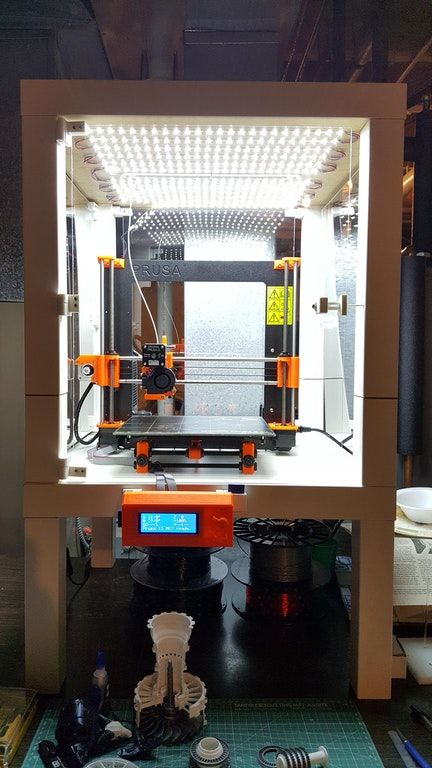

3D print room

Should I Put My 3D Printer in My Bedroom? – 3D Printerly

Anyone using a 3D printer wonders to themselves “where should I put it?” and whether they should put it in their bedroom. It seems like the ideal area because it’s easy to keep watch. There are however some things to keep in mind when thinking about putting it in your bedroom which I will explain in this article.

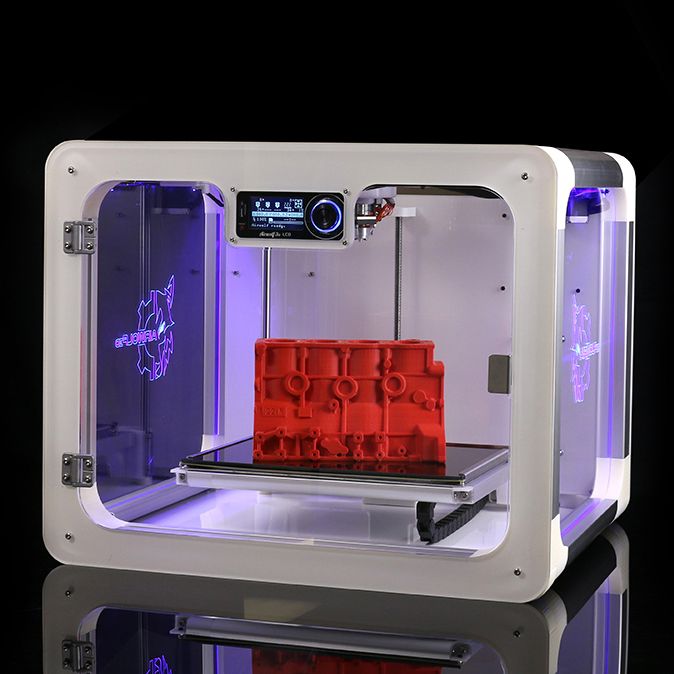

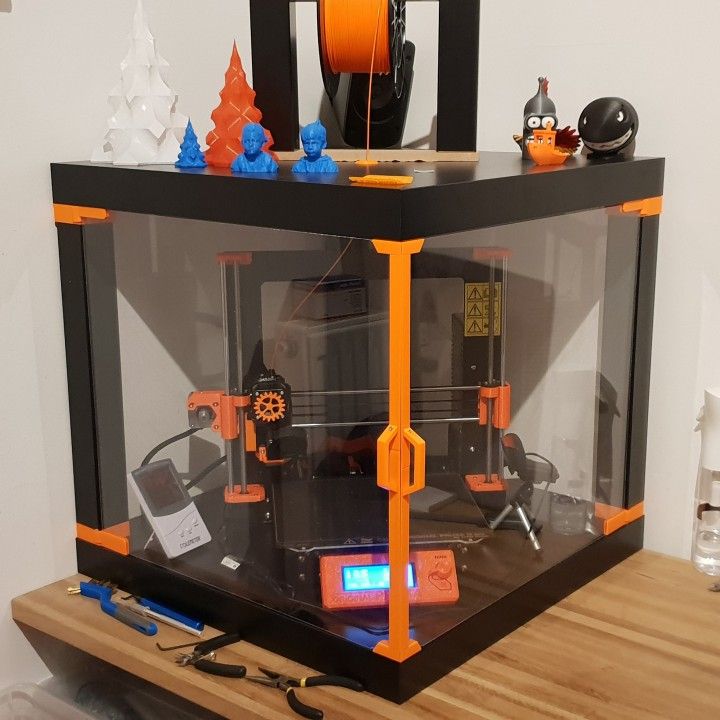

Should you put a 3D printer in your bedroom? No, it’s not advised to put a 3D printer in your bedroom, unless you have a very good ventilation system with a HEPA filter. Your printer should be in an enclosed chamber, so particles don’t spread out easily.

There are a few important things to keep in mind when deciding where to put your 3D printer. In this article, I’ve pointed out red flags to look out for and other common issues that you should know about.

If you are interested in seeing some of the best tools and accessories for your 3D printers, you can find them easily by clicking here (Amazon).

Factors for Good 3D Printer Placement

The ideal place for where to put your printer is where you’ll get the best quality prints. There are a number of factors that can affect the quality of the final print depending on where your printer is placed:

- Temperature

- Humidity

- Sunlight

- Drafts

Temperature

The average temperature of the room you are printing in can have an effect on the quality of a print. You can find the specs of the required ambient temperature of your printer as many will differ.

If your 3D printer finds itself in a cold environment, the difference in the temperature it needs to adequately print can start to increase warping, and cause prints to become loose on the print bed before it finishes.

Ideally, you want your room temperature high as well as constant. A good way to tackle this would be to have an enclosure around your printer to retain the heat necessary for a good quality print.

If you want to take an extra step, get yourself an enclosure. A great one is the Creality Fireproof Enclosure from Amazon. It’s a great long term purchase if you love 3D printing that should last you years and usually results in better prints.

A good idea to lower how much heating your bed has to do is to use a FYSETC Foam Insulation Mat . It has great thermal conductivity and greatly reduces heat and cooling loss of your heated bed.

If your printer is in a cold environment, I’ve heard of people using an electric radiator to keep the temperature high which should work out. The room temperature, if not at an ideal level and fluctuates a lot, can negatively affect the quality of a print and even make some fail.

Humidity

Is your bedroom humid? 3D printing doesn’t tend to work very well in high humidity. When we sleep we let off quite a lot of heat which can increase the humidity of your bedroom and can ruin your filament when it soaks up the moisture in the air.

A high level of humidity in a room where your printer is printing can leave filaments brittle and easily breakable. Now there is a big difference between which filaments will be affected by humidity.

I wrote an article exactly about Why PLA Gets Brittle & Snaps which has good information and prevention methods.

PLA and ABS don’t absorb moisture too quickly but PVA, nylon and PETG will. In order to combat the levels of humidity, a dehumidifier is a great solution as it’s ideal to have as low humidity as possible for your filaments.

A good choice is the Pro Breeze Dehumidifier which is cheap, effective for a small room and has great reviews on Amazon.

For the most part, proper filament storage will fight the effects of humidity but once a filament is saturated from humidity, a proper filament-drying procedure is necessary to ensure high quality printing.

You want a good storage container, with silica gel beads to ensure your filament stays dry and isn’t affected by humidity. Go with the IRIS Weathertight Storage Box (Clear) and WiseDry 5lbs Reusable Silica Gel Beads.

Go with the IRIS Weathertight Storage Box (Clear) and WiseDry 5lbs Reusable Silica Gel Beads.

To measure your humidity levels inside the storage container you should use a hygrometer. You can use something like the ANTONKI Humidity Gauge (2-Pack) Indoor Thermometer from Amazon.

This is how people used to do it, but there are more efficient methods now, like using the eSUN Filament Vacuum Storage Kit with 10 Vacuum Bags from Amazon. It has reusable humidity indicators and a hand-pump to produce a vacuum sealed effect to reduce moisture.

If your filament already has absorbed moisture you can use a professional filament dryer to solve your issues from here on out.

I’d recommend getting the SUNLU Dry Box Filament Dehydrator from Amazon today. These started making an appearance and got people getting them really quickly because of how well they work.

You wouldn’t believe how many people are printing at lower quality because their filament has so much moisture built up, especially if you live in a humid environment.

Sunlight

Sunlight can give the opposite effect from humidity, essentially over-drying out filaments and again, causing a low quality final print.

It can have the effect of making your end product brittle and easily breakable. Make sure the area where your printer is doesn’t have direct sunlight shining on it.

There are some 3D printers that have UV protection to combat against this like the ELEGOO Mars UV 3D Printer. It uses UV photocuring so it’s a necessary protection, but standard 3D printers like the Ender 3 won’t have this.

Drafts

When you have your printer in a bedroom, there can be issues with opening a window in relation to the quality of your prints. Draft from an open window can be a killer for your print quality so ensure your ventilation doesn’t create too much physical disturbance.

There can also be quite a lot of movement going on in a bedroom so you want to make sure your printer is safe during printing and storage to not get bumped in to.

So in brief, you want a room temperature which is fairly constant and not cold, a low level of humidity, out of direct sunlight and with minimal physical movement such as drafts and vibrations from movement.

Getting an enclosure is a great solution to prevent those drafts from affecting your 3D prints. A very popular enclosure that has increased the success rate of many 3D printer hobbyists is the Creality Fireproof & Dustproof Printer Enclosure from Amazon.

Common Complaints About 3D Printers in Bedrooms

There are things that people have in common when having their printer in the bedroom. One of these is the smell and fumes that the filaments give off while high temperatures are used.

PLA generally has a mild smell, depending on how sensitive your sense of smell is, but ABS can be a bit harsher and people do complain about feeling nauseous around it.

Some people will be more sensitive to fumes and respiratory problems than others so you have to take into account the health issues that can arise, especially over many hours in a day.

If you have asthma, the quality of air will be affected when 3D printing if you don’t have adequate ventilation systems put into place so this is something to keep in mind.

To the light sleepers out there, 3D printers do tend to make noise while in action so it may not be a viable option for you. 3D printers can be noisy and cause surfaces to vibrate, so having one printing in your bedroom while you try to sleep can cause issues.

Check out my popular post on How to Reduce Noise on Your 3D Printer.

Using an enclosure should minimize the sound your printer makes, as well as some kind of vibration absorbing pad underneath the printer.

The fan and the motors are the main culprits for the noise made by printers and printers do differ in just how much noise they make. There are many ways to reduce the noise made so it’s not the biggest factor, but does still matter.

Safety Issues with Where to Put your 3D Printer

Surroundings

3D printers get really hot so you wouldn’t want objects that hang over it. Things that are hung up such as paintings, clothing, curtains and pictures can be damaged by the heat of a 3D printer.

Things that are hung up such as paintings, clothing, curtains and pictures can be damaged by the heat of a 3D printer.

So, you want to make sure there aren’t things that can be damaged, which can be difficult especially in a small bedroom.

Another thing to take into account is whether you have a 3D printer kit or a manufactured 3D printer. These are two very different things in regard to fire safety.

When you buy a 3D printer kit, the manufacturer is technically yourself, so the packer of the kit wouldn’t be responsible to ensure the fire or electrical certification of the end product.

As 3D printers develop, the safety features improve so there is a much lower chance of fire risks. This doesn’t mean it’s impossible so having a smoke alarm is a good solution, but isn’t a preventative measure.

Make sure your 3D printer has the latest firmware as it is one of the main things that put safeguards in place.

Possible Fumes & Dangerous Chemicals?

PLA has been considered one of the safest filaments to print with, but since it’s a relatively new material the information on long-term health effects are lacking.

Even though PLA is known for it’s safety and lack of dangerous fumes, it still gives off particles which can still cause health issues.

Some people do complain of respiratory irritation and other related issues when printing with PLA. Even though the fumes aren’t considered dangerous, it doesn’t mean you’ll be able to easily tolerate them while you relax in your bedroom or sleep.

It’s advised, if printing with PLA, to try and use the lower temperature limit of around 200°C to minimize the fumes it gives off.

You probably don’t want to be printing with ABS if you put your printer in the bedroom due to the well-known harsh fumes it can release.

PLA is biodegradable and made from renewable starches, whereas many other filaments are made from less safe material such as ethylene, glycol and oil-based materials and usually require higher temperatures to print.

We deal with harmful fumes on a daily basis, but the difference is, we aren’t subjected to them for longer than a few minutes or in other cases a few hours.

In many cases, simply being in an urban city will expose you to similar harmful particles, but you definitely don’t want to be inhaling that in an enclosed room.

With a 3D printer, you could be running it all day and night resulting in polluted air. It is recommended to not have your printer running while you occupy the room.

This is why putting your printer in a bedroom is not a very good place when taking this into account.

One of the best and most popular filters is the LEVOIT LV-h232 Purifier with HEPA Filter.

You can check out my article about the 7 Best Air Purifiers for 3D Printers.

It’s very effective in removing harmful pollutants in the air due to its advanced 3-Stage Filtration System – pre-filter, HEPA filter & high-efficiency activated carbon filter.

This purifier does an amazing job and removes 99.97% of airborne contaminants as small as 0.3 microns.

It would be ideal to have a printer with an enclosure, as well as with some type of fan or vent to remove harmful fumes. Simply opening a window while your 3D printer prints won’t necessarily direct the particles in the air away.

Simply opening a window while your 3D printer prints won’t necessarily direct the particles in the air away.

Your best bet is using a ventilated enclosure, as well as a high-quality filter. In addition to this, have some kind of vent/window to recirculate fresh air into the space.

Flammable Safety Issue

Bedrooms are prone to have flammable materials and may not have the best ventilation, which are both red flags for where to put your 3D printers.

Now, if a 3D printer is in your bedroom, you are much more likely to catch any electrical or fire issues that occur, but this benefit also comes at a cost where it could cause harm.

Should I Put My 3D Printer on the Floor?

For the most part, if you have a solid floor, it’s going to be a flat surface which is exactly what you want for a 3D printer. Having your 3D printer on the floor, however, does increase certain risks such as accidentally stepping or knocking over your printer.

You’ll also get a lot more dust affecting your printer, filament and bed surface which can decrease print quality and bed adhesion. Rather than put your 3D printer on the floor, you should at least get a small table like an IKEA Lack table, which is popular in the 3D printing community.

Rather than put your 3D printer on the floor, you should at least get a small table like an IKEA Lack table, which is popular in the 3D printing community.

The Ender 3 is around 450mm x 400mm in width and length so you need a table a little bigger to house a medium-sized 3D printer.

A pretty good table that you can get yourself on Amazon is the Ameriwood Home Parsons Modern End Table. It’s highly rated, sturdy and looks good in a home or apartment setting.

Can You Use a Resin 3D Printer Inside an Apartment or Bedroom?

You can use a resin 3D printer inside an apartment or bedroom, but you want to use low-odor resins that have low VOCs and are known to be safe. Many people recommend not to use a resin 3D printer in living spaces, but rather in places that aren’t occupied. You can build a ventilation system to reduce fumes.

Many people do 3D print with resin indoors in their bedroom without issues, though some people have reported that they get respiratory problems or allergies as a result.

One user mentioned how he thought he had the flu for a few months, but was actually being affected by being next to an active resin printer.

Resins should have an MSDS or Material Safety Data Sheet which provides reliable information about the safety of your resin. Generally speaking, resin fumes aren’t considered hazardous and are fairly low-risk if you have the right ones.

The biggest safety risk for resins is getting uncured resin on your skin because they can easily be absorbed and cause skin irritation, or even hypersensitivity after long-term use.

Related Questions

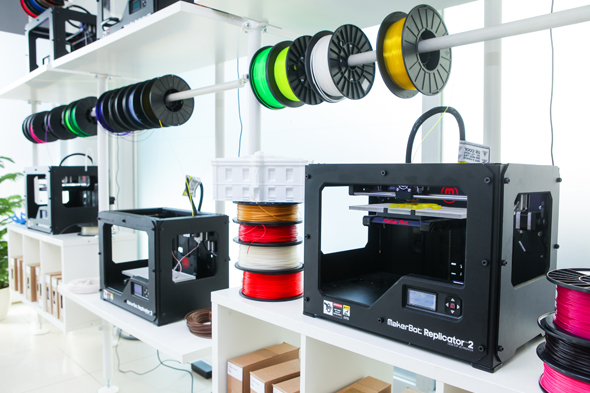

Where is the best place to put a 3D printer? The usual places people put a 3D printer are in a workshop, garage, home office, wash-room, or basement. You’d just need about four square feet of space and a shelf.

It’s not recommended to keep a 3D printer in your bedroom, bathroom, living room/family room or kitchen.

Should I only print with PLA? PLA, for the most part, can do almost everything that you require for 3D printing and is the recognized as the safer option in the 3D printing community.

Only in specific cases will PLA not be feasible for prints so I’d recommend only printing with PLA until you have enough experience.

If you love great quality 3D prints, you’ll love the AMX3d Pro Grade 3D Printer Tool Kit from Amazon. It is a staple set of 3D printing tools that gives you everything you need to remove, clean & finish your 3D prints.

It gives you the ability to:

- Easily clean your 3D prints – 25-piece kit with 13 knife blades and 3 handles, long tweezers, needle nose pliers, and glue stick.

- Simply remove 3D prints – stop damaging your 3D prints by using one of the 3 specialized removal tools.

- Perfectly finish your 3D prints – the 3-piece, 6-tool precision scraper/pick/knife blade combo can get into small crevices to get a great finish.

- Become a 3D printing pro!

Can You 3D Print in a Cold or Hot Room? – Temperature Solutions – 3D Printerly

Getting the perfect 3D printing quality depends on many factors, the temperature is one of the main ones. Based on this, many people wonder whether you can 3D print in a cold or hot room. This article is going to answer exactly that so you have a better idea of your 3D printing capabilities.

Based on this, many people wonder whether you can 3D print in a cold or hot room. This article is going to answer exactly that so you have a better idea of your 3D printing capabilities.

You can 3D print in a cold or hot room as long as your 3D printer has the proper conditions, such as a constant printing temperature and the right kind of materials. If you try to 3D print ABS in a cold room, you are likely to run into massive warping problems, while PLA could be pulled off.

There are many more details that need to be discussed to get the real answer on 3D printing in a cold or hot room. Keep on reading to find out some key information on this topic.

If you are interested in seeing some of the best tools and accessories for your 3D printers, you can find them easily by clicking here (Amazon).

Can You 3D Print in a Cold Room or Cold Weather?

Monitoring temperature while printing is one important step you need to ensure. It can be hard to print in a cold environment hence you need to carefully monitor your environmental temperature while printing.

Different print materials require different optimum temperatures. When you print with ABS, you should keep the entire build area fairly hot to prevent warping. However, PLA is not as meticulous as ABS.

Which means that you can get some 3D prints in a relatively cold environment if you are printing with PLA. Users started to see printing issues with PLA at temperatures below 59°F (15°C).

The main thing you have to control is temperature fluctuations because large changes in temperature can definitely mess a print up. Warping occurs because print layers are cooling down too quickly, meaning they contract too much.

This is when you see corners of your print start to curl away from the print bed, which is bad for print quality and can even lead to prints getting knocked over because it decreases bed adhesion.

Once you control for temperature fluctuations, 3D printing in a cold room isn’t impossible, but it can definitely be difficult. I’m sure there are certain temperatures which are just too cold to operate successfully.

It will come down to how good your power supply is and your heated bed part’s ability to generate enough power to overcome the cooler environment.

Check out this video by Uncle Jessy who actually 3D printed outside in the snow to test out the theory!

Can You Resin 3D Print in a Cold Room?

Yes, it is possible to resin 3D print in a cold room if you keep in mind a few pointers. The resin won’t completely harden if the temperature falls too low if you ensure your workplace temperature stays stable at 75°F (24°C) and doesn’t fall below around the 68°F (20°C) mark.

The resin won’t completely harden if the temperature falls too low if you ensure your workplace temperature stays stable at 75°F (24°C) and doesn’t fall below around the 68°F (20°C) mark.

The operating temperature for a Formlabs resin 3D printer is 64-82°F (18-28°C).

You must ensure your resin is at room temperature if you want it to work fine. Try to keep your workplace temperature stable and make sure humidity level is not above 50 per cent.1

Hence, it is quite possible to get resin 3D print if you ensure a few important steps. By avoiding any temperature fluctuations and high humidity levels, it is possible to get resin 3D print in a cold room.

Cold is actually ideal for storing your resin because the lower temperatures reduce chemical reactions which mature the resin. Warming up your resin before use will get it going. Some resin shouldn’t be stored in environments which are too cool though.

Warming up your resin before use will get it going. Some resin shouldn’t be stored in environments which are too cool though.

You want to try avoiding storing your resin in temperatures below 50°F (10°C) or above 140°F (60°C).

Constant temperature is essential for successful prints. Temperature also has effects on how well your resin hardens from the light and cures with the help of UV. A high quality resin 3D printer will regulate the temperature inside the machine, as well as the curing chambers.

The Peopoly Maoi offers a heater for their printer which makes it much easier to resin 3D print in a cold environment.

Can You 3D Print in a Hot Room?

Most printing occurs efficiently under a hot environment however there is a certain limitation to the temperature.

To allow a better working environment for the printer if your surroundings are hot is to install efficient cooling fans and even a cooler. For even better temperature regulation you can also place an air conditioner.

PLA is relatively easy to work with and is not that sensitive to temperature changes as compared to ABS.

You just want to make sure you don’t have an extremely hot operating temperature because that can mess up some prints, depending on the material.

Materials with a low glass transition temperature like PLA won’t do very well in a hot environment as it won’t harden in time. If you have strong cooling fans it may be able to print successfully, but it does make it harder.

However, regardless of the filament you use, you need to make sure at all times that the overall room temperature even in a hot room doesn’t exceed above 50 Celsius. Beyond this temperature, your prints can get messy and spoiled.

Moreover, your printer can overheat resulting in many other complications.

Can You Resin 3D Print in a Hot Room?

To allow resin 3D printing in a hot room you must observe consistent temperatures. Consistency in your workplace temperature is the key to perfect your resin printing in a relatively hot environment.

You can improve your resin printing by heating the resin in a water bath before starting the printing process. Most resins work best in the temperature range of 25-30°C.

By decreasing the heated bed temperature and using efficient fans for cooling, you can enable printing in a hot room. You should be able to regulate your temperature around 20°C.

3D Printing in a Hot Garage

Yes, it is possible for you to 3D print in a hot garage but for this, you need to have some accurate climate control facilities. By ensuring control over the operating temperature and its fluctuations you can successfully print in a hot room.

In hot garage temperatures, it shall be unlikely to print in PLA, as that specific temperature is way above its glass transition temperature. This therefore could never let it solidify.

But, for ABS it will be great and would also decrease warping. It will also improve surface finish.

Does Room Temperature Affect 3D Printing?

Regardless of the environment, you are working in, you should at all times, ensure stability in temperature. It is best advised to regulate the temperature around 68°F (20°C).

It is best advised to regulate the temperature around 68°F (20°C).

So, yes, room temperature surely has a huge effect on the printer’s performance, efficiency and longevity. No printer likes to work in an extreme climatic environment, whether it’s too cold or too hot.

Extreme high temperature can result in deformation of parts, whereas the cold temperature may result in warping between the print layers.

What is the Best Ambient Room Temperature for 3D Printing?

Technically speaking, there is no exact ambient room temperature for 3D printing. There isn’t actually an ideal ambient room temperature for the 3D printing. Rather a temperature range is to be kept in mind.

But the most foremost factor to practice is temperature stability. Hence, for good print output and overall performance, it’s best you maintain an optimum room temperature preferably around 62-68°F (17-20°C).

Should I Use a Heater for my Printer Enclosure?

If you are printing in a cold environment, it’s good to use a heater so that the overall workplace temperature is suitable for the printer to work in. Temperatures might fluctuate without a heater and hence spoil your printer’s performance.

Temperatures might fluctuate without a heater and hence spoil your printer’s performance.

So, you should place a heater to avoid the area from getting too cold. Extremely low temperatures can exist without there being no heater and this can result in your nozzle and filament getting spoiled.

How to Winterize your 3D Printer to Print in a Cold Room?

Printers might not be able to work in a very cold area, so you can install heating chambers for better results. It is also advised that you install wireless sensors which can monitor temperature and the humidity changes.

The main thing would be trying to increase your overall temperature in the cold room with a heater, or by using better insulation so the warm air doesn’t escape, and cold air doesn’t come in.

If you are having trouble with this, a heated chamber is going to be a lot more efficient compared to heating the whole room. It can be built out of many materials and there are guides on building DIY heated chambers that you can find on YouTube.

Furthermore, for a better printing experience you can also install carbon filters, and even an exhaust system which can filter out toxic fumes. Although you are working in a cold room, try to avoid your printer’s direct contact with sunlight.

This is suggested because, severe temperature fluctuations can prove to be really disadvantageous for the printer’s overall performance.

Apart from that, it is important that you store your materials and other supplies at room temperature and preferably in a vacuum free space.

Conclusion

Temperature regulation is a key step which can promise you a smooth printing experience. Other than that, the aforementioned guidelines will seem to be very effective if you practice them.

If you love great quality 3D prints, you’ll love the AMX3d Pro Grade 3D Printer Tool Kit from Amazon. It is a staple set of 3D printing tools that gives you everything you need to remove, clean & finish your 3D prints.

It gives you the ability to:

- Easily clean your 3D prints – 25-piece kit with 13 knife blades and 3 handles, long tweezers, needle nose pliers, and glue stick.

- Simply remove 3D prints – stop damaging your 3D prints by using one of the 3 specialized removal tools.

- Perfectly finish your 3D prints – the 3-piece, 6-tool precision scraper/pick/knife blade combo can get into small crevices to get a great finish.

- Become a 3D printing pro!

$250 room-sized 3D printer / Habr

Why not make a 3D printer out of a garage or an empty room? An open source project from Sweden makes this possible for $250. Who is less?

Article by Glenn McDonald from Seeker. com translated for you by Top 3D Shop .

com translated for you by Top 3D Shop .

Swedish inventor Thorbjørn Ludwigsen has spent the last three years developing a new kind of large-format 3D printer that can create large objects. His invention can print furniture right in the room - it's very easy and relatively cheap. Ludwigsen's invention, the "Hangprinter", uses a system of wall, floor, and ceiling-mounted cables and computer-controlled drives on a print head unit. The device uses the room itself as a 3D printer case.

Hangprinter is not the first large format 3D printing system, but it is unique. First, it's cheap. All hardware and firmware components can be purchased for approximately $250. In addition, it is an open project, which means that any user can improve the system and use third-party updates. Finally, Hangprinter is self-sufficient - most of the components necessary for its creation can be printed by it.

It all adds up to a system that Ludwigsen hopes will open up the potential of 3D printing to more people. The developer believes that 3D printing should not be an expensive perk. In his opinion, Hangprinter is not only a technical, but also a social experiment.

The developer believes that 3D printing should not be an expensive perk. In his opinion, Hangprinter is not only a technical, but also a social experiment.

“In particular, I want 3D printing to avoid the fate of 2D printing, where machines are programmed to self-destruct after a certain number of objects are made. The best chance to do this is not only to use open source, but also to create self-replicating hardware. Hangprinter manufactures most of the necessary elements for itself.”

- he said.

The Hangprinter project is part of a larger initiative in the 3D printing community known as RepRap. All developers try to optimize prototyping processes as much as possible. The idea is to spread 3D printing technology to low- and middle-income people through open design solutions and self-replicating mechanisms.

“Open technology can empower middle- and low-income families, and I grew up in one of those families,” said Ludwigsen.

The innovator is taking this project very seriously. As a physics student at Umeå University in Sweden, he recently completed his master's thesis on the subject.

As a physics student at Umeå University in Sweden, he recently completed his master's thesis on the subject.

In the Hangprinter video, Ludwigsen showed how a 3D printer creates a relatively simple and functional object - a lampshade.

The Hangmaker has also been involved in more artistic projects - Ludwigsen recently used the system to assemble a five-foot sculpture of the Tower of Babel.

Hangmaker prints the Tower of Babel sculpture. Author: Thorbjorn Ludwigsen.

As the device is optimized, Ludwigsen hopes the Hangprinter will become versatile enough to print furniture, tools and possibly fully functional machines with moving parts. He also hopes to raise money through crowdfunding to continue research and development in this direction.

Although the current version of Hangprinter is fully functional, there are many upgrades ahead of the device, according to its author. In fact, improvements are another reason why the author decided to develop the project as open-source.

“It's a flexible manufacturing technique, so it will be useful in situations I can't foresee. Some of them can be very important/cool/useful. I would not want to interfere with important and useful discoveries.0010 ,

- he said.

Share your opinion in the comments.

Furniture on a 3D printer: 3D printing

In this article we talk about making furniture using additive technologies - 3D printing - about the advantages and examples of using this approach in practice and what technique is best to use.

This article was prepared using a publication from the site 3dsourced.com, which was translated and supplemented for you by the Top 3D Group.

You may have once had the idea of using 3D printing to make furniture for your home, but dismissed it as too labor-intensive, time-consuming or expensive. After all, large industrial 3D printers with a huge print area, like the Farsoon SS403P 3D printer, are usually needed to create large pieces of cabinet furniture, right?

That used to be true, but now there are ways to use 3D printing in the interior without the need for large-format industrial machines.

Read on - we'll take a look at some of these applications with real examples.

Option 1: Build furniture with the Hangprinter

Designed by Torbjørn Ludwigsen, the Hangprinter is a cable-suspended and movable print unit designed to print large objects as cheaply as possible. The Hangprinter doesn't fit in a case, its print chamber is the entire room.

Hoping to inspire others to try frameless 3D printing, Thorbjörn has made the software files for this printer open and free for everyone to copy, use and further refine. Most parts of the Hangprinter can be 3D printed, and the cost of building one yourself is estimated to be as low as $250.

Chris Riley Stool

Introduced in mid-2017, Hangprinter printing immediately began to be tested in the creation of large objects. In the video below - one of the very first examples - Chris Riley's bar stool.

Such videos showed the strengths and weaknesses of Hangprinter, for example, the ability to create really large objects for relatively very little money and the possible delamination due to the lack of a closed camera.

Chris Riley's stool was printed with offset layers and delamination, and it also took two weeks to print because the Hangprinter was so loud it couldn't be used at night and had to be printed only during the day.

Building and operating the Hangprinter requires familiarity with 3D printers, an understanding of the mechanics of how they work, skills in working with electronics and debugging devices, but there are also detailed instructions for beginners, as well as a small but growing community of other Hangprinter users who can be contacted for help.

For those who are willing to put up with the disadvantages described above, or are confident that they can avoid them, Hangprinter remains the most affordable and affordable way to create fully 3D printed furniture.

Option 2: 3D printed furniture on a large 3D printer

3D printed furniture from the “Print Your City” project. This model may not fit in your desktop printer.

The second method is to use a stationary 3D printer with a really large print chamber

Print Your City

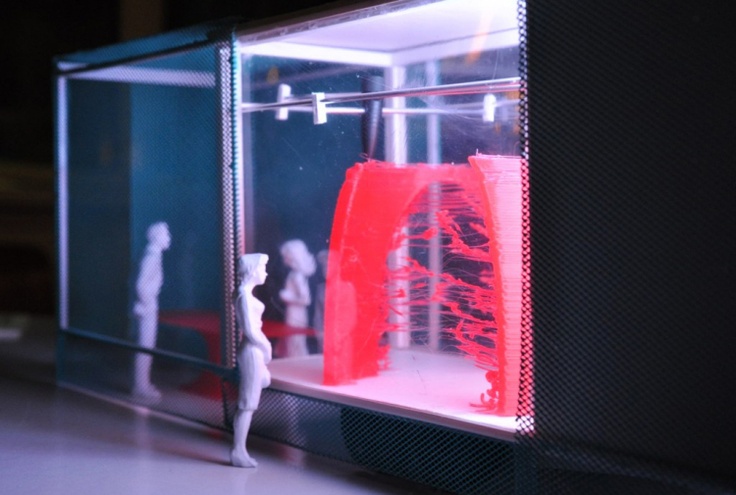

The “Print Your City” project, for example, uses a 3D printer consisting of a robot and a fenced indoor area equipped with a special printing platform to print street furniture and other small architectural forms.

Last but not least, the printing plastic is made from recycled waste.

Despite the simplicity of the idea itself, this method of manufacture is beyond the reach of most people. Large 3D printers not only take up a lot of space, sometimes entire rooms, but are also incredibly expensive. Large industrial 3D printers like the Farsoon HT1001P can still cost hundreds of thousands of dollars.

Large 3D printers not only take up a lot of space, sometimes entire rooms, but are also incredibly expensive. Large industrial 3D printers like the Farsoon HT1001P can still cost hundreds of thousands of dollars.

Because of this, very few furniture projects are carried out by individuals, usually by businesses or very passionate enthusiasts, and the Wilkhahn Printstool stool shown below is an example of both.

Wilkhahn Printstool One

Designed by Thorsten Frank and manufactured by Wilkhahn, this 3D stool was produced on an industrial 3D printer and is available as part of Wilkhahn's premium office furniture range.

Wilkhahn is a German furniture manufacturer that strives to differentiate itself from its competitors.

“Unlike almost any other office furniture manufacturer, Wilkhahn stands for designs made in Germany all over the world. It offers high-quality office and dynamic conference furniture that sets the benchmark for the entire industry,” the company says.

Printstool One is one of the few 3D printed pieces of furniture available commercially. It takes several hours to create and assemble, including 3D printing the base and attaching the seat. The base is printed with lignin, an organic biopolymer that decomposes in nature.

Although the Printstool One is a commercial product, it is not easy to obtain. It is not part of the main Wilkhahn catalog and was released in a limited edition of 500 pieces.

The price for this stool has not been disclosed and probably depends on options, seat material, for example. But given that regular stock stools in this manufacturer's catalog range from $266 to $660, it's safe to assume that the Printstool One costs at least $500, making it quite an expensive plastic stool. However, overpayment for exclusive furniture is a quite common phenomenon.

In recent years, 3D printing has become more and more accessible. Most likely, this will also affect its large-format sector.

RH Engineering & ManoFigura - home furniture

Magna Patero Ortus - 3D printed sink RH Engineering & Manofigura .

In mid-2020, this pair of German designers broke into the luxury furniture and interiors segment with their signature Manoveneer finishing technology and large-scale 3D printing.

Their favorite printer is the BigRep One, large enough to print furniture, with a 1005 mm³ displacement, and costs around $39,000, depending on specifications.

The production process begins with 3D printing of craft furniture based on the client's design, then the ManoVeneer branded coating is applied to the product. What Manoveneer is made of is a company secret, it is only known that the coating is waterproof, can imitate the texture of natural stone and weighs very little.

Option 3: modular printing on a small 3D printer

Large 3D printers will always be a barrier to furniture 3D printing due to their size and cost, prompting designers to look for ways to stop using them, turning to smaller 3D printers and printing smaller parts for later assembly.

Supermod 3D printed wall

Supermod 3D printed wall.

Designed by the founders of Simplus Designs, the Supermod shelving wall consists of individually printed modules that snap together.

Supermod was created for decoration, visual division of the room into zones and storage of small things in cells. As a modular system, Supermod bypasses the need for large scale 3D printers. While the assembled wall may be taller than most people, each module can be printed on an affordable desktop 3D printer.

The next method involves using 3D printed parts in combination with conventional parts such as a table top shield or wooden legs, giving the 3D printed components the role of fasteners and framing elements. This is the most accessible way for a wide range of makers to use 3D printing in the creation or repair of furniture.

Option 4: 3D printed parts as accessories

John Christie Saul Dining Table and Chairs

John Christie, who has been making custom furniture for over 20 years, returned to university at 40.

“During my studies, I became interested in 3D printing and how I could integrate it into the traditional furniture making process. In my projects, I studied how 3D printed parts can be used in the production of furniture.”

John is best known for his Saul Dining Table and Chairs. The table is a handcrafted piece of wood with 3D printed connections.

The author suggested that his connection system would provide "greater customization options, reduced production time and waste" when applied to existing pieces of furniture.

This furniture set was exhibited at the Royal Academy of Arts in Edinburgh in 2016.

This is a craft project to sell products, but similar technology has been used by amateur authors as well.

Alexandre Chappelle Furniture

Designer and YouTuber Alexandre Chappelle has documented the process of making his own wooden table with 3D printed connections. As with John Christie's project, the only 3D printed parts on this table were the articulations, while the rest of the table's parts were made from wood using conventional hand tools.

The chair is another creation of Alexandre Chappelle.

The author has posted the STL files and instructions on his personal website, where they are available for as little as $5.

This is perhaps the most affordable way to 3D print your own furniture, although the fact that John and Alexander's designs are mostly made of wood begs the question: is using 3D printed fittings 3D printed furniture?

Which technique should be used to 3D print furniture?

So which of these methods can you use for your own furniture project?

If you are a professional studio or independent designer with the necessary funds and you have a project that needs to be printed reliably and with high quality, then a large 3D printer will be the best option.