3D print cooling fan

The importance of the layer fan

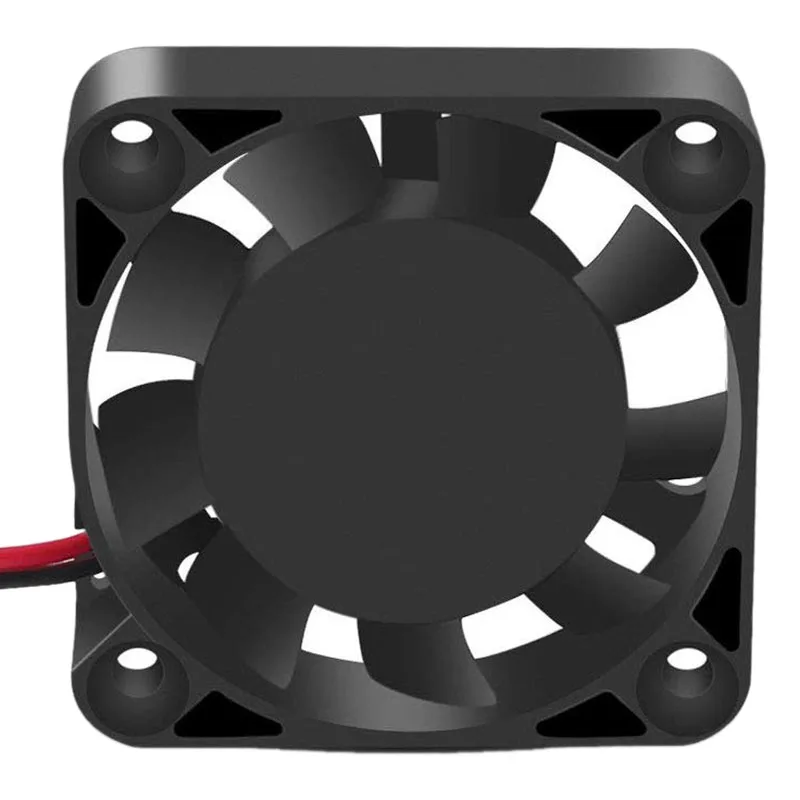

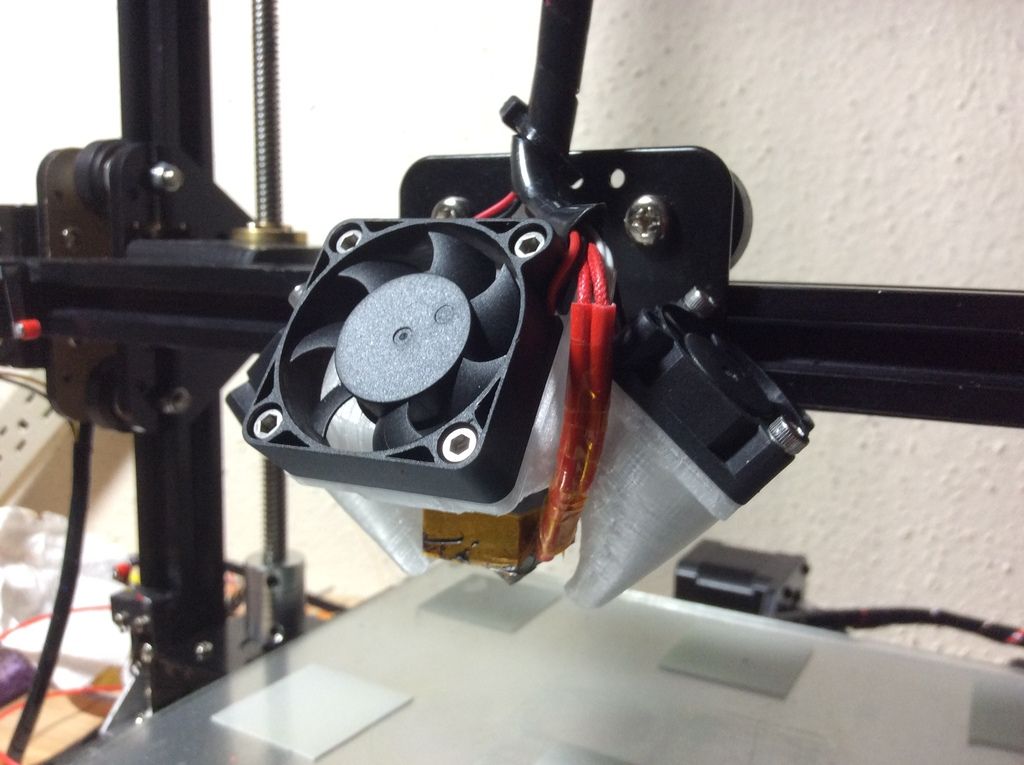

When talking about the functional parts of an FDM 3D printer, the layer fan is one of the most important components that can be found. A 3D printer usually has two fans in the HotEnd area, one in charge of cooling the HotEnd diffuser and another that cools the material that comes out of the nozzle. In this article we will talk about the latter, the layer fan.

When is it necessary

All users have tried to print some part with small area zones, where the nozzle is constantly moving in the same zone, a process that causes an excess of temperature that softens the part. The same happens when printing tall, slender parts, such as a small diameter cylinder, where heat accumulates in the same area and catastrophically deforms the part. Another typical deformation is that which occurs in very steep cantilevers, where the still hot material is deformed by the action of being suspended in the air, until it solidifies.

All these problems are solved simply by using the layer fan correctly.

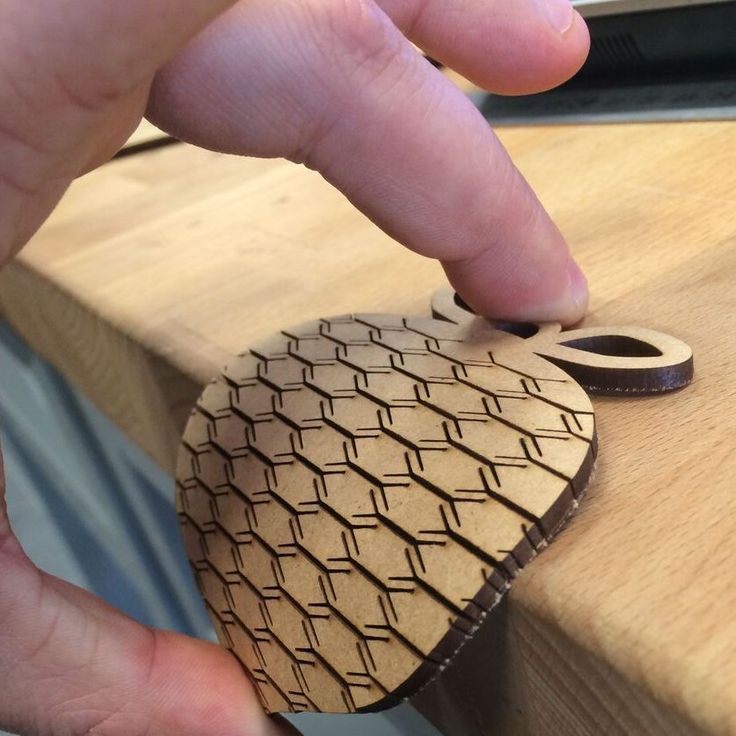

Image 1: Small parts without and with layer fan.

Compatible materials

Before commenting on how to configure the layer fan, the user must take into account with what materials it is recommended to use the layer fan and with which not.

PLA

The PLA is the material par excellence that the layer fan needs, due to its low softening point. This means that if the nozzle is placed in the same area for short periods of time, the piece will suffer irreversible deformation. For this reason, the layer fan is a crucial component in all FDM 3D printers that use PLA or some composite material containing this polymer as a base.

ABS

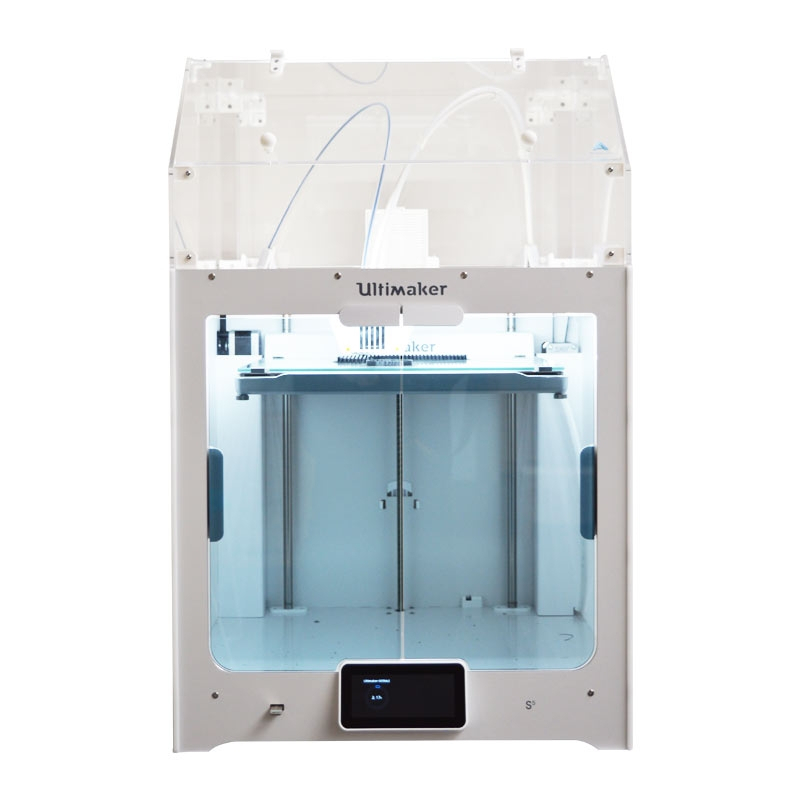

This material and similar ones, such as ASA, are totally incompatible with the layer fan. This is because the ABS is very sensitive to the loss of temperature against drafts, such sharp increases that cause cracking (delamination of the layers) and the total failure of printing. For this reason, it is vital to use ABS and ASA with fully closed 3D printers.

For this reason, it is vital to use ABS and ASA with fully closed 3D printers.

Others

Apart from the materials discussed above, in 3D FDM printing there are many more types of filaments and each with a different print configuration, for that reason a table with the majority of available materials is shown below and it is indicated if they need or no layer fan:

Table 1: Layer fan depending on the material.

Expert Advice

Once the user already knows whether or not he needs to use the layer fan, he must know how to use it and when.

At the beginning of a print the user needs the first layer to adhere to the base with sufficient firmness so that it does not peel off during printing. This is achieved, not only using some product that improves adhesion, but also keeping the temperature stable, so the layer fan must be turned off during the first two layers. Once the print has a certain height, the speed of the layer fan must be adjusted to the geometry of the piece in each layer. In general, there are two cases where the speed must be varied: when the printing time of a layer is greater than 5 seconds and when it is less than 5 seconds. In the first case, the layer fan speed must be increased linearly from 70% with layer times of 20 seconds or more, up to 100% with layers of 5 seconds. When the layer time is less than 5 seconds, the user must use the layer fan at 100% speed, sometimes being an insufficient speed that causes deformation in the part. This problem, which usually occurs when narrow and tall pieces are made, is solved by printing several separate pieces simultaneously as much as possible so that each layer has time to cool.

In general, there are two cases where the speed must be varied: when the printing time of a layer is greater than 5 seconds and when it is less than 5 seconds. In the first case, the layer fan speed must be increased linearly from 70% with layer times of 20 seconds or more, up to 100% with layers of 5 seconds. When the layer time is less than 5 seconds, the user must use the layer fan at 100% speed, sometimes being an insufficient speed that causes deformation in the part. This problem, which usually occurs when narrow and tall pieces are made, is solved by printing several separate pieces simultaneously as much as possible so that each layer has time to cool.

Any lamination software (Cura3D, Simplify3D, Slic3r...) allows you to modify the speed of the layer fan at the height of the piece that the user wants.

Image 2: Configure layer fan in Simplify3D. Source: Simplify3D.

Conclusion

It is important that all users of a 3D FDM printer know how to use the layer fan correctly, as it is a complement that elevates the quality and complexity of the parts.

Do you want to receive articles like this in your email?

Subscribe to our monthly newsletter and you will receive every month in your email the latest news and tips on 3D printing.

* By registering you accept our privacy policy.

Fans for 3D Printers - 3DJake International

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

-

Noctua NF-A4x10 Fan 2 Model types- Ultra-quiet

- Premium quality

- Excellent long-term stability

-

Noctua NF-A4x20 Fan 2 Model types- Ultra-quiet!

- Premium quality

- Excellent long-term stability

-

Anycubic Mainboard Fan 9 Model types- Original spare part

- From Anycubic

-

Noctua NF-A6x25 Fan 2 Model types- Ultra-quiet!

- Premium quality

- Excellent long-term stability

-

Creality Radial Fan Kit 3 Model types- Easy exchange

- Efficient heat dissipation

- Quiet operation

-

Artillery Material Fan- Original spare part

- From Artillery

-

Creality Axial Fan Kit 4 Model types- Easy exchange

- Efficient heat dissipation

- Quiet operation

-

Anycubic Material fan 8 Model types- Original spare part

- By Anycubic

-

FLSUN Part Cooling Fan 3 Model types- Original spare part

- Original material fan

-

Noctua NF-A14 Fan 2 Model types- Ultra-quiet!

- Premium quality

- Excellent cooling performance

-

Anycubic Hotend Fan 8 Model types- Original spare part

- By Anycubic

-

Noctua NF-A9x14 Fan- Ultra Quiet

- Premium quality

- Superior efficiency

-

Zortrax Radial Fan- Original spare part

- Zortrax M200 Plus

- Zortrax M300 Plus

-

Noctua NF-A12x25 Fan 2 Model types- Ultra-quiet!

- Premium quality

- Superior efficiency

-

Noctua NF-A9 Fan 2 Model types- Ultra Quiet

- Premium quality

- Superior efficiency

-

E3D DC Fan 24V - Black 2 Model types- 3D printer spare parts

-

BIQU Part Cooling Fan 3 Model types- Original spare part

-

FLSUN Hotend Fan 3 Model types- Original spare part

-

BIQU Hotend Fan 3 Model types- Original spare part

-

E3D DC Fan 24V - Transparent- 3D printer spare parts

-

Creality Part Cooling Fan- Original spare part

- From Creality 3D

-

E3D Revo Micro Fan- Maximum controller input: 24V

- Low volume

- Good fan performance

-

Slice engineering Mosquito Fan 2 Model types- Perfect cooling

- Fits the Mosquito Hot-End

-

Voxelab Hotend Fan- Original spare part

All prices incl. VAT.

VAT.

Answers to cooling questions

Questions about cooling 3D printers and 3D printed parts.

For questions regarding faults, developments and best practices for cooling 3D printer mechanisms or 3D printed parts.

- Cura: How do I prevent my 3D printer from automatically cooling down after printing Is there a setting or G-code to prevent Ultimaker Cura from setting the nozzle and build plate temperature to 0? I looked and didn't find anything at the beginning/end of the printer's G-code,...

- Cooling fan noise when head moves in X direction I have this fan model , this is SUNON model number MF50151VX-B00U-A99 , and this is the fan type. When the head moves along the x-axis, it makes noise. I think this type is…

- Anycubic i3 Fanless Mega Can't figure out what's going on with the fans on my Anycubic Mega Pro. First, the part cooling fan on the Anycubic i3 Mega stopped working, and then soon the extruder fan also…

- Should the 3D printer be enclosed? I have a home package open on all sides.

. Would there be any advantage to enclosing the printable area in acrylic?

. Would there be any advantage to enclosing the printable area in acrylic? - Calculating the right pressure for cooling based on compressed air I've heard a little about people who use air compressors with tubes to the cutting head and outlets there as part of the cooling. One example is Berd Air, but,…

- What causes my PLA prints to rise like this? I'm Printing the Soma Cube I found on Thingiverse is a puzzle toy that I remember from the early 1970s and the kind of thing that should be very easy to print. Each of the seven parts…

- How to systematically calibrate all variable speed fan parameters? When the part is thin and the total layer time decreases below a certain threshold, the plastic does not have time to cool enough to harden and properly support the next layer, resulting in…

- Thermoelectric cooler for partial cooling fan? Is there any research on using a thermoelectric cooler along with a partial cooling fan for faster cooling without strong air currents that…

- The fan makes a high noise at full power CR-10S, and it makes a very annoying high-pitched noise at full power.

I have read that PWM can cause this, but not at full power...0010

I have read that PWM can cause this, but not at full power...0010 - SKR E3 mini Ender 5 case cooling system I was hoping I could find some help as I am not that familiar with Marlin. I currently have an Ender 5 and am in the process of replacing the stock board. So here's what I...

- Is it possible to replace the hot end cooling fan blade on the creality ender 3? I broke one of the fan blades and it caused the x-box to vibrate. Other than that it works fine and I can still print at very low flow rates and a lot of noise. Will…

- Water cooled stepper motor with aluminum block On a budget, I cool my 3D printer with water. I am using a 5V (\$3) aquarium pump. Initially I tried to only use about as much water in a can of chickpeas, but then I found that I needed…

- All metal hot end, cooling fan failures and PTFE on the cold side I will get my favorite bird soon and I know the gas from heating PTFE above 300 °C creates harmful fumes that are bird killers 1 .

To try and prevent even the possibility that I would replace...

To try and prevent even the possibility that I would replace... - How to find the right part of the cooling fans? I have a 2-pin 40mm axial fan as part of a cooling fan. I am not posting the link because I would like a general answer. It runs on 12V and when I run it...

- Is the cooling fan part turned on when printing TPU? I could have sworn I read somewhere that when printing with TPU you need to make sure the part cooling fan is blowing. But I just did a quick google and couldn't find anything similar in Matter...0010

- Correct way to turn off power to FDM printer I just received my first 3D printer today, QIDI X-ONE[2], and so far so good with setup and getting 1 print. I wanted to turn off the 3d printer, but I don't see any instructions on how to…

- Which filament to use for a water circulation application? Let's say I want to build a water block shaped exactly for my hot end Ubis 13s (similar to this instructable), or that I want to circulate water around certain objects,…0010

- Why does the partial cooling fan cause tension? Really weird observation with my MP Select Mini V2 print board.

I printed out a two-fan shroud so I could have a dedicated fan to keep the parts cool. I noticed that...

I printed out a two-fan shroud so I could have a dedicated fan to keep the parts cool. I noticed that... - Marlin on the RUMBA board automatically switches the extruder fan I connected a new extruder with its own cooling fan and tried to change the Marlin firmware so that it automatically turns on at a certain temperature (50 ° C). I didn't notice in…

- Is it worth using an optional external fan(s) for PLA printing? I was wondering if adding (a) additional fan(s) (not connected to the printer but blowing on the printable area) could improve the quality of PLA-based prints (printing at 210°C). In…

- Replacing FAN0 with FAN1 on the TriGorilla printer board I connected a new fan to the PCB fan (TriGorilla v1.4) Fan0 which I found to be broken. I am trying to upgrade the cooling fan parts for a bigger size. K…

- How can I avoid jamming the feeder? We recently bought a Guider II printer from FlashForge at work.

When we try to print high resolution models or models that take too long to print, the feeder becomes clogged. And...

When we try to print high resolution models or models that take too long to print, the feeder becomes clogged. And... - Can't reach hot end temperature with part cooler on I can't use the part cooler I printed. Every time I turn it on the hot end temperature drops too low and for some reason the PID can't seem to recover...0010

- By upgrading to a silicone heat table, will it start a fire? I'm thinking about upgrading my heated table and replacing it with a silicone table. I know next to nothing about electronics, so I'd like someone more knowledgeable to confirm...

- Understand what CR-10S fans cool I'm designing a fan mount for a CR-10S printer to mount an all-metal v6 HotEnd E3D and sensor BLTuch. The CR-10S printer is equipped with two fans. One on the front…

- Should I do a PID autotune with fan at 100% (Anet A8) I am using Anet A8 with Marlin 1.1.6. I've read countless PID auto tuning manuals and never saw that the fan should be on, but when I look at the ANet configuration.

.. My print is deforming and I suspect this is due to uneven cooling. How to ensure even cooling of my print? Should I put a fan on the table? Will it help ...

.. My print is deforming and I suspect this is due to uneven cooling. How to ensure even cooling of my print? Should I put a fan on the table? Will it help ... - Sanguinololu 1.3a fan connection Can anyone tell me where to connect the cooling fan on the Sanguinololu v1.3a board? Several info pages mention three PWM outputs: extruder, tabletop heater...

- Cooling for large layers Slic3r has the ability to turn off cooling for layers that take more than n seconds. What will be the disadvantages of cooling on large layers?

- Blow against air intake through hotend 9 radiator0009 I built a 3D printer from the original parts and installed a hotend cooler to blow air over the heatsink. Talking to a friend, he said it's better to reverse the airflow over the radiator...

- Soft little top layers? I just added a fan to my printer because very small layers seem to come out really bad. For example, a 5 mm thick PLA cube, which is the top level of the test mold,…

- Does the material that the 3D printer table is made of affect the cooling time of the part? nine0009 Let's say I print an ABS part and wait for it to cool.

Theoretically, I could do this with multiple copies of the same printer modified to use printed...

Theoretically, I could do this with multiple copies of the same printer modified to use printed...

model of the best circular blowing nozzle

How to upgrade the blower unit of a 3D printer and maximize print quality?

One of the parameters of the 3D printer that affects the quality of the model is the cooling of the filament. Airflow is responsible for lowering the temperature of the plastic. It is proposed to increase the capabilities of the cooling unit by installing powerful fans and upgrading the air duct. nine0003

Why do I need airflow for a 3D printer?

The principle of FDM printing is to heat the plastic to a softening temperature and extrude it through a nozzle onto the worktable. Further, the polymer solidifies, the layers at the same time are connected, forming a homogeneous three-dimensional object. But the heated plastic has fluidity, and if the previous layer does not have time to cool down to the curing temperature, the model begins to lose its desired shape. The heat of the heated nozzle also has its effect: the already cooled layer softens again when the extruder moves directly above it. nine0003

The heat of the heated nozzle also has its effect: the already cooled layer softens again when the extruder moves directly above it. nine0003

Temperature deformation is especially noticeable on miniature and thin-walled objects. This is due to the following points:

- small parts are constantly exposed to heat coming from the nozzle;

- thin model elements heat up faster.

To prevent the temperature rise of already finished layers and to cool the last of the printed ones faster, 3D printers are equipped with airflow.

What is a cooling unit? nine0160

The blower unit consists of the following components:

- fan;

- air duct.

Fan speed and start times are set in the slicer. The duct creates a directional flow, providing cooling to the desired area.

Important! Slicer airflow settings are set by default. But for each type of plastic and the shape of the 3D part, it is recommended to set special parameters, which makes it possible to maximize the quality of the model.

nine0003

There are no universal values, each user of a printing device selects them empirically.

How can I improve print quality with airflow?

To set the cooling of the model as correctly as possible, consider the following:

- Type of plastic. ABS and PETG have a high melting point and require less airflow. Large objects sometimes print with the fan turned off. Parts made of PLA, especially small ones, may require 100% airflow; when printing several figures at the same time, the fan speed can be reduced to 60-70%. nine0011

- Model value. When printing large-sized objects, the plastic has time to cool down so much that when the next portion of plastic comes from the extruder, the previous layer does not heat up to the critical fluidity temperature. Accordingly, the formation of a part with a small surface area should occur with blowing, the intensity of which will be the higher, the smaller the size of the print area.

- The shape of the feature.

Here, the wall thickness, the presence of supports and the density of filling are taken into account. Models with small, thin, openwork elements are printed, be sure to turn on the fan. The same requirement applies to parts with less than 30% infill. The higher the percentage of filling, the less airflow is allowed. nine0011

Here, the wall thickness, the presence of supports and the density of filling are taken into account. Models with small, thin, openwork elements are printed, be sure to turn on the fan. The same requirement applies to parts with less than 30% infill. The higher the percentage of filling, the less airflow is allowed. nine0011

Important! When setting the fan operation mode in the slicer, all the above conditions are taken into account. Experienced users recommend keeping statistics on settings and print results. So by trial and error, over time, the maximum quality of the final result is achieved.

It is not always possible to achieve the desired result by changing the software settings of standard equipment. The maximum effect is achieved by installing high-power fans and other designs and replacing air ducts. nine0003

The best airflow models for a 3D printer

To modify the plastic cooling system, three airflow options are most often used:

- Direct (one-sided) with an improved air duct and a more powerful fan.

- Double-sided.

- Circular.

Any of these is suitable for improving the print quality of a 3D model.

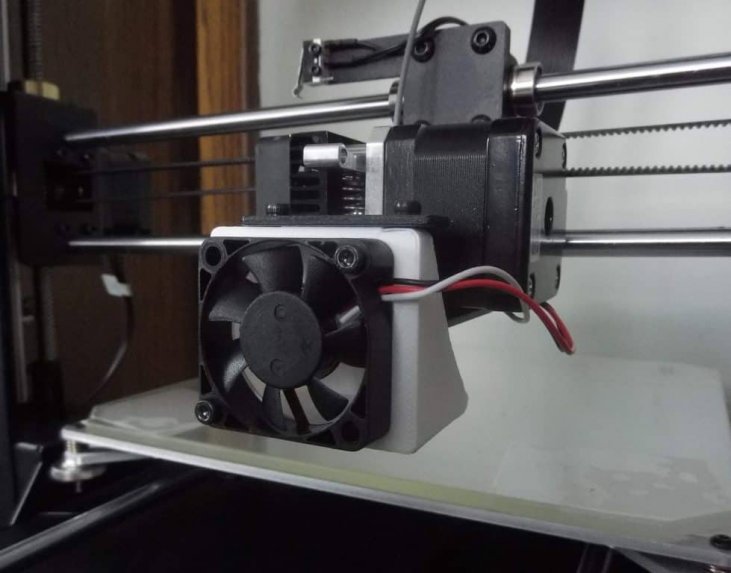

Straight

The simplest option is to replace the stock fan with a "snail" or the same, but more powerful, and leave the standard air duct. But another solution is also proposed: the installation of an improved duct. It has a reshaped spout, which allows for a more directed air flow, and a seat for a fan. nine0003

By redirecting the air jet, more precise cooling of the target area is achieved with minimal impact on nozzle temperature. And due to the installation of a productive fan, a wide adjustment of the blowing speed is provided.

Double ended

Duct with two outlets is another way to improve your airflow system. But separating the air stream into two significantly reduces the power of each. This means that a stronger air blower is needed (the standard one will definitely not cope). Most often, seats for two fans are formed in the duct box - one for each outlet. Double-sided blowing does not have a noticeable disadvantage of one-sided blowing, when, depending on the direction of movement of the extruder, there is a different cooling intensity of the plastic. nine0003

Double-sided blowing does not have a noticeable disadvantage of one-sided blowing, when, depending on the direction of movement of the extruder, there is a different cooling intensity of the plastic. nine0003

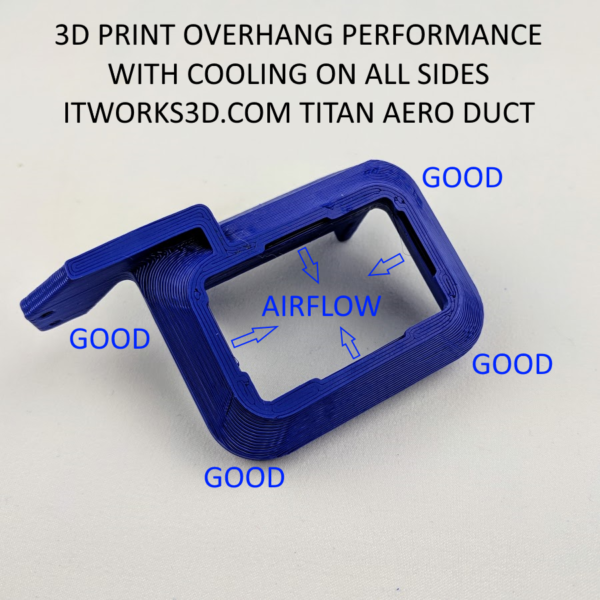

Circular

Circular, or annular, cooling is a uniform blowing of the zone from all sides. The air flow is directed in such a way that it does not affect the nozzle. The standard fan also needs to be replaced here. Instead, they put one or two more powerful ones, for the installation of which a seat is provided on a modified duct box.

Users of 3D printers who have applied this solution note the following drawback: the circular air duct strongly blocks the view, making it difficult to control the quality of the print. nine0003

Important! Any increase in fan power results in increased noise during fan operation. The same can be said about installing two coolers at once. Experienced users recommend paying attention to expensive models of well-known brands, whose developers have made every effort to reduce the noise of their devices.

Learn more