3D print rapid prototyping

Here is Everything you Need to Know

Jul 24, 2020

Fast 3D Prototyping: Rapid prototyping and 3D printing are truly a match made in design heaven!

Rapid prototyping is a common prototyping process used across many industries. Using a 3D printer for prototyping is a smart way to save time and money while also expanding design possibilities. It allows companies to physically conceptualize designs and ideas quickly and at a low cost.

In this article, we’ll dive into how 3D fast prototyping, the rapid prototyping process, and everything else you need to know.

Rapid Prototyping ProcessRapid prototyping is the general term used for the process of quickly creating prototypes and models. This type of prototyping can be done in many different ways and involve several techniques.

As its name implies, this style of prototyping allows designers to:

- Quickly see the functionality

- Test the effectiveness of a design

- Compare variations

Traditional prototyping may take a lot of time and materials. On the contrary, the rapid prototyping process typically involves much quicker and more cost-effective methods.

One of the most popular forms of rapid prototyping is through 3D printing. Many industries, including engineering, architecture, and manufacturing, utilize 3D printing in their rapid prototyping processes to speed up their workflows and save money.

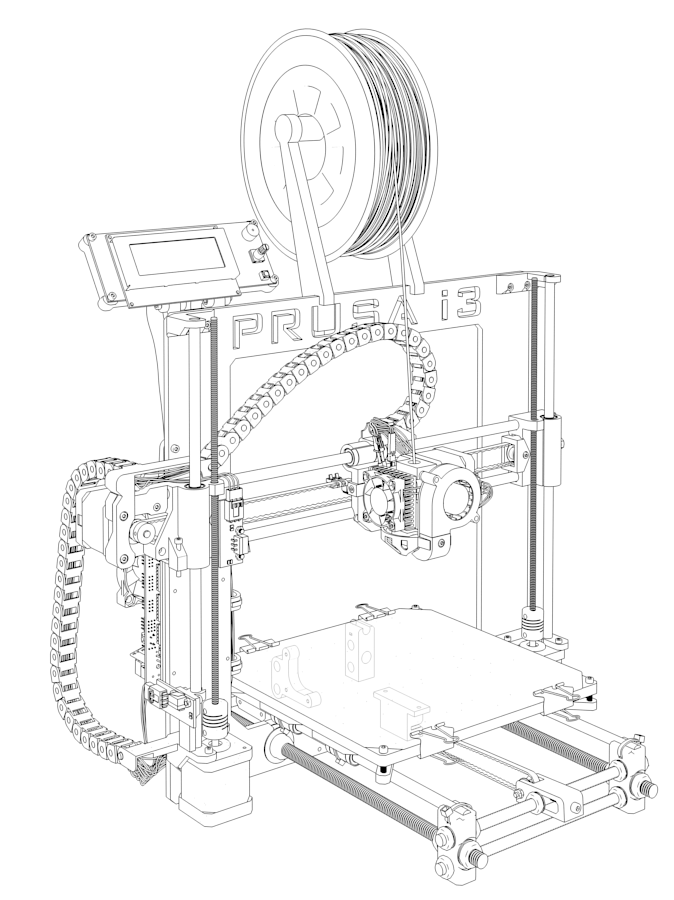

Sometimes the terms rapid prototyping and 3D printing are used interchangeably, which is incorrect. Rapid prototyping is a technique, while 3D printing is one of the technologies that can be used for this technique. While prototyping is a very common use of 3D printers, this technology is also suitable for many other uses and applications.

The Role of 3D PrintingUsing CAD software and a 3D printer, rapid prototyping can be taken to new heights. 3D printing is one of the most common prototyping methods today, simply due to its major benefits.

On the one hand, one of the largest benefits of using 3D printing for prototyping is its ability to save time and money. It does so, avoiding paying an external manufacturer for every iteration and design. Moreover, 3D printing allows designers to save the waiting time until they see a functional prototype. As a result, they can quickly make changes on the spot.

It does so, avoiding paying an external manufacturer for every iteration and design. Moreover, 3D printing allows designers to save the waiting time until they see a functional prototype. As a result, they can quickly make changes on the spot.

Depending on the print job, a design can be printed in a matter of minutes or hours. For particularly large models, leaving the 3D printer on overnight is the best option. It allows you to come back to the office to a fully printed prototype, freeing up space for the next one.

Furthermore, rapid prototyping allows designers to keep their concepts in-house. Therefore, not only speeds up the workflow, but it keeps ideas confidential and secure.

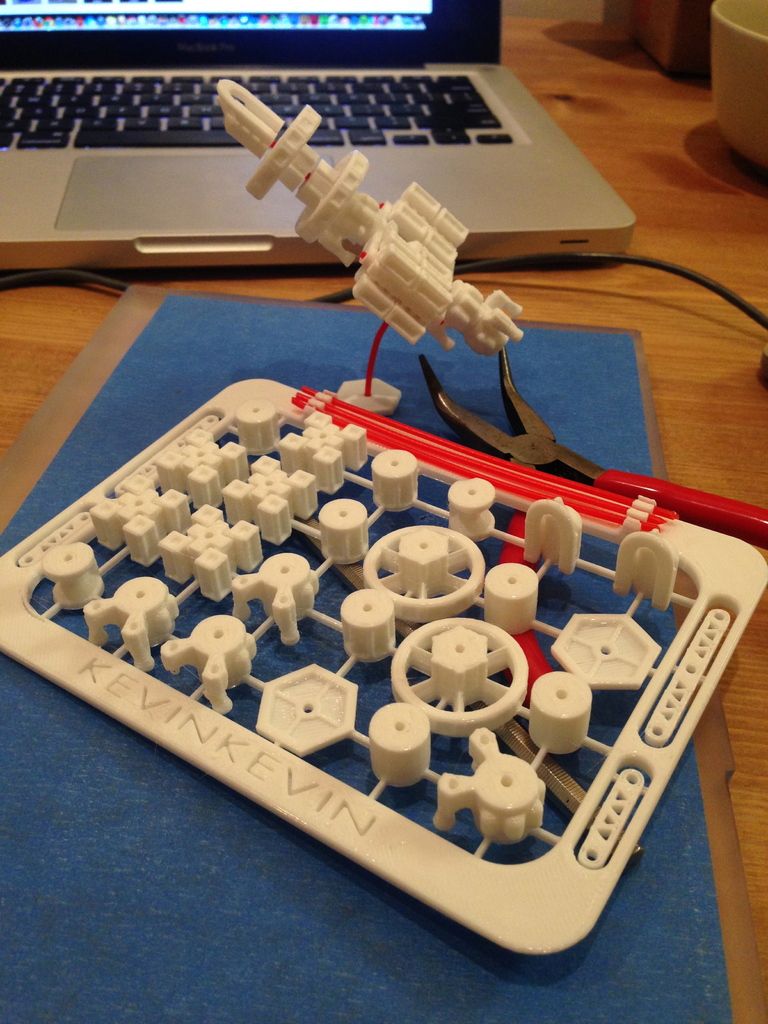

On the other hand, the most valuable role of 3D rapid prototyping is the ability to test and compare different models or design ideas. This applies when testing both functionality and aesthetics.

We recommend using a more durable filament like PA and TPU or a similar filament to your end-use material. This way, you can test if your design will stand up to important elements or factors, such as certain chemicals or the weather. Similarly, 3D prototyping allows you to physically compare different visual concepts and iterations.

This way, you can test if your design will stand up to important elements or factors, such as certain chemicals or the weather. Similarly, 3D prototyping allows you to physically compare different visual concepts and iterations.

Many industries currently incorporate 3D printing into their rapid prototyping process.

Architects and product designers can utilize this technology for building models as well as showcasing difficult designs that may not be accurately represented on a screen alone. Engineers and manufacturers can utilize additive manufacturing for functional prototyping. Consequently, this fact will allow them to test different technical aspects of a tool or part.

Students and researchers also benefit from the speed and versatility of 3D prototyping, as demonstrated by Instituto Europeo di Design Barcelona.

For instance, using 3D printers in class IED Barcelona students can quickly compare different ideas and concepts before settling on a final design. In their very classrooms, they are recreating the real-world effects of using 3D printing for prototyping.

In their very classrooms, they are recreating the real-world effects of using 3D printing for prototyping.

Using 3D printing to speed up your rapid prototyping process will revolutionize your prototyping workflow. The saved costs and time, combined with an easier design testing process, makes additive manufacturing one of the best technologies for prototyping.

What is Rapid Prototyping & 3D Printing? Benefits & How to

Rapid prototyping sounds great, but where can it be used in the engineering process? The answer may not be wholly surprising at this point: from initial proof-of-concept to final-look-and-feel prototype, rapid prototyping can come into play across the entire process.

Concept Prototypes

The earliest prototypes are often conceptual. Proof-of-concept prototypes serve as physical validation of the ideas that may have emerged as a sketch on a napkin. Taking an idea into the three-dimensional real world is the best way to prove viability. Getting hands-on with a concept model can help your engineering team understand their next steps at the same time as it may encourage management to simply move forward with a project.

Getting hands-on with a concept model can help your engineering team understand their next steps at the same time as it may encourage management to simply move forward with a project.

These early prototypes are often the roughest, as they are the lowest-risk representations made in the rapid prototyping cycle. These prototypes are made quickly and generally in different materials and colors than later-stage prototypes, much less final designs.

Aesthetic or Industrial Design Prototypes

Once a design is validated in its roughest form, it moves next into an aesthetic or industrial design step. These next prototypes begin to hone in on how the design should look and feel, with the thought process beginning to turn toward usability and functionality -- without necessarily being fully functional quite yet. To ensure a new part will fit into a greater whole, or a new product will fit with your brand’s existing aesthetic or functional line, these prototypes more accurately look like something that is moving toward a final design. These prototypes also enable engineers to consider how exactly to best manufacture the eventual final design.

These prototypes also enable engineers to consider how exactly to best manufacture the eventual final design.

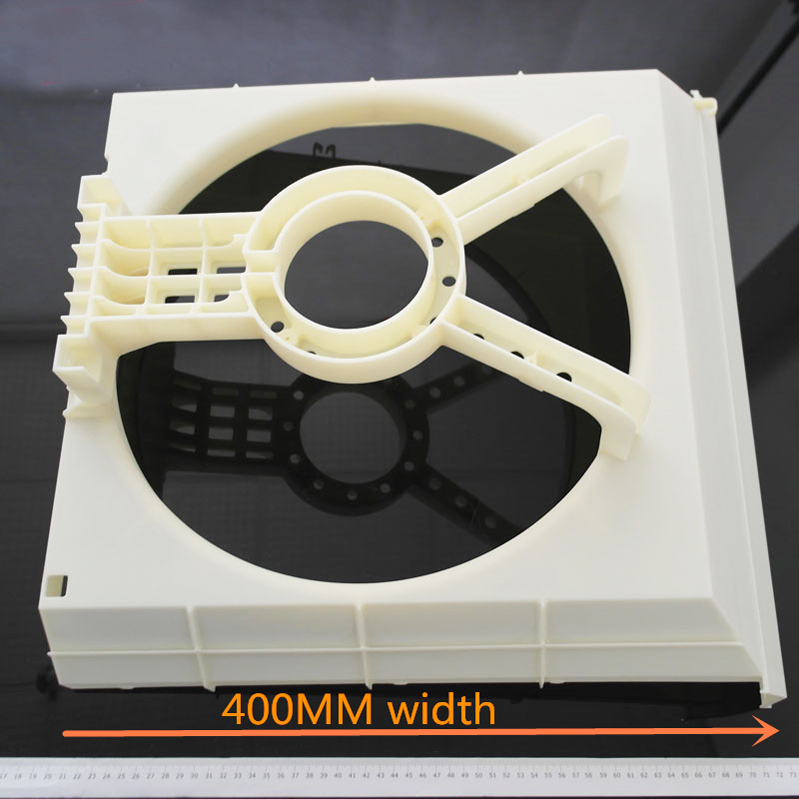

Especially when working with life-sized, larger designs like furniture, having life-sized prototypes to fit to spaces and users becomes ever more important as designs move through the prototyping cycle. Large-scale 3D printing can bring these large-scale designs to life, allowing for a full iteration to be made and tested in less than the time it would take for a traditional tool to be made. Furniture maker Steelcase experienced this benefit first-hand as they use their large-format BigRep 3D printer to create new furniture designs:

Functional Prototypes

A functional prototype does just that: it functions. These later-stage prototypes are often made of materials similar to what will be used in a final product, to validate that everything will work as intended. Engineers at this stage pay attention to performance: does it fit, does it function, do load-bearing parts bear loads?

Attention must be paid to detail, to how the final part will be manufactured (especially if this will be done in a different process than the prototype; for example, 3D printing a prototype for a part that will ultimately be injection molded) as well as how the final part will be post-processed/finished.

Test Serial Production

Many products bound for the mass market are bound for mass production, and this may mean in a different manufacturing process. While 3D printing may be the right technology for both rapid prototyping and serial production of the final part - consider, for example, cases of mass customization - this will not always be the case.

Prototyping must take into account the eventual manufacturing process to be used, and later-stage prototypes should use the same materials and fit into the appropriate manufacturing parameters as the final parts will be. Consideration for traditional production processes comes more into play here, for example for tooling, jigs and fixtures, or any other necessary implements. Design for additive manufacturing (DfAM) may move toward traditional design for manufacturing (DFM) thinking.

Demonstration or Presentation Model Prototypes

The final look is the final stage in prototyping, the last step before full production begins. At this stage, a prototype should not only feel and operate like the final product, but needs to look like it, too. This prototype can be used for marketing materials while production ramps up, for convincing investors of final viability and feasibility, for final field testing, or for any other demonstration or presentation needs. The goal of rapid prototyping is to reach this stage faster than ever before using conventional prototyping workflows.

At this stage, a prototype should not only feel and operate like the final product, but needs to look like it, too. This prototype can be used for marketing materials while production ramps up, for convincing investors of final viability and feasibility, for final field testing, or for any other demonstration or presentation needs. The goal of rapid prototyping is to reach this stage faster than ever before using conventional prototyping workflows.

3D prototyping, development of prototypes in the company Foliplast on favorable terms

In a short time we get accurate samples of various parts and functional models of products.

Rapid prototyping includes a number of technologies that allow you to quickly obtain an accurate layout of various parts, products or a prototype to demonstrate the useful properties of an object. Prototyping allows you to conduct marketing research of products at the stage of its development, evaluate the appearance and ergonomics of the product, check the assembly of all structural elements, identify design errors and make the necessary changes before starting production.

Today, not a single new development can do without rapid prototyping technologies. Prototyping is used in mechanical engineering, printing, electrical and electronic industries, but is not limited to these areas.

Most often, prototypes are made as the first step in the production of pilot or serial batches of plastic parts. Here, these samples act as master models for subsequent vacuum casting into silicone molds or using RIM technology. And it is precisely at the stage of making master models that the foundation for the quality of a future batch of products is laid. The key role here is played by the accuracy of the manufactured prototype and the quality of finishing of its surfaces. Thus, how carefully the prototype was fine-tuned in accordance with the requirements of the customer, such an appearance of the product will be obtained. The labor intensity here is in direct proportion to the required quality. If you want parts like from an injection molding machine, then it will take time, care and experience of modelers.

Industrial prototyping is one of the main activities of Foliplast. In our work, we focus on the wishes of our customers and rely on proven methods. There are more than 20 types of Rapid Prototyping, including those for metals, wax, plastics and other materials. Over many years of practice, we can select from this variety of technologies the most suitable for specific tasks. So, if you need an accurate and high-quality prototype, you need to use SLA 3D printing technology. For simple design testing, assembly checks, you can use more budgetary FDM or SLS technologies. Of course, such a gradation is rather arbitrary, since there are times when more than one technology is applicable.

Each specialist of our company has extensive experience and excellent qualifications, which allows us to provide services of consistently high quality and quickly. 3D prototyping is based on the use of high technologies. We use advanced modern equipment, innovative techniques. The accumulated experience, combined with efficient production, ensures the fulfillment of orders at a high professional level.

We offer not only rapid prototyping of products and parts of any complexity using 3D printing technologies, but also small-scale production of plastic products.

How is product prototyping carried out?

The most modern method of creating a prototype is printing on a 3D printer. In fact, the prototyping of products by 3D printing is a layer-by-layer construction of a physical structure based on the developed mathematical model. Among the advantages of the technology: visibility, reduction of production preparation time, as well as a reduction in the cost of construction and design. Note that if you already have a part sample, then our specialists can use it as a master model in the production of silicone tooling for the vacuum casting method, which is effective for obtaining small batches of parts due to the speed and relative ease of manufacturing silicone molds.

Product prototyping steps

Rapid Prototyping includes the following stages:

- computer modeling, which consists in the development of a virtual three-dimensional model in stl format;

- then follows the development of the adopted technology;

- actual production of a 3D model;

- final refinement of the required texture of view surfaces.

1. Mathematical model of the part 2. SLA 9 prototype0003

By fully complying with the norms at the indicated stages of 3d prototyping using any chosen method, our company guarantees the efficiency and high quality of the final product.

Applied 3d printing technologies

Often, instead of the more correct and accurate term Rapid Prototyping (Rapid Prototyping), the concept of 3d printing is used. To date, there are a large number of volumetric printing technologies, but all of them have the same principle of layer-by-layer build-up. Below are descriptions of the main 3D printing technologies that have received the widest distribution.

SLA - Stereo Lithography Apparatus

SLA is laser prototyping. The technology involves the use of a special photopolymer, a light-sensitive resin, as a model material. The working tool in this process is an ultraviolet laser, which sequentially transfers the cross sections of the model to the surface of the container with photosensitive resin. Liquid plastic hardens only in the place where the laser beam has passed. Then a new liquid layer floats on the hardened layer, and a new contour is drawn with a laser. The process is repeated until the completion of the model building.

The working tool in this process is an ultraviolet laser, which sequentially transfers the cross sections of the model to the surface of the container with photosensitive resin. Liquid plastic hardens only in the place where the laser beam has passed. Then a new liquid layer floats on the hardened layer, and a new contour is drawn with a laser. The process is repeated until the completion of the model building.

Stereolithography is the most common RP technology. It covers almost all branches of material production from medicine to heavy engineering. SLA technology allows you to quickly and accurately build a product model of almost any size. The quality of the surfaces depends on the construction step. Modern machines provide a construction step of 0.1 ... 0.025 mm. Stereolithography gives the best result when creating master models for the subsequent production of silicone molds and casting polymer resins into them, as well as jewelry master models.

SLS - Selective Laser Sintering

Laser prototyping is not limited to liquid foundations. The SLS method allows you to create copies based on powdered components. According to this process, models are created through a sintering effect using the energy of a laser beam. In this case, unlike the SLA process, the laser beam is not a light source, but a heat source. Getting on a thin layer of powder, the laser beam sinters its particles and forms a solid mass, in accordance with the geometry of the part. Polyamide, polystyrene, sand and some metal powders are used as materials. A significant advantage of the SLS process is the absence of so-called supports when building a model. During the SLA process, when building overhanging elements of a part, special supports are used to protect the freshly built thin layers of the created model from collapse.

The SLS method allows you to create copies based on powdered components. According to this process, models are created through a sintering effect using the energy of a laser beam. In this case, unlike the SLA process, the laser beam is not a light source, but a heat source. Getting on a thin layer of powder, the laser beam sinters its particles and forms a solid mass, in accordance with the geometry of the part. Polyamide, polystyrene, sand and some metal powders are used as materials. A significant advantage of the SLS process is the absence of so-called supports when building a model. During the SLA process, when building overhanging elements of a part, special supports are used to protect the freshly built thin layers of the created model from collapse.

In the SLS process, there is no need for such supports, since the construction is carried out in a homogeneous mass. Once built, the model is extracted from the powder array and cleaned up. Models made of polystyrene are designed to produce castings using the "burned-out models" method. The most popular model material is powdered polyamide. This material is used to create layouts, scale copies, functional models, i.e. models capable of performing their function as a part of a machine or device. For example, car interior trim parts or decorative body elements. 9FDM - Fused Deposition Modeling head with a controlled temperature, heating up in it to a semi-liquid state. The extrusion head applies the material with high precision and very thin layers on a fixed base. Subsequent layers also lie on the previous ones, solidify (harden), connecting with each other. The main disadvantage of the method is the insufficiently smooth surface of the created part. In addition, when applying the molten material, some melting of the previous layer occurs. Here, the accuracy of matching with the original model suffers. Therefore, this method has a limitation on the minimum size of gaps in the created product.

The most popular model material is powdered polyamide. This material is used to create layouts, scale copies, functional models, i.e. models capable of performing their function as a part of a machine or device. For example, car interior trim parts or decorative body elements. 9FDM - Fused Deposition Modeling head with a controlled temperature, heating up in it to a semi-liquid state. The extrusion head applies the material with high precision and very thin layers on a fixed base. Subsequent layers also lie on the previous ones, solidify (harden), connecting with each other. The main disadvantage of the method is the insufficiently smooth surface of the created part. In addition, when applying the molten material, some melting of the previous layer occurs. Here, the accuracy of matching with the original model suffers. Therefore, this method has a limitation on the minimum size of gaps in the created product.

You can order rapid prototyping services in our company with delivery of products to Moscow, St. Petersburg, Kazan, Samara, Novosibirsk and other cities of Russia.

Petersburg, Kazan, Samara, Novosibirsk and other cities of Russia.

Make a request by phone 8 (800) 302-13-41.

T You can also leave a request in any feedback form on the site, and you will be contacted as soon as possible.

The exact prices for prototypes, as well as the terms of delivery and payment, will be provided by Foliplast employees.

Rapid prototyping with 3D printing - SKAT3D

WHY CHOOSE US?

Own production areas for quick prototyping

Large Park of Professional and Industrial Equipment for 3D Press: ONSINT, Picaso3D, Stratasys, Formlavs, Concept Laser

already successfully completed prototypes

9000 choice of technologies and available materials.

Experience

Extensive experience in prototyping various devices and parts.

Confidentiality

If the contract includes a confidentiality clause, you can be sure that this requirement is strictly observed.

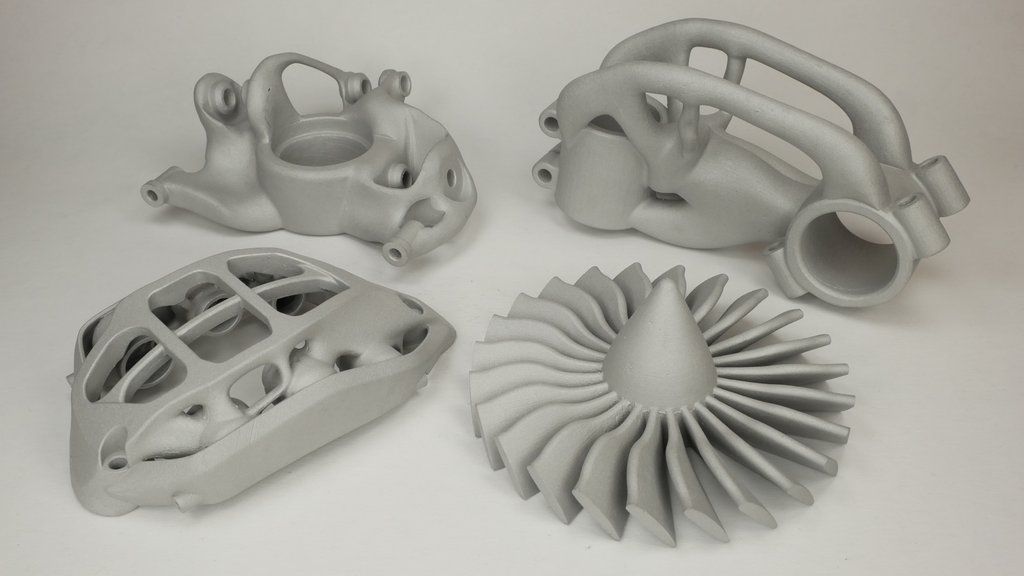

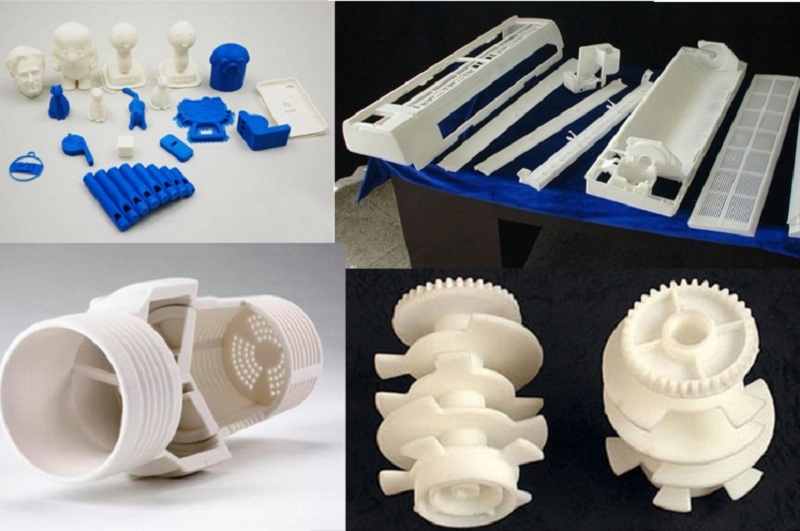

Industrial prototyping examples

Our SKAT 3D center offers prototyping of industrial and artistic products, having a large fleet of production equipment to perform tasks: OnSint, Formlabs, Stratasys, Concept Laser, Picaso. For the production of small-scale batches, we use both additive technologies and polyurethane injection into a silicone mold.

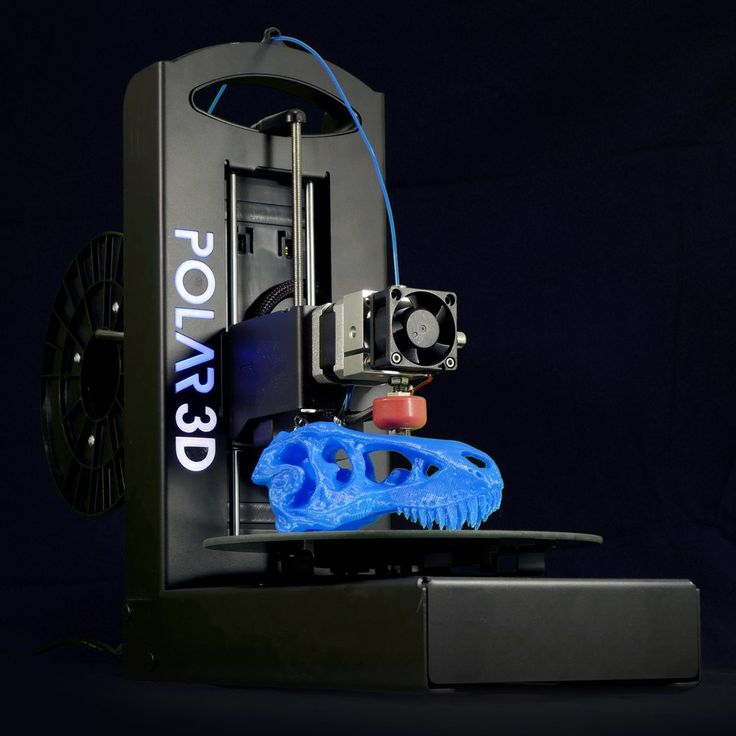

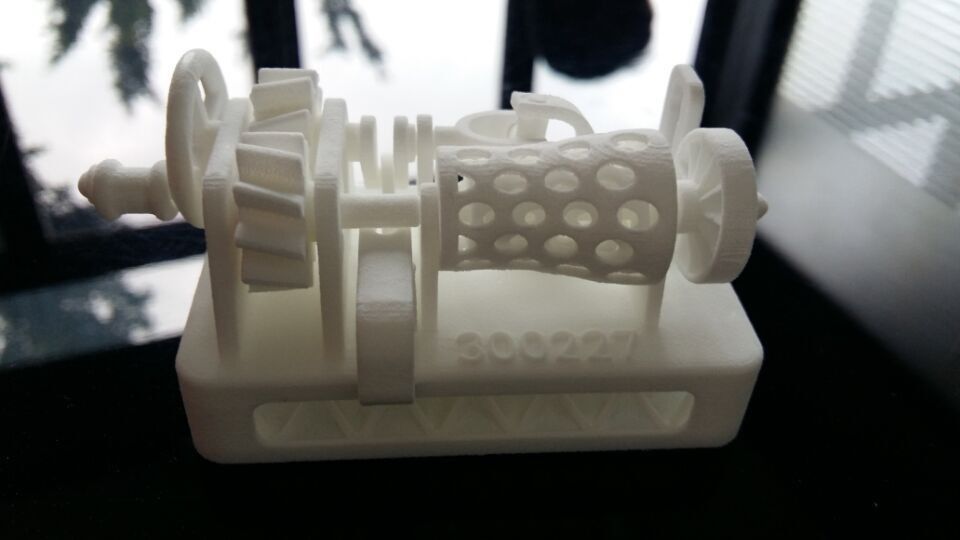

What is rapid prototyping used for? The most common case is for the visual and tactile presentation of a product. It is not enough to see an image of a new device or other commercial product on the monitor. You need to print it, feel its real size and shape. The tactile sensations are just as important as the actual live view. The very name "prototype" implies that this is the very first copy, created before that only in electronic form in CAD. For rapid prototyping, professional 3D printers using FDM technology are used, which, depending on the size of the prototype, allow it to be printed in a period from several hours to several days.

It is not enough to see an image of a new device or other commercial product on the monitor. You need to print it, feel its real size and shape. The tactile sensations are just as important as the actual live view. The very name "prototype" implies that this is the very first copy, created before that only in electronic form in CAD. For rapid prototyping, professional 3D printers using FDM technology are used, which, depending on the size of the prototype, allow it to be printed in a period from several hours to several days.

Industrial prototyping is widely used to fit the resulting part into the final assembly of a device. It does not matter what it is - a housing for an electronic device, a suspension arm of a car with a generational design, a gear or something else. First you need to try on, otherwise, in the case of placing an order for a large batch, the cost of an error is very high. Moreover, modern methods allow you to quickly create a fully functional part that can be immediately put into a working mechanism. Several technologies are used for industrial prototyping: SLS - layer-by-layer selective laser sintering of polyamide powder in a heat chamber. The resulting parts have the same strength and heat resistance as injection molded nylon parts. SLM - selective laser melting of a powdered metal alloy. Upon completion of printing, we get a finished part made of stainless steel or aluminum that requires minimal post-processing and finishing on a CNC machine. Industrial FDM printing on Stratasys Fortus printers allows you to get prototypes from engineering and structural polymers with high accuracy. Of course, ULTEM PEI-based engineering polymers and PEEK-based (PEKK) filaments deserve special attention, which have outstanding physical characteristics, catching up with metal alloys, but at the same time much lighter.

Several technologies are used for industrial prototyping: SLS - layer-by-layer selective laser sintering of polyamide powder in a heat chamber. The resulting parts have the same strength and heat resistance as injection molded nylon parts. SLM - selective laser melting of a powdered metal alloy. Upon completion of printing, we get a finished part made of stainless steel or aluminum that requires minimal post-processing and finishing on a CNC machine. Industrial FDM printing on Stratasys Fortus printers allows you to get prototypes from engineering and structural polymers with high accuracy. Of course, ULTEM PEI-based engineering polymers and PEEK-based (PEKK) filaments deserve special attention, which have outstanding physical characteristics, catching up with metal alloys, but at the same time much lighter.

As an option for the production of prototypes of metal parts by casting in sand, ceramic or plaster molds, we can offer printing of burnt-out models from special wax or burnt-out photopolymer.

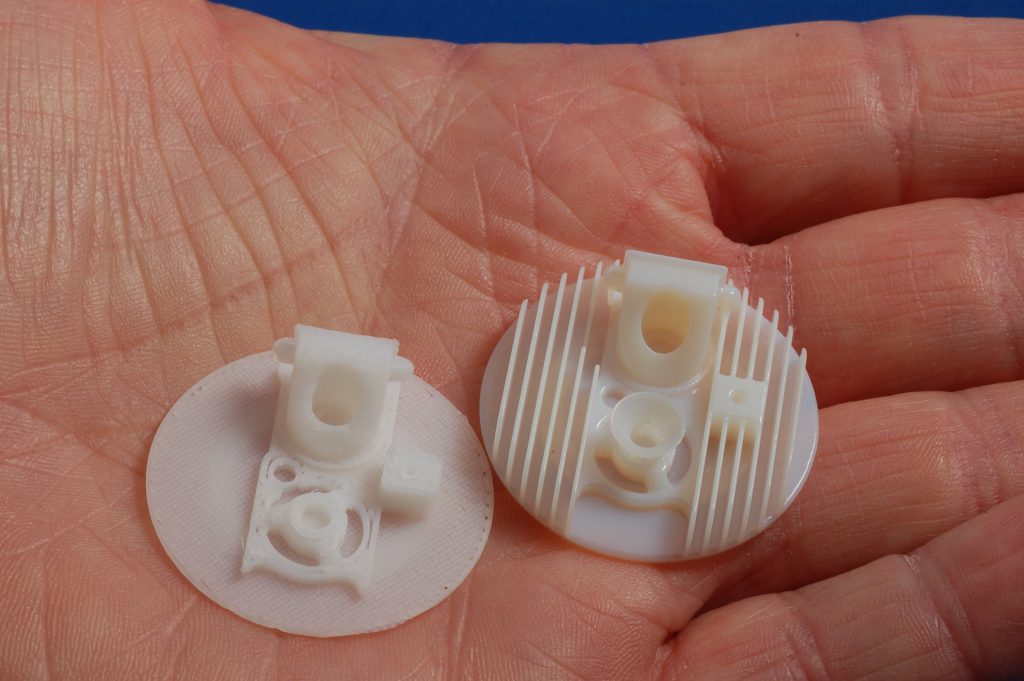

For precise prototyping, we have a Form 2 SLA photopolymer printer and a Polyjet photopolymer printer from Stratasys - Objet 500 Connex 3. They allow you to create small prototypes of parts and housings for later fitting.

| Technology | Equipment | Region | Layer, micron | Accuracy, mm | Materials | Price (r/cm3) |

|---|---|---|---|---|---|---|

| FDM ind. | Stratasys Fortus 450mc | 400x400x355 | 127-254 | +-0.10 | ASA,ABS Nylon 12, PC Ultem 9085 | 55r/cm3 65r/cm3 150r/cm3 |

| FDM prof. | PICASO XL PRO PICASO X PRO | 360x360x610 200x200x210 | 100-350 | +-0. 15 15 | ABS, PETg, PLA, HIPS Composites, Nylon, Flex Ultem 9085 | 15r/cm3 60r/cm3 120r/cm3 |

| SLA | Formlabs Form 2 | 145x145x175 | 25-160 | +-0.05 | Gray | 75r/cm3 |

| PolyJet | Objet 350 Connex | 340x340x200 | 16-32 | +-0.02 | Vero Clear Tango Med610 colored | 150r/cm3 250r/cm3 250r/cm3 150r/cm3 |

| SLS | OnSint 200 | 200x200x200 | 50-100 | +-0.05 | PA12 (EOS) Other | 80r/cm3 individually |

| SLM | Concept Laser M2 | 250x250x280 | 20-80 | +-0. |