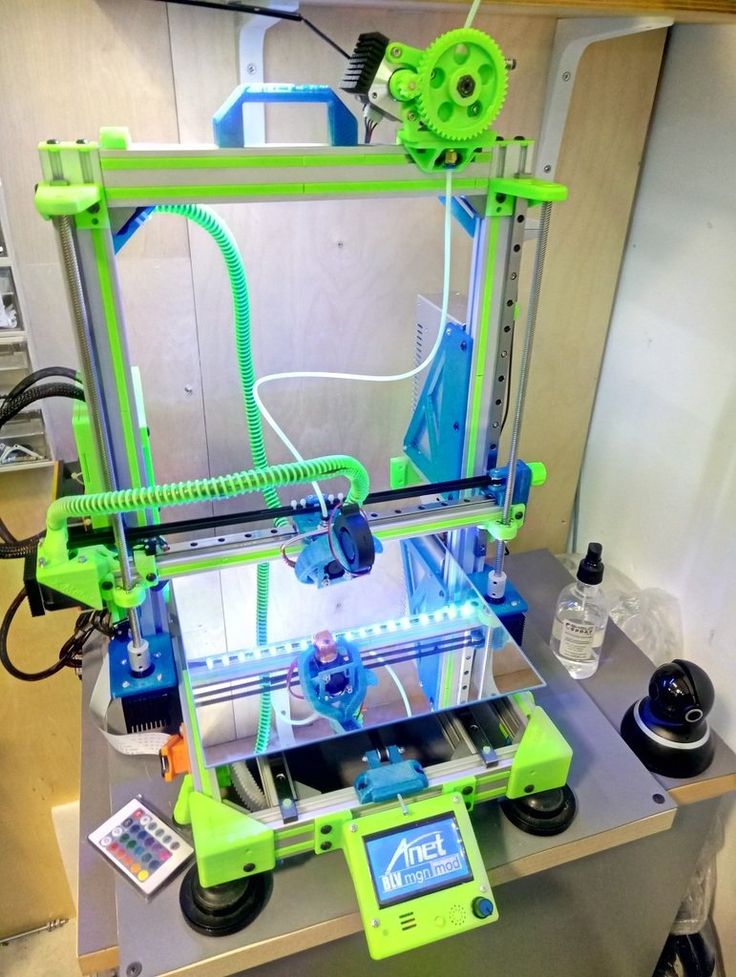

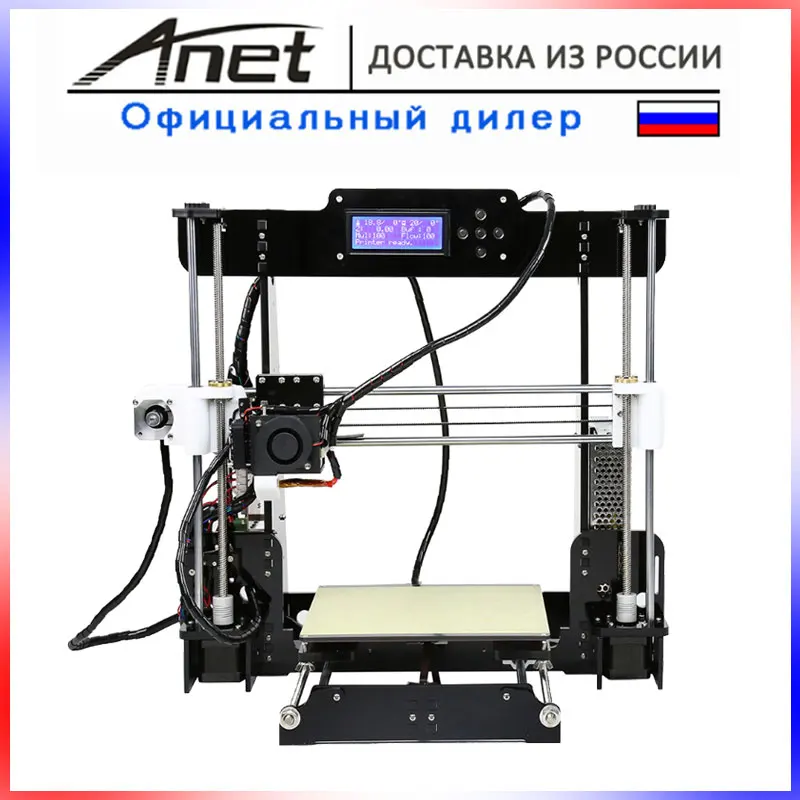

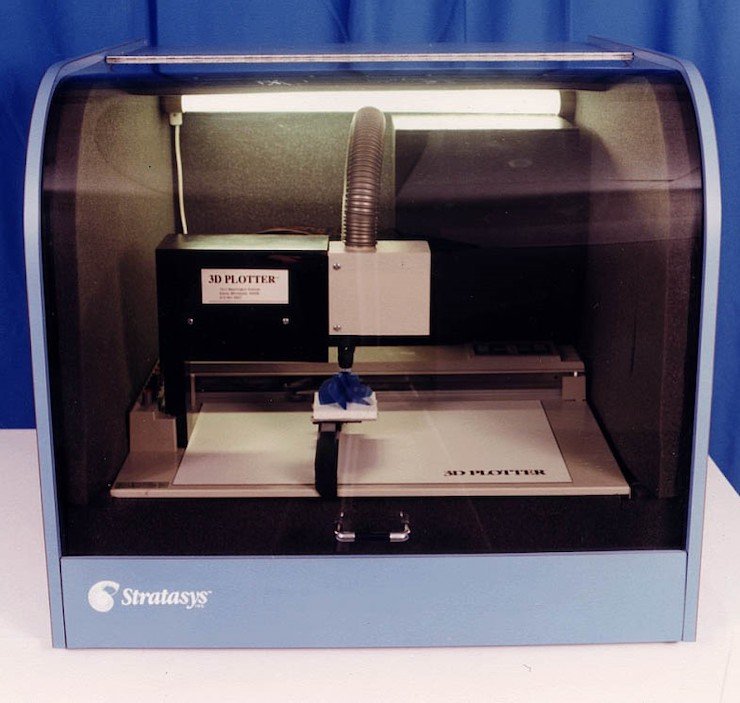

Original 3d printer

Original Prusa 3D printers directly from Josef Prusa

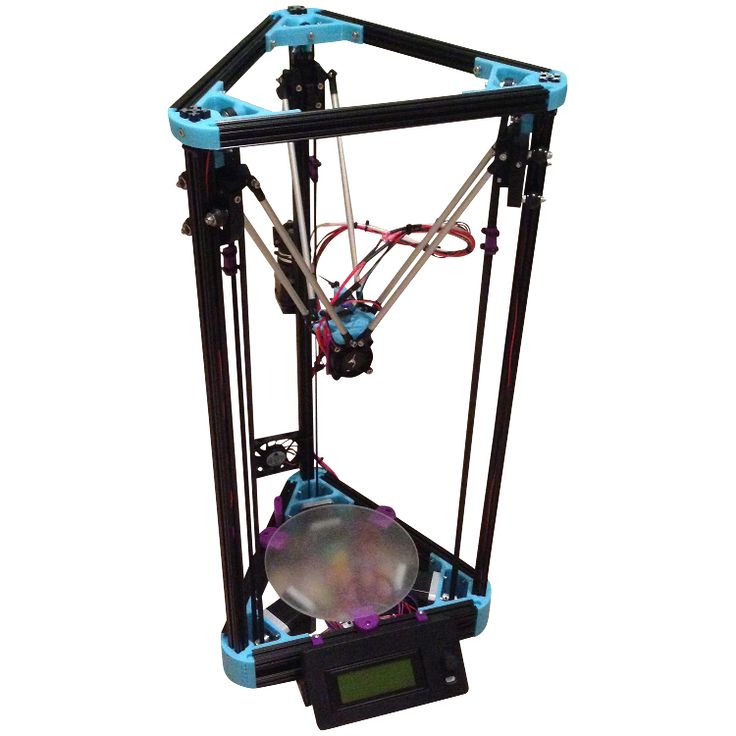

Our 3D Printers

New on e-shop

Prusament PLA Pristine White 1kg

Out of stock

€29.99 with VAT

DetailNoga Teddy Burr - TB1000 Deburring tool

In stock

€13.50 with VAT

Olfa SAC-1 precision knife

In stock

€8.99 with VAT

Prusament PLA Galaxy Green 1kg

In stock

€29.99 with VAT

Prusament Resin Flex80 Transparent Clear 1kg

In stock

€69 with VAT

Prusament Resin Flex80 Black 1kg

In stock

€69 with VAT

Price quote request

Are you considering Original Prusa 3D printers for your classroom, school, library, university or maker space?

Our specialists are here to assist you throughout the whole buying and information-gathering process. To get in touch with us, please fill out the form below and we will take it from there.

Contact us

Bestsellers

Original Prusa i3 MK3S+ kit

In stock

€849 with VAT

Choose variant

Original Prusa i3 MK3S+ 3D printer

Leadtime 1 week

€1,159 with VAT

Choose variant

Prusament PETG Prusa Galaxy Black 1kg

In stock

€29.99 with VAT

Double-sided Textured PEI Powder-coated Spring Steel Sheet

In stock

€39.99 with VAT

Original Prusa MINI+ Semi-assembled 3D Printer

Leadtime for MINI+ is 2–3 weeks

€489 with VAT

Choose variant

Prusament PLA Prusa Galaxy Black 1kg

In stock

€29.99 with VAT

Prusament PETG Prusa Orange 1kg

In stock

€29.

99 with VAT

99 with VATOriginal Prusa Enclosure

New orders have a lead time of 2–3 weeks

€369 with VAT

Choose variant

Spring Steel Sheet With Smooth Double-sided PEI

In stock

€34.99 with VAT

Prusament PETG Jet Black 1kg

In stock

€29.99 with VAT

Prusament Resin Tough Prusa Orange 1kg

In stock

€69 with VAT

Prusament PLA Galaxy Silver 1kg

In stock

€29.99 with VAT

Hello, we are Prusa Research!

And we make more than just amazing 3D printers!

Read our story

Prusa Services

Printables.com

Discover thousands of great printable 3D models

Downloads

Get the latest firmware and apps

Forum

Discuss 3D printing topics with the community

Prusament

Affordable filament for everyday printing in premium quality

Help

Assembly and troubleshooting guides, technical documentation

Blog

3D printing highlights, tips and interviews all in one place

E-Book: Basics of 3D Printing

This book will help you understand what kinds of 3D printing technologies are currently available and how they work. We will take you through the whole process of 3D printing.

We will take you through the whole process of 3D printing.

I don’t agree with subscribing to newsletterand I want to buy the e-book for 5 USD / 5 EUR.

News from the blog

Our printers continue to collect great reviews and awards all around the world. Original Prusa i3 MK3/S is the best 3D Printer in the Ultimate Guide to Digital Fabrication by MAKE: Magazine and our printers also received several editor's choices and awards from respected media outlets like All3DP, PC Mag, Tom's Hardware, TechRadar, Forbes, WireCutter, Windows Central and many more!

When we weigh up the price, performance, reliability and overall product, it is highly recommended for most people to purchase because it does things so well.

– 3D Printerly ReviewThe preassembled version of the Original Prusa i3 MK3S is a cinch to get up and running, is easy to operate, and has a good slicing program. It produced consistently beautiful prints in our testing, with no misprints.

– PC Mag Review

Of the 11 printers we have tested over the past five years, the Prusa i3 MK3S printer has produced the largest and best-looking prints.

– THE NEW YORK TIMES REVIEWWe tested it using its default settings and found it extremely capable. Its print quality is truly exceptional and it’s an easy-to-use, straightforward machine.

– All3DP MK3S ReviewThe team at Prusa Research have made something special with the MK3. If you only ever own one printer, make it this one. Of course, once you buy it you will want more of them, and that's ok too.

– Windows Central ReviewIt is the most well-made resin printer that I have and it objectively produces the best prints.

– The Prusa SL1S redefines SPEED!

Original Prusa i3 MK3S+ | Original Prusa 3D printers directly from Josef Prusa

See the Original Prusa i3 MK3S+ in action!

Assembled Printer & Kit Comparison

Assembled 3D Printer |

3D Printer Kit |

|

| Warranty | 2 Years in EU, 1 Year ROW - Built, calibrated, tested, and with a full warranty | 2 Years in EU, 1 Year ROW - Warranty on parts only |

| Owner Discount | 10% discount on subsequent orders of assembled i3 printer and selected filaments | 5% discount on subsequent orders of selected filament |

| Support | Premium 24/7 support via chat and e-mail + forum | Premium 24/7 support via chat and e-mail + forum |

| Consulting and Documentation | Printed version of 3D Printing Handbook and Free Access to the Prusa Academy - Online Course of 3D Printing and Modeling. |

The best assembly instructions proved by thousands of builders, printed version of 3D Printing Handbook |

| Assembly | Ready to print | Full Assembly Experience (6-8 hours), which teaches you how the printer works |

Main Features

SuperPinda Probe

SuperPINDA probe features a hiqh-quality sensor for a fully-automatic Mesh Bed Leveling process. Before every print, the MK3S+ probes the bed in several places and creates a virtual heightmap of the print area. This process ensures that the first layer will always be spot on!

Quality Bearings & more

The MK3S+ features a new set of metal clips for the bearings on the Y-axis. The belt tensioning mechanism on the X-axis was reworked and the X-end plastic parts reinforced. The filament path in the extruder was altered for better support of flexible filaments.

Removable Print Sheets

Spring steel sheets are easy to maintain and make removing the printed object from the print surface a breeze. We offer three types of print surface: smooth, textured and satin to cover all your needs when printing from a wide range of different materials - most of which do not require any special separation layers or surface preparation.

High-Quality Parts

The MK3S+ features an aluminum extrusion Y-axis assembly. Thanks to the milled dural frame, the MK3S+ is stable, rigid, and easy to assemble. Combined with our internally developed extruder featuring Bondtech gears and the E3D V6 hotend, the MK3S+ can print high-quality objects up to 210 mm in height.

Power Loss Recovery

Are you afraid of a blackout ruining your 48-hour print? Worry no more - the MK3S+ can deal with that! The printer can fully recover from the loss of power and continue printing exactly where it left off. It detects power interruptions and shuts down the heatbed and extruder heating, and saves the last known location.

It detects power interruptions and shuts down the heatbed and extruder heating, and saves the last known location.

Filament Sensor

The MK3S+ further enhances the reworked extruder from the MK3S. The built-in filament sensor uses a reliable trigger system, which detects whether a strand of filament is inserted into the extruder. It can detect any type and color of filament and is not susceptible to mechanical wear.

Mesh Bed Leveling

Thanks to the SuperPINDA probe, the MK3S+ can use the Mesh Bed Leveling process to compensate for microscopic imperfections of the print sheet, and inconsistencies caused by the assembly and stacking of the manufacturing tolerances of various parts. Achieving a great-looking first layer is quick and easy.

Slice with PrusaSlicer

Our internally developed multiplatform slicer comes with in-house made and fully tested profiles for all of our 3D printers and a wide range of filaments. With built-in tools, such as advanced support generation, cutting, automated object distribution, ironing and many others, you will turn your 3D models into print files in no time!

With built-in tools, such as advanced support generation, cutting, automated object distribution, ironing and many others, you will turn your 3D models into print files in no time!

Support for a wide range of Materials

The MK3S+ is fully compatible with a wide range of various types of materials. No matter whether you want to print something for fun from PLA and flexible materials, or you need to produce durable prototypes from PETG, ASA, Polycarbonate and Polypropylene - the MK3S+ can handle them with ease.

Open-source Hardware & Firmware

We develop firmware for all of our 3D printers and test every new version thoroughly before release. Ongoing development and regular updates ensure that our machines are packed with useful features, such as print sheet profiles, automated calibration, Mesh bed leveling, advanced diagnostics, remaining print time estimation, Octoprint support and more!

Original Prusa MMU2S Upgrade

Multi Material Upgrade 2S (MMU2S) is the second generation of our unique multi-material addon, which enables your 3d printer to print with up to 5 colors at the same time.

More details

Awards

Our printers continue to collect great reviews and awards all around the world. Original Prusa i3 MK3/S is the best 3D Printer in the Ultimate Guide to Digital Fabrication by MAKE: Magazine and our printers also received several editor's choices and awards from respected media outlets like All3DP, PC Mag, Tom's Hardware, TechRadar, Forbes, WireCutter, Windows Central and many more!

Reviews

6 reasons to buy the MK3S+

1

Great User Support

We offer 24/7 tech support via live chat and email in seven languages. Our printers come with detailed instructions and guides for easy assembly and maintenance. You can also visit our knowledge base, community forum, Facebook groups and official Blog, where we publish useful 3D printing tips and tricks, contests and more!

2

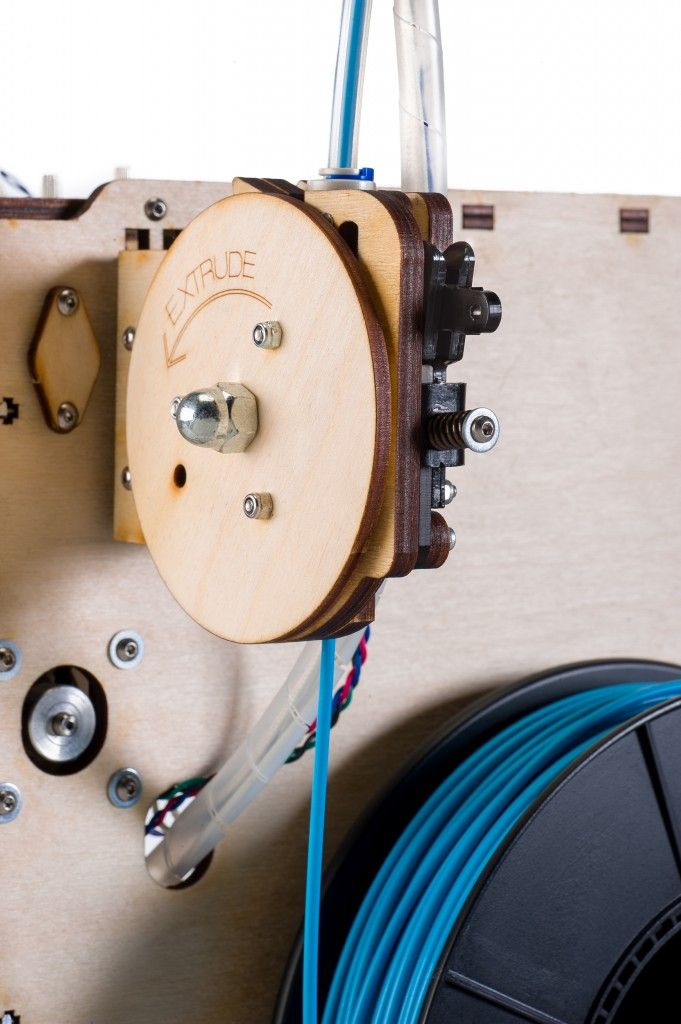

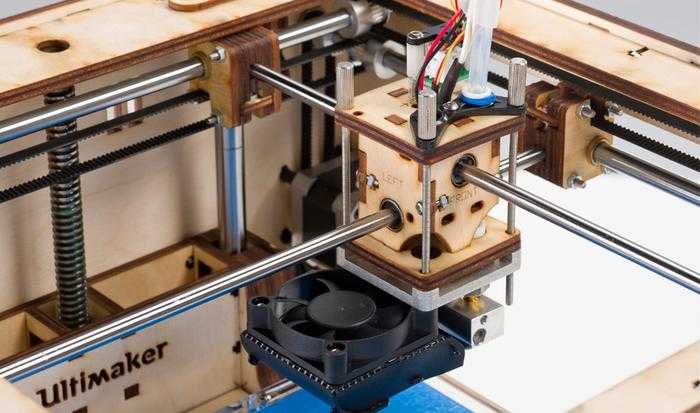

FUN TO ASSEMBLE

The MK3S+ assembly kit is an excellent first step into the world of 3D printing. You will get to know your 3D printer inside out and find out how it works! The assembly is quite easy, requires no soldering, all cables are cut to length and ready to be plugged in. The assembly instructions are easy to follow and all texts are translated into 8 languages. All of this makes the kit very friendly to younger builders, too!

You will get to know your 3D printer inside out and find out how it works! The assembly is quite easy, requires no soldering, all cables are cut to length and ready to be plugged in. The assembly instructions are easy to follow and all texts are translated into 8 languages. All of this makes the kit very friendly to younger builders, too!

3

Built-in Safety Features

Original Prusa 3D printers are well-known for their reliability and safe operation. Every part of our printers is thoroughly tested in-house. The MK3S+ is equipped with three thermistors and comes with a custom-built high-quality Delta power supply. The printer can recognize issues with heating and stop operation to prevent damage.

4

Open-source and Community Friendly

All parts of our printer are open-source, which means we publish all source codes and blueprints online. The community around our products is huge and the feedback is overwhelmingly positive - don't believe us? Check out Facebook groups and YouTube videos! There's so much to do with your 3D printer - buying it is just the beginning!

The community around our products is huge and the feedback is overwhelmingly positive - don't believe us? Check out Facebook groups and YouTube videos! There's so much to do with your 3D printer - buying it is just the beginning!

5

Ready for the Multi-Material Upgrade 2S

Multi Material Upgrade 2S is our unique add-on option for printing with up to 5 different filaments simultaneously. Multi-material could be your next step in the 3D printing world and the MK3S and MK3S+ are completely ready for the upgrade! MMU2S also allows you to print a soluble support interface - check out the video!

6

Upgradability

One of the most popular features of the Original Prusa i3 concept is upgradability. When you buy our 3D printer, you can upgrade it later to a newer version, so you don't need to buy a whole new model every two years like, for example, your phone or laptop. We also keep supporting our 3D printers with regular firmware updates that bring new features!

Get the Original Prusa i3 MK3S+ now

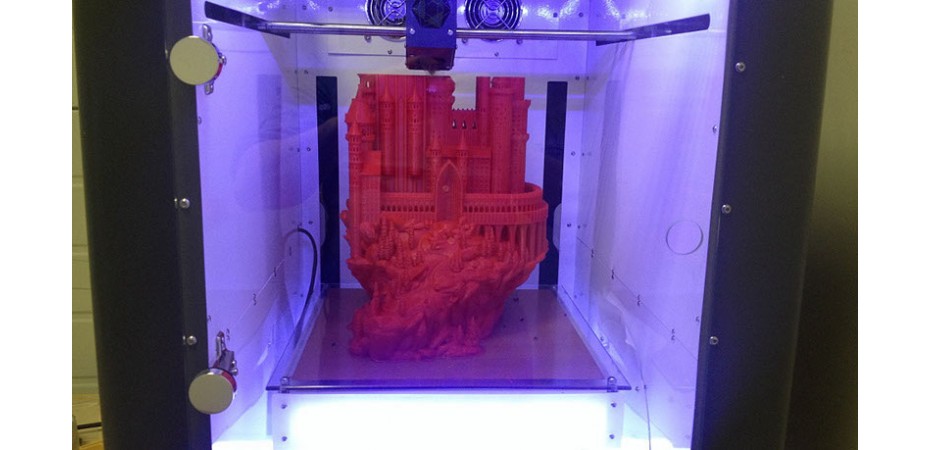

The most original things created on a 3D printer

Sergey Skladny 09/12/2013 Articles 0

The technology of three-dimensional printing of various objects is still very young, and so far it is practically not available to a wide range of users. In the summer of 2013, the first 3D printer for home use appeared on the world market, but its high cost (more than $ 1,500) and small size, which did not allow creating really large objects, contributed to the low popularity of the novelty.

In the summer of 2013, the first 3D printer for home use appeared on the world market, but its high cost (more than $ 1,500) and small size, which did not allow creating really large objects, contributed to the low popularity of the novelty.

Of course, over time, the technology will be refined and significantly cheaper, which means that 3D printing will firmly enter our lives, but now hundreds of enthusiasts around the world are finding very original applications of additive technology. Just about the 10 most unusual, we will tell you below.

Tenth place is occupied by scientists from McGill University, who were able to accurately recreate the hairstyles worn by women in ancient Egypt. They weaved special cereals, ropes and much more into their hair, and then tightened it all in a special way to achieve the desired shape. Wigs exactly repeat all the features of hairstyles of that time, although the practical meaning of this study is still unknown.

Ninth place was firmly established by researchers at Cornell University who experimented with 3D printing and decided to use hydrocooloids as inks, special polymers commonly used in the food industry. With their help, they were able to print many edible objects such as bread, bananas, cheese, chocolate, and more. Each product has its own taste, but they are all approximately the same in shape and have the same textured surface. This discovery is simply unique, especially on the eve of the first flight of people to Mars, who using it will be able to eat not concentrates, but real products, albeit printed on a printer.

With their help, they were able to print many edible objects such as bread, bananas, cheese, chocolate, and more. Each product has its own taste, but they are all approximately the same in shape and have the same textured surface. This discovery is simply unique, especially on the eve of the first flight of people to Mars, who using it will be able to eat not concentrates, but real products, albeit printed on a printer.

Eighth place went to the designers of the fashion studio "Continuum", who were able to set up the production of the perfect 3D-printed swimwear. The essence of the idea lies in the fact that each model is printed on the basis of the exact dimensions of a person, and ideally fits him without causing any discomfort. On the contrary, modern materials and perfect fit allow clothes to be practically not felt on the body. This wonderful know-how can be purchased for only $88.

Seventh place confidently holds the Japanese company Fasotec, which offers future parents to acquire a sculpture of their own child in the womb. To do this, the masters from the company simply need images of the embryo taken by a tomograph, and armed with them, they will create a three-dimensional figure by placing it in a translucent block. Despite the fact that this project is rather controversial, and the fact that the services of specialists cost $ 1,300, there are already many people in Japan who want to use such services.

To do this, the masters from the company simply need images of the embryo taken by a tomograph, and armed with them, they will create a three-dimensional figure by placing it in a translucent block. Despite the fact that this project is rather controversial, and the fact that the services of specialists cost $ 1,300, there are already many people in Japan who want to use such services.

Sixth place went to Princeton Institute doctors, who just recently printed a fully functioning bionic ear. The researchers went to its creation for several months. In theory, if you connect it with electrodes to certain areas of the brain, it will fully function. Such experiments have not yet been carried out, but the prospects for this discovery are really impressive.

Fifth place is occupied by craftsmen from Oxford, who managed to make a complete replacement of the skull from polymer plastic. The peculiarity of this discovery lies also in the fact that a successful operation has already been carried out with such a substitute for the skull. And if not for this original prosthesis, the life of a person could not be saved, because he needed to replace more than 75 percent of the skull.

And if not for this original prosthesis, the life of a person could not be saved, because he needed to replace more than 75 percent of the skull.

Fourth place is occupied by archaeologists from the University of Leicester, who were able to recreate the bust of King Richard III, who lived in 1485. More recently, they were able to find his skeleton, and with the help of three-dimensional modeling, they printed an amazingly believable copy of the monarch, with all the important anatomical details.

Third place goes to doctors who have learned to grow real living human tissues using the capabilities of 3D printers. They used stem cells as ink and synthesized different kinds of tissues. In the future, this may lead to the creation of full-fledged organs, but so far this is very far away.

Second place goes to a young American named Alex Davis, who was able to print a real violin using a home 3D printer, and even posted a video of him playing it on You Tube. Of course, the sound of the instrument is not perfect, but for homemade it is not bad at all.

Of course, the sound of the instrument is not perfect, but for homemade it is not bad at all.

And the first place is definitely departing by the creator of real firearms. A combat pistol with 9-gauge bullets consists of several component metal parts printed on a three-dimensional printer using a special seam sintering technology. As a result, the product is completely ready for firing and has passed all the necessary tests. It is also interesting that not a single detail of the mechanism required manual refinement.

About Sergey Foldy

View all posts by Sergey Skladny →

3d printers

Model Studio CS Power lines - now in 3D

Announcement of Autodesk University Russia 2013

“budget” metal powder 3D laser printer

News

9006

5

The German company One Click Metal has released an updated version of a relatively inexpensive laser additive system for 3D printing with metal powder compositions costing only half a Gelendvagen (we used to measure in Rolls-Royces).

One Click Metal is, in fact, a subsidiary of the well-known German engineering company Trumpf, which is also engaged in the production of industrial additive installations. The startup entered the market in 2019showcasing the first version of a PBF 3D printer of its own design called MPRINT at Formnext. The company is trying to find a specific niche, namely the production of low-cost additive systems for 3D printing with metal powders. Budget is a relative concept, but shortly before the premiere, One Click Metal CEO Bjorn Ullman estimated the cost at fifty thousand euros. In fact, the original 3D printers cost about that much, while the upgraded systems are offered for one and a half times more, but still much cheaper than most competitive offers ranging from a quarter to half a million dollars.

The updated MPRINT+ model differs from the original in a number of improvements aimed primarily at improving performance and resolution. The 3D printer is equipped with a more powerful 200-watt fiber laser compared to the 100-watt in the original version. With the positioning system, not everything is clear yet. The fact is that the original used a moving head with a diode laser from Trumpf - imagine your FDM 3D printer, but with an engraving laser nozzle on steroids. We have already seen something similar on the XM200 and XM300 3D printers of the American company Xact Metal.

With the positioning system, not everything is clear yet. The fact is that the original used a moving head with a diode laser from Trumpf - imagine your FDM 3D printer, but with an engraving laser nozzle on steroids. We have already seen something similar on the XM200 and XM300 3D printers of the American company Xact Metal.

The new system allegedly uses a galvanometric scanning system that provides hatching speeds up to 3 m/s. Ullman at one time argued that a radical reduction in the cost of equipment became possible precisely due to the development of his own, relatively inexpensive scanner, so that a noticeable price jump can be fully explained by the transition to a more complex and expensive, but at the same time faster and more accurate galvanoscanner, if such the transition actually took place. Xact Metal, by the way, did just that, a year after the premiere, remaking the XM200 into the XM200S.

The spot diameter is 45 microns versus 100 microns for the original MPRINT, the layer thickness is set within 20-80 microns, the size of the construction area is 150x150x150 mm, and the density of finished products reaches 99. 5%. Printing is carried out in a sealed chamber with a protective nitrogen atmosphere, which allows you to work with active metals and alloys. The company's range of consumables currently includes powders based on aluminium, stainless steel and tool steel.

5%. Printing is carried out in a sealed chamber with a protective nitrogen atmosphere, which allows you to work with active metals and alloys. The company's range of consumables currently includes powders based on aluminium, stainless steel and tool steel.

The system accepts four consumable cartridges with a 250% overload to reduce downtime. Cartridges are equipped with NFC tags to help you track media type and stock. An optional MPURE station with ultrasonic screening is available for cleaning finished products and preparing residual materials for reuse. The MPREP software is responsible for preparing digital 3D models and managing workflows.

And the moment you've all been waiting for is the cost. The MPRINT+ 3D printer is offered at a selling price of €76,900, and an additional €21,500 will have to be paid for the MPURE station. Additional information is available on the official website of the manufacturer.

Thomas Sunladerer's interview with Bjorn Ullmann about the original MPRINT system (2019):