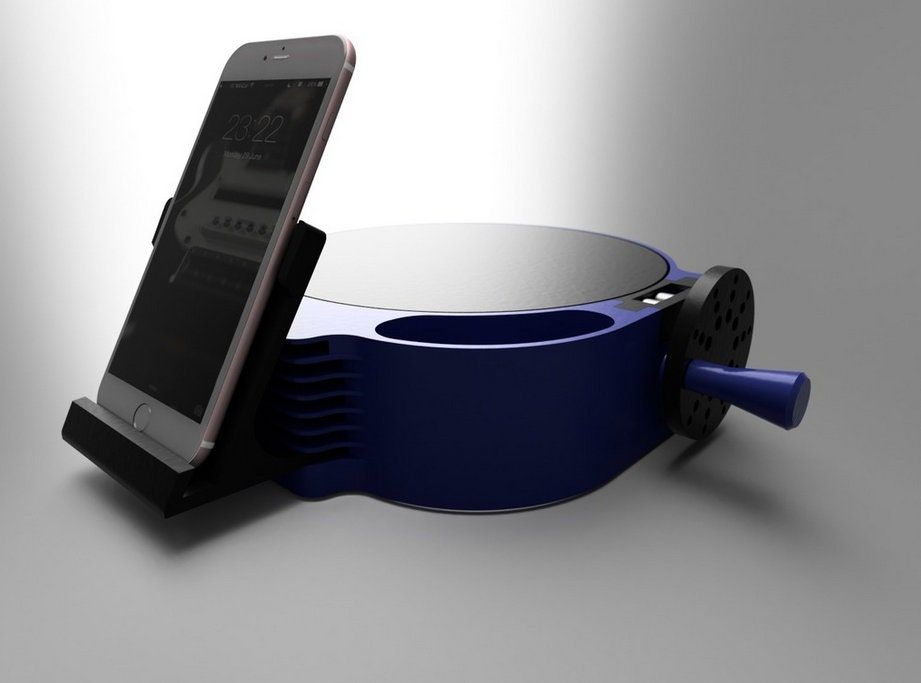

Mobile fusion 3d scanner

MobileFusion: Research project turns regular mobile phone into 3D scanner

By Allison Linn, Senior Writer, Microsoft Research

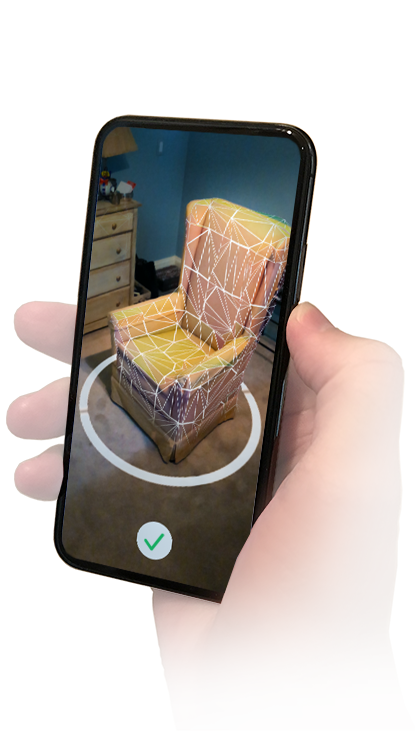

A new Microsoft Research project lets people to create high-quality 3D images in real time, using a regular mobile phone, with about the same effort it takes to snap a picture or capture a video.

Spotlight: On-Demand EVENT

“What this system effectively allows us to do is to take something similar to a picture, but it’s a full 3D object,” said Peter Ondruska, a Ph.D. candidate at Oxford University who worked on the project while he was an intern at Microsoft Research.

The researchers say the system, called MobileFusion, is better than other methods for 3D scanning with a mobile device because it doesn’t need any extra hardware, or even an Internet connection, to work. That means scientists in remote locations or hikers deep in the woods can capture their surroundings using a regular cell phone without a Wi-Fi connection.

“Everything happens on the phone itself,” said Pushmeet Kohli, a principal research scientist with Microsoft Research who also worked on the project.

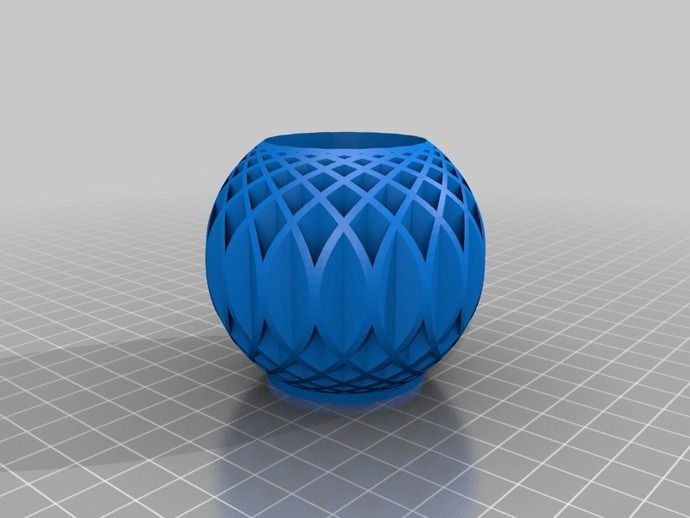

The scans are high-quality enough to be used for things like 3D printing and augmented reality video games.

Shahram Izadi, a principal researcher who also worked on the project, said he imagines people using a tool like this to take a 3D scan of something they see on vacation, such as the Eiffel Tower, and immediately sharing it with friends or family.

He said a person might also use it to take a 3D scan of something they wanted to sell online, such as a vase or a lamp, and post that, instead of the more conventional picture or video.

“This is really about the accessibility and ubiquity of 3D scanning,” Izadi said.

The researchers will present MobileFusion in early October at the International Symposium on Mixed and Augmented Reality.

Kohli and Izadi had previously worked on a similar project, called Kinect Fusion, which lets people build 3D models of their houses, offices or even themselves. However, that system requires a PC and other gadgets, making it difficult to do any 3D scanning on the go.

When Ondruska came to the lab, Kohli said they were curious to see if they could “go to the next level, in the sense of usability.”

They found most mobile devices had become powerful enough that they could build a 3D-scanning system just using the computational power found on a regular mobile phone.

“The great starting point was to take a sensor that everyone has in their pocket, which is the camera you have on your mobile phone,” Izadi said.

The researchers then developed an algorithm that allowed the camera to act as a 3D scanner, using a technique of taking multiple images that is similar to how the human eye works, Izadi explained.

Currently, the researchers are working on making sure the system works with all types of mobile devices, including Windows Phone, Android and iPhone devices. Izadi said they hope to eventually make it available to the general public in some form, but there are no firm plans right now.

Izadi said they hope to eventually make it available to the general public in some form, but there are no firm plans right now.

Related:

- Read more about MobileFusion (PDF, 5.6 MB)

- Microsoft Research’s Interactive 3D Technologies group

- Picture this: Microsoft research can interpret, caption photos

- Microsoft Hyperlapse makes first-person videos smooth and speedy

Microsoft's MobileFusion app makes 3D scans, but it may never come to market

Skip to content

Home / Accessories / News

News

Apparently Microsoft's researchers get to have all the fun.

By Mark Hachman

PCWorld Aug 24, 2015 1:06 pm PDT

Who needs a Microsoft Kinect when your phone’s camera can do the job?

Microsoft Research said Monday it’s working on a technology called MobileFusion for the Android, iOS, and Windows Phone platforms that will allow users to pan a smartphone camera slowly around a 3D object, creating a 3D model that they can later print.

“The great starting point was to take a sensor that everyone has in their pocket, which is the camera you have on your mobile phone,” said Shahram Izadi, a principal researcher on the project.

Why this matters: MobileFusion is designed for a single purpose: 3D printing. The idea, according to the researchers, is for people to bring a smartphone into a museum, on a hike, or somewhere else and scan a 3D memento into their phone for later printing. The only catch right now is that the MobileFusion research is… well, research: Microsoft says it doesn’t have any plans to develop the technology into a full-fledged app.

Microsoft began promoting the use of 3D depth cameras with its PCs through its Windows Hello login process, which uses an embedded RealSense 3D camera from Intel to recognize a user’s face. The Hello technology is based upon the Microsoft Kinect camera, whch was originally designed for the Microsoft Xbox 360 and Xbox One game consoles. Kinect recognizes users by comparing them to a 3D object that the camera has created and stored.

Kinect recognizes users by comparing them to a 3D object that the camera has created and stored.

Microsoft isn’t anywhere close to being the first organization to talk about 3D scanning using a mobile phone. In 2013, ETH Zurich made the exact same promise, claiming they were working to release an app. (To date, they have not.)

AutoDesk’s 123DCapture app allows you to create your own 3D scans.

Several apps have also promised that they can stick two or more 2D pictures of an object into a 3D model. Two that are worth noting include the free 123DCatch app from Autodesk, for both iOS and Android; and Shapematic, a $0.99 iOS app that also turns a few 3D snaps into a 3D object. (Trimensional, an iOS app, also will capture a 3D object, but it seems designed mainly for fun, not printing.) As far as we can tell, no developer has created a 3D scanner app for Windows Phone.

Note that what Microsoft is talking about involves slowly panning a camera around an object, essentially creating a video that the MobileFusion technology can transform into an image. The closest thing we have to that today is the 3D Capture tool you can use with HP’s imaging-focused Sprout PC, which takes a bunch of photos from different angles and stitches them together. Unless someone creates a quality app that can do this, we’ll still be waiting.

The closest thing we have to that today is the 3D Capture tool you can use with HP’s imaging-focused Sprout PC, which takes a bunch of photos from different angles and stitches them together. Unless someone creates a quality app that can do this, we’ll still be waiting.

Application

-

August 29, 2018

Laser scanning and 3D modeling of the Vyksa Steel Works

In January 2018, Trimetari Consulting carried out ground-based laser scanning and 3D modeling of the furnace chamber of walking beam furnaces at the Vyksa Metallurgical Plant. The purpose of the work is the production of a geometric 3D model in Autodesk DWG format for further design of the furnace cleaning system.

-

06 September 2016

Floor surface inspection with Leica Nova MS60 scanning total station

In April 2016, NAVGEOKOM specialists completed a pilot project on the territory of a shopping center under construction in the city of Lipetsk.

-

02 August 2016

3D scanning and creation of a solid measurement model of a factory under construction

-

August 19, 2015

3D laser scanning of Yugo-Zapadnaya CHPP, St. Petersburg

In February 2013, employees of Trimetari engineering and geodetic surveys were carried out using the ground laser scanning of the first unit of the Yugo-Zapadnaya CHPP. Scanning work existing engineering structures were carried out in order to create three-dimensional model for designing the construction of the second power plant lines.

-

27 May 2015

Laser scanning and 3D modeling of the Shukhov Tower on Shabolovka

Radio tower on Shabolovka - a symbol of Soviet radio and television broadcasting, a world-famous architectural monument of the Russian avant-garde.

-

October 27, 2014

Leica TS30 measures cranes

Telescopic boom cranes made of high strength steel are used for loading and unloading ships and trucks, for example lifting equipment and products on board large cruise ships. With ever-increasing traffic volumes, customers are demanding more and more crane capacities, but at the same time want them to remain light, versatile, mobile and take up as little space as possible when folded. Together with his students, Professor Joseph Predan from the Faculty of Mechanical Engineering at the University of Maribor (Slovenia) conducted a series of tests for crane manufacturer Palfinger Systems using a Leica TS30 total station.

-

October 24, 2014

Mighty Mo's Last Voyage

The scan was to be the last stage of the Missouri's conservation project before the ship returned home to the naval base. The Smart GeoMetrics team had a 4-day "window" to scan the vessel between the time the scaffolding and protective casings were removed from it and the launch date.

-

October 16, 2014

Laser scanning and 3D modeling for the restoration of the information model of the Rostov NPP

Despite the fact that the first terrestrial scanners appeared in the last century, there is still no reason to assert that 3D laser scanning technology is widely used in the design and construction of industrial facilities.

- 1

- 2

- Forward

technologies, types, operation of 3D devices

Many digital engineering strategies for the future of development, manufacturing, quality control, and product release start with 3D scanning. 3D scanners work with advanced technologies and specialized software to create a tool that allows you to achieve revolutionary results. For those still working with power tools and traditional coordinate measuring machine (CMM) technology, 3D scanners serve as an easy gateway to advanced manufacturing and engineering strategies.

3D scanners work with advanced technologies and specialized software to create a tool that allows you to achieve revolutionary results. For those still working with power tools and traditional coordinate measuring machine (CMM) technology, 3D scanners serve as an easy gateway to advanced manufacturing and engineering strategies.

Read below to learn more about how 3D scanners work and what the technology can do so you can start enjoying its benefits now.

What are 3D scanners?

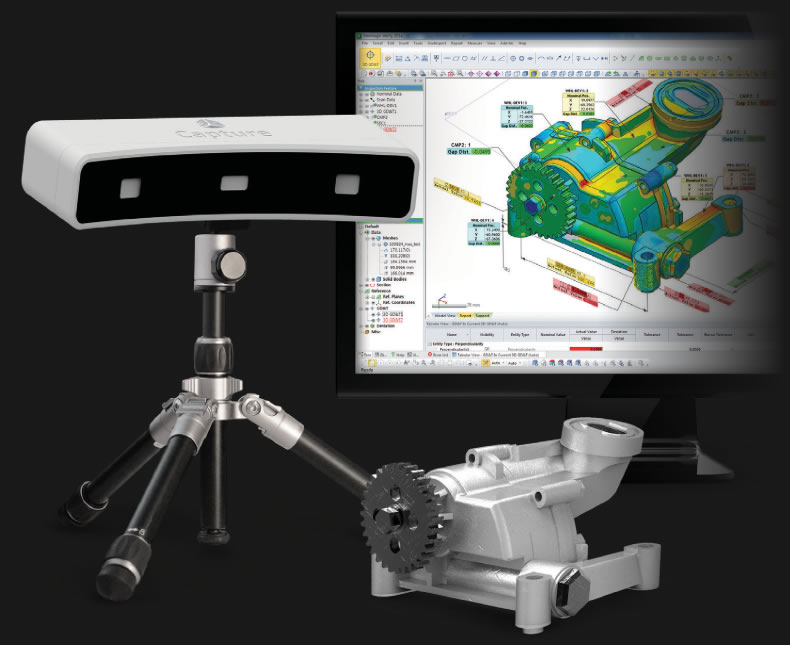

A 3D scanner works by capturing data from the surface of a physical object to describe its shape in an accurate digital 3D format. Unlike CMM measurement data, high quality 3D scan data is used for more than just inspection and dimensional analysis. The data obtained by non-contact measurement allows faster and more accessible digital analysis and inspection using a visual, in-depth method of examination.

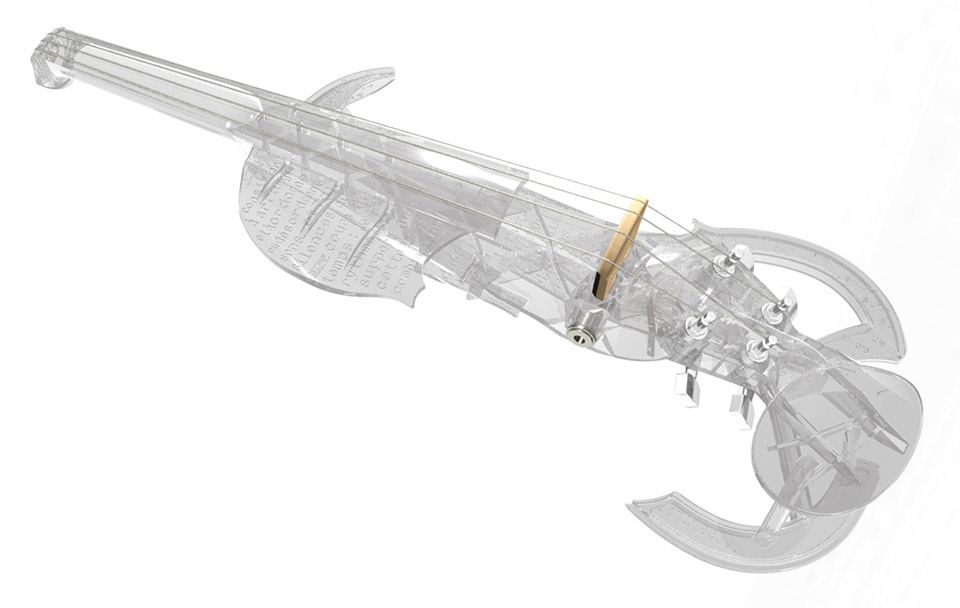

3D scanners are also used to replicate parts in reverse engineering, check the fit, shape and function of components at remote locations, and check CAD models of 3D printed parts. 3D printers can use 3D scan data to create physical objects.

3D printers can use 3D scan data to create physical objects.

What is 3D scanning?

3D scanning is the process of collecting data about the surface of an object in digital format to determine its shape, allowing users to either reproduce the part by reverse engineering or verify it by dimensional analysis.

To do this, operators use scanners that use lasers, light or sensors to determine the surface of the scanned object and assign data points to this surface. These data points will eventually recreate the . Depending on the type of laser, light, or sensor used, the level of detail and scanning performance may vary.

3D Scanning Technologies

Photogrammetry

Originating from photography, photogrammetry is an incredibly useful technology in a variety of fields. This technology allows you to take multiple images taken at different positions and triangulate points on those images to determine their location in 3D space.

For example, cartographers use this technology when compiling maps. When it comes to hard-to-reach places like mountains, surveyors can use photogrammetry to take measurements.

Many modern technologies use photogrammetry, and image quality is the main factor determining accuracy. If the images are poor quality, there will be holes in the grid. The more images you can get, the higher the scan accuracy will be.

Shining 3D offers a solution - DigiMetric Photogrammetric System.

Read also DigiMetric case study “Scanning with a Digimetric Photogrammetric System and a FreeScan Handheld 3D Laser Scanner”

Structured Light

This technology is created by applying geometric patterns to an object while simultaneously capturing an image with a camera. In this case, the camera registers the deviation of the image.

Based on this template offset, all existing points can be located. It is necessary to conduct many scans from different positions, and then merge them until the mesh is 100% complete. Computer programs automatically combine all images to form a complete grid.

Computer programs automatically combine all images to form a complete grid.

3D laser scanning method

3D laser scanning data acquisition

3D laser scanning process

The object to be laser scanned is placed on the scanner platform. Specialized software directs the laser probe over the surface of the object. A laser probe projects a line of laser light onto the surface, and 2 sensor cameras continuously record the change in distance and shape of the laser line in three dimensions (XYZ) as it passes along the object.

Acquired data

The shape of an object is displayed as millions of dots, called “point clouds”, on a computer monitor as the laser moves around, capturing the entire shape of the object's surface. The process is very fast and laser scanning is more accurate than infrared.

Point cloud data for inspection

If the data is to be used for inspection, the scanned object can be compared with the designer's nominal CAD data. The result of this comparison is provided as a “color map deviation report” in PDF format, which clearly describes the differences between scanned data and CAD data.

The result of this comparison is provided as a “color map deviation report” in PDF format, which clearly describes the differences between scanned data and CAD data.

Reverse engineering CAD model

Laser scanning is the fastest, most accurate and automated way to obtain digital 3D data for reverse engineering. Again, with the help of specialized software, point cloud data is used to create a 3D CAD model of the geometry of the part.

The CAD model can accurately reproduce the scanned object, or the object can be modified in the CAD model to correct imperfections.

Types of 3D scanners

Active scanners emit some radiation or light. The scanner detects the reflection to collect information about the object. Let's take a look at the active views of 3D scanners below.

3D Laser Scanners

3D Laser Scanners use a process called trigonometric triangulation to accurately display a 3D shape as millions of dots. Laser scanners work by projecting a laser line or lines onto an object and then capturing its reflection using one or more sensors.

The sensors are located at a known distance from the laser source. Accurate point measurements can be made by calculating the angle of reflection of the laser light.

Laser scanners are very popular and come in many designs. These include handheld, manipulator-based, CMM-based handheld devices, long-range trackers, and long-range single-point trackers.

Benefits of 3D laser scanners:

- Ability to scan complex surfaces such as shiny or dark surfaces.

- Less sensitive to changing lighting conditions and ambient light.

- More accurate data, available for inspection.

Learn about FreeScan UE 3D laser scanner features, features, features and benefits.

An example of using FreeScan UE and photogrammetry can be found on our blog page - 3D Inspection of Large Parts.

As well as the article The rebirth of historic motorsport icons.

Projected or structured light 3D scanners

Historically known as “white light” 3D scanners, most structured light 3D scanners today use blue or white LED projected light. These 3D scanners project a pattern of light onto an object, consisting of stripes, blocks, or other shapes. A 3D scanner has one or more sensors that look at the edges of these patterns or structural shapes to determine the object's 3D shape.

These 3D scanners project a pattern of light onto an object, consisting of stripes, blocks, or other shapes. A 3D scanner has one or more sensors that look at the edges of these patterns or structural shapes to determine the object's 3D shape.

Using the same trigonometric triangulation method as in laser scanners, so the distance from the sensors to the light source is known. Structured light scanners can be mounted on a tripod or hand held.

Benefits of Structured Light 3D Scanners:

- Very fast scan times of just 2 seconds per scan.

- Versatility - multiple lenses for scanning small and large parts in one system.

- Portability - handheld systems are highly mobile.

- Eye friendly for 3D scanning of people and animals.

- 3D color scans available.

- Various price ranges from inexpensive to expensive depending on resolution and accuracy.

Excellent solutions of 3D scanners with structured light, are models:

- Einscan HX

- manual 3D scanner Einscan H.

Examples of scanning using 3D 3D scanners EINSCAN:

- HTTPS: /// www.shining3d.ru/blog/perfectly-equipped-for-emergency-with-the-einscan-hx/

- https://www.shining3d.ru/blog/at-the-intersection-of-craftsmanship-and- technology-einscan-h-and-fusion-360-in-traditional-boat-building/.

Coordinate Measuring Machine (CMM)

Coordinate Measuring Machine (CMM) is mainly used for parts inspection. The machine can be controlled manually or through autonomous control by software and computers. Measurements are determined by attaching a sensor to the machine. The sensor usually has a small ball at the end of a shaft of known diameter. The CMM is then programmed to make contact with the part. When the machine senses contact with the probe tip, a value in XYZ space is measured. The most common type of CMM is the bridge type, which has 3 x, y, and z axes. The attached sensor system can be rotated to provide an additional 3 xyz axes, giving a total of 6 degrees of freedom (DOF).