Interesting facts about 3d printing

Check out these 17 outstanding 3D printing facts

Posted By Lucie Gaget on Oct 30, 2019 |

You may already use 3D printing but here are some great facts you may not know about 3D printing. Indeed, as a 3D printing service, we can see every day that people have misconceptions about this cutting-edge technology! That is why we made this article for you, about the incredible and diverse applications of additive manufacturing, showing you the full potential of this technology.

Are you ready to see what 3D printing can produce? Discover some amazing 3D printing facts and get inspired to give life to your own 3D printing projects!

3D printing is older than you think

Additive manufacturing is often seen as a really new manufacturing technique. But this technology is actually not that new. We can say that 3D printing made kind of a buzz in the 2000s when the general public discovered FDM (Fused Deposition Modeling) technology and nylon filament. But the birth of additive manufacturing is way older than that! First 3D printing experiments and patents appeared in the ’80s

3D printing is a French invention

Indeed, the creation of 3D printing kind of started in France. Jean-Claude André, Alain le Méhauté and Olivier de Witte registered the first patent for this game-changing technology in 1984, but everything didn’t go as expected, and we often credit the American Charles Hull for this innovation. To read the full story, check out our interview with Jean-Claude André, one of the 3D printing creators.

There are numerous 3D printing techniques

People often associate 3D printing with FDM technology and desktop 3D printers, but there are actually various types of 3D printing processes. But that is not the only 3D printing technology. As you can see on our online 3D printing service, we are offering multiple technologies such as SLS (Selective Laser Sintering), HP Multi Jet Fusion, DMLS (Direct Metal Laser Sintering), SLM (Selective Laser Melting), DLS (CLIP), etc.

From plastic to metal and resin, there are different 3D printing processes and even more 3D printing materials available on the market.

3D printing is not only a prototyping technique

3D printing is mainly seen as a prototyping technique. And indeed, it is a very good way to make some rapid prototyping and create functional prototypes, but not only! Additive manufacturing is more and more used for production. Each year, we study the evolution of the uses of additive manufacturing by companies, with the biggest report of the additive manufacturing industry, the State of 3D Printing.

In this report we can notice that year after year, 3D printing is used for more and more different applications by companies. And we can clearly see that a growing 51% of respondents apply 3D Printing technologies for production. This technology is actually more and more used for production purposes!

3D printing materials are more numerous that what you think

We just told you about the numerous 3D printing techniques actually available in the industry. But the industry is also flourishing on the material side. If plastic, metal, and resin, are offering great opportunities. Researchers are developing new material, so this technology can answer all needs possible. 3D printed wood, ceramics or 3D printed meat. Yes, materials possibilities are endless.

But the industry is also flourishing on the material side. If plastic, metal, and resin, are offering great opportunities. Researchers are developing new material, so this technology can answer all needs possible. 3D printed wood, ceramics or 3D printed meat. Yes, materials possibilities are endless.

Additive manufacturing saves lives

3D printing is taking more and more space in the medical industry. This manufacturing technique is actually helping surgeons and doctors in their daily job. That is why we can say that 3D printing is helping to save lives on different levels.

Applications of additive manufacturing in the medical sector are numerous. 3D printing is making it possible to create perfectly adapted devices: from casts to prosthetics. But it also becomes possible to make implants, adapted tools for surgeons, and to print a 3D model to prepare a complex surgery. Indeed, it is becoming common in hospitals to 3D print models of kidneys or hearts and prepare some complex surgeries.

It is possible to print living tissues

Here is an outstanding material that is now 3D printable: Living tissue, or organ parts. It is a kind of part of the new experiments made in the medical industry to save lives.

3D Bioprinting allows creating various tissue structures, such as kidney tissue or skin tissue. Even blood vessels and bones are now becoming 3D printable using this technology. This is definitely offering new possibilities in terms of tissue engineering and regenerative medicine

Another benefit of this great bioprinting technology to create living tissues: it is a great way for medical researchers to make laboratory tests. For example, instead of testing on animals, it is becoming possible to test directly on human tissue or organs as these prints have the exact same properties and reactions.

3D printing is not only possible on earth

Additive manufacturing is not only dedicated to use on earth, and astronauts know it! This game-changing technology is offering great advantages in space, but which ones? 3D printing in space can be used for several projects from creating adapted tools to a 3D printed habitat to live on Mars, or on the Moon. Additive manufacturing and 3D printing without gravity are actually offering brand new possibilities.

Additive manufacturing and 3D printing without gravity are actually offering brand new possibilities.

You can lower your costs using 3D printing

People often see 3D printing as an expensive manufacturing technique, but it could actually help you lower your costs by accelerating your product development. As you know, in business, time is money. Using additive manufacturing is a great way to reduce costs and save time. It can help you with prototyping as it is faster and cheaper than many traditional processes. You only need to create a 3D model of your idea to print it.

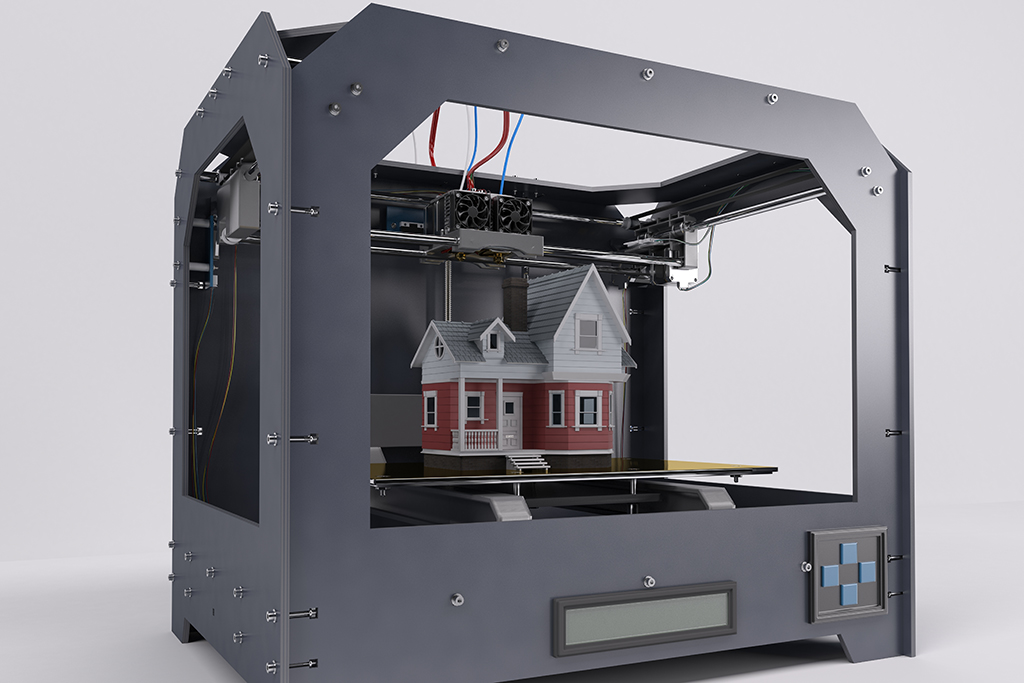

3D printing can help to build houses

Additive manufacturing is also helping to build at an architectural scale! The first big advantage of this manufacturing technique for architecture is that it saves time. 3D Printing in the construction industry means reduced production time. Indeed, machines themselves are very fast, some of them are capable of manufacturing a 600 to 800-square-foot (55 to 75-square-meters) home in just 24 hours.

Additive manufacturing is really seen as a new way to create affordable housing. This new construction method can be used for social housing, but also to face the housing shortage in developing countries. But this technology actually offers possibilities for a large variety of architectural projects and buildings.

Are you ready to live inside a 3D printed home?

You can wear 3D printed parts

Clothes, shoes, jewelry, bags, glasses, watches, all of these elements can be 3D printed! Indeed 3D printed fashion is now a real thing.

Additive manufacturing is widely used by sneaker brands: Nike, Adidas, New Balance, or Reebok to name a few, major brands have tried it out with varying degrees of success. 3D printed glasses are also becoming a big thing. In the eyewear industry, this technology has been used more and more to create 3D printed glasses since it opens a broad range of possibilities to create 3D printed glasses frames totally custom-made.

Optimization of production processes, cost optimization (storage with on-demand printing, manufacturing as there are no material scraps, but also for prototyping …), customization possibilities or creation of complex shapes… 3D printing opens new creative fields for the fashion industry.

3D printing can improve your tooling process

When talking about the benefits of 3D technology, improving a tooling process is certainly not the first that comes to our mind. If your manufacturing process can be improved by a better prototyping or production process thanks to 3D printing, that is not all. Additive manufacturing can help you create tools perfectly adapted to your work.

This technology allows customizations. Surgeons, doctors, are more and more making the most of this technology to create tools adapted to their job, making them more convenient for their use. We had an example on our blog with Marc Soubeyrand. This surgeon is using 3D printing to create his own tools with plastic materials for orthopedic surgeries!

3D printing tools can also be a great way for your business to save money. For example, Volkswagen Autoeuropa, the car manufacturer, is using 3D printing to manufacture some of its tools. The company estimates that thanks to 3D printing they saved 250,000€ in 2017. Reducing your tooling investment thanks to 3D printing could be the perfect solution.

For example, Volkswagen Autoeuropa, the car manufacturer, is using 3D printing to manufacture some of its tools. The company estimates that thanks to 3D printing they saved 250,000€ in 2017. Reducing your tooling investment thanks to 3D printing could be the perfect solution.

3D printing might be part of your favorite movie

A lot of movies now have 3D printed parts in it, the film industry is obviously making the most of all the advantages of additive manufacturing! It can be used to work on the designs of monsters or creatures or to directly manufacture props. You might not know it, but Iron Man’s suit is 3D printed, stormtroopers in Star Wars movies also have some 3D printed parts. 3D printing can also be used in animation film to create 3D printed parts and universes.

In the Black Panther movie, 3D printing actually helped to push the limits of design to create Queen Ramonda’s look, by mixing traditional African culture together with new-age technology.

Marvel Studios’ BLACK PANTHER to R: Shuri (Letitia Wright) and Ramonda (Angela Bassett)Ph: Matt Kennedy©Marvel Studios 2018

Mass-production is possible with additive manufacturing

Additive manufacturing can be used for production, yes, we just saw that. But do you know that this technology can go even further and can also be used for mass-production? Mass producing goods is no longer a problem for 3D technology, and mass manufacturers are already using it. Companies such as Airbus are seeing the full potential of additive manufacturing to mass-produce parts!

You can 3D print food

Do you know that even food is 3D printable? It is already possible to 3D print steaks and vegan steaks. Moreover, the chocolate 3D printer will be the perfect investment for your next Easter.

Regarding meat 3D printing, Giuseppe Scionti, an Italian bioengineer worked on some bioprinting projects, such as creating synthetic tissues, like artificial corneas and 3D printed artificial skin. As you can imagine, working on regenerative medicine can definitely help to recreate meat products. This Italian scientist is on his way to find a way to produce meat and help reduce greenhouse gas emissions from livestock, at the same time.

As you can imagine, working on regenerative medicine can definitely help to recreate meat products. This Italian scientist is on his way to find a way to produce meat and help reduce greenhouse gas emissions from livestock, at the same time.

Chocolate 3D printing is also becoming quite interesting for chefs working in pastry. 3D printers are actually helping them create chocolate designs that are complicated to achieve only using hands.

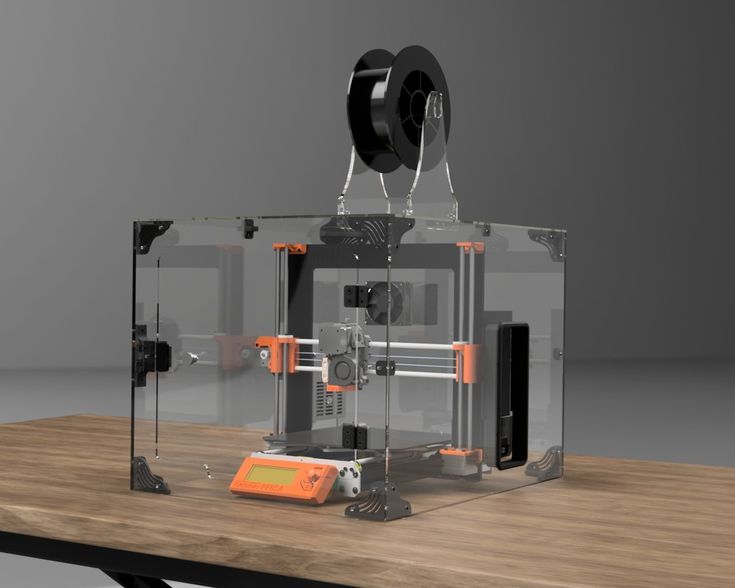

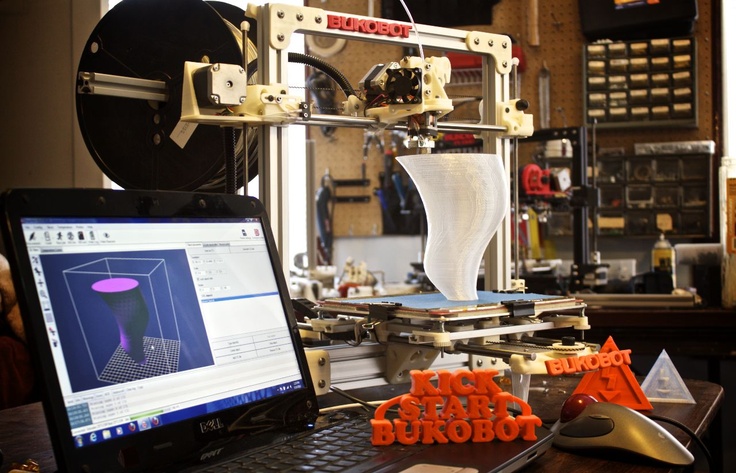

Actually, you can 3D print anything… even a 3D printer

Everything is 3D printable, even 3D printers! You could 3D print a 3D printer by yourself. Some self-replicating 3D printers are already available on the market. But, these types of 3D printers can’t do the whole job themselves, there is still some assembly that can’t be done automatically. And there are still a few parts of a 3D printer that can’t be 3D printed, such as electronic components. So you can 3D print a 3D printer, but not totally for now.

This also stands for plastic 3D printing only. Other types of 3D printers such as metal 3D printers, a liquid resin or ceramic 3D printing can’t be 3D printed!

Other types of 3D printers such as metal 3D printers, a liquid resin or ceramic 3D printing can’t be 3D printed!

The first self-replicating 3D printer was invented by Dr. Adrian Bowyer through the RepRap project and was unveiled in 2008.

4D printing is on its way!

You read it right. 4D printing technology might be the next revolution. But what is 4D printing exactly, how is this different from 3D printing? 4D Printing is referred to as 3D printing transforming over time. For these objects, a fourth dimension is added: time. The big breakthrough about 4D printing over 3D printing technology is its ability to change shape over time.

Are you ready to get 4D printed projects?

Applications of 3D printing are numerous, as you can see. Have you discovered some interesting 3D printing facts in this blog post? Share your discoveries with us. Are you ready to use 3D printing for your own projects?

Try to upload your 3D file on our online 3D printing service and get your 3D objects in a few days. As we just saw, this technology could help you improve both prototyping and production processes, but could also help you go through brand new challenges.

As we just saw, this technology could help you improve both prototyping and production processes, but could also help you go through brand new challenges.

11 Fascinating Facts About 3D Printing | Blog | 3D Printing Blog

by Jon Cooper | November 4, 2021

If you’re reading this blog, chances are you’re no stranger to 3D printing and know a fair bit about it — but we reckon we can still surprise you with our 11 fascinating facts from the wide world of additive manufacturing.

Every day’s a school day here at i.materialise. We’re always learning something new, and we’re more than happy to share that knowledge with you. That’s why we’ve dug a little deeper into the past, present, and future of 3D printing to come up with the greatest listicle the internet has ever seen.

OK, so we’re exaggerating a little. But what we DO have are some entertaining facts that we think you will enjoy. Let’s take a look!

- It’s older than you think

Many see 3D printing as something for the future or consider it a budding technology. Compared to some of the alternatives, that’s arguably true, but it doesn’t change the fact that 3D printing is older than you might think. It started in the mid-1980s when Chuck Hull invented the stereolithography process. That makes it pre-internet old and not much younger than the earliest CD. Nintendo hadn’t even brought out the Gameboy before the first 3D printer was up and running!

Compared to some of the alternatives, that’s arguably true, but it doesn’t change the fact that 3D printing is older than you might think. It started in the mid-1980s when Chuck Hull invented the stereolithography process. That makes it pre-internet old and not much younger than the earliest CD. Nintendo hadn’t even brought out the Gameboy before the first 3D printer was up and running!

To put it in context, look no further than Materialise CEO Fried Vancraen. In 1985, Fried was already creating his own non-computer FDM models before establishing Materialise, one of the first 3D printing companies, just five years later.

Fried Vancraen, CEO of Materialise with one of the earliest 3D printers.

- It’s not just for prototyping

While 3D printing is definitely an important technology for creating prototypes — many large manufacturing companies continue to use it to test their latest innovations — it’s not limited to a one-and-done design. As the technology improved over the years, it became an affordable option for mass production. Many companies are successfully using AM in full production lines, creating everything from insoles to metal parts.

As the technology improved over the years, it became an affordable option for mass production. Many companies are successfully using AM in full production lines, creating everything from insoles to metal parts.

Of course, it’s not just for the multinationals out there. Independent designers can also bring their creations to life thanks to 3D printing.

Module.MGX is a modular table system that is 3D printed in FDM.

- It’s called fashion, Brenda

From catwalks to streetwear, we’ve seen some truly inspiring 3D-printed designs over the years. Fashion designers love the freedom that AM brings to their trade, with handbags, eyewear, entire dresses, and other wearables getting the 3D printing treatment more and more regularly. Who knows how long it’ll be before it becomes a high street mainstay?

Synapse Dress by Anouk Wipprecht

- It lets you print (almost) anything

Many people might not look past plastic when it comes to 3D printing materials, but there are plenty more options to choose from. Just ask the jewelers who use AM to create their latest pieces out of various precious metals!

Just ask the jewelers who use AM to create their latest pieces out of various precious metals!

There are many materials to choose from with 3D printing.

- It gets BIG

Really big. If you thought that printing an entire bike frame was impressive, what about a full-blown mammoth skeleton? With the potential of mammoth stereolithography, size is much less of an issue than it was in the past, making for some exciting opportunities.

With Mammoth Stereolithography, you can really afford to think big.

- It’s on the big screen

Did you know that 3D printing has a starring role in many of your favorite movies? The technology is a great option for a variety of props as they can be created and re-created faster and easier than doing it all from scratch. It’s a great way to showcase the quality and style that AM can offer — just take a look at this gorgeous headpiece worn by Black Panther’s Queen Ramonda, a collaboration between Head Costume Designer Ruth E. Carter and inter-disciplinary designer Julia Koerner.

Carter and inter-disciplinary designer Julia Koerner.

Queen Ramonda’s beautiful headpiece is a prime example of 3D printing in cinema.

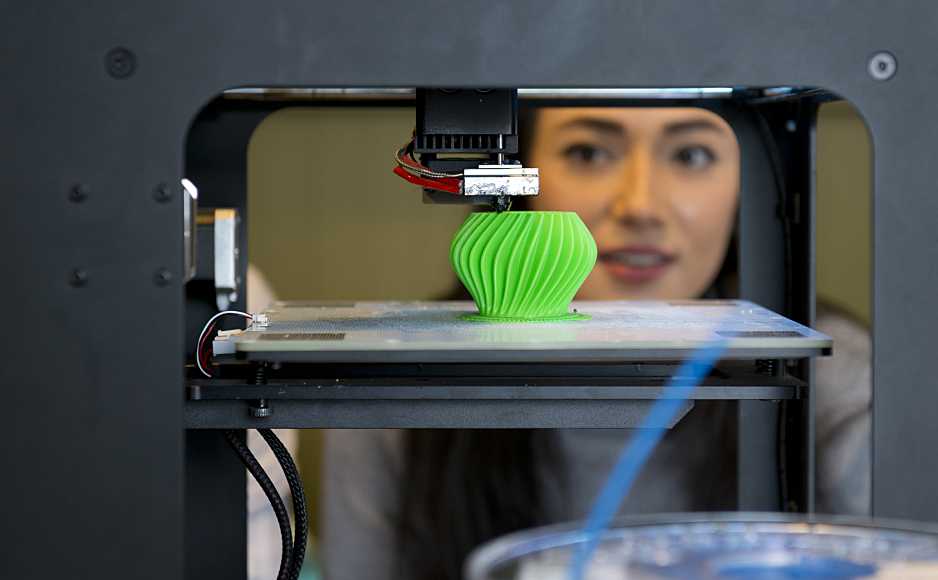

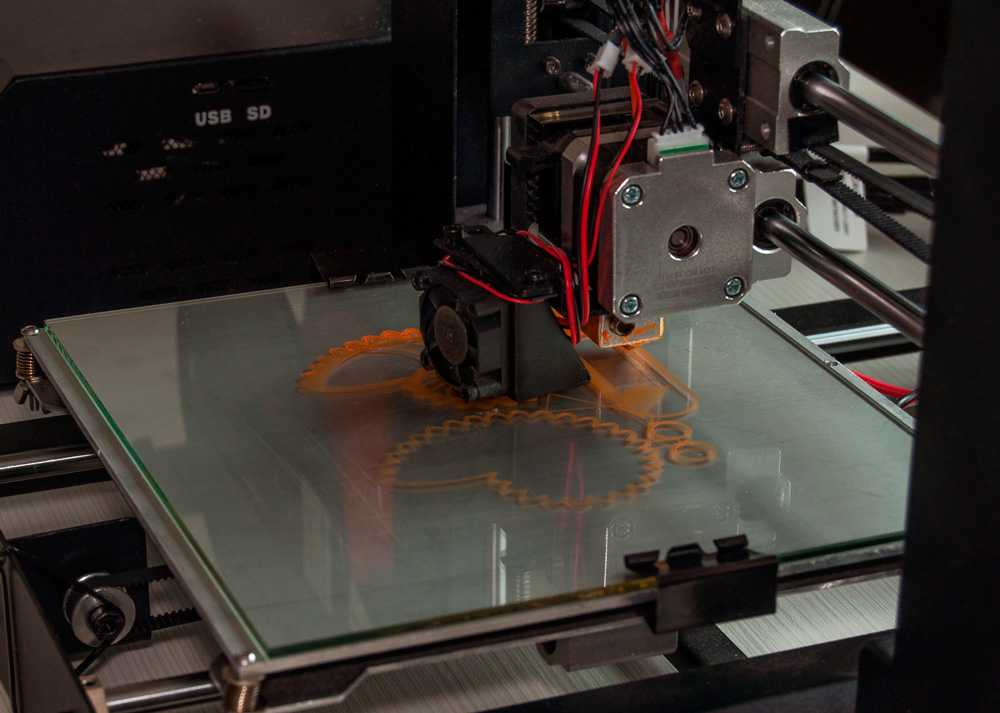

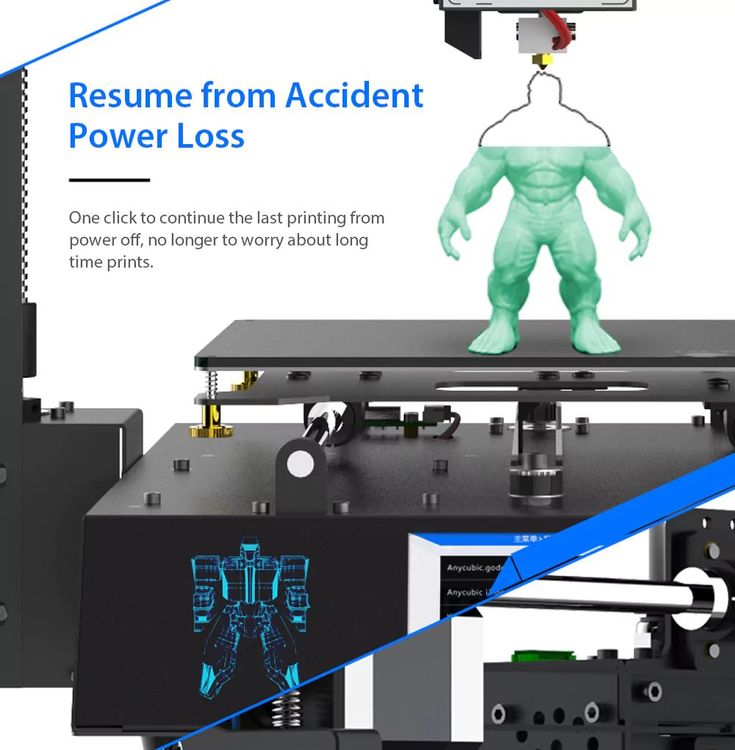

- It prints in layers

Yes, much like onions and lovable green ogres, your 3D-printed part has layers. That’s because additive manufacturing works a lot like your inkjet printer at home. The inkjet printer puts a single layer of ink on top of the page, while a 3D printer adds new layers on top of one another until the object is finished. Take a look at 3D printing in action via the video below.

- It helps save lives

Perhaps the noblest use of 3D printing can be found in the medical sector. Surgeons bring 3D-printed guides into the OR or practice on true-to-life 3D models before they even step foot in the room. It is likely to have an important role in making personalized healthcare a widespread reality. Of course, its use in this context is very heavily regulated and should only ever be handled by the professionals, but it’s pretty inspiring, nonetheless.

Surgeons bring 3D-printed guides into the OR or practice on true-to-life 3D models before they even step foot in the room. It is likely to have an important role in making personalized healthcare a widespread reality. Of course, its use in this context is very heavily regulated and should only ever be handled by the professionals, but it’s pretty inspiring, nonetheless.

Surgeons can prepare for surgery with personalized models of their patients.

- It can help build ‘soft’ robots

The only thing worse than a grabby robot is a grabby robot that likes to crush things. Luckily, 3D printing can help avoid that. In 2015, Rob Scharff created a soft robotic limb that can shake hands with people and even respond to the firmness of said handshake. Aside from the ability to build new robot friends, advances like this are already helping to develop new prosthetics, make them more accessible to patients, or aid rehabilitation.

- It can create moving parts

We’ve seen many beautiful 3D-printed models and gorgeously crafted jewelry, but few designs truly express the potential intricacy of this technology than complex moving parts, like these polyamide puzzles created by David Pitcher. These colorful, twisty, geometric puzzles are truly a work of art.

But that’s not all…

Tetracopter puzzle by David Pitcher. Polyamide (SLS) black dye with colored vinyl stickers.

Polyamide (SLS) black dye with colored vinyl stickers.

- It might soon become 4D printing

3D-printed objects that adapt and move over time? That might just be the future, with a whole host of exciting potential uses. With the right materials, exposure to environmental stimuli such as temperature, light, and water could result in predetermined changes in shape. Whether it’s self-assembling flatpack furniture, new designs in the aerospace and automotive industries, or maybe even something fun like realistic 3D-printed sunflowers, it’s definitely something that we want to keep an eye on.

Feeling inspired?Get started by uploading your 3D model today!

Interesting facts about 3D printing and 3D printers - 3DDevice

Interesting facts about 3D printing and 3D printers

3D printing technology is very versatile and often used for quite unusual purposes. Of course, this leads to interesting results that attract a lot of attention. But all events cannot be covered, and some achievements remain behind the scenes. We believe that this is wrong and in this section we want to list interesting facts about 3D printing that you may not have known. We will tell you about something that goes beyond the usual applications of 3D printing, but, nevertheless, is of great practical value. nine0005

Interesting facts about 3D printing

Let's start with some interesting facts about 3D printing. Of course, many more points can be attributed here. It all depends on the awareness of people. Indeed, today everyone already knows that with the help of a 3D bioprinter it is possible to create artificial organs and living tissues, as well as a lot of other similar information. Therefore, we have chosen revolutionary techniques that are only gaining popularity and are of particular interest and value in certain circles. nine0005

Of course, many more points can be attributed here. It all depends on the awareness of people. Indeed, today everyone already knows that with the help of a 3D bioprinter it is possible to create artificial organs and living tissues, as well as a lot of other similar information. Therefore, we have chosen revolutionary techniques that are only gaining popularity and are of particular interest and value in certain circles. nine0005

1. 3D printing of all-in-one pills

In the US, 3D printed pills for epilepsy can already be found in pharmacies. And scientists do not intend to stop at the production of only one drug. Currently, new methods for 3D printing of medicines are being developed, and researchers pay special attention to SLA technology. The main advantage of using 3D printing for this purpose is the possibility of gradual release of active substances. That is, such a tablet can be programmed for sequential dissolution over a certain time. If you need to take several different medications a day, this can be a real breakthrough in treatment. nine0005

nine0005

2. 3D food printing

You probably already know about this, but this fact is worth talking about in more detail. To date, this branch of 3D technology is not too developed, but progress is moving forward rapidly. There are already several 3D printed food restaurants operating around the world, and some culinary specialists are using 3D printing to bring their creative ideas to life. On top of that, 3D printed products represent a real possibility for astronauts. Indeed, with the help of 3D printing, it is possible to endow food with the maximum amount of useful substances and serve it in the most convenient way. nine0005

3. 3D printing of living tissues

Interesting facts about 3D printing are simply unthinkable without this item. 3D bioprinting is a real panacea in the world of medicine. With its help, scientists intend to create full-fledged living tissues suitable for implantation into the human body. Experiments are now being actively conducted on the manufacture of artificial organs, bones, blood vessels and even hair using living cells. And such initiatives are extremely successful! Of course, mass 3D printing of full-fledged organs is still a long way off, but we are definitely moving in the right direction. nine0005

And such initiatives are extremely successful! Of course, mass 3D printing of full-fledged organs is still a long way off, but we are definitely moving in the right direction. nine0005

4. Space

3D printing promises to be a major technology in space. With its help, people will not only conquer the expanses of the universe, but also explore new territories. 3D printing is used to produce parts for rockets, satellites and other spacecraft, and the ISS even has its own 3D printer that works in zero gravity. Moreover, 3D printing is being considered as a potential technology for creating human settlements on the Moon and Mars. Who knows how far 3D technology will take us. nine0005

Don't miss also:

Interesting facts about 3D printers

This is not the end of the facts about 3D printing, but we decided to highlight some of them in a separate paragraph. Here we will write interesting facts about 3D printers that you might not know.

1. Industrial robots-manipulators

This approach is increasingly used in production: industrial robots-manipulators adapted for 3D printing are used as 3D printers. This is interesting primarily because the construction area in such cases is practically not limited by either the dimensions or the X, Y, Z axes. Some companies are even touting the approach as "5D printing" while the work platform is also in motion. And recently, a presentation of the concept of a 3D printer with six axes took place, which allows printing products without supports. nine0005

This is interesting primarily because the construction area in such cases is practically not limited by either the dimensions or the X, Y, Z axes. Some companies are even touting the approach as "5D printing" while the work platform is also in motion. And recently, a presentation of the concept of a 3D printer with six axes took place, which allows printing products without supports. nine0005

2. 3D printer tattoo machine

Tattoo artists immediately noticed the possibilities of 3D printing and decided to use it for their own purposes. Today, there are several projects for the use of 3D printers as tattoo machines at once, and their results are quite successful. Needless to say, such an application is extremely specific and is unlikely to be widely used. But the idea is interesting.

3. Huge 3D printers and smartphone printers

3D printing technology is more extreme than ever. This is due to the huge functionality of the technique, which allows it to be applied in a variety of directions. 3D printers print houses, huge metal structures and other large-scale structures. But in parallel with this, the developers also take care of the production of smaller parts. So, the whole world is waiting for a 3D printer for smartphones, the concept of which rocked Kickstarter some time ago. And scientists print microscopic structures and full-fledged electronics, giving odds to professional manufacturers. nine0005

3D printers print houses, huge metal structures and other large-scale structures. But in parallel with this, the developers also take care of the production of smaller parts. So, the whole world is waiting for a 3D printer for smartphones, the concept of which rocked Kickstarter some time ago. And scientists print microscopic structures and full-fledged electronics, giving odds to professional manufacturers. nine0005

4. 3D printer with artificial intelligence

For such an unusual development, the already mentioned robotic arm was used, for which not only the control code was written, but also the artificial intelligence algorithm. As a test, the 3D printer printed an impressive 4-meter structure: a design pavilion. The developers were pleased with the result, but said that this was just an experiment and the technique needed further optimization.

This concludes our "Interesting Facts About 3D Printing" section. We hope it was informative. And if you think that we have not touched on some interesting facts about 3D printing and 3D printers, write to us by e-mail and we, if necessary, will add your information! Best regards, 3DDevice team. nine0005

nine0005

Also look into our online store and choose 3D pens, 3D printers, 3D scanners and other equipment. In addition, we will readily provide you with 3D printing, 3D modeling, 3D scanning, etc. services. Call or write for any questions. We look forward to collaborating!

Back to home page

Surprising facts about 3D printing: how tea and beer are related to 3D printing, what dental fillings have to do with it, why hairspray and PVA glue are used in 3D printing. nine0001

3D printing seems to have already firmly entered our lives, but at the same time, most people have about the same idea about it as about the design of a spaceship.

And some facts about 3D printing can surprise you a lot.

- Sweet tea and dark beer for 3D printing.

- What is PVA glue used for in 3D printing?

- Why are dental fillings and office stamps sisters of photopolymer 3D printing? nine0065 Plastic for 3D printing is made from corn

- 3D printer is CNC machine

- Fancy Printing: Office Paper

Sweet tea and dark beer for 3D printing.

How does the simplest 3D printer work? The plastic is heated inside to the desired temperature and squeezed out, like toothpaste from a tube, onto a special “table”.

It's hard to believe, but as we found out by experience, in order to fix the product on the table during printing, sweet tea (5-6 tablespoons of sugar) or beer, always dark, are best suited. You can also use glue stick for paper and ... hairspray. Of course, not every varnish or glue will work perfectly, but some will very much...

The fact is that 3D printing is a relatively young field, and here you often have to improvise.

What is PVA glue used for in 3D printing?

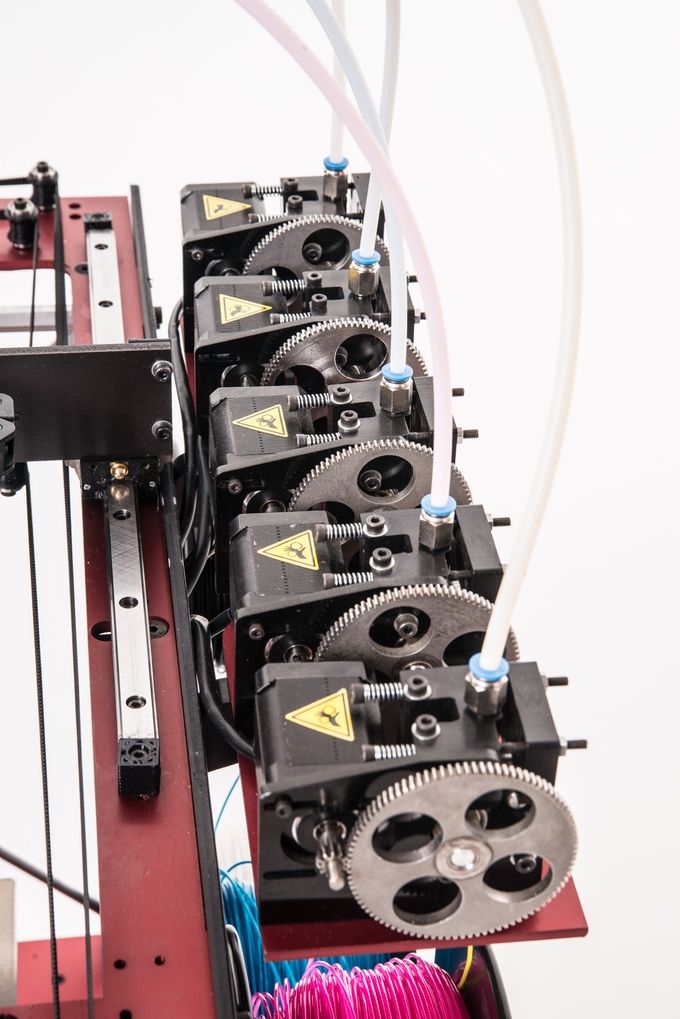

3D printing has found an unusual use for PVA glue. The fact is that it not only adheres well to plastic, but also dissolves easily in water, so it serves as an excellent support for overhanging parts. Thin plastic support sticks are necessary so that strongly protruding parts do not deform during printing, but subsequently they are very troublesome to remove. If the 3D printer has a second nozzle, hardened PVA glue can be fed into it instead of plastic. As soon as the product is ready, it remains to throw it into the water - the PVA will gradually dissolve, and we will get a beautiful model without the hassle and worries! nine0005

If the 3D printer has a second nozzle, hardened PVA glue can be fed into it instead of plastic. As soon as the product is ready, it remains to throw it into the water - the PVA will gradually dissolve, and we will get a beautiful model without the hassle and worries! nine0005

Why are dental fillings and office stamps sisters of photopolymer 3D printing?

What can these seemingly completely different things have in common? Material.

Photopolymer is a gel that cures when exposed to light (laser or LED).

Do you remember how the dentist used a special lamp when placing your light filling? The fact is that this seal is a photopolymer, which hardens under the influence of an LED, and then grinds by hand. nine0005

A photopolymer 3D printer works in a similar way, only it grows the model, layer by layer.

And where does the office stamp for documents? For its manufacture, a photopolymer is also used. First, a negative (mirror reflection) is printed on paper on a conventional printer, and then it is translucent - this is how a stamp cliché is created, which is glued to the snap.

Plastic for 3D printing is made from corn

You may have heard that buttons were once made from ordinary cottage cheese: when hardened, it becomes very durable. And PLA plastic is made from corn and is used, for example, for the production of dishes or confectionery molds. Outwardly, it practically does not differ from the usual one, but at the same time it is completely environmentally friendly, it can even be swallowed without harm to health. However, the above does not mean, for example, that PLA is able to decompose in a week of exposure to the street - it can serve for years even in the open air. nine0005

A 3D printer is a CNC machine

The principles of modern 3D printing appeared long before the printers themselves. But how did this become possible? It turns out that all the main technologies and methods used in 3D printing came from CNC machine tool building. A CNC machine is a computer numerically controlled machine.