3D print dome without support

How to 3D Print a Dome or Sphere – Without Supports – 3D Printerly

3D printing can do many things but people wonder whether you can 3D print a dome or sphere without supports. This article will answer that question, as well as other related questions.

Keep on reading for the details on how to do this properly.

Can You 3D Print a Sphere Without Support?

Yes, you can 3D print a sphere without supports by splitting the sphere into two halves, then joining them together afterwards, simply by gluing it. You can split the model by editing it in a CAD software, or simply by lowering the sphere into the bed by half of its height, then duplicating it for the second half.

You can use a software like TinkerCAD to create a sphere from the “Shapes” menu within the program.

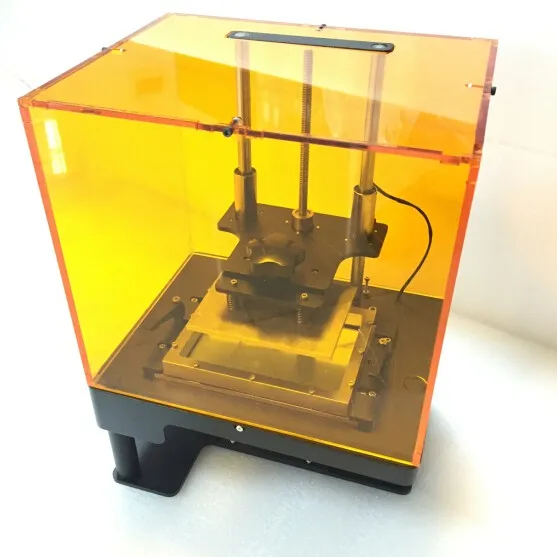

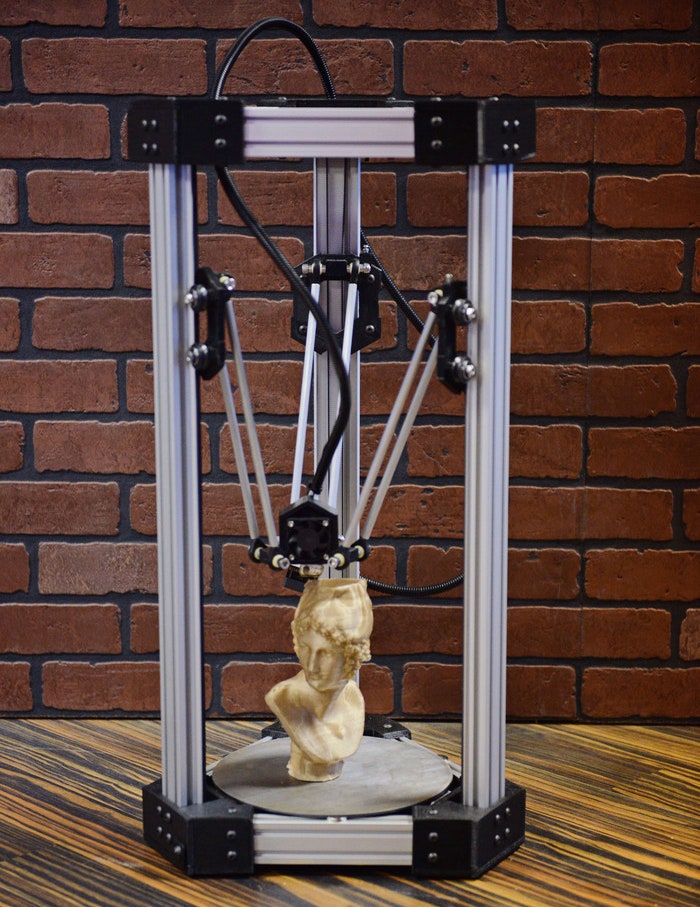

It’s difficult to 3D print a really good sphere without supports, especially because of the nature of 3D printing. You would be able to 3D print a good sphere with resin 3D printing rather than filament 3D printing since you can get finer layers.

Below is a great example of this.

I have done the impossible! I printed a sphere. from 3Dprinting

One user gave some tips for 3D printing spheres:

- Slow the print speed down

- Use a lot of cooling

- Use supports with dense top layers

- Print the supports on a raft

- Optimize your printing temperature

- Have thinner layers at the top and bottom (0.1mm), then thicker through the middle (0.2mm)

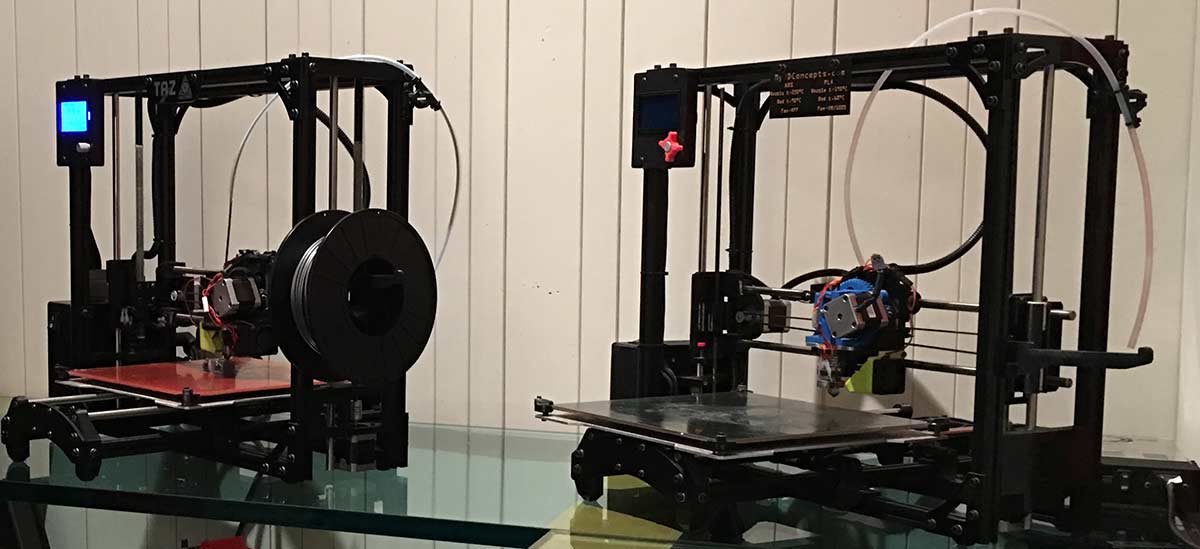

He mentioned that it’s possible to 3D print spheres without supports, but it’s better to accept some minor damage from support removal, unless you 3D print with a dual extruder and dissolvable supports.

Here is a video by “Lithophane Maker” about 3D printing a Moon Lithophane Lamp on a CR-10S. The model is a sphere with a bottom stand. There is an open weave to insert the light bulb, once it is printed.

An example of 3D printing a sphere is this 3D printed Pokéball from Thingiverse. You can see more in the video below.

You can see more in the video below.

How to 3D Print a Dome

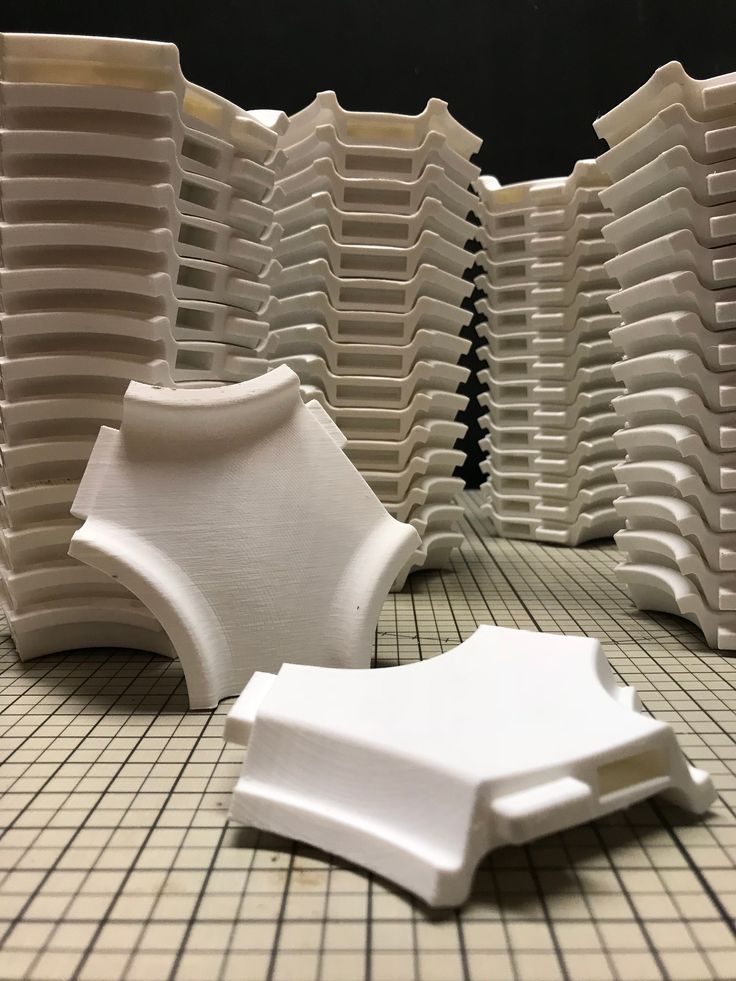

To 3D print a dome, you want to keep the flat side down on the bed, while the round side will be built on top. For big domes, you may need to slice them in half and then glue them together once they are printed.

Below are some examples of domes that you can 3D print:

Below are some examples of Domes, or Spheres that are made by combining two domes (hemispheres) together. You may try printing one to see how it goes.

- Pokéball (made suing two domes, hinge, and a button)

- Guardians of the Galaxy Infinity Orb

- Star Wars BB-8 (two hollow domes joined together)

- Flexible Mini Greenhouse Dome with Pot

- Droid Dome – R2D2

- Geodesic Dome Cat House Bed Parts

There is a standard rule in 3D printing that you can print overhangs as long as it doesn’t exceed the 45° mark.

Printing at this angle ensures that each layer has 50% contact with the previous layer that supports the new layer to build on. With this rule, printing domes is quite easy.

Below are some tips that can help you out in tackling the overhangs while printing domes:

- Increase the cooling fan speed

- Decrease your printing temperature

- Decrease printing speed

- Reduce layer height

- Add a chamfer (a straight 45° wall) at the inside of the dome to offer support

- Tune up your 3D printer

One user said that he has 3D printed a 20″ dome for his R2-D2 model with 10% infill, 4-5 walls and no support. Decreasing your print speed, lowering the printing temperature, and using vase mode can give you great results.

Take a look at the video by John Salt about R2-D2 dome printing and its complete assembly.

Here is another short video by Emil Johansson showing a dome print with large and adaptive layer height.

Can You 3D Print a Hollow Sphere?

You can 3D print a hollow sphere but you’ll need to add supports to the base of the sphere. The other good way is to print a sphere in two halves or hemispheres. To make a larger sphere, you could even do it in quarters.

A user suggested printing a hollow sphere by putting settings as 0% infill, along with adding brims, supports, while tweaking outer wall thickness as well.

Another user said that no print can be printed in the air so you need to add support at least at the initial layers or base section to get appropriate results.

However, printing in two halves will be great as both parts will be printed on their flat base. You can join them together in post-processing using glue.

Guides to 3D Print Without Supports: Top Secrets and Tricks

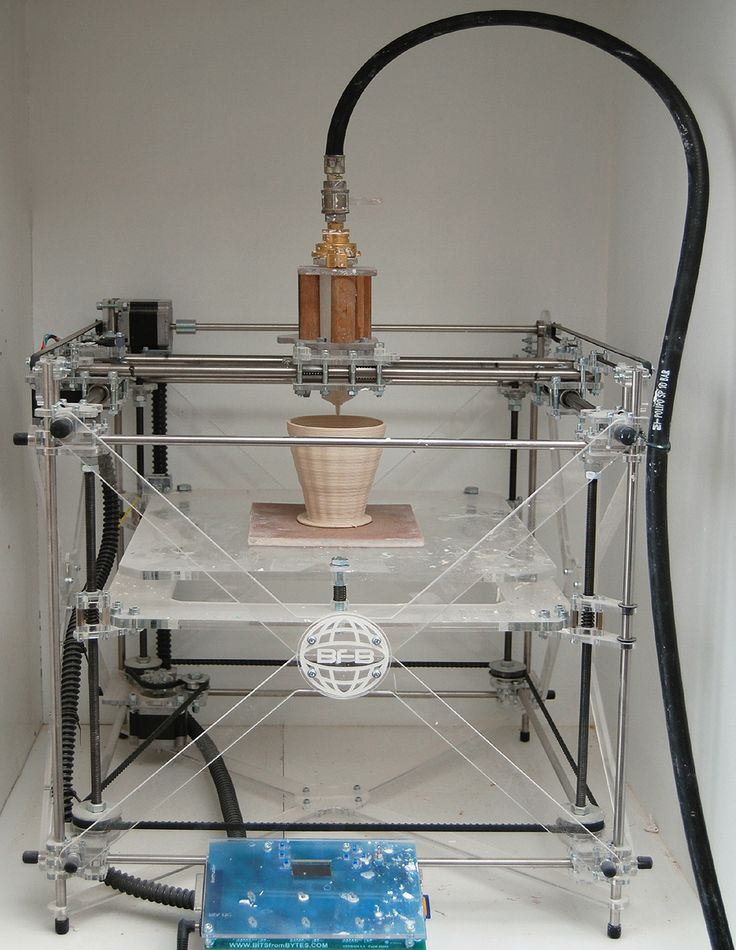

Modern technologies continually develop. Experts are always in search of new methods to simplify everyday tasks, and such positive changes are widely used everywhere, including the 3D printing industry. You can 3D print without supports, eliminate additional structures, save filament and your time. And your result will look fantastic and professional even if a 3D print is crafted at home, on an affordable FDM, SLA and other types of 3D printers.

Gambody recently discussed the two main types of supports used in 3D printing. However, it is also possible to eliminate the use of the support structure and create impressive complicated models at home with no additional material.

3D Print Without Supports

Gambody – Premium 3D printing marketplace offers many remarkable character models and 3D printing figurines from famous movies and games. Many of the models require the least amount of support structures while being printed. While some parts of the projects require no supports at all.

While some parts of the projects require no supports at all.

It is a must to talk about different methods that allow you to create fantastic 3D prints with no supports even when the model requires them. Sometimes you might experience issues while trying to 3D print a model without support material. In this case, read Gambody’s troubleshooting guide to fix the most common 3D printer problems as your issues might not be connected to support structure at all.

There are several rules to follow when you wish to eliminate supports and 3D print impressive masterpieces. It is also interesting to learn more about the new support-free technology called mid-air 3D printing and watch some stunning videos.

Mid-air 3D Printing

Several experiments were conducted by the University of Illinois, which led to the development of an impressive technique. It is called mid-air 3D printing.

Such method proved to work in the university laboratory. A new 3D printer created by the university engineers was capable of 3D printing dissolvable sugar scaffolds. The machine does not use layer-upon-layer technology. Instead, it creates a network of thin isomalt ribbons and builds complex shapes around them.

The machine does not use layer-upon-layer technology. Instead, it creates a network of thin isomalt ribbons and builds complex shapes around them.

This new creation cannot be used at home at the moment since no slicing program supports mid-air 3D printing settings. Still, if you are interested in this new technology, you can learn more about a custom g-code generation and try your luck in this sphere.

While mid-air 3D printing is being developed and tested to be possibly used in tissue engineering in the future, you can learn how to craft overhangs without supports today.

3D Printing Without Supports: Under 45 Degrees Rule

It is simple to eliminate complex support structures if you follow the under-45-degrees rule. What does it mean?

What does it mean?

Any model that is designed with all the angles being less than 45 degrees can be 3D printed at home with no supports at all. It is a real-working solution which requires some extra work while designing or cutting your 3D printing model in slicing software. But all the spare time spent to comply with the rule is worth it.

When you follow the under 45-degree angle rule while 3D printing without supports, you make your 3D printer craft layer by layer with each new one being offset by no more than 50 per cent. It means that at least half of the new layer area contacts the previous layer and stays put because there is enough base onto which to grab.

Complex objects often have complex shapes where you cannot escape angles over 45 degrees. In such situations, you can follow the second “background as support” rule and 3D print impressive models with severe overhangs.

Experiments with a 45-degree 3D printing rule3D Prints with No Supports: Background as Support Rule

The designing of a future 3D print model is similar to the work of a sculptor. You have to think about every part of the project, especially the ones that require support or they could collapse because of the weight.

You have to think about every part of the project, especially the ones that require support or they could collapse because of the weight.

Many complex 3D printing models require supports, but it is always possible to make all the supports a part of the print. You can use background and additional objects to hide supports and get rid of extra filament because there will be no support structures to clear after the printing process.

In other words, the background can become the support on its own. For instance, if your model has cushions or clothes folds, they can be used to support the figure’s arms or legs. The hair can naturally support the character’s chin. A long gown can hide supports for the legs, etc.

Image: @fantasygraph (Twitter)There are many fantastic ideas on how to 3D print without supports while still using them as non-removable hidden structures.

Playing with the model’s poses and additional objects (base, stones, armour, etc. ) can save you many nerves and filament.

) can save you many nerves and filament.

3D Print Without Support Structure: Bridge Rule

If your 3D printing model consists of bridges, the chances of using the support structure are incredibly high. A bridge is considered the most challenging overhang of all.

There is a bridge rule to avoid supports. Any bridge that is 5mm or less in length can be 3D printed with no support material.

When working with bridges, slow down. The slower your 3D printer goes, the smoother the final result will be. Layers will adhere better, and the bridge will become stronger and neater.

Tricks on how to eliminate supports while 3D printing bridgesThere is also one trick when you have to 3D print a sophisticated bridge that is longer than 5mm and wish to eliminate support material.

Look attentively at your project. When the bridge looks complicated and challenging when viewed vertically, it might become an easy no-support print when you rotate the model at 90 degrees and print on the back.

Such orientation change can work fantastically and help you to create an outstanding bridge without support. Of course, such a trick will not work with bridges that are not perfectly levelled and require many layers of filament.

Wise Tips When You Can’t 3D Print Without Support Material

No matter how hard you try to apply the bridge and under-45-degree rules while designing 3D printing MechWarrior models, famous DC Comics villains and other characters, sometimes it is impossible to eliminate supports.

Tips on how to 3D print without support structureComplex objects such as humans, spacecraft with interior details, robots with detailed armouring often have angles that exceed 45 degrees, overhangs and bridges. Still, some wise decisions can minimize the use of supports in 3D printing:

Still, some wise decisions can minimize the use of supports in 3D printing:

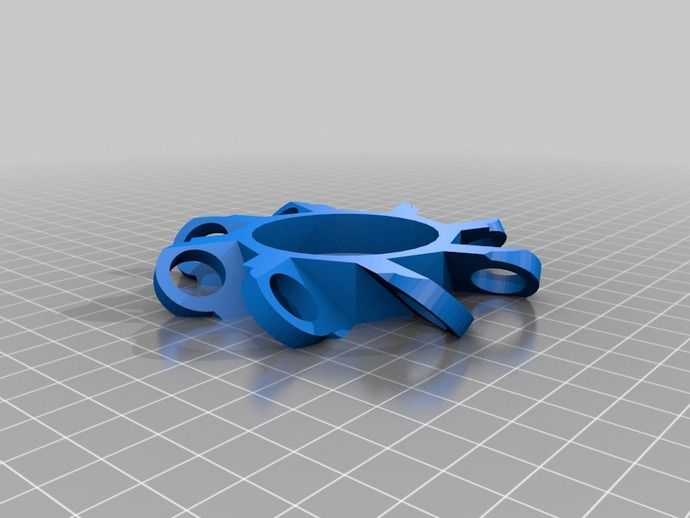

- Using a round base can prevent warping

- Oval/round bases improve the model’s adhesion to the bed

- Rotating a model with a horizontal arm to 45 degrees requires fewer supports under its base

- Using a chamfer to “cheat” angles that violate the 45-degree rule might sometimes work fine

- Slowing down the printing speed can improve your prints with and without supports

- Learning how to store filament can prevent moisture from ruining your 3D prints without supports

- With complicated shapes you can save the 3D print from deforming by using cooling fans aggressively

- Sometimes cutting the model in half can eliminate the use of the support structures but require extra glueing

Try to add supports to areas which won’t spoil the whole look of the model once they are removed.

3D printing at a 45-degree angleFor example, adding support material to the underside of the base is a smart decision. Even if the bottom gets damaged, you can clean it and sand it to remove the defects while saving the more complex object from support usage.

3D Print with Soluble Supports

Modern materials are impressive. Many printers support HIPS and PVA filament that is soluble in different substances (water, limonene).

Image: ultimaker.comUsing HIPS or PVA soluble materials as additional supports is an excellent idea. There will be no need to spend much time on clearing and smoothing the 3D print with such overhangs. All is required is the substance that can dissolve the extra filament once the print is submerged in a container with the correct type of solvent.

About water-soluble support filamentUsing the best tips on how to 3D print without supports in your projects can help you to defy gravity. It is impressive how simple everything will become once you start to apply the under-45-degree rule, work with bridges and hide support structures in useful background and intricate object details. Just make sure to showcase your best models in Gambody Facebook group.

(Visited 19,658 times, 1 visits today)

Author

(There is a solution) Hemispherical bowl: how is this possible?

I was reading about how to extrusion print over a 45 degree overhang when something weird stuck in me.

I see many and many 3D extrusion printed bowls with perfectly printed hemispherical surfaces. However, given that some deformation is expected during the printing process, how can a perfect hemispherical bowl be obtained in which both the inner and outer surfaces are perfectly hemispherical?

However, given that some deformation is expected during the printing process, how can a perfect hemispherical bowl be obtained in which both the inner and outer surfaces are perfectly hemispherical?

Note: I'm not talking about the smoothness of the surface, but the shape of the bowl itself. I understand that smoothing the surface will make the bowl look great, but it won't fix the warp in the shape of the print.

▲ 8

There are several factors at play. For example, orientation, printer and slicer settings, and more.

First of all, not all protrusions over 45° need to be supported. Many printers operate up to 60°, even 70° is not unheard of - with the right settings. Nearly all printers manage tiny 90°.

Let's look at the bowls, which are shaped like a U - the dome is at the bottom. With a flat contact surface, only the following areas need support, and with PVA or other easy-to-remove support structures on the incline, it's no problem to use the support and leave no marks. With a support, there is no sagging, so the bowl gets its "ideal" appearance, even though the ledges and support are used.

With a support, there is no sagging, so the bowl gets its "ideal" appearance, even though the ledges and support are used.

On the contrary - the dome is on top - probably more "smooth", using various tricks to install it.

The outer wall is now on infill, like the inner one we had before, perfect, but we used it for the inner wall before. But what about the inside?! Well, we don't need side support until we reach, say, a 55° angle. Can we move on without support? YES... if we are cunning!

- Print the walls from the center to the outer wall, because then the inner walls will stand on the bottom layer and will be able to hold the new, adjacent, floating 92)$ before our walls are more than half a wall below the wall. As you can see, $z$ and $d$ are fixed in this calculation, while a higher $n$ factor directly increases the value of the angle. As long as there is a support for the wall (for example, an adjacent, already printed wall), you get some kind of dome.

- Printing in thinner layers. If you decrease $z$, you will also increase the maximum angle at which one wall sits on half of the supporting wall.

- Type slowly. Printing more slowly allows the material to cool and solidify, although it is still somewhat held in bond with the filament exiting the nozzle. This can support a higher overhang angle.

- Cooling. In combination with slow printing, it may be necessary to use a particularly strong cooling solution to speed up curing. Aim well.

- Printing Narrow Domes 1. Why is it so much easier to print narrower domes than wider domes? Part of the answer is how much geometry doesn't need to be supported on its own, the other part is the weight of the entire structure: a narrow dome spans less distance. This means it has less area at a greater angle to the last layer and the overhangs are shorter overall. This may result in improved printing.

1 What is considered narrow depends on the printer and filament. It is not a problem to print small spherical indentations in the seal if they are small enough, as the protrusion is then short enough that it can carry itself. However, at some point it becomes too much.

It is not a problem to print small spherical indentations in the seal if they are small enough, as the protrusion is then short enough that it can carry itself. However, at some point it becomes too much.

, @ Trish

💯 Best Unsupported Model STL Files for 3D Printing・Cults

💯 Best Unsupported Model STL Files for 3D Printing

Download unsupported print-in-place 3D object files

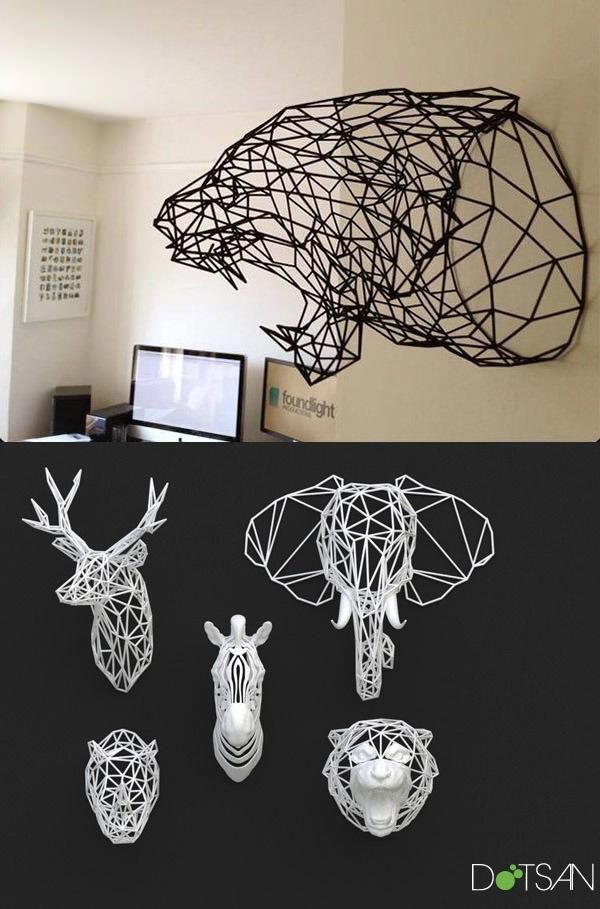

A big trend in 3D printing for several years, "Print-in-Place" or unsupported printing in place, has revolutionized 3D modeling for 3D print. Indeed, 3D files are now easily printed without support and can be used and sometimes even articulated when printed.

SPRING BOX FOR FIELD PRINTING

Free

Articulated Dragon

4.04 €

flexible turtle

Free

Field Print Engine Benchmark

Free

flexible mammoth

Free

flexible puppy

Free

Cute mini octopus

Free

Articulated Lizard v2

Free

PRINT-IN-PLACE PHONE HOLDER - FOR SPACE?!

Free

Articulated Shark

Free

flexible bear

free

Print-in-Site - Distance Measuring Roll Tool

Free

Predator Action Pliers

Free

Cute frog with flexi print

1,97 €

FLEXI BEETLE

Free

Cute skeleton with flexi print

2. 99 €

99 €

CUTE CROCODILE WITH FLEXIBLE PRINT IN PLACE

2,99 €

Print In Place PCB-Holder / Gripper

Free

Flexi PRINT-IN-PLACE Hand

1,97 €

flexible zombie animals

Free

Fighter Jet with print stand and articulation

Free

Flexi-print "Fish"

1,97 €

Cute Flexi Print-in-Place Ant

1,97 €

Cute turtle with flexi print

1,97 €

Cute spider with flexi print

1,97 €

Surprise Egg #4 - Tiny Excavator

Free

Flexi Print-in-Place llamacorn

1.97 €

Folding sword - Épée dépliable - Unsupported / Printed in place Version 1

Free

SD Card Toaster Print-on-Site

Free

Surprise Egg #1 - Tiny Truck

Free

Scorpio with flexi print

1,97 €

CUTE FLEXI PRINT-IN-PLACE FISH - keychain

Free

Lazy Cat

4. 04 €

04 €

Surprise Egg #3 - Tiny Wheel Loader Toy

Free

Fidget Gears Revolving V2 (print on site!)

Free

Skeletonized V-Twin!

Free

Surprise Egg #7 - Tiny Car Transporter

Free

Lazy Dogs

5.05 €

Surprise Egg #5 - Tiny Fire Truck

Free

Seal-in-place Fixing box - no assembly required!

Free

Articulated Fish Print in Place

Free

Surprise Egg #2 - Tiny Forklift

Free

Swing-out calibration cube

Free

Surprise Egg #8 - Tiny Racecar

Free

Predator Action Pliers Mk2

Free

SCARAB 4WD Buggy - Print In Place

Free

Cute caterpillar with flexi print in place

1. 97 €

97 €

Flexi Print-in-Place Foot

1,97 €

Cute skeleton with flexi print

Cute skeleton with flexi print

Flexi Print-in-Place Foot

Articulated dragon

Here is our selection of best STL files without print support in space. They are all beautiful creations from the Cults 3D file library and are 3D printable without media . This means these creations can be used straight out of 3D printing, are articulated or flexible, and you don't even have to remove the print supports.

All 3D printing designers have this wish: create files that are easy to print and very pretty or practical . This has led to the trend "Print-in-Place no support" with files that are easy to print without the need to add print media.