Raze 3d printer

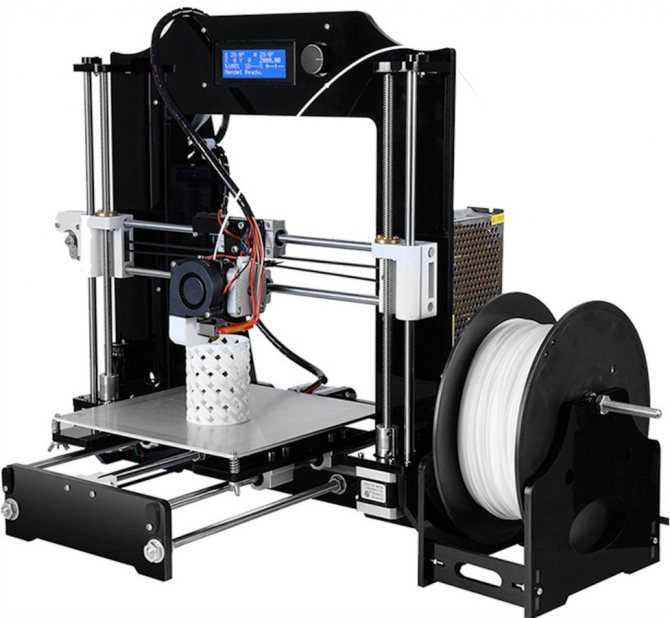

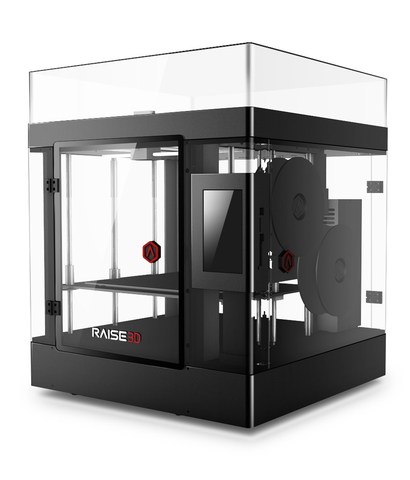

Reliable, Affordable, Industrial 3D Printer Solution

Reliable, Affordable, Industrial 3D Printer Solution | Raise3DSearch for:

Raise3D products offer a range of solutions for Flexible Manufacturing.

Learn More

Don’t miss the opportunity to see our products in real life and find out what our team of 3D printing experts can do for you.

See when and where Raise3D solutions will be showcased this year.

Raise3D Events in 2023

Discover Raise3D’s industrial 3D printers for manufacturing with composite and metal materials, including the RMF500, a reliable, precise, and flexible 3D printer that produces high-performance end-use parts with repeatability; and the MetalFuse, a complete solution consisting of an indirect metal 3D printing process.

RMF500 MetalFuse

Professional 3D Printers

Discover Raise3D’s professional segment with the Pro3 Series, Raise3D’s latest line of professional dual extruder 3D printers; the E2, a desktop 3D printer with independent dual extruders; and the E2CF, an IDEX 3D printer optimized for 3D printing carbon fiber-reinforced filaments.

Pro3 Series E2CF E2 Pro2 Series

Software SolutionRaise3D provides software solutions for a seamless production workflow.

ideaMaker

RaiseCloud

ideaMaker Library

Materials

Raise3D premium and industrial filaments, and other compatible filaments and their manufacturers are available here.

Filaments Open Filament Program

Solutions

Find out more about the solutions Raise3D offers and see how Raise3D production workflow has helped many enterprises like yours.

Manufacturing & Engineering

Manufacturing & Engineering

Explore Raise3D 3D printing industry solutions in manufacturing and engineering.

Design, Education & Consultancy

Design, Education & Consultancy

Explore Raise3D 3D printing industry solutions in design, education and consultancy.

Medical

Medical

Explore Raise3D 3D printing industry solutions in medical field.

What Makes a Raise3D Printer Great?

At Raise3D, we set out to build an industrial 3D printer that is durable enough to withstand the rigors of industrial environments, reliable enough to run 24/7 and able to repeat the process of manufacturing finished parts with precise replication.

As a customer-driven company, our products are created with input from a diverse field of professionals on the cutting edge of design, engineering and manufacturing. The result is a 3D printer ready to integrate print factories and build customized parts on demand.

Discover the Pro3 Series from Raise3D!

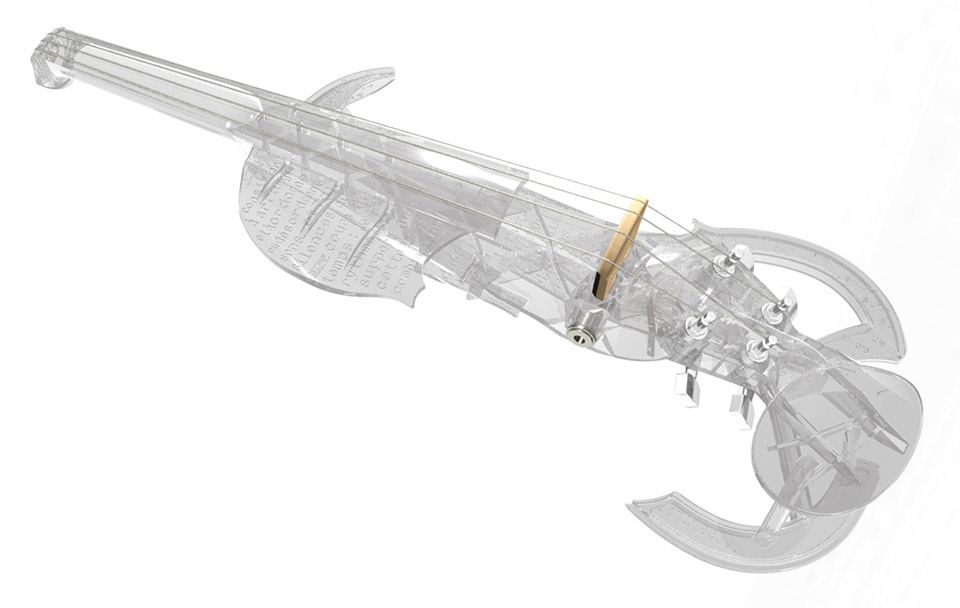

We invite you to spend some time on our website to explore all the possibilities that a Raise3D printer can deliver. You may find the case study section of particular interest, from education and the arts to engineering feats and medical device breakthroughs. A few short years ago, these applications were all but impossible to cost-effectively manufacture.

A few short years ago, these applications were all but impossible to cost-effectively manufacture.

Contact us with confidence; our staff is here to answer all your questions about owning an industrial 3D printer, understand your 3D printing needs, and offer the right solution. It’s your turn to build something extraordinary! Contact us today.

Recent Updates

Nov 10, 2022

Additive Productivity: a new era in FFF professional 3D Printing is born

Additive Productivity: a new era in FFF professional 3D Printing is born

Learn More

Feb 17, 2023

Raise3D Announces ideaMaker 4.3.2 Version

Raise3D Announces ideaMaker 4.3.2 Version

Learn More

Oct 26, 2022

Raise3D Announces Its Go Green Initiative

Raise3D Announces Its Go Green Initiative

Learn More

Oct 26, 2022

Raise3D E2CF review: a compact carbon-fiber low-volume production 3D printer for under 4k€?

Raise3D E2CF review: a compact carbon-fiber low-volume production 3D printer for under 4k€?

Learn More

Oct 28, 2021

Raise3D Launches MetalFuse, a 3D Printing Full in-house Solution

Raise3D Launches MetalFuse, a 3D Printing Full in-house Solution.

Learn More

Nov 15, 2021

Raise3D Announces the RMF500, a Large Format FFF 3D Printer

Raise3D Announces the RMF500, a Large Format FFF 3D Printer.

Learn More

3D Printer | Raise3D: Reliable, Industrial Grade 3D Printer

3D Printer | Raise3D: Reliable, Industrial Grade 3D PrinterSearch for:

Raise3D proudly presents the Pro3 Series, E2CF, E2, and Pro2 Series professional 3D printers, along with RMF500 industrial 3D printers and MetalFuse System for metal 3D printing. All 3D printers come with free slicing software, a free cloud platform, and great tech support, and are capable of printing a variety of filaments.

Raise3D professional 3D printers are high quality, easy to use, and affordable for both office and manufacturing use.

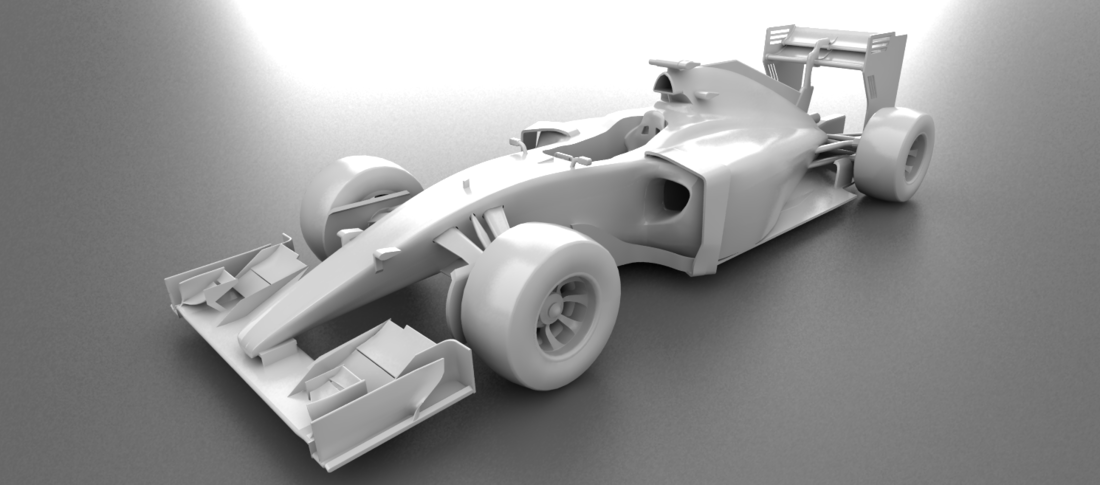

Raise3D industrial 3D printers deliver high productivity and repeatability to manufacturing applications including automotive and aerospace.

For all sizes of companies, Raise3D offers the most cost-effective solution in manufacturing from jigs & fixtures, 3D printed tools, quick prototyping, mass customization, and spare parts.

Industrial FFF 3D Printers

Professional FFF 3D Printers

RMF500

Flexible Manufacturing Productivity for Composite End-Use-Part Based on FFF ProcessThe RMF500 is a reliable, precise, and flexible 3D printer that produces high-performance end-use parts with repeatability, making it an excellent option for small batch manufacturing, as well as for other applications.

Learn More

MetalFuse Cost-effective Metal Printing Made PossibleMetalfuse offers a complete solution, consisting of an indirect metal 3D printing process, paired with a special edition of ideaMaker compatible with MIM equipment. With this solution, Metalfuse’s advantages include low overhead costs and the ability to perform batch production. Metalfuse saves more energy and is more environmentally friendly when compared to processes such as CNC and SLM (Selective Laser Melting).

With this solution, Metalfuse’s advantages include low overhead costs and the ability to perform batch production. Metalfuse saves more energy and is more environmentally friendly when compared to processes such as CNC and SLM (Selective Laser Melting).

Learn More

Pro3 –

Agile Production Made Simple Professional Dual Extruder 3D printerA professional dual extruder 3D printer with user-friendly features for a better 3D printing experience and a larger build volume, making it an excellent option for production and multi-sized rapid prototyping.

Starting at $5,599.00

Buy Now Learn More

Pro3 Plus –

Agile Production Made Simple Professional Dual Extruder 3D Printer for Large PrintingA professional dual extruder 3D printer with user-friendly features for an easier 3D printing experience, and a large build volume making it well suited for large-scale production and multi-sized rapid prototyping.

Starting at $7,599.00

Buy Now Learn More

E2CF –

Carbon Fiber Printing Made Simple IDEX 3D Printer for Carbon Fiber PrintingAn IDEX 3D printer optimized for carbon fiber-reinforced filaments making the printer well suited for applications requiring parts with a high strength-to-weight ratio.

Starting at $4,499.00

Buy Now Learn More

E2 –

Precise, Reliable, Affordable Desktop 3D Printer with Dual ExtrudersAdvanced 3D printing capabilities for desktop engineering, schools, and small batch manufacturing.

Starting at $3,499.00

Buy Now Learn More

Pro2 –

Fully Enclosed, Industrial Grade Workhorse Dual Extruder 3D Printer with High ResolutionPrint complex parts, support a variety of filaments and improve print speed. Recognized as the benchmark and gold standard for serious 3D printing applications and 24/7 reliability.

Starting at $3,999.00

Buy Now Learn More

Pro2 Plus –

Fully Enclosed, Dual Extrusion, and More Large Format 3D Printer with a Large Build VolumeWhen big jobs call for big parts, professionals choose the award-winning Pro2 Plus. With high-resolution printing capabilities, the Pro2 Plus was manufactured to produce final-product printing quality.

Starting at $5,999.00 Starting at $4,999.00Buy Now Learn More

Pro3 Pro3 Plus E2CF E2 Pro2 Pro2 Plus

Pro3 Pro3 Plus E2CF E2 Pro2 Pro2 Plus

Pro3 Pro3 Plus E2CF E2 Pro2 Pro2 Plus

Pro3

Starting at $5,599. 00

Build Volume (W × D × H)

Single Extruder Print

11.8 × 11.8 × 11.8 in/ 300 × 300 × 300 mm

Dual Extruder Print

10 × 11.8 × 11.8 in/ 255 × 300 × 300 mm

Print Head System

Dual-head with electronic lifting system

Build Plate Leveling

Mesh-leveling with Flatness Detection

Supported Materials

PLA/ ABS/ HIPS/ PC/ TPU/ TPE/ PETG/ ASA/ PP/ PVA/ Nylon/ Glass Fiber Infused/ Carbon Fiber Infused/ Metal Fill/ Wood Fill

Connectivity

Wi-Fi, LAN, USB port, Live camera

Filter

HEPA filter with activated charcoal

Power Loss Recovery

Available

Pro3 Plus

Starting at $7,599.00

Build Volume (W × D × H)

Single Extruder Print

11.8 × 11.8 × 23.8 in/ 300 × 300 × 605 mm

Dual Extruder Print

10 × 11. 8 × 23.8 in/ 255 × 300 × 605 mm

Print Head System

Dual-head with electronic lifting system

Build Plate Leveling

Mesh-leveling with Flatness Detection

Supported Materials

PLA/ ABS/ HIPS/ PC/ TPU/ TPE/ PETG/ ASA/ PP/ PVA/ Nylon/ Glass Fiber Infused/ Carbon Fiber Infused/ Metal Fill/ Wood Fill

Connectivity

Wi-Fi, LAN, USB port, Live camera

Filter

HEPA filter with activated charcoal

Power Loss Recovery

Available

E2CF

Starting at $4,449.00

Build Volume (W × D × H)

Single Extruder Print

13 × 9.4 × 9.4 inch/ 330 × 240 × 240 mm

Dual Extruder Print

11.6 × 9.4 × 9.4 inch/ 295 × 240 × 240 mm

Print Head System

IDEX Independent Dual Extruders

Build Plate Leveling

Mesh-leveling with Flatness Detection

Supported Materials

PA12 CF, PA12 CF Support (PPA CF, PPS CF and PET CF Coming soon)

Connectivity

Wi-Fi, LAN, USB port, Live camera

Filter

HEPA filter with activated charcoal

Power Loss Recovery

Available

E2

Starting at $3,499. 00

00

Build Volume(WxDxH)

Single Extrusion Print

13 × 9.4 × 9.4 inch/ 330 × 240 × 240 mm

Dual Extrusion Print

11.6 × 9.4 × 9.4 inch/ 295 × 240 × 240 mm

Print Head System

IDEX Independent Dual Extruders

Build Plate Leveling

Mesh-leveling with Flatness Detection

Supported Materials

PLA/ ABS/ HIPS/ PC/ TPU/ TPE/ PETG/ ASA/ PP/ PVA/ Nylon/ Glass Fiber Infused/ Carbon Fiber Infused/ Metal Fill/ Wood Fill

Connectivity

Wi-Fi, LAN, USB port, Live camera

Filter

HEPA filter with activated charcoal

Power Loss Recovery

Available

Pro2

Starting at $3,999.00

Build Volume(WxDxH)

Single Extrusion Print

12 × 12 × 11.8 inch/ 305 × 305 × 300 mm

Dual Extrusion Print

11 × 12 × 11. 8 inch/ 280 × 305 × 300 mm

8 inch/ 280 × 305 × 300 mm

Print Head System

Dual-head with electronic lifting system

Build Plate Leveling

Pre-callbrated leveling

Supported Materials

PLA/ ABS/ HIPS/ PC/ TPU/ TPE/ PETG/ ASA/ PP/ PVA/ Nylon/ Glass Fiber Infused/ Carbon Fiber Infused/ Metal Fill/ Wood Fill

Connectivity

Wi-Fi, LAN, USB port, Live camera

Filter

HEPA filter with activated charcoal

Power Loss Recovery

Available

Pro2 Plus

Starting at $5,999.00

Build Volume(WxDxH)

Single Extrusion Print

12 × 12 × 23.8 inch/ 305 × 305 × 605 mm

Dual Extrusion Print

11 × 12 × 23.8 inch/ 280 × 305 × 605 mm

Print Head System

Dual-head with electronic lifting system

Build Plate Leveling

Pre-callbrated leveling

Supported Materials

PLA/ ABS/ HIPS/ PC/ TPU/ TPE/ PETG/ ASA/ PP/ PVA/ Nylon/ Glass Fiber Infused/ Carbon Fiber Infused/ Metal Fill/ Wood Fill

Connectivity

Wi-Fi, LAN, USB port, Live camera

Filter

HEPA filter with activated charcoal

Power Loss Recovery

Available

Filaments/ Spare Parts/ Certified 3rd Party Products

How do I remove the 3D printing media?・Cults

3D printing support is required to successfully design your 3D printed part. Once the 3D printing is complete, these support structures must be removed from the printed model. Cults shows you how.

There are various methods for removing supports for 3D printing. To get a quality printed part without debris, learn here about methods for removing unwanted 3D printing supports.

Manual removal of 3D printing support structures

This is the easiest technique to remove support material that is damaging your 3D printed model. All you need to process the printed parts is your hands and small sharp tools. To do this, you need to go through several stages.

Plate Removal

Using a cutter or thin blade, carefully remove the plate seal from your printed model .

Media Removal

Removing the print layer makes it easier to remove the support material from the 3D print. However, you should be careful not to damage the 3D printed part, because without the printed layer, it becomes more brittle. The best way to do this is to cut the support structures at various points of contact. The cutting pliers that come with your 3D printer are essential for this operation.

Elimination of deficiencies

Now you have your part, but with fragments of supporting structures and imperfections. To get better access to certain parts, use your cutter or other small sharp tool and remove any remnants of printed paper.

Sanding

After removing excess printed material from the printed part, you should already be able to see its shape, but it still looks rough. To bring the printed model to perfection, it must be polished. To do this, you can use ordinary files or sandpaper. If you chose the latter, use sandpaper 9 first0005 low grit (150). Then, if necessary, continue with a finer grit sandpaper.

Whichever tool you use, sand the printed part in small sections. After filing, part of your printed model becomes more brittle.

Finishing part

Dust may remain on the printed object after sanding. To remove it use a soft cloth or microfiber cloth . You can also clean the dust layer with mineral oil. The advantage of this technique is that it instantly adds shine to the print. However, be careful not to use too much mineral oil. A few drops are more than enough.

Always have a photo or image of your 3D printed model handy. This will prevent you from cutting the printed part. Use a small knife or a heated blade to make cutting easier, especially if the material is a bit hard. 9The 0005 Dremel and the hand sander can be useful if the backing material is resistant to the sharp object you are using.

It is important to be careful when doing this, as you may break some of the staples with your fingers.

Other methods are also effective for removing the 3D print support from your printed object. However, they are more complex and require the use of special products and equipment.

Acetone vapor smoothing for finishing your 3D model

This post-processing method is for small parts made of ABS filament and FDM . It is mainly used to improve the 3D printed model. During the vapor smoothing process, your 3D printed part will be exposed to acetone vapor in an enclosed area. The fumes will melt the remaining supporting structure and layer lines. After removing the backing material, the acetone vapor polishes and smoothes the surface of the printed model's outer layer, giving it a glossy appearance.

In practice, you will need acetone, a glass or metal container and a lid. A piece of wood or a block of rigid cardboard wrapped in aluminum foil will also come in handy to support the printed product, as well as a hot plate from a printer (any other hot plate will do).

Proceed as follows:

- Pour a few millimeters of acetone into the container.

- Place the container on the hot plate of the printer and wait for the acetone to boil.

- Place the holder at the bottom of the container if the acetone does not reach the part where you will place the 3D printed object.

- Place the 3D printed part on the holder and close the container.

- Let the acetone vapor work. The smoothing time depends on the size of the part (for a small part with a surface area of 3 cm, for example, it may take 3 to 4 minutes).

- Remove the workpiece from the container as it is still soft at this stage.

3D printed part should be allowed to air dry for at least 2 hours .

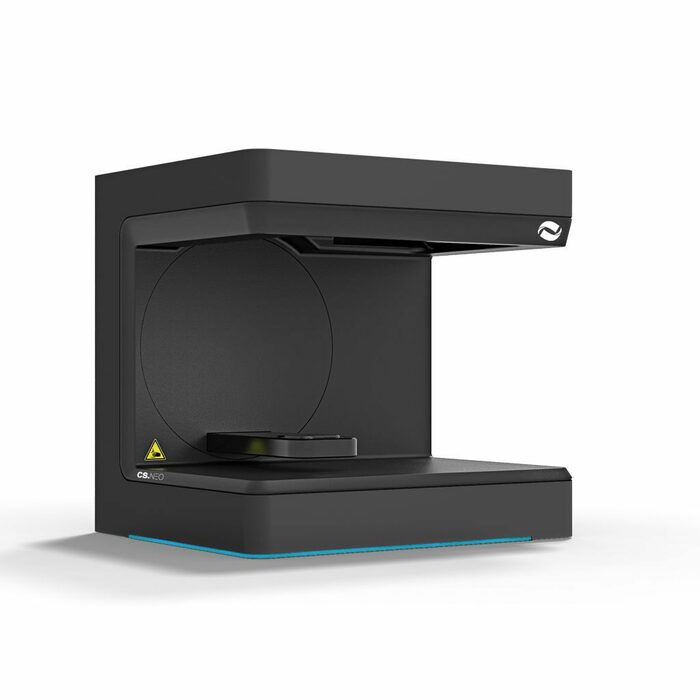

Using the Support Removal Machine

There are machines on the market today that remove print media from a 3D part for you. Such a device is designed for faster cleaning. This not only ensures that there is no media in the printed part, but also gives it a uniform look.

Ultimaker Cura software

If you use the 3D printer, you must have heard of Cura. It is often seen as a solution for removing unnecessary supports from a 3D object. In reality, Ultimaker Cura is a software slicer. More precisely, it is for setting up your 3D printer. ¿Cómo se retira el soporte de impresion 3D?

How to clean the 3D printer tray?・Cults

The plate is one of the most important parts of a 3D printer. For optimal printer performance, it must be properly cleaned after each print session. Traces of the thread are deposited on it over time. While cleaning a 3D printer plate is not a difficult task, it can quickly become one if you don't have an effective method or the right cleaner. How to clean this important part of the 3D printer? We invite you to identify the most effective methods.

Do you have a 3D printer? So how do I properly maintain my 3D printer is probably a question you often ask yourself, the first element of which lies, in fact, in the quality of the material you are using. As far as the print plate is concerned, when using the correct cleaning tools, the various parts of your 3D printer will have good adhesion of .

To clean the plate of your 3D printer, you will need the following tools: sandpaper, scraper, sponge, paper, cotton or microfiber towels and cleaners such as acetone or propanone, isopropyl alcohol (IPA) with a minimum concentration of 70%, soap for dishes. .. Ideal for effective cleaning of your 3D printer .

Cleaning your 3D printer's plate depends mainly on the plate material, as well as the product used for printing. Most often the printing plate is made of glass, polyesterimide (EPI) or is covered with adhesive tape. The printing plate of the printer can also be made of plastic, garolite, ceramics, granite, aluminum, but this is much less common. When cleaning the 3D printer plate, you must also consider the use of surface treatments that promote adhesion of parts to the plate.

Cleaning the glass 3D printing plate

Glass is a common material used for 3D printing. It has a much longer lifespan than PEI. In addition, the glass plate makes it easier to use the adhesive and varnish in the 3D printing process. This is because its surface does not react with any material. It is also relatively easy to clean. The 3D printer's glass printing plate is commonly used with adhesives such as glue stick and hair sprays. They increase the adhesion of the surface for the first print layer, which is necessary to ensure the stability of the rest of the model.

The glass plate can be heated to remove material residue. Heat makes it easier to scrape off these materials. However, care must be taken when scraping, as the glass is easily scratched by sharp objects. It is best to use aligned objects such as a metal spatula or plastic ruler. If you choose to use metal, we recommend applying only as much pressure as is necessary to avoid scratching the glass plate. A metal scraper or spatula is also very useful for cleaning the print tray if you are using ABS, PLA, or nylon filament.

Alternatively, you can use the scraper blade to clean the glass plate of your 3D printer. This tool is very sharp. To do this, press down with one hand while holding the edge of the print tray with the other. This will allow you to effectively remove the remaining material from the 3D printer's print tray. Then make sure you clean the part of the plate that is in contact with your hands. It very often leaves residues of oil and dirt.

Plate cleaning PEI

PEI sheets are also used as printing plates for 3D printers. Their resistance to wear under extreme temperatures and radiation levels is well rated. Regular maintenance of the PEI printing plate allows the plate to maintain its quality. Over time, the adhesion of PEI sheets weakens under the influence of temperature, printing radiation or inks. Traces of dirt, oil, glue, etc. eventually settle on the surface of your 3D printer's PEI plate. However, physical cleaning procedures such as scraping and scraping are not the most effective and may even damage the print plate.

The best solution for cleaning the EPI print tray is to use a cleaner such as unflavored IPA at 70% strength. In the case of a plate surface that is more exposed to dirt and oil, purer IPA can be used. However, before you start cleaning, wait for your 3D printer's PEI plate to cool down. For your protection, make sure you use this cleaner in a well ventilated area.

You can also use acetone to remove ink and plastic residue stuck to your 3D printer's PEI plate. This cleaner should not be poured directly onto the plate. Although PEI does not dissolve in acetone, acetone can damage PEI if you pour a large amount of it onto the plate. To do this, it is recommended to pour acetone on the fabric, and then wipe the print tray in a circular motion.

Ribbon plate cleaning

Adhesive tape is inexpensive and easy to replace product. Therefore, it is widely used by people who are just starting to master 3D printing. Ribbon is mainly used with non-heated printing plates due to its thermal sensitivity.