with the material manufacturer Fillamentum, she 3D printed the outer sole of the sandal on which she sewed several organic fabrics made from fibers extracted from pineapple or coconut leaves. The printed sole had to be strong enough to support this fabric, so Lucie chose a TPU that was flexible enough but resistant to abrasion and wear. It also has a recyclable character, a key component for the young woman.

It also has a recyclable character, a key component for the young woman.

Mycelium Shoe, Futuristic Shoes

Imagined by the design studio Ica and Kostika, the Mycelium Shoe pair is entirely 3D printed on an SLS machine. Rather imposing by its shape, its size and its design, it does not go unnoticed in the street – besides, only 5 pairs were created. Its designers claim that these 3D printed shoes are very comfortable because they are entirely customized to the person’s feet: the 3D file is made from scanned data. It remains to be seen if walking in them is fun!

Only 5 pairs were created

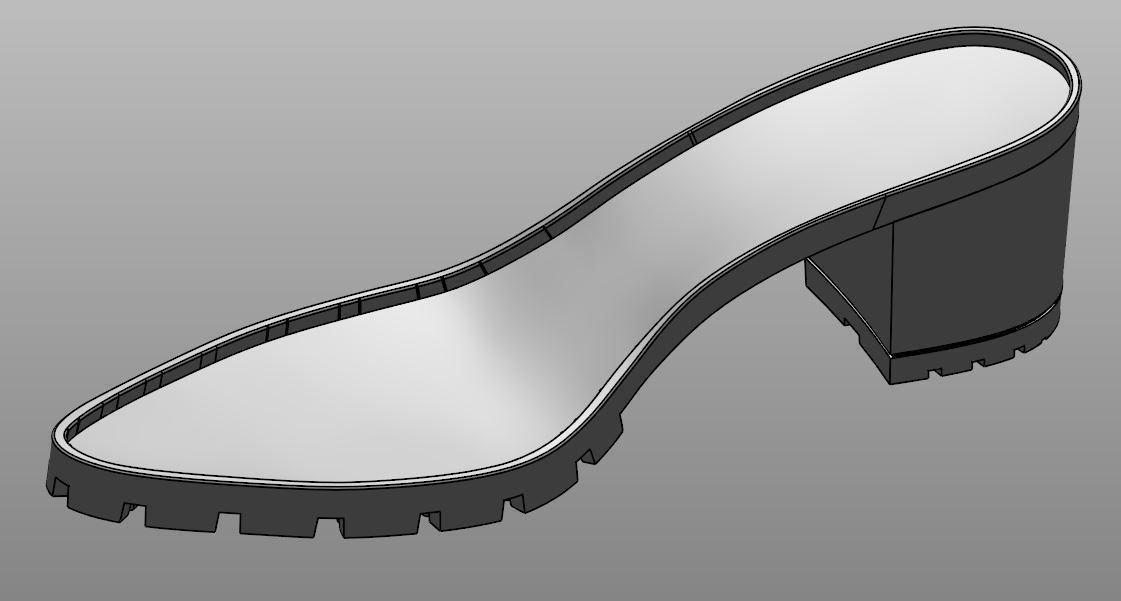

Hilos, The Sustainable 3D Printed Shoe

Portland-based startup Hilos was founded in 2019 and wants to transform the way shoes are made, combining technology and craft. Through additive manufacturing, the company hopes to address environmental issues, while providing quality footwear. Recyclable, this shoe is made through selective laser sintering and is designed from TPU, because of its flexibility and strength. The company confides that, with the help of 3D printing, it is able to bring new product lines to market in just two weeks, compared to the industry average of 12 to 15 months.

The company confides that, with the help of 3D printing, it is able to bring new product lines to market in just two weeks, compared to the industry average of 12 to 15 months.

ATHOS, 3D Printed Climbing Shoes

Developed by a group of students in Barcelona, ATHOS climbing shoes are gaining in popularity. Also known as “climbing shoes”, this type of shoe must fit the athlete’s foot perfectly to improve grip and prevent slipping. Usually, to make sure they have a good fit, athletes wear climbing shoes that are smaller than theirs, which causes pain and deformity of the foot. This is why the team behind ATHOS wanted to create custom-made climbing shoes that meet the needs of each climber. To do this, they use HP’s MultiJet Fusion 3D printing technology and BASF’s TPU material. The process to get the ATHOS shoes is very simple: just scan your feet with 3 photos, customize the shoes to your liking, and once you get them home, you can start climbing!

Photo Credits: ATHOS

Pleko, the Carbon Fiber Shoe for Running

The brainchild of Italian middle-distance runner Miro Buroni and the Diadora company, the Pleko is a shoe made up of many 3D printed components. The 3D printed parts include the insole, outsole, spikes and ribs. Designed from composite materials, carbon fiber to be precise, and with the help of the powder sintering process, these different elements have made it possible to manufacture a shoe that is flexible, resistant to wear and tear and above all customizable. Indeed, thanks to 3D scanning and software that simulates the movements during a race, the teams behind the shoe are able to offer a durable and comfortable solution to athletes.

The 3D printed parts include the insole, outsole, spikes and ribs. Designed from composite materials, carbon fiber to be precise, and with the help of the powder sintering process, these different elements have made it possible to manufacture a shoe that is flexible, resistant to wear and tear and above all customizable. Indeed, thanks to 3D scanning and software that simulates the movements during a race, the teams behind the shoe are able to offer a durable and comfortable solution to athletes.

Photo Credits: CRP Technology

A 3D Printed Shoe for Dance

The Purmundus Challenge 2021 competition was won by Act’ble, a start-up company that collaborated with top athletes to develop a new pointe shoe. Intended for classical ballet and contemporary dance, the shoe is called “New Pointe Shoe Sole”. Expected to last five times longer than traditional pointe shoes, the shoe was designed to significantly reduce the physical pain dancers experience during ballet. To make the shoe, the team 3D printed the sole, but did not specify what process they used or the materials that make up the shoe.

Photo Credits: Act’ble

The Parametriks Print 001, a Shoe Entirely Printed from a Single Material

Earlier this year, designer Nathan Smith unveiled the Parametriks Print 001 sneaker, a 3D printed shoe designed using parametric design. This method, using design and material science to engineer parts, resulted in a shoe that stands out from the crowd for its comfort. To develop the Parametriks Print 001, Nathan Smith says he used Grasshopper, a plug-in included in Rhinoceros 3D modeling software. As for the manufacturing of the shoe, the designer explains that he relied on SLA machines and used TPU.

Photo Credits: Parametriks

What do you think of these 3D printed shoes? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

what is available on the market today?

In August 2020, the research company SmarTech Analysis presented its second study of the 3D printing and footwear market. According to the report, this industry is expected to generate over $8 billion in profit by 2030. And it must be said that additive manufacturing offers a number of advantages in the production of shoes, the most important of which is the ability to customize the final product. Consumers are looking for difference and uniqueness, and 3D technology can fill that need. They can also offer custom made products with intricate designs perfectly tailored to each individual's morphology. Thus, through 3D scanning and 3D printing, companies create more efficient sneakers, futuristic high fashion shoes, or comfortable and durable soles. Yes, it should be noted that not all shoes are always 3D printed, which is actually quite rare, but, for example, the upper or sole. In any case, 3D printing and shoes go hand in hand and the market is definitely showing great promise! For that reason, we wanted to introduce you to some of the most impressive 3D printed running shoes currently available, whether for sports, the beach, or just for work.

According to the report, this industry is expected to generate over $8 billion in profit by 2030. And it must be said that additive manufacturing offers a number of advantages in the production of shoes, the most important of which is the ability to customize the final product. Consumers are looking for difference and uniqueness, and 3D technology can fill that need. They can also offer custom made products with intricate designs perfectly tailored to each individual's morphology. Thus, through 3D scanning and 3D printing, companies create more efficient sneakers, futuristic high fashion shoes, or comfortable and durable soles. Yes, it should be noted that not all shoes are always 3D printed, which is actually quite rare, but, for example, the upper or sole. In any case, 3D printing and shoes go hand in hand and the market is definitely showing great promise! For that reason, we wanted to introduce you to some of the most impressive 3D printed running shoes currently available, whether for sports, the beach, or just for work.

3D Printed Adidas Shoe Range

When it comes to 3D printed shoes, it would be remiss not to mention the offerings from famed shoe manufacturer adidas. The company has been using 3D printing since 2017, when it partnered with Carbon to create the new Futurecraft 4D shoe, , which is still on sale today. Since then, the company has continued to use additive manufacturing to create unique sustainable footwear. For example, just last year, the company launched two new 3D printed running shoes, the 4D Fusion and the adidas 4DFWD, the latter specifically designed to improve performance. According to the company, 3D printing increases productivity with the lattice structure, as well as increasing flexibility, from reducing lead times to offering reasonably priced shoes that can be fully customized.

With Carbon DLS technology, the adidas 4DFWD shoes feature a unique 40% bio-based lattice midsole (photo adidas).

Liquid Speed from Reebok

Reebok is one of the largest and most well-known brands in the footwear industry. That's why, a few years ago, the company decided to use additive manufacturing to create soles for one of its athletic shoe collections. While the rest of the shoe was made using traditional methods, the Liquid Speed has the ultimate outsole. Reebok partnered with chemical company BASF, which used a liquid polyurethane material. A programmed robot was used to create successive layers. In addition to better performance and durability, Liquid Speed has a very original design.

Liquid Speed design is original.

New Balance includes 3D midsole

In the same vein, New Balance is partnering with 3D Systems to develop 3D printed midsoles. DuraForm Flex is an SLS insole made from a thermoplastic elastomer material. They combine strength and flexibility and provide maximum comfort for sports shoes. 3D printing technology allows the production of complex designs that optimize cushioning and make shoes lighter. The American brand is working with Formlabs and its stereolithography technology to develop the Triple Cell platform to produce the FuelCell Echo.

3D printing technology allows the production of complex designs that optimize cushioning and make shoes lighter. The American brand is working with Formlabs and its stereolithography technology to develop the Triple Cell platform to produce the FuelCell Echo.

The sole of the sneaker was 3D printed.

ECCO and its customizable insoles

ECCO is a Danish footwear manufacturer with many years of experience in the industry. In 2019, the company launched the Quant-U service aimed at customizing shoes using 3D printing. Using the 3D foot scanning process, it is possible to determine the orthopedic fit required for each individual. With this device, ECCO develops 3D printed insoles tailored to the needs of its customers. This part is made of silicone, a material that provides stability as well as a sufficient degree of cushioning. In addition, the company says the insoles are easy to replace and machine washable.

Photo Credit: ECCO Quant-U

Wiivv meets customer

Wiivv is a young Canadian company that specializes in the production of 3D printed soles and flip flops that are fully adapted to the wearer's morphology. Thanks to the smartphone app, the user can directly scan their foot, send their data to the company and receive a customized solution in a few weeks. Take flip-flops, for example: Wiivv can use 3D printing to personalize certain elements of the shoe, such as straps or a vertical strap. The goal, of course, is to offer the user more comfort. The company is equipped with a machine park in San Diego, and products are manufactured using SLS technology.

Thanks to the smartphone app, the user can directly scan their foot, send their data to the company and receive a customized solution in a few weeks. Take flip-flops, for example: Wiivv can use 3D printing to personalize certain elements of the shoe, such as straps or a vertical strap. The goal, of course, is to offer the user more comfort. The company is equipped with a machine park in San Diego, and products are manufactured using SLS technology.

Wiivv Fully Customizable Slippers

3D printed sustainable shoes

How best to combine fashionable shoes with a responsible approach to the environment? With additive manufacturing! Chris Margetts, founder of The Sole Theory and fashion brand Humans Are Vain, uses recycled textiles to make his 3D printed shoes. He explains: “There is a lot of demand for more sustainable products. There is no doubt that there will be consumers who will want to buy these shoes when we launch them on the market. ” He intentionally uses fibers from clothes he once loved to make composite materials. Thus, they can be used as a 3D printing material to create new shoes. The fibers are shredded and turned into filament for the ZYYX Labs 3D printer.

” He intentionally uses fibers from clothes he once loved to make composite materials. Thus, they can be used as a 3D printing material to create new shoes. The fibers are shredded and turned into filament for the ZYYX Labs 3D printer.

Photo Credits: The Only Theory

HERON01 fully 3D printed sneakers

Attention sneaker lovers, the 3D printed HERON01 is sure to please the public. This shoe was completely made by additive manufacturing by the American company Heron Preston, named after its founder Heron Preston Johnson. For this model, the founder of Heron01 paid special attention to the theme of sustainability, since no glue or toxic materials were used in the production process. We also managed to do without the use of seams, which means that shoes can be completely recycled. The scraps and scraps can eventually be used to make a new product. A design idea that goes beyond traditional shoemaking is also reflected in the shoe's features: low ankle cutouts, printed scales and textures, and a bird's foot pattern on the sole.

Sneakers HERON01 (photo HERON01)

Natives shoes and 3D printed shoes

Canadian manufacturer Native Shoes launched the Liquid Printed Natives project with the goal of designing everyday items using advanced techniques such as additive manufacturing. As part of this, the company used liquid rubber to 3D print shoes. The manufacturer says it has used 50% recycled ethylene vinyl acetate (EVA) material to achieve more flexibility and a more stretchy appearance. What stands out about the Native Shoes project is the speed of production: the company explains that 3D technology has significantly reduced production time compared to traditional methods. They also offer consumers a high level of customization.

Shoes will be 3D printed directly in a tray containing a reusable water-based viscous gel formula.

Eco sandals

We continue this trend of 3D printed sandals with the Organic collection, designed by young fashion design student Lucy Treitnarova. In collaboration with materials manufacturer Fillamentum, she 3D printed the outsole of the sandal, onto which she sewed several organic fabrics made from fibers extracted from pineapple or coconut leaves. The printed outsole needed to be strong enough to withstand this fabric, so Lucy opted for TPU, which is flexible enough yet resistant to abrasion and wear. It also has the ability to be recycled, which is a key ingredient for a young woman.

In collaboration with materials manufacturer Fillamentum, she 3D printed the outsole of the sandal, onto which she sewed several organic fabrics made from fibers extracted from pineapple or coconut leaves. The printed outsole needed to be strong enough to withstand this fabric, so Lucy opted for TPU, which is flexible enough yet resistant to abrasion and wear. It also has the ability to be recycled, which is a key ingredient for a young woman.

Mycelium shoes, futuristic shoes

Created by design studio Ica and Kostika, the pair of Mycelium sneakers is completely 3D printed on an SLS machine. Pretty impressive in shape, size and design, it does not go unnoticed on the street - besides, only 5 pairs were created. Its designers claim that these 3D printed shoes are very comfortable because they are fully adapted to the human foot: a 3D file is created from the scanned data.

Only 5 pairs were created

Hilos 3D Printed Eco Shoes

Portland-based startup Hilos was founded in 2019 and wants to change the way shoes are made by combining technology and craft. Through additive manufacturing, the company hopes to solve environmental problems while producing quality footwear. Made from selective laser sintering of TPU, these recyclable shoes are known for their flexibility and durability. The company admits that with the help of 3D printing, it can bring new product lines to market in as little as two weeks, while the industry average takes 12 to 15 months.

Through additive manufacturing, the company hopes to solve environmental problems while producing quality footwear. Made from selective laser sintering of TPU, these recyclable shoes are known for their flexibility and durability. The company admits that with the help of 3D printing, it can bring new product lines to market in as little as two weeks, while the industry average takes 12 to 15 months.

ATHOS 3D printed climbing shoes

The ATHOS climbing shoes, developed by a group of students in Barcelona, are becoming more and more popular. This type of shoe, also known as "climbing shoes", must fit the athlete's foot perfectly to improve traction and prevent slipping. Usually, to make sure they fit well, athletes wear climbing shoes that are smaller than the size of the foot, which causes pain and deformity of the foot. That's why the ATHOS team wanted to create bespoke mountaineering shoes that would meet the needs of every climber. For this, HP MultiJet Fusion 3D printing technology and BASF TPU material were used. The process of getting ATHOS shoes is very simple: just scan your feet with 3 photos, customize the shoes to your liking and once you get them home you can start climbing!

The process of getting ATHOS shoes is very simple: just scan your feet with 3 photos, customize the shoes to your liking and once you get them home you can start climbing!

Photo: ATHOS

Pleko Carbon Fiber Running Shoe

The brainchild of Italian middle distance runner Miro Buroni and Diadora, the Pleko shoe is made up of many 3D printed components. The 3D printed parts include the insole, outsole, studs and ribs. Designed from composite materials, carbon fiber to be exact, and through a powder sintering process, these various elements have made it possible to produce a shoe that is flexible, resistant to wear and, above all, customizable. Indeed, thanks to 3D scanning and race simulation software, shoe designers can offer athletes a reliable and comfortable solution.

Photo : CRP technology

3D Printed Dance Shoes

The Purmundus Challenge 2021 was won by start-up company Act'ble, which collaborated with top athletes to develop new pointe shoes. Designed for classical ballet and contemporary dance, the shoe is called the New Pointe Shoe Sole. These shoes are expected to last five times longer than traditional pointe shoes. It was designed to greatly reduce the physical pain that dancers experience during ballet. To make the shoes, the team 3D-printed the sole, but did not specify what process or materials they used.

Designed for classical ballet and contemporary dance, the shoe is called the New Pointe Shoe Sole. These shoes are expected to last five times longer than traditional pointe shoes. It was designed to greatly reduce the physical pain that dancers experience during ballet. To make the shoes, the team 3D-printed the sole, but did not specify what process or materials they used.

Photo: Act'ble

Parametriks Print 001, shoes printed entirely in one material

Earlier this year, designer Nathan Smith unveiled the Parametriks Print 001, a 3D printed shoe using parametric design. This method, using design and material science to develop details, has resulted in shoes that stand out from the crowd for their comfort. According to Nathan Smith, he used Grasshopper, a plug-in included with the Rhinoceros 3D modeling software, to design Parametriks Print 001. In terms of shoe production, the designer explains that he relied on SLA machines and used TPU.

Photo: Parametriks

Source

SmarTech Analysis, 3D printed shoes, 3D printing, Carbon DLS technology, adidas 4DFWD sneakers, Reebok, 3D technology, 3D scanning, 3D Systems, SLS technology, 3D foot scanning, 3D printed soles

3D knitting technology in the production of special shoes. New reality

The technology of 3D knitting of the shoe upper is a high-quality alternative to natural leather.

You can often observe such a picture when workers of small construction or manufacturing companies perform their professional duties in everyday shoes. If employers still pay attention to providing employees with overalls and gloves, then special footwear for workers, as a rule, is purchased only at fairly large enterprises and industries. In small companies, the working staff puts on their own shoes and in 99% of cases the employee chooses for himself not work shoes, but light sneakers or sneakers, that is, textile sports shoes.

You yourself, having started a renovation, are unlikely to wear old leather shoes or a pair of dress shoes that have gone out of fashion. Why is this happening? The answer is obvious. Sports shoes are very light, breathable, sit well on the foot, the feet do not sweat in such shoes, it is really convenient to move and perform work related to physical activity in sports shoes. Leather shoes do not provide the same comfort of wearing, can crush or rub, are quite stiff, poorly ventilated, and a heavily worn pair can also be heavily soiled from the inside and have an unpleasant odor.

But sports models are not designed to protect the legs while working. In sneakers or sneakers, the foot is not protected from accidental impacts and cuts, since the material of the toe and upper of the shoe is very soft and not resistant to wear, the sole is easily pierced, not resistant to mechanical stress, and is destroyed by aggressive solutions and oils.

How to make sports shoes protective?

Taking into account the choice of the workers themselves and the high ergonomics of sports shoes, the world's leading manufacturers of safety shoes over the past years have been striving to create new safety shoes that have the necessary protective properties and at the same time are close in design and ergonomics of socks to sports models.

One of the newest shoe upper manufacturing technologies appeared relatively recently and almost simultaneously on the sports and safety footwear market - this is the production of the shoe upper using the three-dimensional knitting method (3D knitting) and the assembly of the upper using seamless technology.

The new technology of 3D knitting of the textile blank of the upper opens up endless possibilities for any design and individual execution of shoes. Ready-made shoe models have the following advantages:

- High breathability

- Minimum seams increase wearing comfort

- Reliable attachment of the molded sole - more than 90 N/cm²

- Unsurpassed lightness - knitted material is 2.5-3 times lighter than natural leather

- High abrasion, tensile and tear strength

- Shoes can be washed up to +40°C

- Hygiene and comfort

How is it done?

The upper of the shoe is made on special knitting equipment with a programmable pattern of configuration, texture of the knitted fabric and upper design. The threads in the structure of such a fabric are intertwined not only in a flat direction, but also perpendicular to the plane, creating the necessary thickness and high strength of the fabric.

The threads in the structure of such a fabric are intertwined not only in a flat direction, but also perpendicular to the plane, creating the necessary thickness and high strength of the fabric.

The finished fabric is thermally bonded, giving it abrasion resistance and dimensional stability. The shoe blank consists of a single piece, which is cut out using a laser.

The assembly of the upper is carried out according to an efficient technology (there is only one assembly seam on the heel), due to which high performance is achieved, as well as the reliability and durability of the shoe during subsequent operation.

Finished shoes are equipped with a protective shock-resistant toe cap, oil-and-petrol-resistant molded soles, and can be additionally equipped with a flexible anti-puncture insole, that is, working in such shoes is not only convenient, but also safe.

3D knitting technology for shoe uppers - a high-quality alternative to genuine leather

As the realities of today show, the use of natural leather for the manufacture of special footwear is not always justified.

Changes in working conditions, improvement of technological processes of production in order to eliminate the formation of hazards, comprehensive mechanization and automation of production processes; carrying out sanitary and technical measures in order to remove harmful factors from the production environment or weaken their effect lead to the emergence of clean and high-tech industries. Working in such conditions does not require the use of closed leather shoes to protect against aggressive environments and increased pollution.

The use of leather shoes in industrial premises with constant optimal temperature and humidity is not justified from a hygienic point of view. It is hot in leather shoes, as a result, the feet in it quickly get tired and sweat, which creates a favorable environment for the reproduction of bacteria.

It should also take into account the growing shortage of natural raw leather, accompanied by rising prices, which leads to an increase in the cost of special leather shoes.

Special shoes with leather uppers are relatively heavy and require difficult care.

For a long time, there was no alternative to natural leather. Today, shoe materials production technologies in the world have reached a level where modern materials have undeniable advantages, which consist, first of all, in those properties of protection and comfort for a person that natural materials cannot provide.

As the largest industrial safety exhibition A + A 2017 in Düsseldorf showed, light weight, comfortable fit on the leg, high breathability and hygiene of socks are the main advantages of new developments in special footwear. Shoes with 3D knitting technology are actively conquering the European and world market.

Knitted footwear of domestic production

JSC PTK Moderam, a manufacturer of special footwear from St. Petersburg, has developed and introduced into serial production new models of protective footwear of the Space series using 3D upper knitting technology.

Appropriate laboratory tests were carried out before launching into production:

- certification tests for compliance with the current regulations TR CU 019/2011 "On the safety of PPE";

- laboratory tests for slip resistance of soles according to EN 347;

- testing of the upper material according to physical and mechanical parameters for shoe materials;

- testing for the possibility of repeated washing of finished shoes and checking their properties after washing.

Models successfully passed all tests with a good margin of safety and quality. Patents have been obtained for new developments.

The collection of lightweight shoes with textile uppers won the competition at the international exhibition "Safety and Labor Protection" in the nomination "It's easy for the feet - it's convenient to work." Received an honorary silver medal at the All-Russian week of labor protection in Sochi in the nomination "Innovative solutions in the means of protecting workers.