3D print google home mini

Original Prusa 3D printers directly from Josef Prusa

Our 3D Printers

New on e-shop

Prusament PLA Galaxy Green 1kg

In stock

€29.99 with VAT

ColorFabb varioShore TPU Green filament 700g

In stock

€49.99 with VAT

ColorFabb varioShore TPU Black filament 700g

In stock

€49.99 with VAT

ColorFabb varioShore TPU Natural filament 700g

In stock

€49.99 with VAT

Prusament Resin Tough Classic Red 1kg

In stock

€69 with VAT

Official Printables.com T-shirt (L)

In stock

€24.99 with VAT

Price quote request

Are you considering Original Prusa 3D printers for your classroom, school, library, university or maker space?

Our specialists are here to assist you throughout the whole buying and information-gathering process. To get in touch with us, please fill out the form below and we will take it from there.

Contact us

Bestsellers

Original Prusa i3 MK3S+ kit

Leadtime 1–2 weeks

€849 with VAT

Choose variant

Original Prusa i3 MK3S+ 3D printer

Leadtime 1–2 weeks

€1,159 with VAT

Choose variant

Prusament PETG Prusa Galaxy Black 1kg

In stock

€29.99 with VAT

Double-sided Textured PEI Powder-coated Spring Steel Sheet

In stock

€39.99 with VAT

Original Prusa MINI+ Semi-assembled 3D Printer

Leadtime for MINI+ is 4–5 weeks

€489 with VAT

Choose variant

Prusament PLA Prusa Galaxy Black 1kg

In stock

€29.99 with VAT

Prusament PETG Prusa Orange 1kg

In stock

€29.99 with VAT

Original Prusa Enclosure

New orders have a lead time of 5-6 weeks

€369 with VAT

Choose variant

Spring Steel Sheet With Smooth Double-sided PEI

In stock

€34.

99 with VAT

99 with VATPrusament PETG Jet Black 1kg

In stock

€29.99 with VAT

Prusament Resin Tough Prusa Orange 1kg

In stock

€69 with VAT

Prusament PLA Galaxy Silver 1kg

In stock

€29.99 with VAT

Hello, we are Prusa Research!

And we make more than just amazing 3D printers!

Read our story

Prusa Services

Printables.com

Discover thousands of great printable 3D models

Downloads

Get the latest firmware and apps

Forum

Discuss 3D printing topics with the community

Prusament

Affordable filament for everyday printing in premium quality

Help

Assembly and troubleshooting guides, technical documentation

Blog

3D printing highlights, tips and interviews all in one place

E-Book: Basics of 3D Printing

This book will help you understand what kinds of 3D printing technologies are currently available and how they work. We will take you through the whole process of 3D printing.

We will take you through the whole process of 3D printing.

I don’t agree with subscribing to newsletterand I want to buy the e-book for 5 USD / 5 EUR.

News from the blog

Our printers continue to collect great reviews and awards all around the world. Original Prusa i3 MK3/S is the best 3D Printer in the Ultimate Guide to Digital Fabrication by MAKE: Magazine and our printers also received several editor's choices and awards from respected media outlets like All3DP, PC Mag, Tom's Hardware, TechRadar, Forbes, WireCutter, Windows Central and many more!

When we weigh up the price, performance, reliability and overall product, it is highly recommended for most people to purchase because it does things so well.

– 3D Printerly ReviewThe preassembled version of the Original Prusa i3 MK3S is a cinch to get up and running, is easy to operate, and has a good slicing program. It produced consistently beautiful prints in our testing, with no misprints.

– PC Mag Review

Of the 11 printers we have tested over the past five years, the Prusa i3 MK3S printer has produced the largest and best-looking prints.

– THE NEW YORK TIMES REVIEWWe tested it using its default settings and found it extremely capable. Its print quality is truly exceptional and it’s an easy-to-use, straightforward machine.

– All3DP MK3S ReviewThe team at Prusa Research have made something special with the MK3. If you only ever own one printer, make it this one. Of course, once you buy it you will want more of them, and that's ok too.

– Windows Central ReviewIt is the most well-made resin printer that I have and it objectively produces the best prints.

– The Prusa SL1S redefines SPEED!

V5 Home | Simplify3D Software

Learn MoreAvailable Now!Years of R&D Innovation90 New Supported Printers3.0x Faster Slicing Performance120 New Features and ImprovementsUnleash the Power of Additive Manufacturing

Our Product

Simplify3D Desktop Software

Build preparation software that delivers innovation to every step of the 3D printing process. Upgrade your machine capabilities with trusted software that supports hundreds of popular OEM brands.

Upgrade your machine capabilities with trusted software that supports hundreds of popular OEM brands.

Explore Software Features

Our Story

For more than a decade our team of engineers, software developers, and 3D printing experts have been committed to providing tools that push the boundaries of additive manufacturing. Our products are rigorously tested through in-house labs containing one of the largest collections of different 3D printers in the world, ensuring the software delivers unparalleled results across a wide range of machines.

With customers in over 170 countries, Simplify3D has become the leading global provider of commercial 3D printing software, allowing customers to unleash the full potential of their hardware with a simple software upgrade.

Learn More About Us

Our Customers

Expert Resources

Simplify3D provides world-class educational resources to help others expand their knowledge of additive manufacturing. Learn to understand common print quality issues, explore new build materials, or discover new settings that can improve your results.

- Print Quality Guide

- Materials Guide

- In-Depth Articles

Unrivaled Compatibility

Simplify3D has worked closely with OEM partners around the world to seamlessly integrate our software with hundreds of popular 3D printers. Our in-house experts optimize the settings for each machine to ensure customers achieve exceptional results right out of the box! Click below to see if your 3D printer is supported.

Check Compatibility

Recent News

Simplify3D Releases Version 5.0 with Breakthrough Performance, Automation, and Intelligence

Introducing Version 5.0

Learn more >

Top 10 Tips of 2021

From temperature settings to infill options, each week our engineers share 3D printing tips on social media. Here is a list of your 2021 favorites.

Learn more >

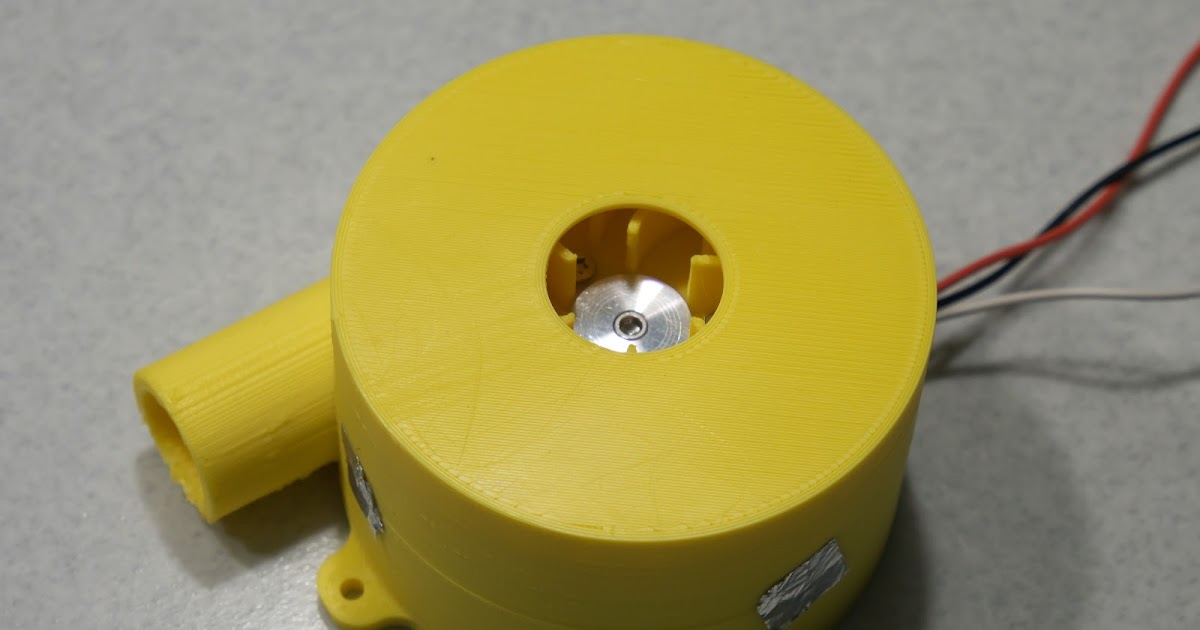

3D Printing the Perfect Sprinkler

A sprinkler may look simple, but there was quite a bit of planning and testing to perfect the internal water channels, threads, and moving parts.

Learn more >

How to Use Supports

Printing parts with overhangs, arches, or shallow angles can be challenging. Supports make printing these geometries possible and your imagination a reality.

Learn more >

5 Simple Steps to a Perfect First Layer

As the foundation for the entire 3D print, the first layer has a big job to do. Even experienced 3D printer users know how challenging it is to get the first layer right.

Learn more >

Stronger Web Infrastructure Key to Future Growth

Launching our largest infrastructure update yet, paving the way for a generation of advancements that our customers will benefit from for years to come.

Learn more >

Achieve More With Simplify3D

Explore Software Features

Build a house and transplant a heart: what 3D printers are capable of

Is it possible to print anything, including clothes and food, and how 3D printers helped save lives during a pandemic, we understand the new episode of the RBC Trends podcast “What has changed? »

Your browser does not support audio player .

Listen to us on any convenient platform: Apple Podcasts, CastBox, Yandex Music, Google Podcasts, Spotify and VK Podcasts. And also follow us on Telegram and Instagram "What has changed?" - there we share interesting materials on the topic. nine0003

Guests of the issue:

Sergei Nefedov, technical director and founder of Arfin. Sergey explained how 3D printers print entire houses and why such construction has not yet taken root in Russia.

Alexander Kornveits, founder and CEO of Tsvetnoy Mir. Alexander told how modern medicine uses 3D printing and when it will be possible to transplant printed organs.

Host of an artificial intelligence podcast from the future especially for RBC Trends. nine0003

Conversation timeline

1:34 — How 3D printing works

6:58 — Is it possible to print an organ: bioprinting

8:14 — Why don't we print clothes?

17:30 — How and from what do they print at home?

21:54 — Should the state regulate 3D printing technologies

25:27 — The future of additive technologies

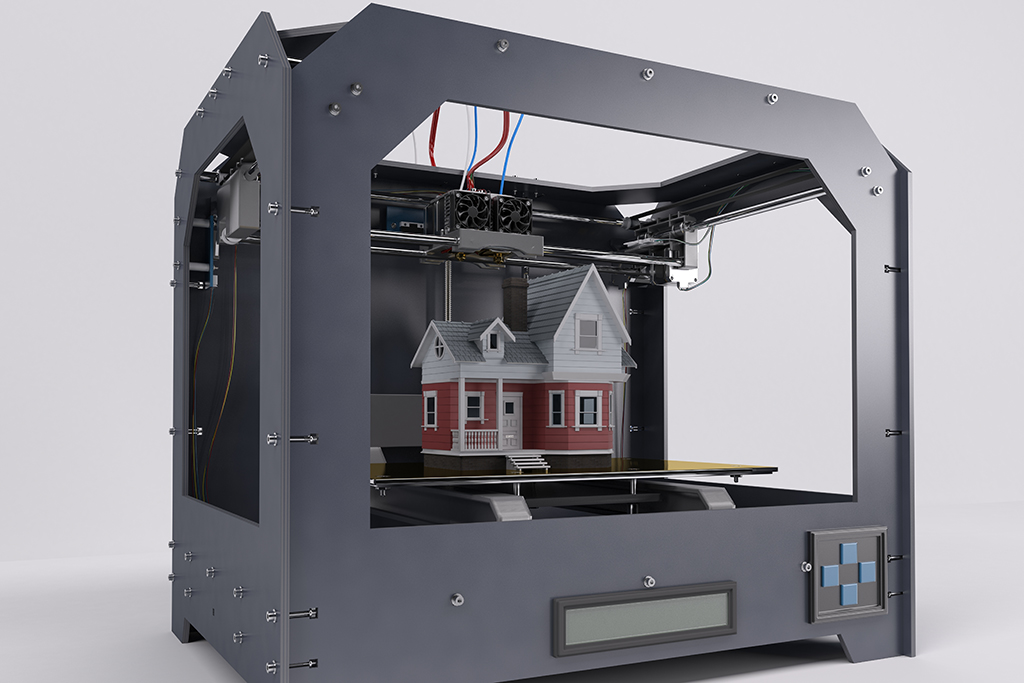

How 3D printers work

The basic principle of a 3D printer is layer-by-layer application of material. At the same time, you can print anything: concrete, living cells, plastic, chocolate. 3D printing is simply the principle of creating an object, along with any other method of production. nine0003

At the same time, you can print anything: concrete, living cells, plastic, chocolate. 3D printing is simply the principle of creating an object, along with any other method of production. nine0003

The main use of 3D printing in life is prototyping and creating unique objects. When prototyping, you can print several versions of a product and choose the one that turned out better than the rest. There are industrial enterprises that print plastic items, but it is too early to talk about the widespread use of 3D technology. She has two problems: slow production speed and not high enough quality. Indeed, you can print anything you want, but now it is not economically feasible to launch such mass production, Alexander Kornveits explains. nine0003

On the other hand, 3D printing can be used to create unique, design elements, sculptures, monuments. For example, in Moscow you can see printed sculptures like “Girl with an oar”. Often, such sculptures are additionally processed to give the appearance of a monument we are used to, made of marble or plaster.

Prospects for 3D printing for medicine

In the medical industry, the most active use of 3D printing is in dentistry. If you go to the dentist now, you will be faced with a 3D scan; or you will be offered 3D printed aligners. This is no longer prototyping, but the creation of final products or blanks for final products. nine0003

Bioprinting - organ printing - is currently under development. First, a cell of a damaged organ is taken from a person - skin, liver, kidney. After that, the cell multiplies in a special solution, and then, using a special bio-3D printer, the organ that needs to be replaced is produced. In this case, layer-by-layer stacking of living cells on top of each other also occurs, resulting in living tissue. The ability of such an organ to take root is much higher than that of a donor organ. According to the guests, this technology will be able to be used to treat specific patients in 5-10 years. nine0003

Printing a house: 3D printers in construction

Building 3D printing developments are very popular because there is a shortage of housing in the world. In Russia, this area is also developing, but many construction companies work abroad, since there is a higher demand for 3D technologies, Sergey Nefedov explains. For example, the founders of the California startup Mighty Buildings are from Russia. The essence of 3D printing is that it is effective where labor resources are expensive. For example, Australia and New Zealand have a norm that allows construction to be done only for 6 hours a day. This is based on the loads that a person can withstand. The cost of housing in these regions is very high, so it is advisable to replace a person with a robot. nine0003

In Russia, this area is also developing, but many construction companies work abroad, since there is a higher demand for 3D technologies, Sergey Nefedov explains. For example, the founders of the California startup Mighty Buildings are from Russia. The essence of 3D printing is that it is effective where labor resources are expensive. For example, Australia and New Zealand have a norm that allows construction to be done only for 6 hours a day. This is based on the loads that a person can withstand. The cost of housing in these regions is very high, so it is advisable to replace a person with a robot. nine0003

The problem with 3D construction is that automation and robotization of this industry has not yet occurred, in contrast to the automotive industry, where production is divided into separate operations. 3D building at the moment is a layered construction of walls, which is not difficult to handle. The portal system allows you to print the entire house: first, a portal is built that is larger than the house in size, and the building is printed inside it. But at the stage of finishing and engineering, problems begin. If a company can streamline all this R&D and replace people with machines, then it might work. nine0003

But at the stage of finishing and engineering, problems begin. If a company can streamline all this R&D and replace people with machines, then it might work. nine0003

3D printing eliminates the human factor: for example, building mix will always have the right consistency thanks to the settings. But in Russia, all cities are growing skyward, and 3D printing technologies are more applicable to low-rise construction. Unlike the markets in the US and the Netherlands, our market is still unfavorable for 3D construction.

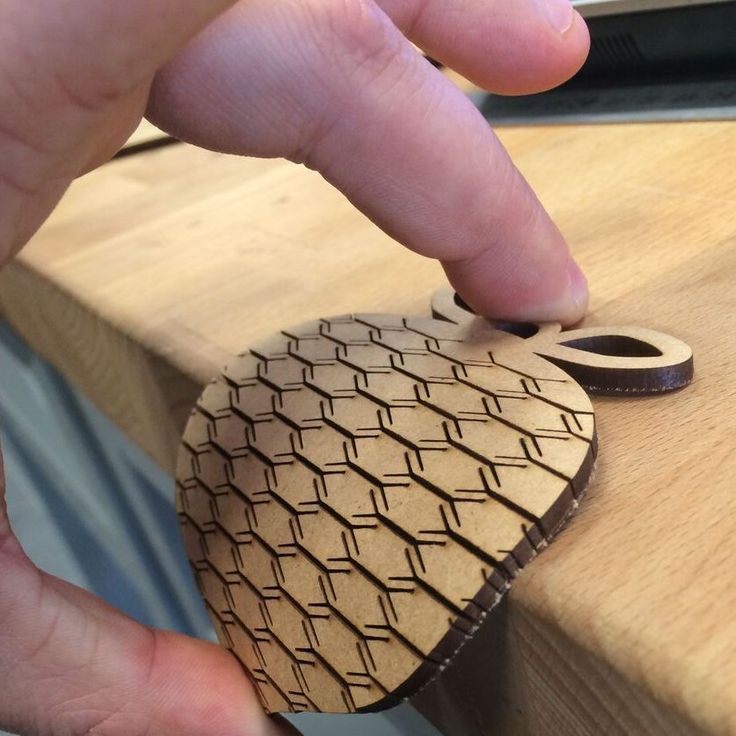

The future of 3D printing: orthopedic insoles and space colonization

The main advantage of 3D printing is customization, the ability to create a unique product, says Kornweitz. For example, the creation of orthopedic insoles will soon be actively developed. Another example is the frames and lenses of glasses, which take into account all personal characteristics. That is, the entire development of 3D technology will take place in areas where a personalized product is created for each individual person. nine0003

nine0003

The second promising direction is to use 3D printing where there is a gain in time and a shortage of something. For example, if there is a shortage of housing in the country, and classical technology does not allow it to be repaid, Sergey Nefedov adds. During the pandemic, a similar situation occurred with a shortage of valves for ventilation. 3D printer owners around the world have teamed up and started printing ventilator parts and sending them to hospitals. The same thing happened with the seal of PPE for doctors.

Finally, 3D printing is essential for colonizing other planets. It is impossible to predict what may be needed during a space mission, but if there are materials and apparatus, then at any time you can print what you need. nine0003

Related reading:

- How 3D printers work

- From bunkhouses to palaces: ten 3D printed buildings

- First fully artificial heart transplanted in the USA

- Is it safe to 3D print aircraft engines

- VR models and surveillance drones: how technology is changing construction sites

Breakthrough innovation, but not sure: how and who will make money on 3D printers

Andrey Stetsovsky. Photo: Alexander Glebov, probusiness.io

Photo: Alexander Glebov, probusiness.io 3D printers are called a revolutionary solution. But the businesses that work with them do not always think so. Andrey Stetsovsky, Business Development Director of PassivDom (3D printing of ready-to-live-in houses) says: the principle of automation has been used in construction for a long time, in this case, the new technology did not offer any breakthrough improvements.

What needs to happen for 3D printing to become a breakthrough? Under what conditions can the same technology be both an innovation and just a useful solution? How to see opportunities and make money on promising ideas? Andrey shared his thoughts at the HI-TECH NATION forum. nine0080

The Forum was organized by Pro Business. General partner - Alfa-Bank (Belarus) .

3D printing is an innovative technology, but it's not exactly

- We work in one of the most conservative industries, in my opinion. If we compare it with other areas, then in the entire history of mankind they have stepped forward very much. For example, transportation: we started with horses, and today there are cars on the market that are controlled by artificial intelligence. Innovations in medicine have made it possible to increase life expectancy by almost 2 times. nine0003

If we compare it with other areas, then in the entire history of mankind they have stepped forward very much. For example, transportation: we started with horses, and today there are cars on the market that are controlled by artificial intelligence. Innovations in medicine have made it possible to increase life expectancy by almost 2 times. nine0003

What happens in the construction site? Just like hundreds of years ago, we stacked stones one on top of the other, and so we continue to stack. Yes, now it’s a little different: they added glass and plastic. But they are still stones.

Let's put all this in the context of 3D printing technologies. Any search on Google will return a roughly similar definition of what it is: "the process of recreating a real object from a 3D model." Those. the digital model is transferred as a file for printing - to a 3D printer. In the field of construction, such a model, for example, drawings, a three-dimensional model of a house, is transferred to a construction company. And she creates a real object layer by layer using a 3D printer. nine0003 Photo from Andrey Stetskovsky's presentation

And she creates a real object layer by layer using a 3D printer. nine0003 Photo from Andrey Stetskovsky's presentation

But can all this be called an innovation? I do not know. The maximum is automation. But process automation has been used in construction for many hundreds of years. Watch this video. Here is an example of a machine that lays out a brick.

Attention! You have JavaScript disabled, your browser does not support HTML5, or an older version of Adobe Flash Player is installed.

The difference between traditional construction technologies and construction using 3D printers is only in who creates the layering process: either a robot, or people, or machinery. If a crane has already been invented and exists, you can hang a concrete mixer on it - and this will not differ in any way from the result that a 3D printer gives. nine0003

In addition, in working with 3D printers, the question arises of how to “print” a large building. As we have seen, a wall is a very complex three-dimensional object, consisting of materials that are drastically different from each other. It is practically impossible today to make a printer that will print walls for skyscrapers: the cost of the machine will be very high.

As we have seen, a wall is a very complex three-dimensional object, consisting of materials that are drastically different from each other. It is practically impossible today to make a printer that will print walls for skyscrapers: the cost of the machine will be very high.

I don't know of any major company that uses 3D printing technology in mass production. This approach was recently announced by General Electric, which is going to print blades for aircraft engines. When they come out with such a product, we'll see - perhaps there will be a first breakthrough. nine0003

How to see the possibilities in new technologies

Our company really wanted to use 3D printing technology. We understand that it is just beginning to develop, but this is the future. Here are the opportunities we saw:

1. The population of the earth is increasing, the need for housing is growing at a rapid pace. The US construction market has doubled since the end of the 2008 crisis.

Screenshot from Andrey Stetsovsky's presentation Approximately the same situation in Europe. nine0003

nine0003

2. In addition to stacking stones, humanity has another “hobby”: burning natural resources. That is, we are constantly burning something to provide ourselves with warmth, comfort, energy, etc. It is customary to say that environmental pollution is associated with industry. I would say this is not entirely true. The construction industry, together with the housing infrastructure, generates 30% of all harmful emissions into the atmosphere. Something had to be done about this. Europe, America began to develop regulations that would change the situation. Buildings must stop burning energy, emitting CO 2 should be reduced to a minimum.

What does this have to do with 3D construction? All these initiatives gave impetus to the so-called modular building (prefabricated house).

The point is to create an object using 3D printing not on the construction site, but in the production cycle: to make a roof, walls with already built-in pipes, communications.

Then the elements are brought to the construction site and assembled like Lego.

Modular construction is quite a promising piece of the market, now it is developing very well in Europe and America. One of the most advanced is Germany, it is called a country that will "consist" of only modular houses. nine0003

After studying the entire market, looking at who does what, where everything goes, we came up with our product: an autonomous, completely 3D-printed, disconnected from all networks modular home. We used:

Polymer composites. In our opinion, they are the future. With their help, you can create any shape of any object, which will be very light, very strong. Traditional materials are not well suited for 3D printing.

Screenshot from Andrei Stetsovsky's presentation Thanks to the use of polymer composites, we use 3D printing to create a ceiling, roof, walls. And we get the structure from which the house is assembled. It has high strength, high energy efficiency, low heat loss. If, for example, it is -20º outside, and there are 6 people inside the house, it is not necessary to heat it. The temperature will even rise a little.

If, for example, it is -20º outside, and there are 6 people inside the house, it is not necessary to heat it. The temperature will even rise a little.

The materials we use are very durable. They are not afraid of water, they are not afraid of the sun, wind, nothing. We believe that our home is practically eternal. nine0003

Energy management . We use only solar energy to provide the house with all the necessary energy. It has a serious drawback: the sun does not shine all the time. We were puzzled by this issue and solved it as follows: there are about 24 engineering systems in the house that are fully computerized.

Screenshot from Andrey Stetsovsky's presentation Of course, all this requires competencies in the field of hi-tech. We have a team of programmers who develop artificial intelligence: they analyze the behavioral model of residents, the energy consumption of certain systems, even in conjunction with the weather forecast, make decisions on how to spend this energy. The CEO of our company has a PhD in solid state physics, and he has a lot of experience in construction. The team also has an engineer who has been in construction for ten years. nine0003

The CEO of our company has a PhD in solid state physics, and he has a lot of experience in construction. The team also has an engineer who has been in construction for ten years. nine0003

Conclusion: what to do with 3D printing in the future

We are not a company that is engaged in chemical processes, the invention of materials. There is a lot of construction in our background. That is, we did not invent anything new - but we figured out how to use the opportunities and the trend for 3D printing.

Photo: Alexander Glebov, probusiness.ioIf we talk about the development of this area in general, its potential is huge. But on the condition that a serious issue with the materials is resolved. Following the path of automation, trying to mechanize processes, we stop paying attention to them. And in the materials that are used today, there is just a "trap": they are not suitable for 3D printers. nine0003

Therefore, the main problem, in my opinion, is the problem of materials in 3D printing.