3D print floating object

Float best 3D printing models・Cults

pool thermometer float

Free

Simple parametric raft inspired by Thor Heyerdahl's Kon-Tiki

Free

ET950 carburetor float valve

€5

Donut Cat

€1.88 -50% €0.94

Brain Bots

€0.94

Line/rope float for Kayak/Boating

Free

Aquarium floating Mine

€0.94

Sleeping Beauty Cutter

€2.71

Small buoy (Ø24mm) - Fishing Float

€2.44

Swimming Frog

€4. 24

fishing float

Free

Magnetic toy - Float spin

€0.95

CalCarb v1.2

€3.05

Royal Chariot House Targaryen - House of the Dragon (GOT)

€4.50

Keurig Float valve

Free

Flower petal rings

€0.90

2D Silhouette/Stencil You'll Float Too Balloon

€0.61

Insta360 Go 2 Floating Case

Free

Fishing Float

Free

Crab Pot Float

Free

Gopro Float

Free

Shelves

Free

Fishing Float

€0. 54

54

FISHING Boilies press 19mm,20mm,22mm,24mm

€0.83 -20% €0.66

bait press

Free

SMALL CHLORINE DOSING FLOAT

€3

Beach Pig

€3.76

FREE Fishing float 80x24mm and 90x34mm

Free

Fishing Plop Float

€2.81

Vocho Float

€4.76

Pool / whirlpool float

€1.25

Ducki from Ducktales

Free

Boom Boat/ Mini Dozer Ship

Free

fishing rod float

Free

Hexagon Bath Bomb Float-Commercial License

€9. 41

41

Heart Bath Bomb Float-Commercial License

€9.41

Articulated Forest Wish Spirit

€2.75

Fishing float v2

€0.58

floats collection 6 types

€0.58

Articulated Spider Crab Flexi Toy

€1.38

Albin 25 keyfob

Free

floats collection 17 types

€0.83 -15% €0.70

Avocado Boat Float

€0.69

Fishing boat (Bathtube/Pond)

€0.50

Moss Eater Flexi

€1. 04

04

Fancy Goldfish Flexi

€1.04

Water Flyer Flexi

€1.38

fishing feeder with integrated weights threaded nuts

€0.58

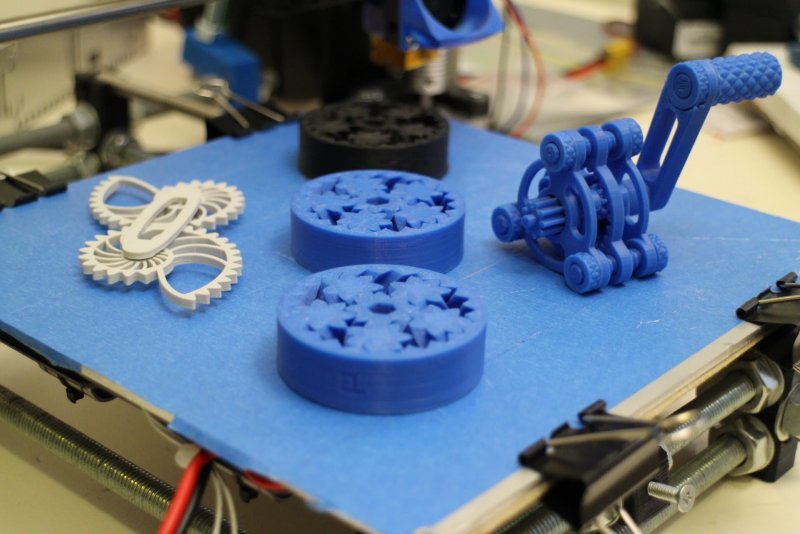

Thingiversity Science Challenge: Make It Float - Challenge

Challenge Entry Tips: Increase your chances of winning!

While owning a 3D printer is not a requirement for entry, printing and documenting printability will go a long way toward winning. You might consider getting your design 3D printed locally at a service such as 3DHubs so you can test it and take photos.

While owning a 3D printer is not a requirement for entry, printing and documenting printability will go a long way toward winning. You might consider getting your design 3D printed locally at a service such as 3DHubs so you can test it and take photos.3D Design Tips: How to get started...

Just draw, take a photo of your drawing, and extrude to make a 3D model. Then use MakerBot Desktop to export your model as an .stl file.

Just draw, take a photo of your drawing, and extrude to make a 3D model. Then use MakerBot Desktop to export your model as an .stl file.  There are lots of tutorials on YouTube that can help you get started. It's easier than you think, and will allow you to make customizable designs that you can include in the MakerBot Customizer!

There are lots of tutorials on YouTube that can help you get started. It's easier than you think, and will allow you to make customizable designs that you can include in the MakerBot Customizer!OFFICIAL RULES as defined by MakerBot Industries, LLC (“Sponsor”).

THINGIVERSITY SUMMER S.T.E.A.M. CHALLENGES: Thingiversity Summer Science Challenge: “Make It Float”, Thingiversity Summer Technology Challenge: “Light it Up”, Thingiversity Summer Engineering Challenge: “Catch the Wind”, Thingiversity Summer Art Challenge: “See the World”, Thingiversity Summer Math Challenge: “Build a Castle” (each challenge individually a “Contest” and collectively “Contests”).

CONTEST ENTRY DATES: Contest start date & time and end date & time as outlined on website is Friday, 06/12/2015 at 12:00AM EST to Sunday, 7/19/2015 at 11:59PM EST. All entries must be received no later than 7/19/2015 at 11:59PM EST.

All entries must be received no later than 7/19/2015 at 11:59PM EST.

WHO MAY ENTER: Contest submissions are only open to Thingiverse Account Holders who are 13 and over at the time of entry (“Contestant” or “Contestants”). Contestants are subject to all notices posted online, including but not limited to, the MakerBot Terms of Use (MakerBot Industries, LLC). Employees and their immediate families (spouse, parent, child, sibling and their respective spouses, regardless of where they reside) or those living in the same household (whether or not related) of Sponsor, and their respective parents, affiliates, subsidiaries, prize suppliers, distributors and advertising and promotion agencies (collectively, “Contest Parties”) are not eligible to enter or win.

Contestants under 18 years old must obtain written consent of a parent or legal guardian in order to be eligible to receive any prizes. Please see the “ACKNOWLEDGMENT” section in these Official Rules for details. Contest is subject to all federal, state and local laws and regulations and is void where is prohibited, taxed, or restricted by law. Residents of the province of Quebec in Canada, Cuba, Iran, Syria, North Korea, Sudan, Myanmar (Burma), or other individuals restricted by U.S. export controls and sanctions are ineligible to participate. The Contest is void in these countries and where prohibited or restricted by U.S. or local law.

Residents of the province of Quebec in Canada, Cuba, Iran, Syria, North Korea, Sudan, Myanmar (Burma), or other individuals restricted by U.S. export controls and sanctions are ineligible to participate. The Contest is void in these countries and where prohibited or restricted by U.S. or local law.

CONTEST OBJECTIVE: The objective of the Contest is to invite Thingiverse Account Holders to create a 3D design based on the specific STEAM topic of the Contest (“Contest-Topic Design”) that fits within a build volume of a MakerBot Replicator Desktop 3D Printer (5th Generation) or MakerBot Replicator 2 Desktop 3D Printer (“Entry” or “Entries”). All valid Entries must include a description of how and why the submitted Contest-Topic Design is relevant to the specific STEAM topic of the Contest.

CONTEST ENTRY: To enter, click “Enter Challenge” on the Contest’s click-through landing page and upload the Contest-Topic Design with one of the following hashtags that corresponds to a Contest and the Entry: #MakeItFloat, #LightItUp, #CatchTheWind, #SeeTheWorld, or #BuildACastle. For purposes of these Official Rules, “receipt” of entry occurs when Thingiverse’s server records the entry information resulting from Contestants’ entry being received. Any automated computer receipt (such as one confirming delivery of entry) does not constitute proof of actual receipt by Sponsor for purposes of these Official Rules. Sponsor reserves the right to disqualify any entry for any reason, in its sole and absolute discretion.

For purposes of these Official Rules, “receipt” of entry occurs when Thingiverse’s server records the entry information resulting from Contestants’ entry being received. Any automated computer receipt (such as one confirming delivery of entry) does not constitute proof of actual receipt by Sponsor for purposes of these Official Rules. Sponsor reserves the right to disqualify any entry for any reason, in its sole and absolute discretion.

JUDGING: The Sponsor will select a first, second, and third place winner (“Winner” or “Winners”) based on the following criteria: creativity, printability of the Contest-Topic Design from a MakerBot Replicator Desktop 3D Printer (5th Generation) or MakerBot Replicator 2 Desktop 3D Printer and relevance of the Entry to the STEAM topic of the Contest. The odds of winning depend upon the number of entries received. In the event of any ties, Winners will be determined based in the Sponsor’s sole discretion. In all cases, Sponsor’s decision is final and binding.

WINNER NOTIFICATION: Winners will be determined after each Contest’s specific end date and announced on the Sponsor’s Blog (http://www.makerbot.com/blog) as follows: on Saturday, July 25, 2015 for the “Make It Float” Contest, on Saturday, August 1, 2015 for the “Light It Up” Contest, on Saturday, August 8, 2015 for the “Catch The Wind” Contest, on Saturday, August 15, 2015 for the “See The World” Contest, and on Saturday, August 22, 2015 for the “Build A Castle” Contest.

PRIZE(S): The first place Winner will: (a) receive a MakerBot Replicator Desktop 3D Printer (Fifth Generation Model) valued at $ $2,899.00 + tax USD, (b) have his or her Contest-Topic Design featured on www.thingiverse.com, and (c) the opportunity to participate in a future giveaway event of Sponsor. The second place Winner will: (a) receive two (2) spools of MakerBot PLA filament, with a retail value of up to $100.00 + tax and (b) have his or her Contest-Topic Design featured on www.thingiverse. com. The third place Winner will have his or her Contest-Topic Design featured as an honorable mention on www.thingiverse.com.

Winners are solely responsible for all expenses, costs or fees associated with acceptance and/or use of the prize, including without limitation, all taxes (if any). A Winner is not a recipient of a prize until Sponsor has verified him or her as a Winner. Sponsor will be deemed to have awarded the prize to a Winner after it has been formally transferred and such Winner will then assume full responsibility for the prize(s). When shipping overseas, Winners are responsible for any and all fees associated with value added tax (VAT), taxes or customs. All prize selections are at Sponsor’s sole discretion.

com. The third place Winner will have his or her Contest-Topic Design featured as an honorable mention on www.thingiverse.com.

Winners are solely responsible for all expenses, costs or fees associated with acceptance and/or use of the prize, including without limitation, all taxes (if any). A Winner is not a recipient of a prize until Sponsor has verified him or her as a Winner. Sponsor will be deemed to have awarded the prize to a Winner after it has been formally transferred and such Winner will then assume full responsibility for the prize(s). When shipping overseas, Winners are responsible for any and all fees associated with value added tax (VAT), taxes or customs. All prize selections are at Sponsor’s sole discretion.

ACKNOWLEDGEMENT: By entering in this Contest:

- Contestants agree and accept these Official Rules.

- Entry must be the creative work of the Contestant and must not infringe upon the copyrights, trademarks, rights of privacy, publicity or other intellectual property or other rights of any person and must not violate any law. Contestant assumes all responsibilities and consequences if submission is found to be otherwise. Sponsor will not be held responsible if legal action results from public exhibition.

- Contestant acknowledges that MakerBot will use 3D-printed prints of the winning Contest-Topic Designs and images of the winning 3D-printed prints of the winning Contest-Topic Design for promotional and commercial purposes, including, but not limited to, events, marketing material, retail store displays, and use by distributors and resellers of products of Sponsor.

- Contestant waives any right to inspect or approve finished photographs, audio, video, multimedia, or advertising recordings and copy or printed matter or computer generated scanned image and other electronic media that may be used in conjunction therewith or to approve the eventual use that it might be applied.

- Winning constitutes permission (except where prohibited by law) to use Winner’s name, images, hometown, likeness, prizes won, stories, audio, video and photograph (all at Sponsor’s discretion) for future advertising, exhibition, publicity in any and all media including, without limitation, cable and broadcast television and the Internet, now or hereafter devised throughout the world in perpetuity, without additional compensation, notification or permission.

Contestant assumes all responsibilities and consequences if submission is found to be otherwise. Sponsor will not be held responsible if legal action results from public exhibition.

- Contestant acknowledges that MakerBot will use 3D-printed prints of the winning Contest-Topic Designs and images of the winning 3D-printed prints of the winning Contest-Topic Design for promotional and commercial purposes, including, but not limited to, events, marketing material, retail store displays, and use by distributors and resellers of products of Sponsor.

- Contestant waives any right to inspect or approve finished photographs, audio, video, multimedia, or advertising recordings and copy or printed matter or computer generated scanned image and other electronic media that may be used in conjunction therewith or to approve the eventual use that it might be applied.

- Winning constitutes permission (except where prohibited by law) to use Winner’s name, images, hometown, likeness, prizes won, stories, audio, video and photograph (all at Sponsor’s discretion) for future advertising, exhibition, publicity in any and all media including, without limitation, cable and broadcast television and the Internet, now or hereafter devised throughout the world in perpetuity, without additional compensation, notification or permission. - After the winning notifications, written consent of acceptance of these Official Rules for any Winner under the age of 18 must be given via electronic mail to [email protected] or via regular mail to Sponsor’s address listed in these official rules (“Sponsor Address”) within fifteen (15) business days, after which consent will be confirmed by Sponsor. The written consent must contain: (a) name, (b) regular mailing address, (c) telephone number, and (d) email address for the parent or guardian granting consent for the minor. Except where prohibited by law, parent or guardian of a Winner may be required to sign and return an Affidavit of Eligibility and Liability and Publicity Release and provide any additional information that may be required by Sponsor. If required, parent or guardian of a Winner must return all such required documents via fax (or as otherwise instructed) within forty-eight (48) hours and via U.S. Mail within seven (7) days following attempted notification or such Winner will be deemed to have forfeited the prize and another Contestant may be selected based on the judging criteria described herein.

- After the winning notifications, written consent of acceptance of these Official Rules for any Winner under the age of 18 must be given via electronic mail to [email protected] or via regular mail to Sponsor’s address listed in these official rules (“Sponsor Address”) within fifteen (15) business days, after which consent will be confirmed by Sponsor. The written consent must contain: (a) name, (b) regular mailing address, (c) telephone number, and (d) email address for the parent or guardian granting consent for the minor. Except where prohibited by law, parent or guardian of a Winner may be required to sign and return an Affidavit of Eligibility and Liability and Publicity Release and provide any additional information that may be required by Sponsor. If required, parent or guardian of a Winner must return all such required documents via fax (or as otherwise instructed) within forty-eight (48) hours and via U.S. Mail within seven (7) days following attempted notification or such Winner will be deemed to have forfeited the prize and another Contestant may be selected based on the judging criteria described herein.

SUBMISSION PROBLEMS: Sponsor is not responsible for lost, misdirected, damaged, altered, garbled, incorrect, incomplete or delayed entries; all of which will be void. Additionally, Sponsor is not responsible for problems related to technical malfunctions of electronic equipment, computer online systems, computer hardware or software failures, or failure of any entry to be received by Sponsor on account of any technical problems, including miscommunication or connection failure, which may limit a Contestant’s ability to participate in this Contest. Sponsor reserves the right to modify or terminate the Contest in the event it becomes technically impaired, and to cancel or suspend the Contest in its entirety should unauthorized intervention corrupt the administration of the Contest and, if terminated, at Sponsor’s discretion, determine the Winner using all non-suspect, eligible entries received up to time of cancellation using the judging procedure outlined above. In the event of a dispute regarding entries received from multiple users having the same email account, the authorized subscriber of the email account at the time of entry will be deemed to be the Contestant and must comply with these Official Rules. Authorized subscriber is the natural person who is assigned the email address by the online service provider. Sponsor reserves the right at its sole discretion to disqualify any individual it finds to be tampering with the operation of this Contest.

Authorized subscriber is the natural person who is assigned the email address by the online service provider. Sponsor reserves the right at its sole discretion to disqualify any individual it finds to be tampering with the operation of this Contest.

DATA PRIVACY: Data privacy and protection is very important to Sponsor. The privacy practices of this Contest are governed by the Thingiverse.com Privacy Policy and the privacy provision in the MakerBot.com Terms of Service.

INTELLECTUAL PROPERTY ASSIGNMENT OF RIGHTS: Each design shall be ascribed a Secondary License as stipulated in the MakerBot Terms of Use to allow for Sponsor’s use for marketing and promotional purposes. Sponsor shall have the exclusive authority to remove or retain entries and to repost on any of Sponsor’s websites or social media sites. By submitting an entry, Contestant acknowledges and agrees that Sponsor may obtain many submissions under this Contest and that such entries may be similar or identical in format to others submitted under this Contest and/or other contests staged and/or sponsored by Sponsor, and waive any and all claims Contestant may have had, may have, and/or may have in the future, and that any composition or design accepted, reviewed and/or used by Sponsor (or its respective designees) may be similar to his/her entry. Contestant acknowledges and agrees that Sponsor does not have now, nor shall have in the future, any duty or liability, direct or indirect, vicarious, contributory, or otherwise, with respect to the infringement or protection of any copyright in and to Contestant’s entry.

Contestant acknowledges and agrees that Sponsor does not have now, nor shall have in the future, any duty or liability, direct or indirect, vicarious, contributory, or otherwise, with respect to the infringement or protection of any copyright in and to Contestant’s entry.

LIMITATION OF LIABILITY: By entering and/or accepting prize, Contestants and Winners agree to hold and assign Sponsor and its promotional partners, directors, officers, and employees harmless for liability, damages, or claims for injury or loss to any person or property, relating to, in whole or in part, directly or indirectly, participation in this Contest, the acceptance and/or subsequent use or misuse or condition of any of the prizes awarded, or claims based on publicity rights, defamation, or invasion of privacy.

Under no circumstances will Contestants be permitted to obtain awards for, and Contestants hereby waives all rights to claim, punitive, incidental or consequential damages, or any other damages, including attorneys’ fees, and Contestant (or, if an eligible minor, his/her parent or legal guardian) further waives all rights to have damages multiplied or increased.

CHOICE OF LAW: All issues and questions concerning the construction, validity, interpretation and enforceability of these Official Rules, or the rights and obligations of Contestants and Sponsor in connection with this Contest, shall be governed by, and construed in accordance with, the substantive laws of the State of New York, USA without regard to New York choice of law rules.

SEVERABILITY: If any provision of these Official Rules is found to be invalid or unenforceable by a court of competent jurisdiction or appointed arbitrator, such determination shall in no way affect the validity or enforceability of any other provision herein.

WINNERS LIST: Winners will be announced at http://www.makerbot.com/blog as follows: on Friday, July 24, 2015 for the “Make It Float” Contest, on Friday, July 31, 2015 for the “Light It Up” Contest, on Friday, August 7, 2015 for the “Catch The Wind” Contest, on Friday, August 14, 2015 for the “See The World” Contest, and on Friday, August 21, 2015 for the “Build A Castle” Contest.

SPONSOR ADDRESS: MakerBot Industries, LLC, One MetroTech Center, 21st Floor, Brooklyn, NY 11201

Read an article about the first 3D printed houses?

3D printing has been used in construction for several years now. In this article, you will learn about the first real houses printed on 3D printers.

3D printing of houses is still quite new to the layman. While construction 3D printing technologies have been developed for many years, only a few "real" projects have already seen the light of day. We are still far from technology taking over conventional construction methods. But with each new project, she is getting closer to becoming mainstream. nine0005

There are many benefits to 3D printing. For example, the cost of a 3D printed house can be much lower. And it will take much less time to build.

In order to draw a line under what has already been achieved in this area and show some interesting projects, we have devoted an article to the "first" and the best. These projects will always remain milestones in the 3D construction printing industry as they set the stage for future advances in the field.

These projects will always remain milestones in the 3D construction printing industry as they set the stage for future advances in the field.

First 3D printed house in Germany

Germany is a country often associated with cutting edge engineering, so let's start our list with Germany's first ever 3D printed house.

The house itself is located in Beckum, a city that is partly located in North Rhine-Westphalia, next to Holland and Belgium. This is the first 3D printed house to be fully certified to official building codes. This project will give way to many other 3D printed construction projects in Germany as well as the rest of Europe. nine0005

The project is the result of a collaboration between German construction company Peri and Danish construction 3D printing firm COBOD. Peri is a large corporation that operates not only in Germany, but throughout the EU. Its portfolio includes many products, including scaffolding and formwork solutions that every construction site needs.

Peri followed the construction 3D printing segment for years before acquiring a stake in COBOD in 2018. Now they are pushing the technology together and further. The construction of the house in Beckum began two years after the acquisition of the share. nine0005

For 3D printing at home, a BOD2 modular 3D printer from COBOD was used. The printing itself took just over 100 hours.

• Built: (started) September 17, 2020

• Commissioned: summer 2021

• Where: Beckum, North Rhine-Westphalia, Germany

• By: Peri, COBOD

First occupied 3D printed home in the US

Several homes have been printed in the US, but this home is the first officially occupied home, according to CNN. Its creators: the construction company Alquist and the humanitarian organization Habitat for Humanity Peninsula. nine0005

From a distance, you might think that this is an ordinary house. However, when approaching it, the layered structure of the concrete walls becomes noticeable. After all, 3D printing creates an object in layers.

After all, 3D printing creates an object in layers.

Surprisingly, the 111.5 square meter concrete structure of the house (was printed in about 12 hours, significantly faster than traditional construction methods would allow.

The house was reportedly purchased by April Springfield, who lives there with her son and dog She bought the house through Habitat for Humanity's housing program, and given that the nonprofit's goal is to help solve the global housing crisis, it makes sense to use 3D printing to create affordable homes that will make many people's dreams of home ownership come true.0005

• Built: 2021

• Commissioned: December 22, 2021

• Where: Williamsburg, Virginia, USA

• By: Alquist 3D, Habitat for Humanity Peninsula, Greater Williamsburg

The first five-story 3D printed house

This project, made by the Chinese company WinSun, is a real record holder. It is a 3D printed five-story residential building with a height of 10 meters - the tallest 3D printed building so far.

The house is located in Suzhou Industrial Park in Jiangsu province in eastern China. It stands next to a mansion that was also built by WinSun using a concrete 3D printer.

Looking at the WinSun designs, you can't help but notice that they don't look like they've been 3D printed. Usually 3D printed structures are gray in color, the layer lines are clearly visible. But WinSun adds color and makes walls smoother. Nowhere is it stated how the company achieves the smoothness of the walls, but we assume that the workers smooth them by hand. WinSun projects are not like the ones we're used to. nine0005

• Built: Winter 2014

• Commissioned: Not specified

• Where: Suzhou, Jiangsu, China

• By: WinSun

First 3D printed biodegradable house

Can you guess that there is rice in the walls of this house?

Most 3D printed buildings are made from concrete mix. But this project is different from the rest. With the aim of creating housing solutions with little to no environmental impact, Italian company WASP 3D printed Gay's house using soil and agricultural waste. nine0011 WASP developed the sustainable blend in collaboration with Ricehouse, a company that specializes in using natural and agricultural materials such as clay and rice in construction.

nine0011 WASP developed the sustainable blend in collaboration with Ricehouse, a company that specializes in using natural and agricultural materials such as clay and rice in construction.

The house is named Gaia in honor of the ancient Greek goddess of the earth. In fact, 25% of the mixture contains local soil, 10% hydraulic lime, 25% rice husks and 40% crushed rice straw (a by-product of rice production at harvest).

An innovative solution not only in terms of material, but also in the design of the walls themselves. The specific corrugated structure was used to provide ventilation on warm days as well as insulation on cold periods, virtually eliminating the need for air conditioning. nine0005

Gay's house is small - about 20 square meters. The wall printing took only 10 days, while the estimated materials cost is just under $1,000.

• Built: not specified

• Commissioned: October 7, 2018

• Where: Massa Lombarda, Ravenna, Italy

• By: WASP, Ricehouse

AirBnB's first 3D printed house

The perfect weekend getaway.

You can find many different types of accommodation on AirBnB, but what about a 3D printed home? nine0005

The so-called Fibonacci house is the first 3D printed house to be offered for booking through AirBnB. Considering that it is located in rural British Columbia, it will be a wonderful place to stay.

Although the Fibonacci house looks small, it has a lot to offer vacationers. About 35 square meters is enough to accommodate up to four people.

The concrete walls of the house were designed and printed by Dutch 3D printing firm Twente. 20 concrete parts were produced offsite in just 11 days. The material was produced by Laticrete. The parts were later transported and assembled at their current location. nine0005

• Built: 2020

• Commissioned: Not specified

• Where: Kootenays, British Columbia, Canada

• By: Twente Additive Manufacturing

First 3D printed houseboat

Prvok is not only the first 3D printed house in the Czech Republic, but the world's first floating 3D printed house on a pontoon.

The project was implemented by the start-up company Scoolpt. The concrete structure of the houseboat took only 22 hours to print. nine0005

Approximately 43 square meters of living space divided into bathroom, bedroom and living room with kitchen. Weight isn't usually discussed in the context of houses, but given that this one is on water, it's interesting to note that Prvok weighs 43 tons.

The house is equipped with a built-in recirculating shower and tanks for drinking and municipal water and has a service life of at least 100 years.

• Built: June 2020

• Commissioned: August 18, 2020

• Where: Prague, Czech Republic

• By: Scoolpt

Europe's first 3D printed residential house

Not every 3D printed house has visible line layers.

More often than not, 3D printed houses are demos made to show what the technology can do. For most of them there is no information about the actual residents. But in 2017, the couple did move to live in a 3D printed house located in Nantes, France. Thus, the house of "Yanov" became the first of its kind, which was inhabited in Europe. nine0005

Thus, the house of "Yanov" became the first of its kind, which was inhabited in Europe. nine0005

The house is a project of the University and the Laboratory of Digital Sciences of Nantes. An interesting aspect of the project is the special technique used in its construction by BatiPrint3D. Instead of 3D printing a concrete structure, the robotic arm created wall shells using polyurethane, a material used for insulation. Later, these membranes were filled with concrete.

It took a total of 54 hours to print. It took a little over 4 months to complete the construction. Mainly due to the fact that the rest of the components were created using conventional means. House area - 95 square meters.

• Built: 2017

• Commissioned: March 2018

• Where: Nantes, France

• By: University of Nantes, Nantes Digital Science Lab

India's first 3D printed house

This building was built in a couple of days.

India's first ever 3D printed house was completed back in 2020. The project was carried out by construction startup Tvasta, founded by graduates from the Indian Institute of Technology Madras. In fact, the institute's Chennai campus was chosen as the location of the building. nine0005

The project was carried out by construction startup Tvasta, founded by graduates from the Indian Institute of Technology Madras. In fact, the institute's Chennai campus was chosen as the location of the building. nine0005

The significance of this project lies in its possible impact on the solution of the housing crisis worldwide and in India in particular. The ability to build such a house within a few days and at a low cost cannot be underestimated.

House 55.7 sq.m. with a spacious layout, one bedroom, combined kitchen and living room.

The concrete structure of the house was 3D printed off site and the parts were later transported and assembled on campus. The foundation, meanwhile, was built using the conventional method of pouring concrete into the ground. nine0005

• Built: 2020

• Commissioned: Not specified

• Where: Chennai, India

• By: Tvasta Construction

Africa's first 3D printed house

Back in 2019, in the Moroccan city of Ben Guerir, Spanish firm Be More 3D created Africa's first 3D printed house. The project originated during the team's participation in the Solar Decathlon in Africa. This is an international competition during which teams design and build solar-powered houses. nine0005

The project originated during the team's participation in the Solar Decathlon in Africa. This is an international competition during which teams design and build solar-powered houses. nine0005

Be More 3D printed house 32 sq.m. in about 12 hours, took first place and received the title of the most innovative startup.

Be More 3D didn't stop building in Africa and later created the first 3D printed house in Spain and developed its own concrete 3D printer in partnership with several corporations from the automation and materials industries.

• Built: 2019

• Commissioned: Not specified

• Where: Ben Guerir, Morocco

• By: Be More 3D

First 3D printed home for sale in the US

Last on our list is the first 3D printed home for sale in the US.

This house was printed in the same place by SQ4D, a company specializing in the development of robotic building systems. The building was printed with SQ4D's Arcs concrete extrusion system and has a 50-year warranty on the printed structure.

Living area of 130.7 sq.m. with three bedrooms and two bathrooms. There is also a garage for 2 cars. nine0005

The house was listed for sale in January 2021 for $299,999. Considering the size of the house and the fact that it is priced 50% below the cost of comparable newly built houses in the same area, the deal is pretty good.

• Built: 2020

• Commissioned: 2021

• Where: Riverhead, New York, USA

• By whom: SQ4D

Translation source: https://m.all3dp.com/2/first-3d-printed-house/

On our website you can choose and order a construction 3D printer for both building construction and small building forms. To do this, go to the catalog of construction 3D printers. nine0003 "Tsvetnoy Mir" is a reliable supplier of 3D printers with many years of experience, supplying directly from manufacturers and guaranteeing their quality.

What is 3D printing in 2021

3D printing technology has changed the manufacturing process of everything that surrounds us. From children's toys and clothes to prostheses, implants, etc.

From children's toys and clothes to prostheses, implants, etc.

The 3D printing process is also known as additive manufacturing. In simple terms, a computer program tells the printer where to lay thin layers of material that gradually turn into a solid object. nine0005

Types and processes of 3D printing technologies

The first mention of 3D printing technology appeared in the late 1980s. They were called rapid prototyping technologies. The name refers to a process that was conceived as a faster and more cost-effective method of prototyping in product development. The very first patent application for this technology was filed by Dr. Hideo Kodama in May 1980. But, unfortunately for the inventor, the full patent specification was not submitted until one year after the application was filed. Kodama used ultraviolet light to cure plastic and create an AM object. nine0005

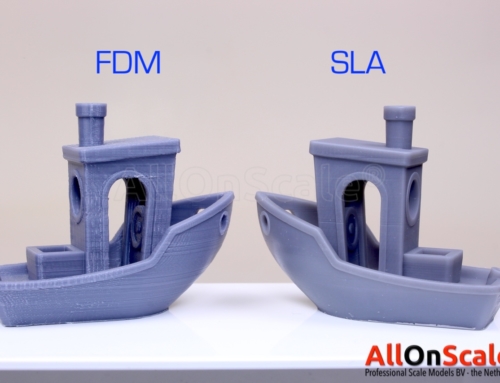

Years later, American Scott Crumb developed the most common type of 3D printing today - FDM (Fused deposition modeling). This technology stands for deposition modeling. This type is characterized by the fact that the thermoplastic material is heated to a liquid state and extruded through the nozzle layer by layer.

This technology stands for deposition modeling. This type is characterized by the fact that the thermoplastic material is heated to a liquid state and extruded through the nozzle layer by layer.

Charles Hull, co-founder of 3D Systems, was one of the inventors of the 3D printing technology known as stereolithography. The technology is based on photochemical processes. nine0005

But Kodama, Crump, and Hull weren't the only developers of 3D printing techniques.

WINBO 3D printer at Art-Up Design Studio

Here are some other types of 3D printing in use today:

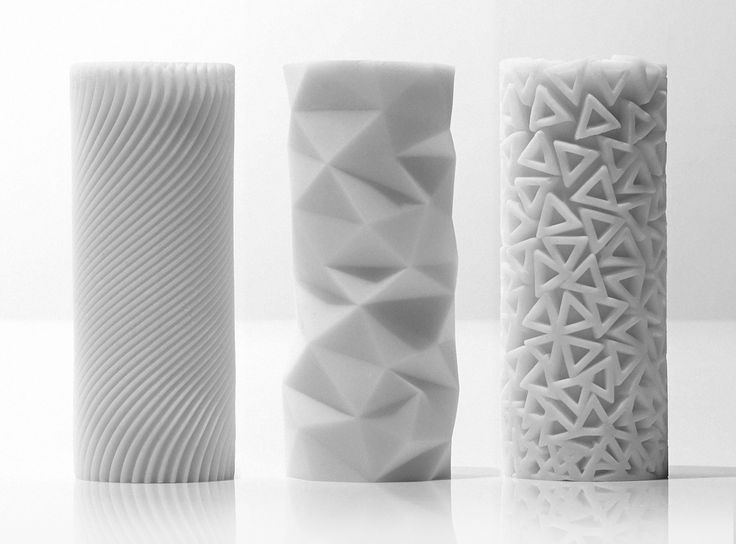

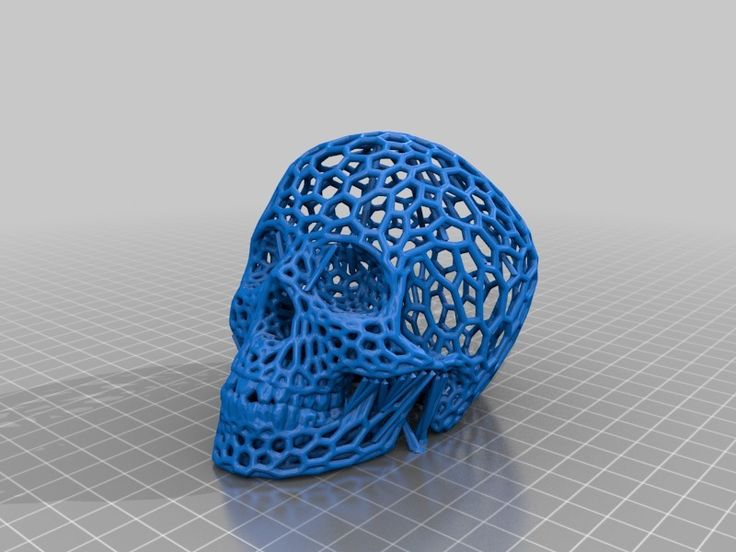

- FDM (Fused Deposition Modeling) is by far the most common method of producing thermoplastic parts and prototypes today. Based on the melting of the filament in the nozzle with its subsequent laying in layers. It is also the most economical way of 3D printing due to the availability of a wide range of thermoplastic materials with different technical characteristics, which allow generating both functional parts of mechanism prototypes and volumetric cases, as well as any free spatial decorative forms.

nine0208

nine0208 - SLA (Stereo Lithography Apparatus) is based on the layer-by-layer curing of a liquid photopolymer material under the influence of UV study. Can print objects in multiple colors and materials with different physical properties, including rubber-like parts. The high printing accuracy of this method makes it more expensive and not optimal for simple plastic structures.

- DLP (Digital Light Processing) cures polymers using a light projector rather than an ultraviolet laser. This allows you to create a whole layer in one exposure, thus increasing the speed of production. nine0208

Metals too have their own 3D printing techniques. The type of technology is selected depending on the features of the object.

- SLS (Selective Laser Sintering) is based on layer-by-layer sintering of polymer powder particles using laser radiation. The nylon powder melts into a strong, hard plastic. Due to the peculiarity of the technology, the surface of the part is not ideal, but very functional for use in prototypes with hinges and latches.

nine0208

nine0208 - SLM (Selective Laser Melting) is based on layer-by-layer sintering of metal powder under the action of a laser beam. Used in the manufacture of decorative items. Therefore, it is useful for applications in medicine and lightweight structures. Often this method is used in conjunction with traditional metal casting technology to create prototypes or final products.

- EBM (Electron Beam Melting) is based on layer-by-layer melting using an electron beam. The printing uses electromagnetic coils to superheat the metal powder in a vacuum. nine0208

How 3D printing works

3D printing is the process of layering one on top of another. Every 3D printed object starts life as a 3D model in a computer program.

You can create your own design in programs such as Maya, Blender, ZBrush, CATIA, Solidworks. In addition, ready-made 3D models of parts can be downloaded from sites such as Thingiverse or CGTrader.

Once you have a 3D model obtained in one way or another, you “run” it through the “slicer” program (from the English word “to slice”), which converts the original 3D model in STL format into print layers. The information received is eventually converted into a special data format called G-code for further printing on a 3D printer. nine0011 Such programs usually come with the 3D printer, or they can be freely downloaded, such as the Cura program. What these softwares have in common is that they create thousands of lines of code for layers. This code tells the printer how to print.

The information received is eventually converted into a special data format called G-code for further printing on a 3D printer. nine0011 Such programs usually come with the 3D printer, or they can be freely downloaded, such as the Cura program. What these softwares have in common is that they create thousands of lines of code for layers. This code tells the printer how to print.

Next, you need to set up your 3D printer, select the print quality and the correct material settings. To start printing, you load your "sliced" part into the printer via a USB stick, SD card, or send directly from your computer. And the printer starts a slow additive layering process. nine0005

Photo of Christian Reil from Pixabay

3D printing materials

The materials available for 3D printing have come a long way. Currently, there is a wide range of materials that differ both in properties, types, and in the states supplied (powder, threads, granules, resins, etc. ).

).

Some materials are developed for specific applications to perform special tasks. For example, the medical sector, where special photopolymer resins (SLA 3D printing technology) are used, the properties of which make it possible to print implants, casts, and so on. nine0005

Some of the most commonly used materials:

- Plastics. Sintering (SLS) typically uses polyamides or nylon supplied in powder form. It is a strong, flexible and durable material. It is white in color, so it needs to be tinted before or after printing. The most common 3D printing technology today is FDM, which uses ABS or PLA plastic filaments. These plastics are available in a wide range of colors. Compared to PLA, ABS plastic has higher strength characteristics. But PLA is biodegradable, so it's as widespread as ABS. nine0208

- Metals. More and more metals and metal composites are finding their way into industrial 3D printing. The most common of them are derivatives of aluminum and cobalt.

Due to its strength characteristics, stainless steel is often used in powder form in 3D printing technologies such as sintering, melting, EBM. In the last couple of years, silver and gold have been added to the list of metals suitable for printing. This made it possible to significantly expand the possibilities of jewelry production. nine0208

Due to its strength characteristics, stainless steel is often used in powder form in 3D printing technologies such as sintering, melting, EBM. In the last couple of years, silver and gold have been added to the list of metals suitable for printing. This made it possible to significantly expand the possibilities of jewelry production. nine0208 - Ceramics. A relatively new group of materials used in 3D printing. The peculiarity of printing with these materials is that the printed ceramic parts must go through the same processes as ceramic products made by traditional methods - firing and glazing.

- Biomaterials. Currently, a large number of studies are being conducted aimed at exploring the possibility of 3D printing from biomaterials for the needs of medicine. This includes the printing of human organs for transplantation, external tissues for replacement of body parts. To do this, leading institutions research living tissues. nine0208

- Food. Over the past few years, there has been an increase in experimentation with food 3D printing extruders.

Chocolate printing is the most widely used. There are 3D printers that use sugar, pasta, meat, dough.

Chocolate printing is the most widely used. There are 3D printers that use sugar, pasta, meat, dough.

Photo of mebner1 from Pixabay

What 3D printing is used for

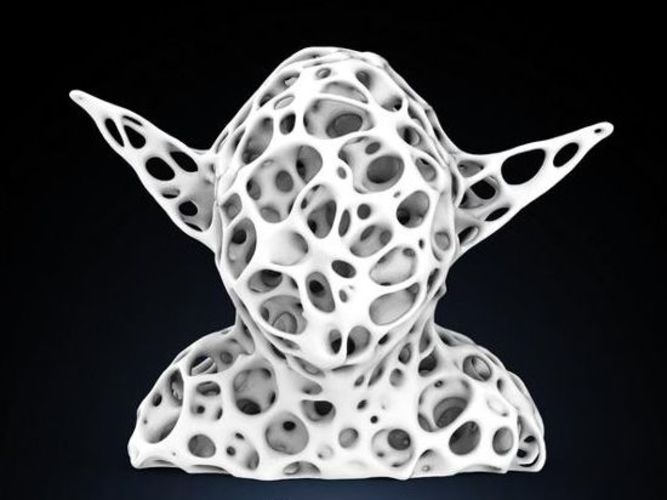

If you can think of an item, then most likely you can print it. Children's toys, jewelry, phone cases and much more are already being printed by enthusiasts on 3D printers. Some use 3D printing for fun. Fun projects already exist: a printed guitar, a loom, and an intricate sculpture created from a combination of laser-fused glass and nylon. 3D printing has already moved beyond its origins in plastic printing and has moved into the use of metal, rubber, wood, synthetic fabrics, and ceramic resins. Functional 3D-printed human organs have not yet been created, but scientists say that this is a matter of the near future. nine0005

Because additive manufacturing of complex objects is faster and cheaper than traditional molding and casting methods, it has found its way into industry and the arts. The possibilities of this technology are almost limitless, but 3D printers are not perfect machines. In addition to all the advantages, there are also reasons for concern.

The possibilities of this technology are almost limitless, but 3D printers are not perfect machines. In addition to all the advantages, there are also reasons for concern.

Ethical issues in 3D printers

3D printers consume a lot of energy and emit ultra-light plastic particles into the air, which are then inhaled by humans. These harmful emissions can be compared to a cigarette lit indoors. nine0005

While humanity is trying to reduce the use and consumption of plastic, 3D printers are another technology heavily dependent on it. This presents a problem for all ecosystems, in particular for the already suffering oceans with their floating islands of plastic.

A few years ago, the news of the first 3D printed firearm caused a media frenzy. The creation of untraceable weapons by a private individual remains a modern security problem. nine0005

From a legal point of view, there is no clear answer to the question of who is responsible in the event of harm to health caused by a printed object. Indeed, in most cases, the developer of a 3D model, the manufacturer of a 3D printer, and the one who printed it are different people or organizations. Determining liability for potential injury and death is a new challenge.

Indeed, in most cases, the developer of a 3D model, the manufacturer of a 3D printer, and the one who printed it are different people or organizations. Determining liability for potential injury and death is a new challenge.

At the same time, the use of 3D printing technology in the medical field to print tissue raises a number of ethical and moral questions. These issues are similar to the talk of stem cell research and gene editing that has been going on for decades. nine0005

On the other hand, we have a powerful tool in our hands that is changing the way we create and produce things. We still don't fully understand what this means for our future.

Potential effect on the global economy

If 3D printing continues to develop at the same pace as it is now, then its use could potentially affect the global economy. The transition of production and distribution from the current model to localized custom manufacturing can reduce the imbalance between exporting and importing countries. nine0005

nine0005

3D printing is creating new industries and new professions. Professions related to the production of 3D printers or, for example, a vacancy for a rapid prototyping technician at the Cartier jewelry house. New professional services are emerging, such as supply of materials, printer operator, legal services in dispute resolution and intellectual property issues. With the development of 3D printing technology, the issue of "piracy" becomes an urgent problem.

The impact of 3D printing on developing countries is a double-edged sword. The positive effect for such countries is the reduction in the cost of production through the use of recycled and other local materials. But the loss of manufacturing jobs could hit these economies hard, and it will take time to find a balance. nine0011

Where can I use a 3D printer

Owning a 3D printer with the necessary software and materials can still be expensive for individual needs, so public 3D printers are becoming more common.

There are places like labs and 3D printing shops. You can send your design and pick up the finished part in a couple of days. Some companies, such as ART AP Design Studio, also do 3D printing. nine0005

If you are a student or student, 3D printing services may be available at your school.

Printed products in Art-Up Design Studio

Where can I learn how to use the 3D printer

For those who already have the specialty of an engineer, there are advanced training programs (Additional education) from the Russian Academy of Crafts, designed for 36 or 72 academic hours.

The training course in an accessible lecture form reveals the issues of theoretical and practical foundations of design, three-dimensional modeling, design of plastic products. It provides for the performance of work and tests within the framework of the design tasks of the course and the final exam. nine0005

As a result of mastering the program, the trainee receives a certificate "Specialist in Additive Technologies".