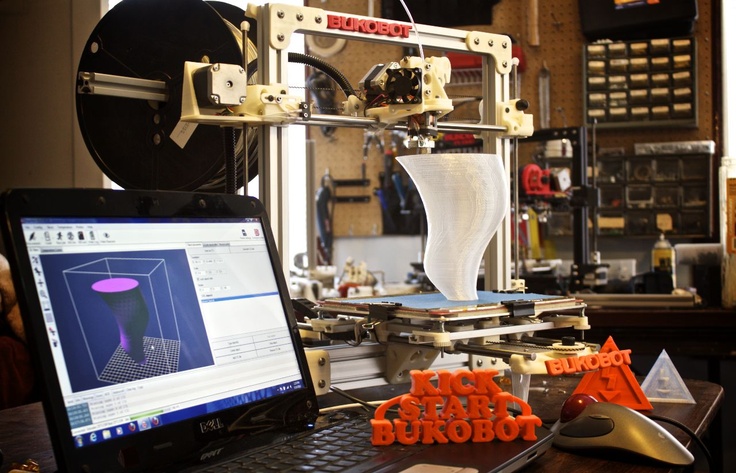

Nyc 3d printing store

3D Printing | Large-Scale | The Factory NYC

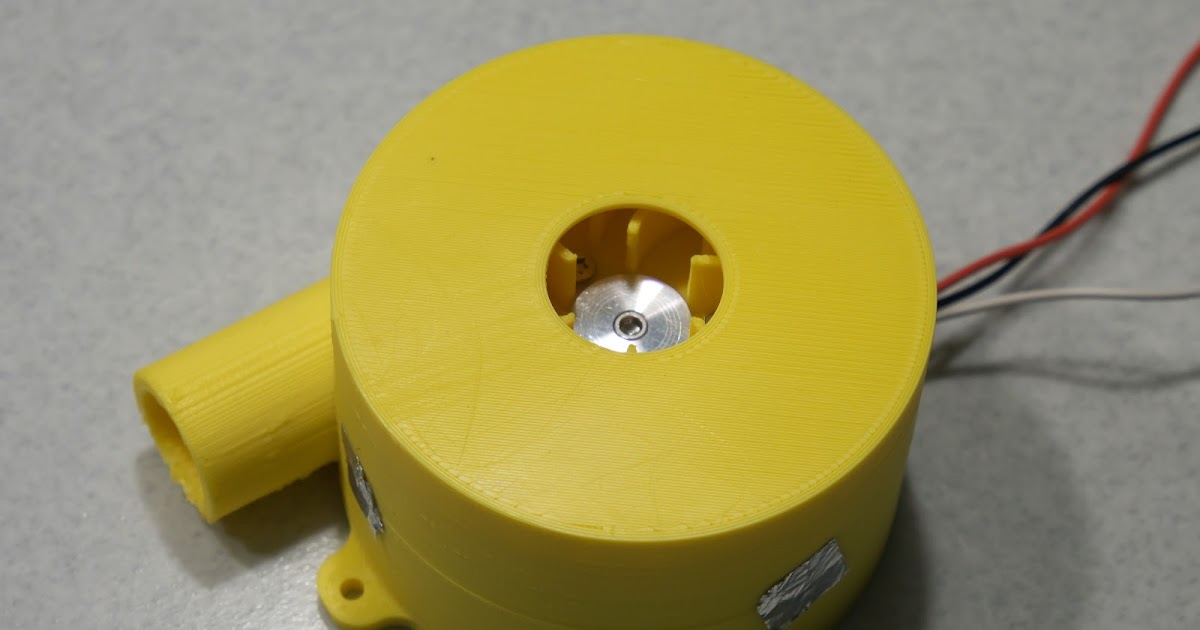

3D-Printing

LARGE-SCALE 3D-PRINTING SERVICES

Massive 3D PrintsWe offer large-scale 3d printing for artists, engineers, and designers. Individual parts at 72" (177cm), and even larger with sectional fabrication. Start with a napkin sketch, a physical object to scan, or with fully engineered CAD files. Our design and production team at The Factory NYC will bring your project to life. Start your Project |

Oversized 3D-printed headphones with built-in audio made for City Eventions |

Start thinking in 3DRapid large-scale 3D Printing opens up a world of possibilities.

|

The future of storytelling is sculptural(and it's here)

Click to set custom HTML |

Big Print EnergyThe Factory NYC is the only event fabricator in NYC with a large-format 3D-printer — and its up to a 100x times faster than typical 3D Printing; and there is no size limit. |

Requirements

| Adding sculpture to your next event is easy. You don't need 3D modelers on your team — we have you covered. The only requirement is bring your vision with a budget. We can accommodate your design concept for most situations:

Even if you just have a 2D logo or design on pen and paper. We can create a digital model from scratch, and/or use 3D models from open source libraries. There are many ways to get started. |

Huge 3D-Printing — Get Inspired and Imagine

Delivering amazing projects, daily. | Our team of installers works throughout the New York City greater area. Local, domestic, and international delivery available through air, land, and sea. |

Join our Email list:

Sign up, and we'll share the latest event fabrication technologies:

Shapeways: 3D Printing Service Online

3D Printing Service

Create and customize. Streamline and save. Break down design barriers and scale your business with Shapeways 3D printing services.

Why 3D Printing?

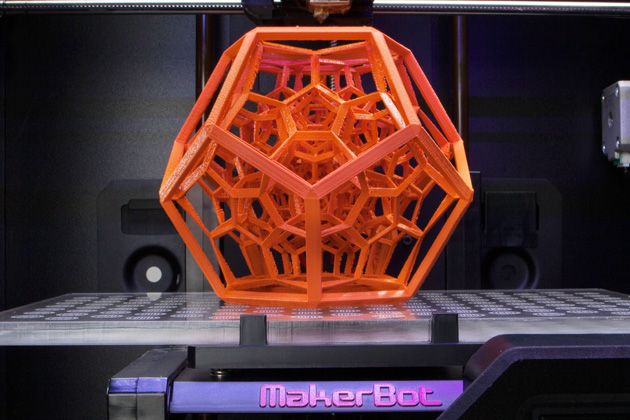

Reduce Assembly Time

Don’t waste time putting products together! Rely on 3D printing to make complex geometries that can be printed as one piece—or consolidated in one build.

Fast Turnaround

Working on a project for a customer that has to be just right? Get models back fast, and 3D print new iterations, if needed, for final feedback and production.

Reliable Quality

Proprietary processes, expert 3D printing operators, and inspections are our secrets to delivering exceptional, quality products every time.

Parts 3D Printed

3D Printing Technologies

Materials and Finishings

Countries Shipped

Customers Served

Cutting Edge Technologies

Manufacture high-quality products in over 90 of the best materials and finishes, from plastics to metals.

HP Multi-Jet Fusion

- Nylon 12 with a smooth and finished surface

- Exhibits incredible strength, durability and stiffness

- Supports complex geometries and thin features Learn More

ExOne Binder Jetting

- Steel infused with Bronze

- Supports large parts

- Strong metal with an industrial look and feel Learn More

Our Services

Production Parts

Upload customized models for 3D printing service—ensuring durability and strength in materials that result in end-use products meant to last. Learn More

Learn More

Rapid Prototyping

Take the guesswork out of product development with 3D printing services for high-performance models used in meetings, testing, and perfection of final parts. Learn More

Finishing

Whether designers prefer polishing, smoothing, dyeing–or a combination of finishing techniques–Shapeways 3D printing services can perfect those final touches with shine, gloss, and color. Learn More

Professional Design Services

Bring your idea to life with 3D file design and optimization. Through our partnership with ZVerse, every customer has access to expert 3D Design solutions for any project need. Learn More

Rapid Prototyping

Our high quality printing enables you to assess factors such as ergonomics, usability, manufacturability, and material testing. Learn More

E-commerce Integrations

Launch your business through our marketplace by connecting to the Shapeways platform through our API, Shopify, or Etsy E-commerce Integrations. Learn More

Learn More

Materials

Nylon 12 [Versatile Plastic]

Nylon 12 [Versatile Plastic] is a durable nylon plastic that can be used for a wide range of applications, both for prototyping and for end products. Printed using Selective Laser Sintering (SLS) 3D printing services, when thin, it's flexible enough for hinges and springs and when thick, strong enough for structural components. Learn More

Accura 60

Accura 60 is a translucent and rigid acrylate-based plastic. Shapeways 3D prints this material using a large-format Stereolithography (SLA) printer capable of producing small to large parts with high resolution and detail as well as smooth surfaces with limited layer lines. Learn More

Stainless Steel 316L

Stainless Steel 316L is manufactured using ExOne’s ‘Triple Advanced Compaction Technology’ with Binder Jetting. Unlike our Steel that is infused with bronze, this material is a single alloy, composed of pure Stainless Steel. Learn More

Nylon 12

Nylon 12 (Versatile Plastic) is a durable nylon plastic that can be used for a wide range of applications, both for prototyping and for end products. Printed using Selective Laser Sintering (SLS), when thin, it's flexible enough for hinges and springs and when thick, strong enough for structural components. Learn More

Printed using Selective Laser Sintering (SLS), when thin, it's flexible enough for hinges and springs and when thick, strong enough for structural components. Learn More

Accura 60

Accura 60 is a translucent and rigid acrylate-based plastic. It is 3D printed using a large format stereolithography (SLA) printer capable of producing small to large parts with high resolution and detail as well as smooth surfaces with limited layer lines. Learn More

Stainless Steel 316L

Stainless Steel 316L is manufactured using ExOne’s "Triple Advanced Compaction Technology" with a binder jetting system. Unlike our Steel that is steel infused with bronze, this material is a single alloy, 100% Stainless steel 316L. Learn More

Testimonials

I like the ease of use in the Shapeways platform, being able to 3D print on-demand orders for the first time, and most of all–being able to scale my business. In the beginning years ago I basically had the change in my pocket and a credit line at my bank so I couldn’t order a ton of things, and you never know what’s going to sell. ”

”

Steven Jaworski

Owner | Voytek Medical

During the process, we used Shapeways capabilities to 3D print many prototypes. That meant we had the option to iterate very quickly, print objects, and test them to see if they were working correctly in terms of complexity, or too much complexity.”

Yonatan Assouline

Manager & Co-Founder | Flamingo Works

Shapeways was really great when we worked together before, which led us to reach out again. It’s been so helpful to talk with them about what we could do in every aspect of 3D printing and finishing, and it saved us a lot of time in experimentation.”

Nathan Lachenmyer

Director of Technology | Sitara Systems

I like the ease of use in the Shapeways platform, being able to 3D print on-demand orders for the first time, and most of all–being able to scale my business. In the beginning years ago I basically had the change in my pocket and a credit line at my bank so I couldn’t order a ton of things, and you never know what’s going to sell. ”

”

Steven Jaworski

Owner | Voytek Medical

During the process, we used Shapeways capabilities to 3D print many prototypes. That meant we had the option to iterate very quickly, print objects, and test them to see if they were working correctly in terms of complexity, or too much complexity.”

Yonatan Assouline

Manager & Co-Founder | Flamingo Works

Shapeways was really great when we worked together before, which led us to reach out again. It’s been so helpful to talk with them about what we could do in every aspect of 3D printing and finishing, and it saved us a lot of time in experimentation.”

Nathan Lachenmyer

Director of Technology | Sitara Systems

Previous Next

Recent Articles

Trusted by Businesses Around the World

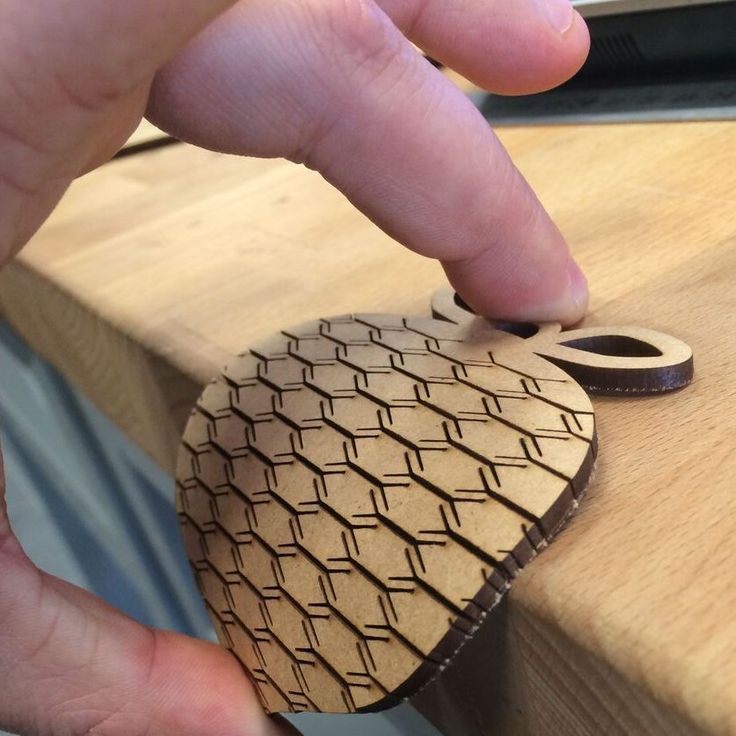

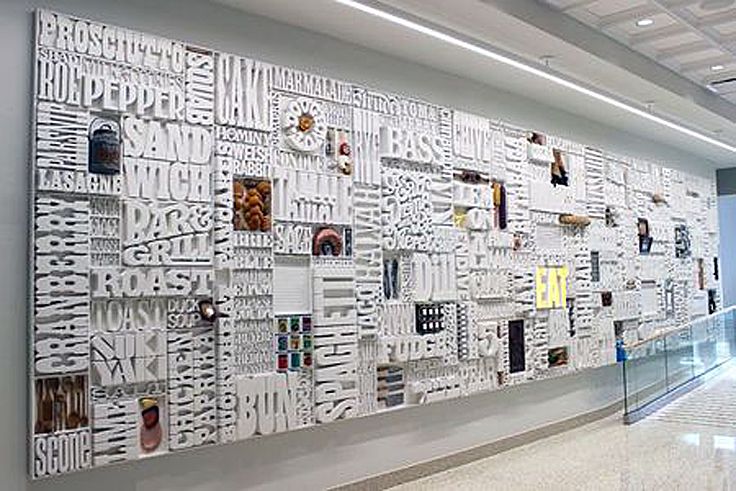

3D printing helped New York architects restore the facade of an old building

News

MakerBot Replicator Z18 voxeljet VX1000

New York-based architecture firm EDG has used 3D printing technology to restore a historic building that was about to be demolished. 3D-printed molds helped to restore the unique façade. nine0003

3D-printed molds helped to restore the unique façade. nine0003

EDG's team is focusing on a 1940s building on Fifth Avenue. At the time of construction, the facade of the building was decorated with a beautiful bas-relief with intricate patterns. The city authorities intended to demolish the dilapidated house, as the restoration of the facade would have cost too much, but EDG architects managed to save the building, promising to restore the main decoration to its original state without excessive costs.

Digital technologies helped to complete the task. The facade was digitized using a 3D scanner, and then the resulting models were corrected in 3DSMax and Rhino. The next step was prototyping with the MakerBot Replicator Z18 desktop FDM 3D printer. Architects printed plastic molds, then inserted rebar into them and filled them with cement mixtures, testing different materials in search of the optimal solution. nine0003

The final, full-sized elements are made in a similar way, according to 3D printed forms, but using an industrial 3D printer Voxeljet VX1000, capable of printing sand forms up to 2000x1000x1000 mm in size.

“This project had a clear goal - to find a way to save and restore decaying architectural treasures in New York and around the world. The beauty and historical value of many buildings threaten to sink into oblivion due to the ever-increasing cost of restoration work. Often we realize the tragedy of such losses too late, as was the case, for example, with the demolition of the old Pennsylvania Station complex. Therefore, we decided to find an economical method of repair and restoration. The simplicity and affordability of these technologies could very well lead to a revolution in architecture,” said EDG Chief Architect John Meyer. nine0003

Impressed by the results, the team has taken on two more AM restoration projects and even intends to build their own 3D printer optimized for architectural printing.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at news@3Dtoday. ru.

ru.

Follow author

Follow

Don't want

7

Article comments

More interesting articles

eleven

Subscribe to the author

Subscribe

Don't want

The detail in the illustrations is a fragment of the core baffle ring, made by the Institute of Laser...

Read more

five

Subscribe to the author

Subscribe to the author

Don't want to

The new service of the Moscow Innovation Cluster will help Russian start-ups and technology compa...

Read more

sarkazm

Loading

04/01/2016

40029

68

Subscribe to the author

Subscribe

Don't want

News from the world of printing short line

FDplast announced the release of a free. ..

..

Read more

Read the blogs

How does the international company Tapestry use it?

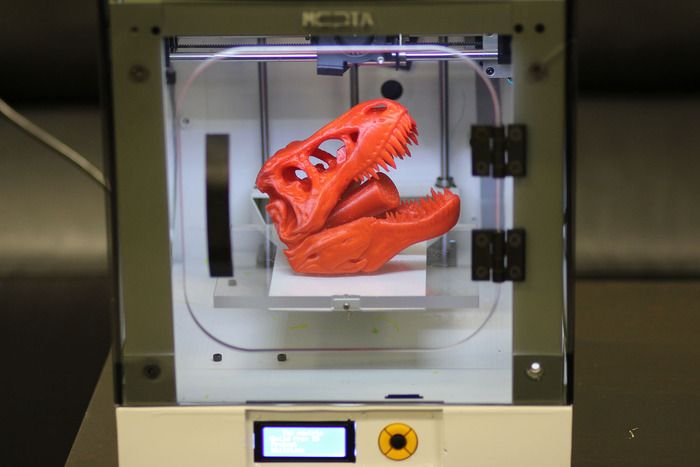

What happens when fashion and 3D printing join forces? It's becoming more and more likely that the fashion you see on the runway and the merchandise from hardware and jewelry to the shoes you see in stores have been prototyped using 3D printers. Tapestry, the first New York fashion house for contemporary luxury brands and the parent company of established high fashion brands Coach, Kate Spade and Stuart Weitzman, uses 3D printing in the early stages of product development. nine0003

Long before Tapestry and shortly after graduating in industrial design, Tomer Emmar founded a jewelry design company called Studio Forty Seven, where he was first introduced to 3D printing. There, for the first time in his career, he combined metal fabrication technologies with 3D printing. “After doing the necessary verification of the integration of 3D printing into the process, it became very clear to me that 3D printing would make any design process more efficient. It will help you quickly check the concept and get the job done. You can be sure that the concepts will be developed and the work can be done without having to allocate storage space for inventory,” said Emmar. nine0003

It will help you quickly check the concept and get the job done. You can be sure that the concepts will be developed and the work can be done without having to allocate storage space for inventory,” said Emmar. nine0003

After moving to New York, Tomer worked at a 3D printing office where he learned how to work with various 3D printing technologies, including SLA, before joining Tapestry.

3D printing as a means of communication: design intent + functionality

As Rapid Prototyping Manager at Tapestry, Tomer Emmar manages a 3D print shop in New York and a team of prototyping specialists. They use various additive manufacturing technologies to speed up both the design process and the process of prototyping products across various categories. “We use 3D printing early and in the product design and development process. 3D printing is used to test aesthetics, functionality and help early in product development. The technology complements traditional fabrication methods early on,” Emmar said. nine0003

nine0003

Preparing a 3D Model for 3D Printing

3D Printed Products

The future of 3D printing in Tapestry

Tapestry has embraced 3D printing to meet the demands of the rapidly changing fashion industry. The team can build a prototype overnight. It is faster and more economical than relying on overseas factories. Tapestry designers also benefit from the flexibility and speed of the technology, as they can make more informed decisions faster. Prototyping is carried out within the company. “This allows us to reduce the consumption of raw materials and reduce the cost of shipping samples from abroad. Doing less is better,” Emmar said. nine0003

3D printing is also helping Tapestry facilitate communication between international offices." COVID-19 has been a catalyst in accelerating the adoption of 3D printing. We have seen the importance of flexibility and the ability to prototype locally and regionally.

We can print and assemble hundreds of parts to build forms at colossal scales.

We can print and assemble hundreds of parts to build forms at colossal scales.