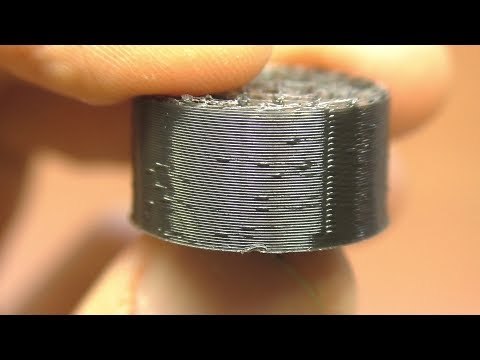

3D print infill problem

Weak Infill in 3D Printing – What Causes It and How to Fix

3D Insider is ad supported and earns money from clicks, commissions from sales, and other ways.

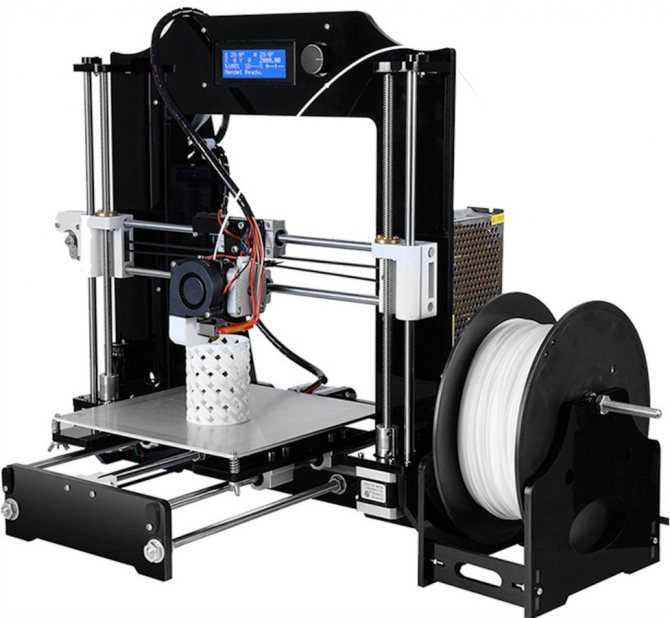

The infill is one of the fundamental parts of any 3D-printed project. It provides mechanical reinforcement to the object while helping to control its weight and density, all while maintaining the model’s intended physical appearance.

However, there is also plenty of room for error in printing the infill of any project. In many cases, the infill can be quite weak and unable to provide the expected physical support. What causes a weak infill and how can this be avoided?

What causes weak infill?

For the most part, printing the infill of your project should proceed without a hitch if it is being printed at the same settings as the shell or top layers. There are a few settings that you can tweak, but the most common cause of a weak infill is under-extrusion.

Under-extrusion can be caused by several factors – a printing speed that is too high, a printing temperature that is too low, skipping in the extruder gear, or a clogged nozzle. In any case, artifacts of under-extrusion should show up not just on the infill of the project, but also on the shell. Typical signs include missing layers or prominent gaps on the surface of the print.

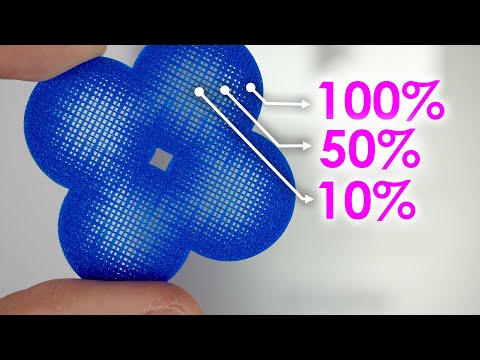

If you are having problems only with the infill, then there are probably improvements that you can make to the infill settings. The infill may be printed too quickly, or you may simply need to increase the infill density. You may also have the option of printing the infill at thicker layer widths – quite useful for prints that have to be very robust.

Troubleshooting a weak infill problem

If you are having issues with a weak infill, we suggest tweaking your infill settings first before investigating the possibility of under-extrusion. Here is our recommended troubleshooting process that starts off with the most obvious and easily addressed possible causes.

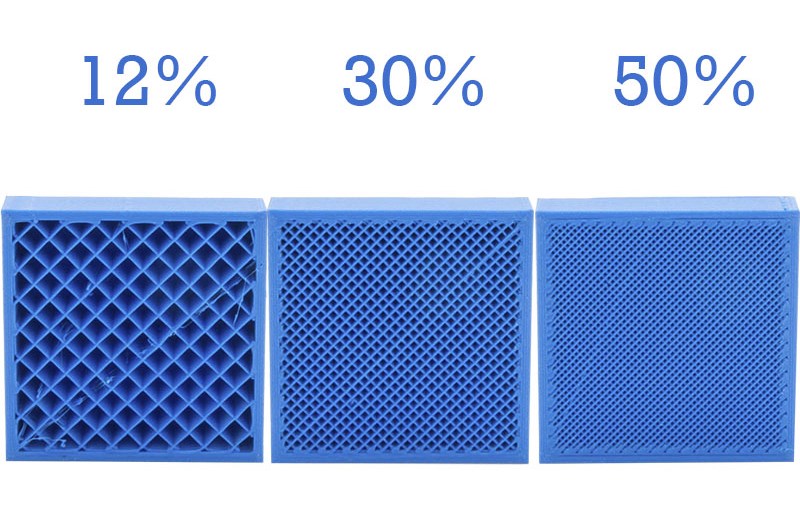

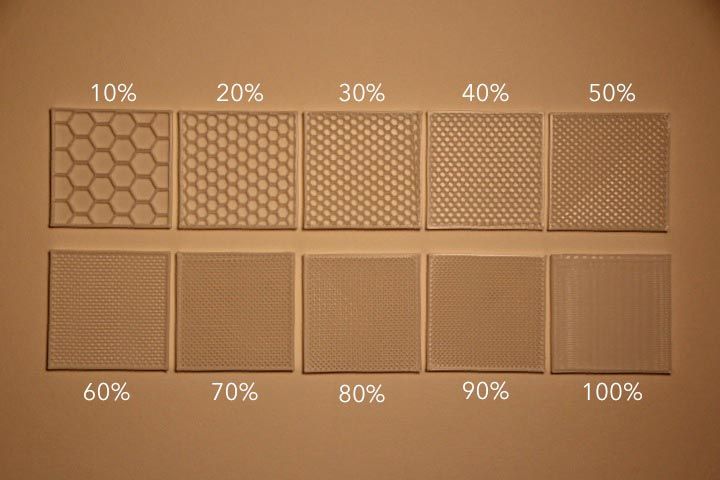

Set infill density to at least 20%

Before you go prodding around your 3D printer’s finer details, take the time to make sure that you are printing your infill at least at 20% density. This is the rule-of-thumb value that balances filament usage and mechanical strength. Anything lower will be quite weak, regardless of how finely tuned your 3D printer is.

This is the rule-of-thumb value that balances filament usage and mechanical strength. Anything lower will be quite weak, regardless of how finely tuned your 3D printer is.

Check for nozzle clogging

Clogging a nozzle with burnt material is something that is bound to happen to any FDM printer. Missing layers and inconsistent extrusion are some of the most apparent signs of a clogged nozzle.

In any case, cleaning your nozzle regularly is considered good practice in 3D printing. The easiest way to do this is via the cold pull method – using a piece of filament to remove any stuck material in the nozzle. There are several other methods to clean a 3D printing nozzle.

Calibrate your extruder

Your hardware is clean and should be extruding seamlessly, but you feel like there still is not enough material being extruded to make your infill stronger. If this is the case, then your extruder might need some calibration. You will need a bit of knowledge in manipulating G-Code to do this, but it really is not that hard.

The point of calibrating an extruder is to ensure that it is extruding the correct length of filament per step of the motor. This naturally drifts within the lifetime of an extruder or stepper motor. Extruder calibration is something that needs to be done regularly for a 3D printer.

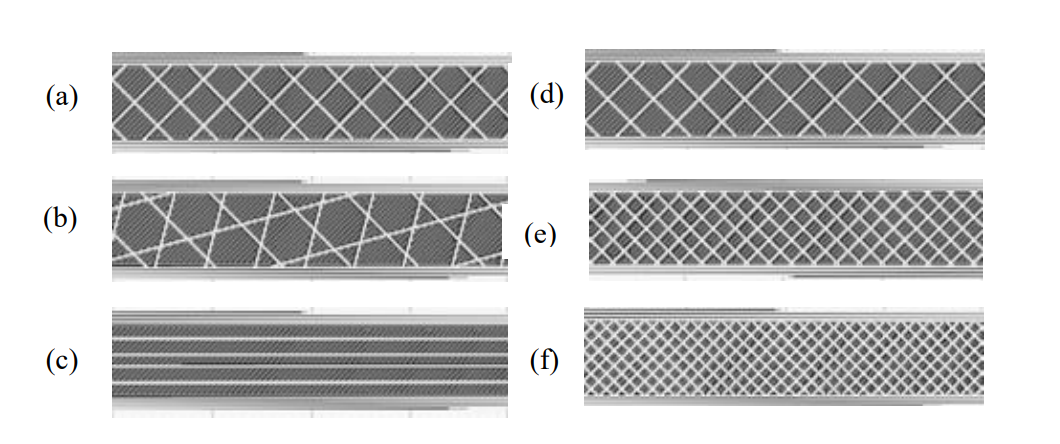

Reduce the print speed

If you are still experiencing extrusion problems, then you may need to play around with your slicer settings. Under-extrusion can also be caused by an excessively high value for printing speed. This can be quite problematic in the infill, as some slicers allow for faster printing speed when printing the infill.

A good rule of thumb is to try and reduce the printing speed by 20% to 30% and check if this improves extrusion performance. If it does not help, then it’s worth exploring other options.

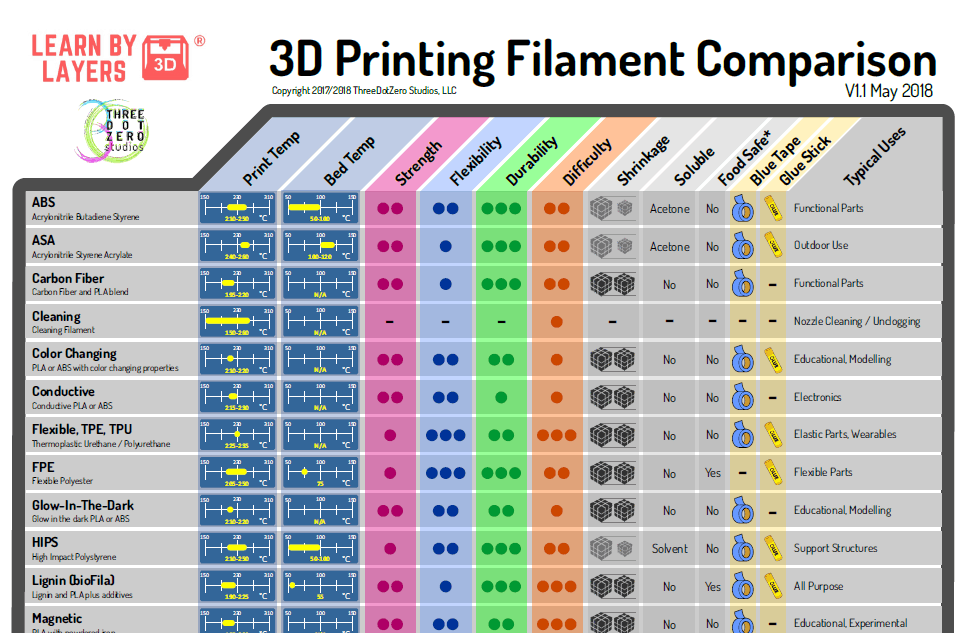

Increase the print temperature

The other half of the extrusion equation is the print temperature. Are you printing at the recommended range for the filament you are using? Do you still have wiggle room to increase that temperature by 5 or 10⁰C? Again, making a small change within the range of the accepted values may be what it takes to fix any extrusion-related issues in your print.

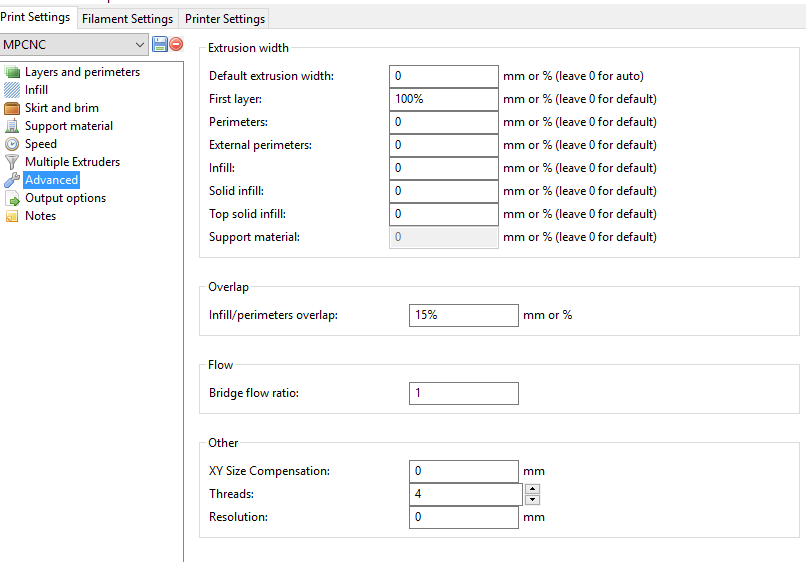

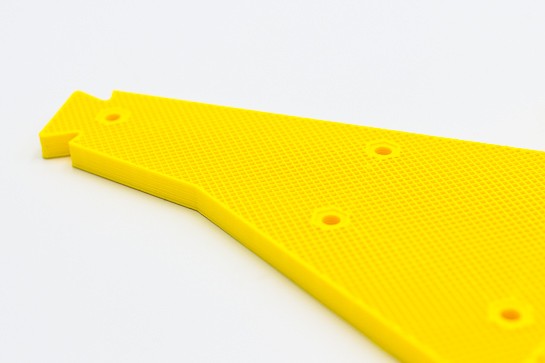

Increase infill line width

Some slicers allow you to modify settings specifically for the infill of any 3D printing project. For instance, the line width for the infill can be increased, which is a certain way to make your 3D print stronger. The tradeoff is that this increases the amount of filament used for the infill, as well as the printing time.

Keep in mind that printing with thicker layers may also mean that you can reduce the infill density, otherwise the whole interior section of your model can get pretty crowded.

Adjust the orientation of the model

Lastly, it may be worth considering changing the orientation of the model as it is printed. The strength of any infill pattern varies significantly between the X-Y axes and the Z-axis. The optimal orientation for your print relies mostly on how you intend it to be used. Orienting the model by 45 degrees from the horizontal plane is considered the default option for making its mechanical strength a little more equal across all directions.

In any case, inconsistent extrusion is something you will need to address early on. This affects not just the infill strength, but also a host of performance and quality parameters of your 3D printing project.

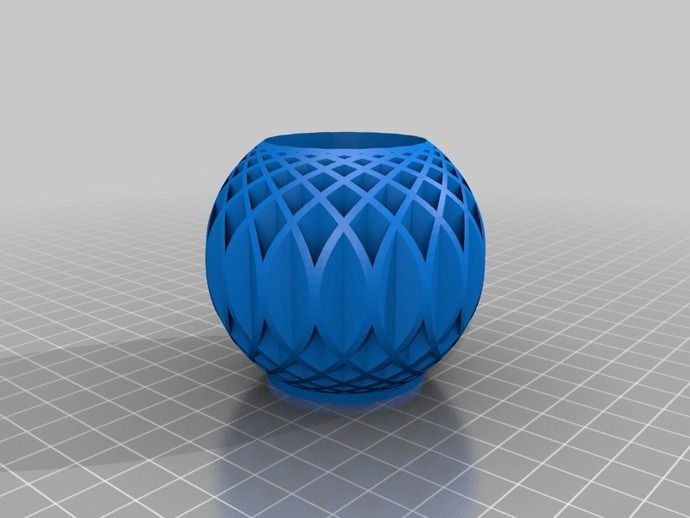

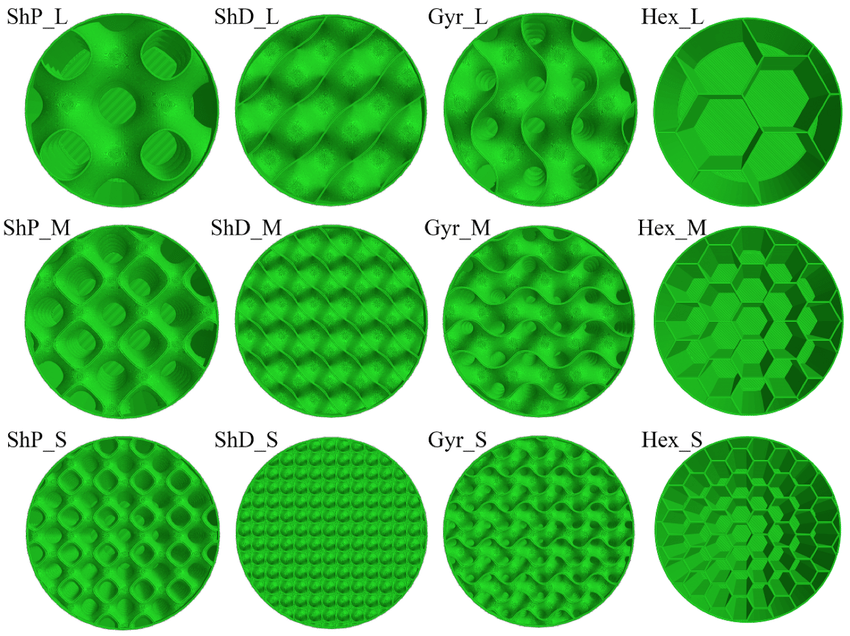

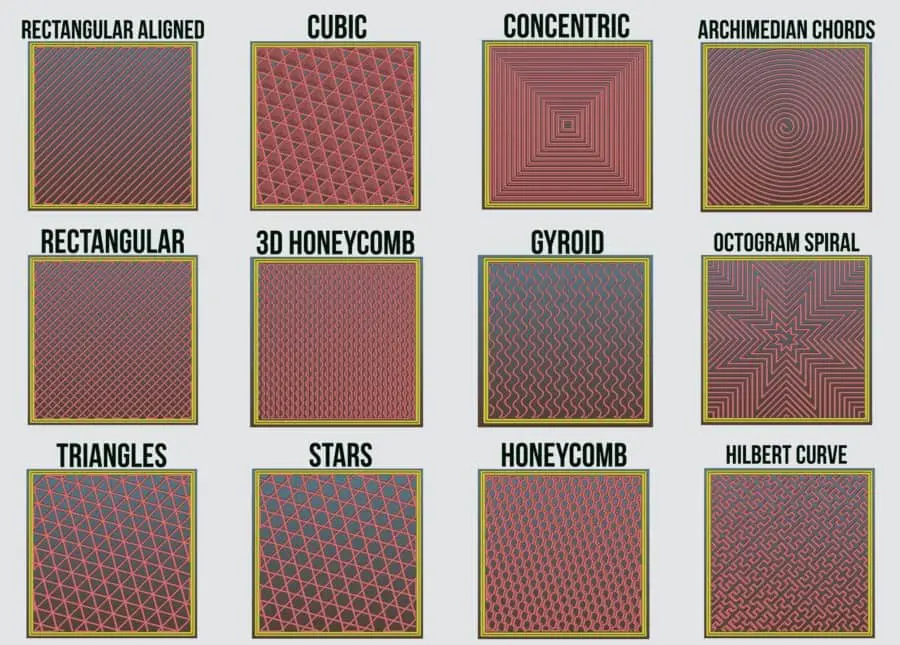

A word on infill patterns

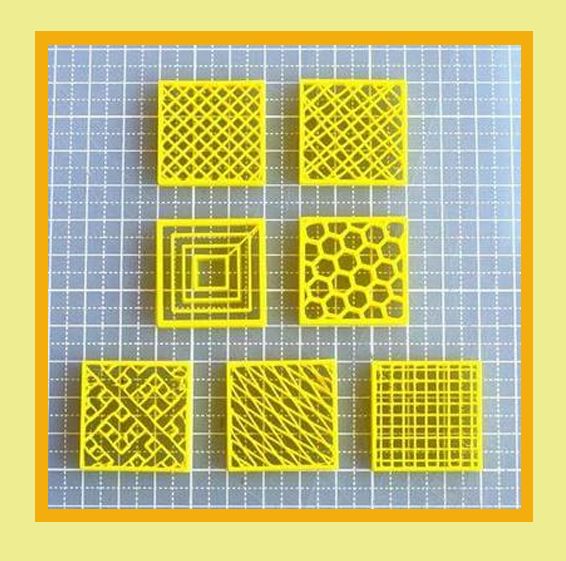

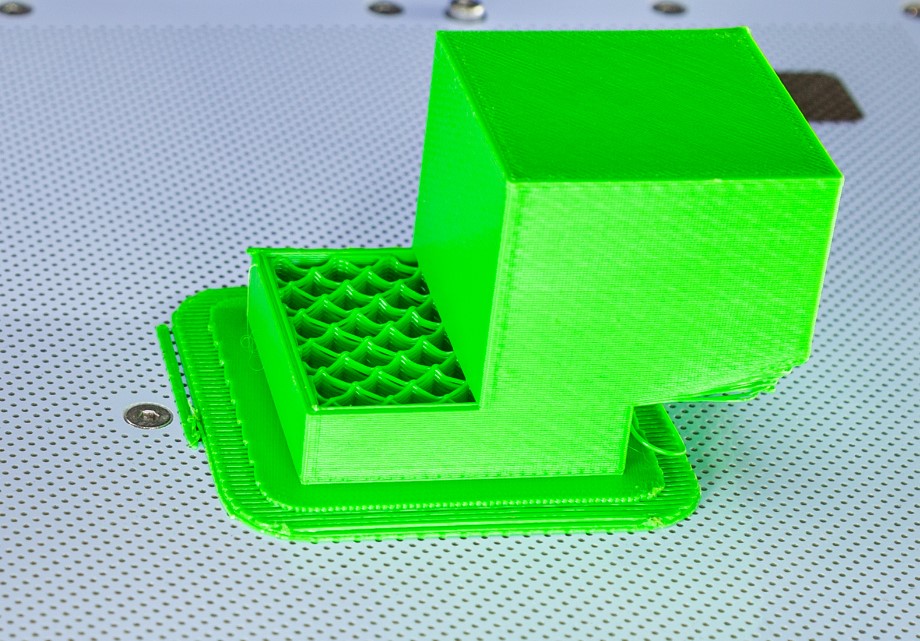

If a weak infill is being caused by 3D printing errors, then you certainly need to check your hardware or do some edits to your slicer settings. However, it is also possible for your infill to be weaker than expected if you’re not using the proper infill pattern.

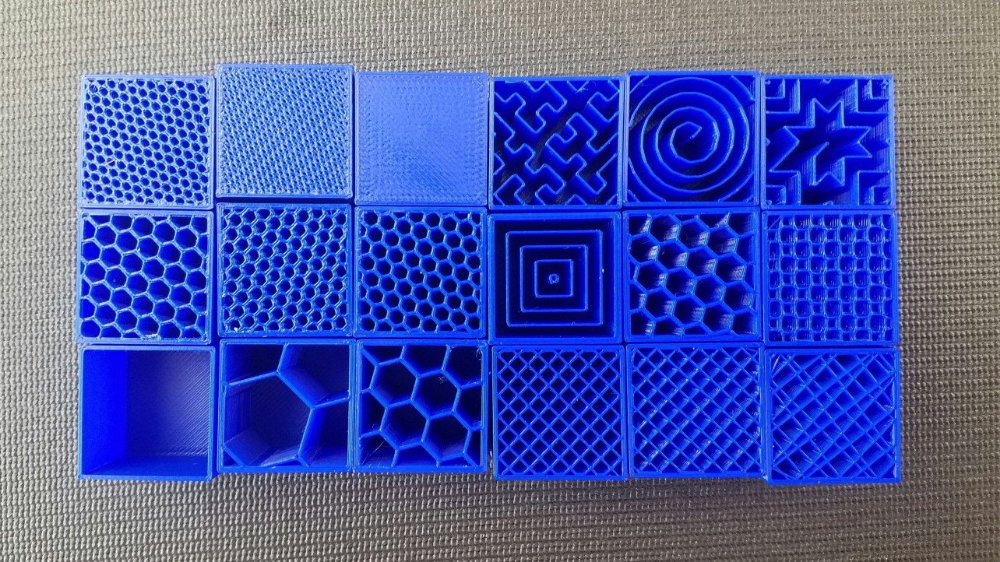

Most slicers have a selection of fairly common infill patterns. Each pattern has benefits for specific use cases, but also some drawbacks. If you’re just going for maximum strength, then a cubic pattern offers excellent mechanical support and rigidity.

Another option is the gyroid infill pattern. This pattern is a bit more complex and will likely take a long time to slice, but it also gives good strength while maintaining some flexibility for the finished print.

Other infill patterns are specialized for different reasons – faster printing, more flexibility, or low filament use. However, ascribing strength to the infill pattern is something you can only do once you have dealt with possible under-extrusion issues.

However, ascribing strength to the infill pattern is something you can only do once you have dealt with possible under-extrusion issues.

Final thoughts

Creating a strong infill is a necessary step in 3D printing, especially if you’re making any object for functional strength. Just like any other part of a 3D-printed object, the infill needs consistent extrusion to be printed properly.

If you have your slicer settings to the right values and you detect no hardware problems, then it is easy enough to strengthen your infill by increasing the infill density, infill layer width, or infill pattern.

Warning; 3D printers should never be left unattended. They can pose a firesafety hazard.

Weak Infill | Simplify3D Software

Weak Infill

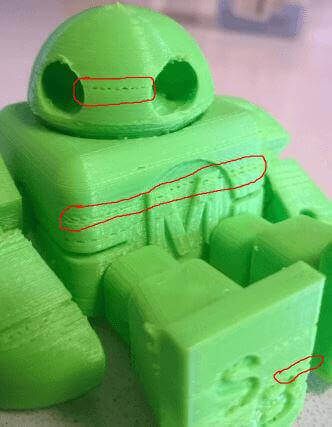

The infill inside your 3D printed part plays a very important role in the overall strength of your model. The infill is responsible for connecting the outer shells of your 3D print, and must also support the upper surfaces that will be printed on top of the infill. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print.

If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print.

Common Solutions

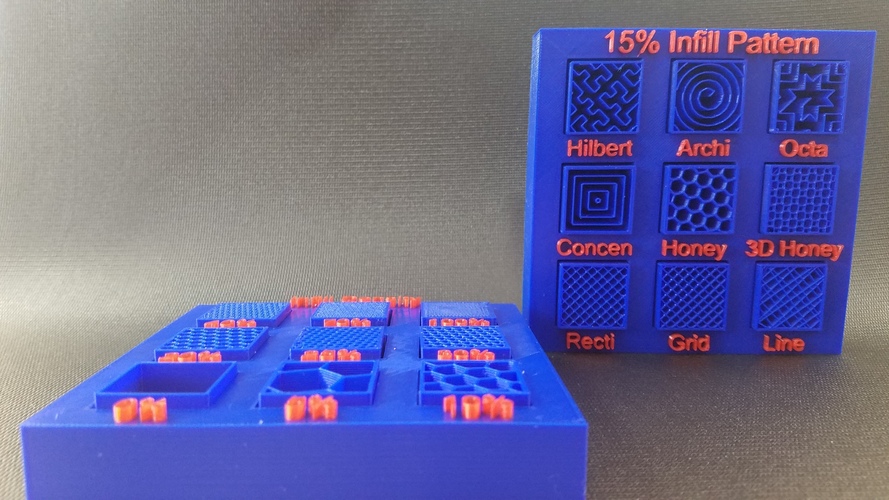

Try alternate infill patterns

One of the first settings you should investigate is the infill pattern that is used for your print. You can find this setting by clicking “Edit Process Settings” and going to the Infill tab. The “Internal Fill Pattern” determines what pattern is used for the interior of your part. Some patterns tend to be more solid than others. For example, Grid, Triangular, and Solid Honeycomb are all strong infill patterns. Other patterns like Rectilinear and Fast Honeycomb may sacrifice some strength for faster printing speeds. If you are having trouble producing strong reliable infill, try a different pattern to see if it makes a difference.

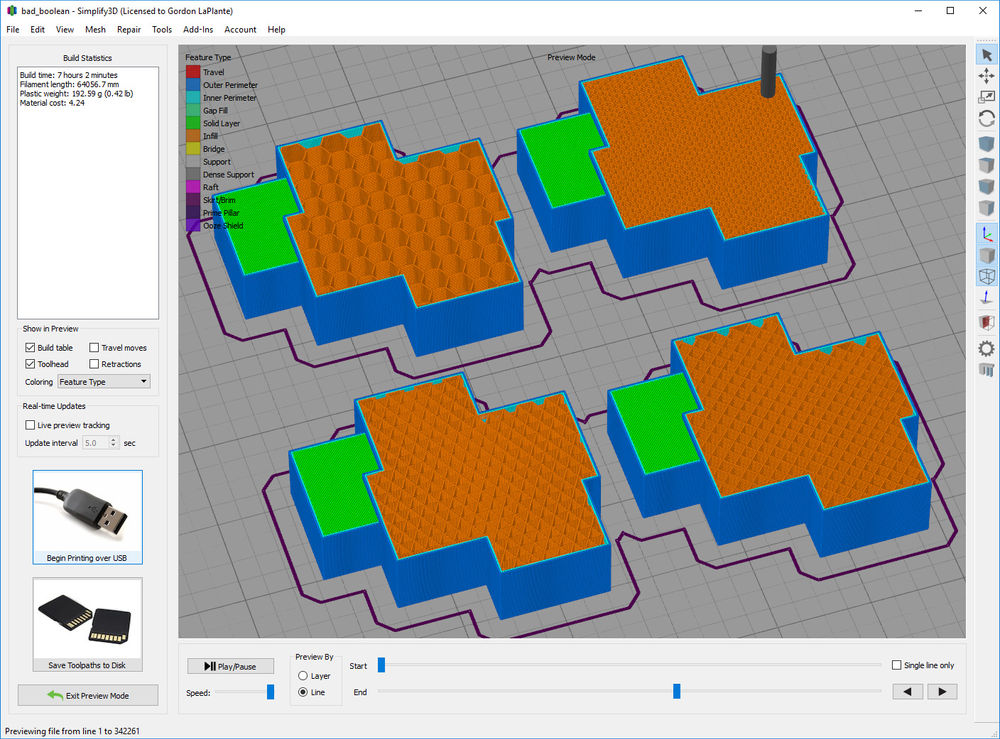

Lower the print speed

The infill is typically printed faster than any other portion of your 3D print. If you try to print the infill too fast, the extruder won’t be able to keep up and you will start to notice under-extrusion on the inside of your part. This under-extrusion will tend to create weak, stringy infill since the nozzle is not able to extrude as much plastic as the software would like. If you have tried several infill patterns, but continue to have problems with weak infill, try reducing the print speed. To do this, click “Edit Process Settings” and select the Speeds tab. Adjust the “Default Printing Speed”, which directly controls the speed that is used for the infill. For example, if you were previously printing at 3600 mm/min (60 mm/s), try decreasing that value by 50% to see if the infill starts to become stronger and more solid.

This under-extrusion will tend to create weak, stringy infill since the nozzle is not able to extrude as much plastic as the software would like. If you have tried several infill patterns, but continue to have problems with weak infill, try reducing the print speed. To do this, click “Edit Process Settings” and select the Speeds tab. Adjust the “Default Printing Speed”, which directly controls the speed that is used for the infill. For example, if you were previously printing at 3600 mm/min (60 mm/s), try decreasing that value by 50% to see if the infill starts to become stronger and more solid.

Increase the infill extrusion width

Another very powerful feature within Simplify3D is the ability to modify the extrusion width that is used for the infill of your part. For example, you could print the outline perimeters with a very fine 0.4mm extrusion width, but transition to a 0.8mm extrusion width for the infill. This will create thicker, stronger infill walls that greatly improve the strength of your 3D printed part. To adjust this setting, click “Edit Process Settings” and select the Infill tab. The “Infill Extrusion Width” is set as a percentage of the normal extrusion width. For example, if you enter a value of 200%, the infill extrusions will be twice as thick as the outline perimeters. One thing to keep in mind when adjusting this setting is that the software must also maintain the infill percentage that you specify. So if you set the infill extrusion width to 200%, the infill will use twice as much plastic for each line. To maintain the same infill percentage, the infill lines must be spaced further apart. For this reason, many users tend to increase their infill percentage after increasing the infill extrusion width.

To adjust this setting, click “Edit Process Settings” and select the Infill tab. The “Infill Extrusion Width” is set as a percentage of the normal extrusion width. For example, if you enter a value of 200%, the infill extrusions will be twice as thick as the outline perimeters. One thing to keep in mind when adjusting this setting is that the software must also maintain the infill percentage that you specify. So if you set the infill extrusion width to 200%, the infill will use twice as much plastic for each line. To maintain the same infill percentage, the infill lines must be spaced further apart. For this reason, many users tend to increase their infill percentage after increasing the infill extrusion width.

Related Topics

Problems, defects, 3D printing errors and solutions

Often during the operation of a 3D printer, problems may arise due to which defects appear on the finished model. Or instead of a neat product, plastic noodles suddenly appear on the table.

In fact, the causes of defects can be conditionally divided into 2 types - these are physical and software.

Physical ones are those that arise due to problems with the mechanics or any other causes that can be eliminated physically. These include problems with printer mechanisms (belt tension, backlash), clogged or deformed nozzle, incorrect table geometry, etc.

Software - these are defects that occur due to incorrect slicer settings or, less often, errors in the printer firmware. For example, incorrectly selected print speed, retract settings, incorrectly selected temperature for plastic, etc.

Very rarely, the problem may lie in the wrong or “flying” printer firmware (although usually the printer simply will not start then), overheating of some boards during printing, etc. These are rather special cases, so we will not consider them.

Model peels off or does not stick to the build plate

This is the most common 3D printing problem. Every 3D printer has had a case when the first layer treacherously rolls, clinging to the extruder, or the most offensive - when it tears off a partially printed model from the table. The first layer must stick tightly otherwise nothing will be printed.

Every 3D printer has had a case when the first layer treacherously rolls, clinging to the extruder, or the most offensive - when it tears off a partially printed model from the table. The first layer must stick tightly otherwise nothing will be printed.

Gap between table and nozzle 9 too large0023

This is the most common reason. You just need to set the correct gap between the table and the nozzle.

Modern printers often use an auto-calibration (auto-leveling) table system or an auxiliary table leveling program. To calibrate such printers, use the instructions. If there is no manual, it can be downloaded from the manufacturer's website.

If you have a simple printer without auto-calibration, a self-assembly or KIT kit, use a probe or a piece of paper folded in half to calibrate. The probe should be slightly pressed against the table by the nozzle. Before calibration, the table and extruder must be heated. Align the table surface over each adjustment screw (there may be 3 or 4) in turn, and only then check the center point.

If you're having trouble getting your table surface perfectly level, try raft printing. Raft is a thick substrate in several layers that is printed under the model. It will help smooth out the slight curvature of the table.

A small cheat sheet to determine the correct gap on the first layer

Plastic with poor adhesion

Some types of plastic, due to various reasons, such as large shrinkage, do not adhere well to the surface of the printing platform. In this case, try using stickers or special 3D adhesives to improve adhesion between the table and the first layer of plastic.

In the early days of 3D printing, there were experiments with different homemade 3D adhesive recipes. ABS diluted in acetone, BF glue, sugar syrup and even beer. Some experiments have been successful. Until now, some enthusiasts use some types of hairspray or glue sticks as 3D glue. But still they are inferior in their properties to industrial 3D adhesives.

Some types of high temperature plastics with a high percentage of shrinkage (ABS, Nylon, etc.) may peel off the table during printing. This is due to uneven cooling and “compression” of the model (the lower layers have already cooled down, but the upper ones have not yet). For such plastics, it is imperative to use a 3D printer with a heated table and a closed case.

Plastic temperature too low

The hotter the plastic is when it exits the nozzle, the better it will adhere to the print bed. It is better to print the first 5-10 layers at a higher temperature (+ 5-10 degrees) and turn off the blower fan.

Wrong first layer settings (speed and thickness)

A thicker layer sticks easier, so the standard first layer is 0.3mm thick. With an increase in print speed, the heating block may simply not have time to heat the plastic to the desired temperature and it will stick to the table worse. Before printing, check the speed and thickness settings of the first layer in the slicer.

A lot depends on how the 3D printer prints the first layer. Try to control the printing of the first layer and only then leave the printer to work alone.

Plastic does not choke from nozzle

The printer has already begun to print, but the print table remains empty. Or part of the model did not print.

Clogged nozzle

In 3D printing, a nozzle is a consumable. The nozzles are clogged or worn out (frequency depends on the type of plastic). The simplest thing is to replace the nozzle. But if there was no spare at hand, you can try to clean the old one. To do this, there is a whole set of thin needles. Or you can heat a clogged nozzle above the melting point of the plastic and “burn out” the blockage. But later it is still better to replace the nozzle.

Low temperature nozzle

You need to increase the temperature of the extruder in the slicer settings or check the thermistor and heating block. Sometimes the thermistor may not read the temperature correctly due to a malfunction or incorrect 3D printer firmware settings.

Sometimes the thermistor may not read the temperature correctly due to a malfunction or incorrect 3D printer firmware settings.

If the problem occurs after replacing the thermistor - contact the manufacturer or read articles about PID tuning.

Empty extruder

As the extruder heats up, plastic begins to ooze out of the nozzle. Because of this, the extruder may start printing half empty. Because of this, part of the first layer is not printed. You can push the plastic manually by simply pushing the bar into the nozzle. Or solve this problem programmatically - in the slicer, add a contour print around the model (one line).

Some manufacturers and 3D enthusiasts add a line print on the edge of the table at the beginning of each GCode. This is done so that there is plastic in the nozzle by the time the model is printed.

Feed mechanism does not push through plastic

The plastic pushes the feed mechanism to the extruder - a motor with a special pulley put on the shaft. If for some reason the plastic is not pushed through (nozzle clogged, extruder temperature low, etc.), then the pulley “gnaws” through the bar. You need to push the plastic bar with your hands or cut off the damaged piece.

If for some reason the plastic is not pushed through (nozzle clogged, extruder temperature low, etc.), then the pulley “gnaws” through the bar. You need to push the plastic bar with your hands or cut off the damaged piece.

Elephant foot

The first layers of the model are wider and protrude beyond the boundaries of the model. This is due to the fact that the upper layers put pressure on the first ones that have not yet cooled down and flatten them.

High table temperature

Due to the too high temperature of the table, the lower layers remain soft for a long time. Try lowering the table temperature. It is better to reduce gradually (in increments of 5 degrees). You can try to turn on the blower when printing the first layers.

Small gap between nozzle and platen

If, when printing the first layer, the nozzle is too close to the table, then excess plastic will be forced out. After a few coats, this will not be as noticeable, but can lead to the effect of an “elephant's foot”.

Plastic re-extrusion

When too much material is squeezed out of the nozzle, the walls of the model are not smooth, but bumpy, with sagging.

The solution is software - in the settings of the slicer, you need to set the material feed rate (fluidity) to a lower value. The average value is 95-98%.

It is worth checking the diameter of the rod. If its size is greater than 1.75, then the plastic will be squeezed out more than necessary.

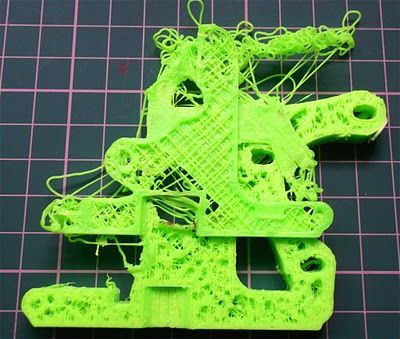

Plastic underextrusion

The plastic is squeezed out too little, because of this, gaps may appear between the layer. The finished model will be fragile and fragile.

Wrong thread diameter

Check the filament diameter in the slicer settings. Sometimes, instead of the popular 1.75, the default is 2.85.

Incorrect feed rate settings

Check the fluidity settings in the slicer. The average should be 95-98%.

Clogged nozzle

Something could get into the nozzle and partially block the exit of the plastic. Visually, the plastic will choke from the nozzle, but in a smaller amount than necessary for printing.

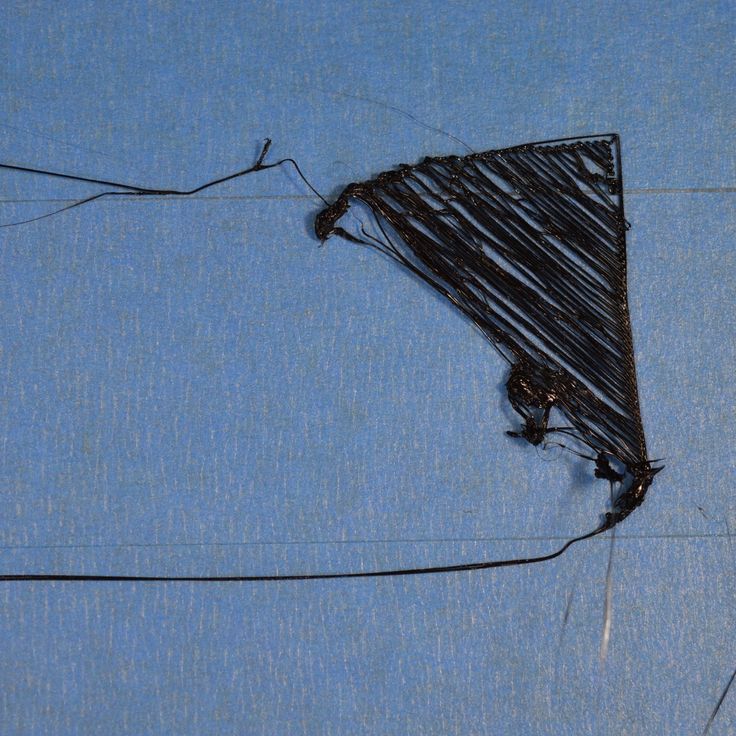

Hairiness or cobwebs on finished model

Thin threads of plastic protrude from the outer wall of the model (most often on one side). The defect appears due to the flow of plastic from the nozzle during idle movement.

Insufficient retract

A retract is a slight pull of a plastic filament from an extruder. Due to the retract when the extruder is idle (from layer to layer or from model to model), heated plastic does not drip from the nozzle. For some flowable plastics (eg PETG) the speed and amount of retraction must be increased.

"Hairiness" can be easily removed by grinding or cutting off the threads with a sharp scalpel.

High temperature extruder

The higher the extruder temperature, the more liquid the plastic becomes. It is important to find a balance so that the plastic is not too liquid and sticks well in layers.

It is important to find a balance so that the plastic is not too liquid and sticks well in layers.

In the selection of the optimal extruder temperature, a test model - a tower - helps a lot. It clearly shows how plastic behaves when printed at different temperatures.

.

Temperature test

Top "perforated" or uneven

The top of the model is bumpy or with holes. The problem may arise if the top of the model is flat. For example, like a cube.

Insufficient airflow

When printing the top plane (cover), the plastic does not have time to cool down and remains too liquid. Because of this, the threads are torn and holes are formed. Increase the fan speed on the last layers.

Few top layers

The top of the print may be too thin and deform as a result. Check slicer settings. The number of upper layers is not recommended to be set less than 6.

Low percentage of filling

If the infill percentage is too low, then the top layer will simply have nothing to rely on. Increase the fill percentage in the slicer settings.

Increase the fill percentage in the slicer settings.

Model deformation

Some parts of the model seem to have melted in some places or on one side. The problem most often occurs when printing with PLA plastic. The defect appears due to the fact that the plastic does not have time to cool and deforms.

Insufficient airflow model

Turn the fans on to maximum. If their power is not enough (in some printers, the fan is located only on one side), you can put a regular desktop fan and direct it to the 3D printer table.

Small model

Small models are difficult to blow well. Try to print small items alongside larger ones, or place several identical models in different corners of the table. So the plastic will have more time to cool.

Layer offset

Layers shift along the x or y axis during printing.

Print head jam

Turn off the printer and try to move the extruder along the x and y axes with your hands. The extruder must move freely. If there are jams, check the mechanics of the printer. Bearing wear or the curvature of the shafts may be to blame.

The extruder must move freely. If there are jams, check the mechanics of the printer. Bearing wear or the curvature of the shafts may be to blame.

Electronics overheating

Sometimes electronics problems can be to blame for misaligned layers. The most common cause is overheating of the drivers or too low current exposed to them.

Table top is loose

This is most often seen in 3D printers with glass. During printing, the nozzle may hit the model and move the glass slightly. Before printing, check if the glass or other printing surface is well fixed on the heating table.

Skip layers

Small holes are visible on the print, or the shell of the model is not continuous.

Teflon tube deformed

There are 2 types of thermal barriers - all-metal and with a Teflon tube. If overheated, the Teflon tube may deform. Plastic will pass through it, but in a smaller amount.

Low extruder temperature or high print speed

If the extruder is not heated enough, then the plastic will not be liquid enough and simply will not have time to be forced through the nozzle. The higher the print speed, the higher the extruder temperature should be.

Sometimes the outer walls print well, but the infill is “torn”. In this case, slow down the infill print speed in the slicer.

Model bundle

Cracks form on the surface of the printout during or after printing. Cracks can be large or very small. Most often, this problem occurs with plastics with a high percentage of shrinkage - ABS or Nylon.

Sudden temperature difference (if model delaminates during printing)

With a sharp temperature difference (for example, a draft), part of the model cools down faster. This leads to uneven shrinkage and incorrect distribution of internal stress. For plastics with low shrinkage, this is not critical. But if the shrinkage percentage is more than a few percent, the model may burst in layers.

But if the shrinkage percentage is more than a few percent, the model may burst in layers.

For printing with such plastics, it is recommended to use a printer with a closed housing. If this is not possible, try to avoid drafts and sudden temperature changes in the room where the 3D printer prints as much as possible.

Print temperature

Due to too low printing temperatures, the layers may not “stick” well to each other. Raise the print temperature in the slicer settings.

Hardening (if the model cracks after printing)

Sometimes cracks appear on the model a few days after printing. This is due to uneven distribution of internal stress after cooling. You can try to “harden” the finished product.

For hardening, the model is placed, for example, in an oven, and heated to the softening temperature of the plastic. After that, the heating is turned off and the oven is left to cool slowly with the model inside. Due to this, the stress inside the print is distributed more evenly. But accuracy is very important in this method - if you make a little mistake with the temperature, the finished product can “float”.

Due to this, the stress inside the print is distributed more evenly. But accuracy is very important in this method - if you make a little mistake with the temperature, the finished product can “float”.

Ringing

In places where the extruder changed direction, ripples are visible. Most often it looks like a shadow around the “sharp” protruding elements of the model.

Mechanical problems

Sometimes the problem occurs due to extruder play. Check if the extruder mount to the rails is loose. Be sure to check the tension of all belts.

High print speed or high accelerations

Moving the extruder too fast can cause vibrations that cause ripples on the wall of the model. The lighter the weight of the extruder, the less noticeable the ripples will be. To get rid of ringing, simply reduce the print speed in the slicer settings.

Slits for thin-walled models (not solid shell)

The thin wall of the model is not solid, but consists of two thin walls with a narrow gap between them. This problem is often faced by fans of printing "cutting" for baking.

This problem is often faced by fans of printing "cutting" for baking.

Left model with wall defect, right without

Wall thickness and nozzle diameter mismatch

If the wall thickness is 1 mm, and the nozzle diameter is 0.4, it turns out that for a solid wall, 2 nozzle passes are few, and 3 are already many. The result will depend on the slicer algorithm, but most often you will get 2 walls with a thin slot in the middle (the slicer cannot change the wall thickness). The solution to the problem may be a slight refinement of the 3D model or the use of a different slicer.

Algorithms for calculating 3D models are constantly being improved and refined, and now this problem is less common.

When modeling, take into account not only the thickness of the nozzle, but also the percentage of “overlapping” of lines on each other. If you have a nozzle with a diameter of 0.4 - make the wall in your model not 0.

8, but 0.7 - 0.75.

Wrong model geometry

When instead of a circle you get an oval, and instead of a square you get a semblance of a rhombus.

The main reason is malfunctions in the mechanics of the printer. Be sure to check:

Belts

Check belt tension in x and y. Belts stretch over time and may need to be tightened or replaced. Each 3D printer has its own way of tightening the belt. If the belts are slightly stretched, you can tighten them with the help of a "spring".

Loose pulleys, etc.

Check if all bolts and nuts are tight. Are there backlashes. Pay special attention to tightening the pulleys located on the motors along the x and y axes.

Sagging of some parts of the model

Some parts are not printed, broken, or instead of a neat surface, a swollen plastic snot is obtained.

No support for overhangs

A 3D printer cannot print in the air, so if there are overhanging elements in the model, you need to set supports - supports. The slicer can set the necessary support itself, you need to check the appropriate box in the settings.

The slicer can set the necessary support itself, you need to check the appropriate box in the settings.

When printing with soluble support, you can set the gap between the model and support - 0. This will make the surface smoother. If the support material and the model are the same, you need to add a small gap. Otherwise, it will be difficult to separate the support from the model.

Split model

Sometimes the supports can take more plastic than the model. In this case, to save material and time, it will be more convenient to cut the model. If you have more than one 3D printer, then the model will print several times faster.

When cutting the model, you can leave grooves or mortgages so that the pieces of the model are connected without displacement.

Totals

In this article, we talked about the most popular 3D printing defects and how to solve them. Don't be intimidated by such a long list. Some problems are rare and you are unlikely to encounter them.

Some problems are rare and you are unlikely to encounter them.

There is a list of problems that arise due to the design features of a 3D printer, so try to choose a printer that suits your needs. To do this, you need to understand what products and what material you need.

Problems associated with printing algorithms are quickly eliminated by software developers.

Do not be afraid of possible difficulties and each print will be successful.

Troubleshooting 3D printing・Cults

This article should help you identify various 3D printing problems. Find the image or description in this list that best describes the problem you're experiencing. We offer some tips that should help you solve this problem.

As you know, 3D printing is an empirical process and it is through mistakes that you learn to understand, set up and use your machine. With the help of this list, you should be able to resolve the major bugs. If you are still experiencing issues or have additional tips to add to this list, feel free to contact us and let us know!

#1 Drooling

Symptom

Thin threads are woven into gaps between different parts of a 3D printed part.

Common Name: oozing

Possible Cause

Plastic continues to leak out of the head as it moves due to residual pressure in the heater and fluidity of the molten plastic.

Suggested remedies

Increase filament retraction length in Slic3r, retraction distance in CuraEngine. Retracting the filament will cause the pressure in the print head heater to drop. The effect can be modulated by adjusting the retraction speed directly in the slicer.

Increase print head speed. This allows the melted plastic to spread less time and leave marks between the printed parts.

Reduce the extrusion temperature of your plastic. If it is too high, the plastic becomes more fluid and flows out of the extruder faster.

#2 It is collapsing

Symptom

Collapse or poor quality of the overhanging surface, leaving small bumps.

Common name: overhang

Possible cause

The plastic deposited on the periphery of the protrusion does not solidify fast enough, so the deposited filament moves before it solidifies. The phenomenon is repeated or emphasized from one layer to another.

The phenomenon is repeated or emphasized from one layer to another.

Suggested fixes

Vent the deposited plastic more efficiently, for example by adding a fan to the extruder or directly with a portable fan.

Create print supports under the overhangs.

Reorient the part to avoid overhangs.

#3 Flaky sides or top

Symptoms

Contours not bonded enough.

Flat surfaces are not completely covered.

Possible cause

Not enough material is deposited. Too narrow, the deposited wires do not touch each other enough and therefore do not stick to the adjacent wire.

There is dirt in the nozzle, which prevents the passage of the melt.

The extrusion temperature is too low, the wire dries out too quickly or shrinks and therefore does not stick to the adjacent wire.

Suggested Tools

Calibrating the extruder to obtain material flow according to data received from the slicer.

Unlock the extrusion nozzle.

Increase extrusion temperature.

Increase the blending speed in your slicer.

#4 Not enough material on thin parts

Symptom

The edges of a very thin area are not strong enough, not enough material.

Possible cause

Recycling or reworking is not effective enough.

Incorrect filament solidification.

Slippage of the thread drive during retraction.

Suggested remedies

Reduce the retraction speed and length while printing.

Increase "extra leg length when retracting" when using Slic3r.

Increase the spring pressure on the driven gear.

#5 Blisters

Symptom

Blisters, mismatched geometry, such as small bumps that are seen mostly in areas with a small surface area.

Possible cause

The filament is too hot during extrusion or the filament cooling system is not effective enough.

Suggested media

Place more parts on the plate while printing. In this case, the nozzle will print more objects and therefore allow more time for the part to cool before passing over it again.

Improve the cooling of your 3D printed object by adding cooling systems.

#6 Thin walls delaminate

Symptom

At a thin wall without filler, the threads diverge, they are not glued together on the sides.

Possible Cause

The walls of your 3D print are too thin or they don't fit so small.

Suggested tools

Draw thicker walls to adapt to the thread thickness.

In the slicer settings, set a sludge width that is a sub-multiple of the wall width while remaining consistent with the extrusion diameter and layer height.

Change slicer.

#7 Layer shifts horizontally

Symptom

The layer is shifting in the X or Y axis (or both).

Possible Cause

Print head or plate movement problem.

Suggested fix

Reduce the acceleration on the axis that has the problem.

#8 Layers shift evenly

Symptom

Layers almost always shift along the X and/or Y axis after a certain print height.

Possible Cause

Head or plate offset failure due to overheating of motors going into safe mode.

Suggested fix

Cool engines with cooling systems (fans).

#9 Corners curl up

Symptom

Deformation in Z direction during 3D printing. This figure increases in case of a strong overhang.

Common name: curling

Possible cause

Poor curing, shrinkage effect due to temperature difference of the wire deposited on the previous cooled layer.

Suggested Solutions

Increase slope in the 3D part to reduce overhang.

Further cooling of the deposited plastic using a ventilation system.

Add print supports to affected areas.

#10 Corners fall off

Symptom

The corners of the printed object are peeling off the plate, creating an uneven base.

Common name: warping

Possible cause

Poor fit between workpiece and insert.

Material shrinkage factor too high.

The first layer is not pressed enough against the board.

Suggested Solutions

Change media as PLA is less likely to warp.

Apply adhesive to the printing plate (glue, tape, varnish, etc.).

Correctly adjust the plate height before printing.

Apply a thinner first layer to further crush the deposited wire.

Add a bezel under the first layer.

Heat up the stove.

Clean and degrease the base.

Change the filling strategy. Fill the bottom concentrically instead of linearly, then fill the inside in a honeycomb pattern to avoid any shrinkage effect.

Reduce the internal fill density of your 3D printed object.

#11 Extrusion density too low

Symptom

Incorrect material density.

Possible cause

Material consumption too low

Suggested remedies

Unlock the extrusion nozzle.

Filament blocked upstream of extruder (e.g. spool assembly)

Check thread drive (e.g. knurled screw problem)

Corners #12 not forming correctly

Symptom

The corners are not straight enough, they can even stick out and increase the size of the part.

Possible Cause

Too much material is deposited in the corner because the nozzle slows too much as it passes through the corner.

Suggested remedies

Intentionally soften the corner of the part in the 3D modeling software.

Increase the "jerk" on your 3D printer's axis control.

#13 There are black drops

Symptom

Burnt (blackened) plastic in some areas of the printed object.

Possible Cause

Poor nozzle seal causing burnt PLA or ABS to drip around the nozzle.

Suggested fix

Remove the nozzle and close it again.

#14 Layers poorly welded

Symptom

Part breaks at attachment point between two printed layers.

Possible cause

Too much cooling, the deposited layer does not adhere well to the previous layer, because it was not hot enough during the deposition.

Suggested remedies

Reduce fan speed during printing.

Increase the minimum print speed in the slicer.

#15 Bubbles form on the first layer

Symptom

The first layer comes off the plate locally in the form of bubbles.

Possible Causes

Moisture present in the material which gradually evaporates upon contact with the heating plate.

Insufficient heating plate temperature for the material being used.

Suggested products

Store raw material rolls in a dry place, in closed packaging, with a desiccant bag.

Dry damaged material: place in a rotary oven at 40°C for approximately 3 hours. Be careful not to heat above 45°C or 50°C as this may cause the threads to stick together in the bobbin and even lose their cylindrical shape.

Increase the temperature of the heating plate.

Printing on tape or special adhesive.

#16 Fragile top and bottom

Symptom

Horizontal sides too thin and brittle.

Possible Causes

Insufficient material thickness above and below thin fill print. The laid threads have too few support points and break between the threading ribs.

Suggested products

Place at least 2 or 3 fully filled layers ("Solid layers" option in Slic3r) for the "top" and "bottom" faces.

Increase the fill of your object.

#17 Hole tops collapse

Symptom

Horizontal center hole top wires collapse during construction.

Possible causes

Plumb line too horizontal.

Mismatch between nozzle temperature, wire cooling and speed.

Suggested fixes

Reduce or eliminate this overhang area by modifying the 3D file geometry. An example is in the large hole in the photo, shaped like a drop of water, not a cylinder.

Add print supports below this area if the ledge is too difficult for the 3D printer.

Avoid too much slowdown in this area, even if the layer print time is short.

#18 Color or clarity varies

Symptom

The color or transparency of the material changes in different areas during 3D printing.

Possible causes

Different crystallization of the material due to different cooling rates. This may be due, for example, to the printing time of individual parts of the object or to the power of the fan.

Radiation from the nozzle can affect the thermal cycle of the previous layer and thereby change its appearance.

The applied layer is too hot because the underlying layer has not had time to cool.

Be careful, the physical-mechanical properties of the part may change due to these differences in crystallization!

Suggested fixes

Better control of cooling with slicer settings: change fan power based on plate cooling time or slow print speed in proportion to plate surface.

Reduce extrusion temperature for faster and more uniform phase transition.

#19 Layers are delaminating

Symptom

Some layers are flexing and cracks appear between the different printed layers.

Possible causes

Twisting phenomenon due to the effect mentioned in #9 the above happens between layers.

The wire cools too quickly at the exit of the nozzle, it does not weld properly with the previous layer.

Severe contraction of the material during cooling or phase change.

Some materials extruded at high temperature (ABS, PC...) may present a significant shrinkage phenomenon.

Suggested remedies

Change the extrusion temperature.

Change the media.

Avoid blowing on a deferred wire, reducing fan power, or placing the printer in a draughty room.

Close the assembly area in a controlled cabinet at a temperature close to the glass transition temperature of the material.

#20 Drops appear

Symptom

Drops of material are deposited at various points on the side surface of the 3D printed object.

Possible causes

Excessive extrusion when resuming extrusion after stopping extrusion when moving from one point of the part to another or when changing layers.

Suggested Remedies

Some slicers have a setting that allows, after a pause in printing, to request that more be pushed in before resuming normal printing than was removed by retraction.

#21 Bowden extruder salivation

Symptom

Extruder Bowden is either running too hard or not running enough. First impressions of your extruder are not great, too much extruded material, bridges between different areas in motion where extrusion should stop.

Possible cause

Insufficient thread shrinkage to compensate for gap in Bowden tube. Depending on the diameter of the tube and filament, as well as the length of the body, the motor must draw a certain length of filament through the bends of the tube before the filament is drawn out of the heating head.

Suggested fixes

Increase the "pull" distance in the slicer. The detail on the left was printed with 1.5 mm of indentation, which was clearly not enough. When the pull-in distance was increased to 6mm, the center part was printed. Too much shrinkage causes hot material to enter the thermal break, the temperature of the thermal break gradually rises, and the melting thread eventually gets stuck in the thermal break. The engine is no longer able to effectively push it. Reducing the retraction distance to 4 mm results in the part shown on the right.

#22 Streaks or regular patterns on extrusion

Symptom

Repeating patterns appear on the walls of 3D prints.

The pattern may change depending on the direction of movement of the motors.