3D print bump key

▷ bump key 3d models 【 STLFinder 】

Bump Key

thingiverse

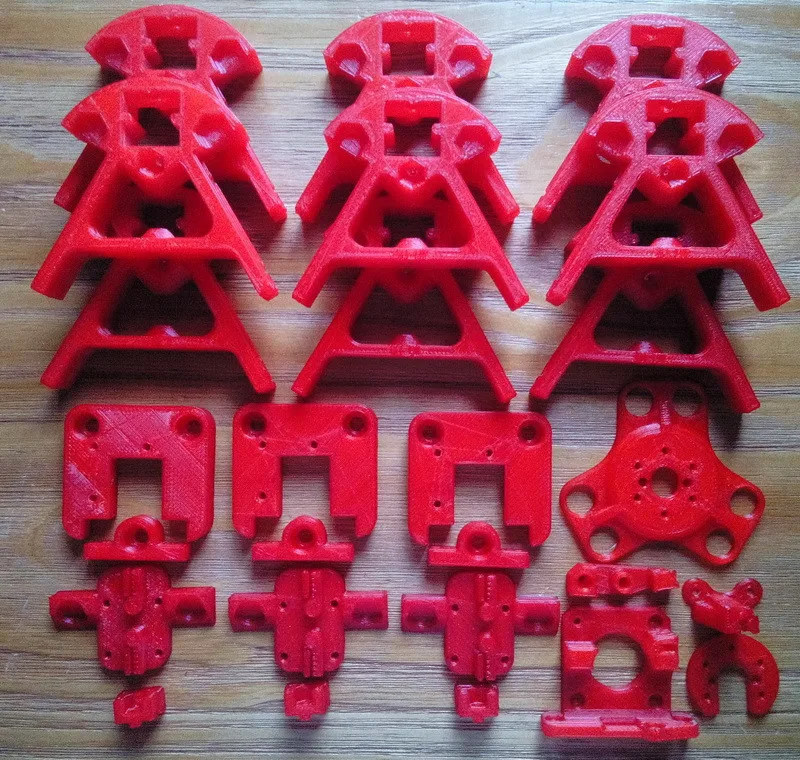

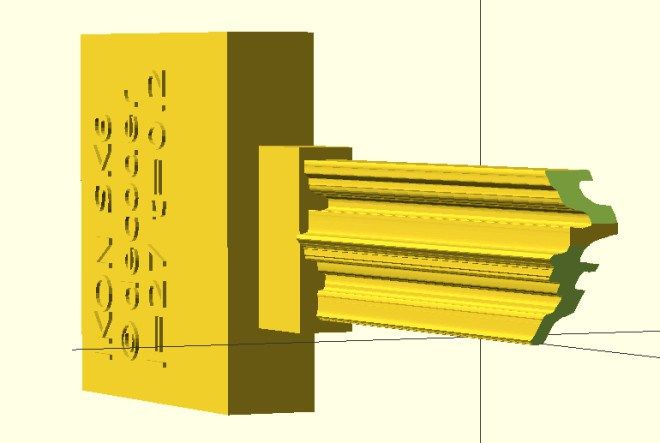

type_of_key = 0 backslotangle = [210,210] topslotzoffset = [(4layer_thickness),(3*layer_thickness)] keytipbotangle = [225,225] layersthick = [3,3] straightlength = [27,22] frontslotyoffset = [0.60,0.00] cylseparation = [4.00,3.00] keytipbotyoffset =...

Bump Key

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=56795 Instructions Using the following options: keytipbotyoffset = [key_bslot_yoffset,(blade_height/2),0.00] topslotangle = [30,30,0.00] keytipbotangle = [225,225,0.00] backslotangle =...

bump key

thingiverse

http://www. thingiverse.com/apps/customizer/run?thing_id=56795 Instructions Using the following options: keyringradius = [4.5,4.0,4.0] cylinder_z_rotation = [0,45,0,45,0,45,0,45] straightlength = [27,22,0.00] safe_pin_xoffset =...

bump key

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=56795 Instructions Using the following options: keyringradius = [4.5,4.0,4.0] frontslotzoffset = [(5cyl_front_slot_layerslayer_thickness),0.00,0.00] topslotangle = [30,30,0.00] backslotzoffset =...

bump key

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=52761 Instructions Using the following options: topslotangle = [30,30] firstcyloffset = [6. 00,5.00] custom_key_text = keytipbotangle = [225,225] keybladelength = [28.50,18.50] keycylindercount =...

00,5.00] custom_key_text = keytipbotangle = [225,225] keybladelength = [28.50,18.50] keycylindercount =...

bump key

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=52761 Instructions Using the following options: keytiptopyoffset = [(key_bslot_yoffset+key_bslot_height),(blade_height-key_tslot_height)] keycutcode = 99999 build_plate_selector = 2...

Bump Key

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=56795 Instructions Using the following options: layersthick = [3,3,3] print_layer_thickness = 1 cylinder_z_rotation = [0,45,0,45,0,45,0,45] topslotangle = [30,30,0.00] cylpinbotdiameter =...

Bump key

thingiverse

http://www. thingiverse.com/apps/customizer/run?thing_id=56795 Instructions Using the following options: cylseparation = [3.81,3.00,0.00] cyldiameter = [2.921,1.00,0.00] keycutcode = 99999 topslotzoffset =...

thingiverse.com/apps/customizer/run?thing_id=56795 Instructions Using the following options: cylseparation = [3.81,3.00,0.00] cyldiameter = [2.921,1.00,0.00] keycutcode = 99999 topslotzoffset =...

Bump Key

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=56795 Instructions Using the following options: keycutcode = 999999 straightlength = [27,22,0.00] topslotangle = [30,30,0.00] keytipbotangle = [225,225,0.00] style_of_key = 0 5cyltopslotlayers =...

bump key

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=56795 Instructions Using the following options: frontslotzoffset = [(5cyl_front_slot_layerslayer_thickness),0. 00,0.00] frontslotheight = [1.60,0.00,0.00] cyldiameter = [2.921,1.00,0.00]...

00,0.00] frontslotheight = [1.60,0.00,0.00] cyldiameter = [2.921,1.00,0.00]...

bump key

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=56795 Instructions Using the following options: cyldiameter = [2.921,1.00,0.00] keyringradius = [4.5,4.0,4.0] keycylindercount = [5,4,7] numberofsteps = [cutting_steps,10,10] keybladeheight =...

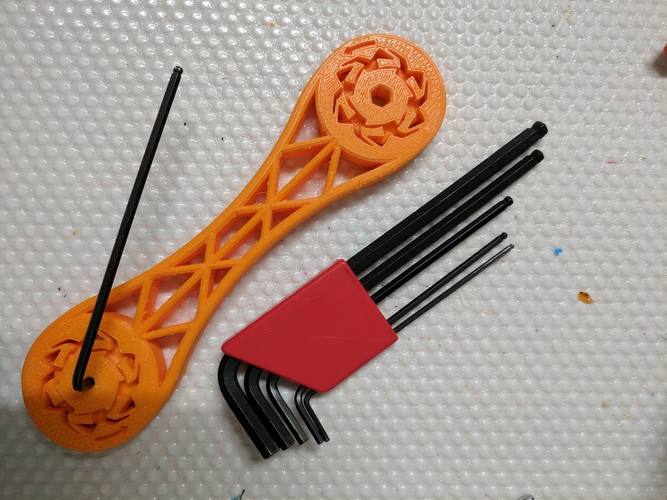

Mini Bump Key Hammer

thingiverse

https://www.3dlocksport.com/products.php#!/Small-Bump-Hammer/p/155655426/category=39551008 I bought a Sparrows Bump Key Hammer. It is a great piece of equipment, however it is very large, as are most Bump Key Hammers. I wanted to make a smaller one. ..

..

Bump Key Hammer

thingiverse

A simple bump key hammer.. BUT this one has a replaceable hammer face for when you wear it out, or to use a different material for printing.. It might be good with flexible filament, but I don't have any!!! EDIT..... I have tried hammer faces...

Bump Key Hammer

thingiverse

... to make. See a video of me using it here: [](https://www.youtube.com/watch?v=ZOsHhFzJw7c) If you are looking for the mini version it is here: https://www.thingiverse.com/thing:2707828/

Bump Key Hammer

thingiverse

Use this to tap your bump keys. Designed off center to be better-suited for a right-handed person. I included the sketchup file if any lefties want to modify the design. Instructions So the .stl file...

Designed off center to be better-suited for a right-handed person. I included the sketchup file if any lefties want to modify the design. Instructions So the .stl file...

Bump Key Hammer

prusaprinters

https://www.3dlocksport.com/products.php#!/Bump-Hammer/p/155651360/category=39551008 I bought a Sparrows Bump Key Hammer. It is a great piece of equipment. I wanted to see if I could replicate it and make one cheaper. From Sparrows the cost of the...

bump key

thingiverse

Customized version of https://www.thingiverse.com/thing:52761

Created with Customizer! ... https://www.thingiverse.com/apps/customizer/run?thing_id=52761

https://www.thingiverse.com/apps/customizer/run?thing_id=52761

bump key

thingiverse

Customized version of https://www.thingiverse.com/thing:52761 Created with Customizer! ...https://www.thingiverse.com/apps/customizer/run?thing_id=52761

Padlock bump Key

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=52761 Instructions Using the following options: keytipbotangle = [225,225] topslotangle = [30,30] keybladelength = [28.50,18.50] straightlength = [27,22] backslotzoffset =...

channy's bump key

thingiverse

http://www. thingiverse.com/apps/customizer/run?thing_id=56795 Instructions Using the following options: keybladelength = [29.00,18.50,13.00] 5cylbackslotlayers = [2,3,3,3,3,3] frontslotzoffset = [(5cyl_front_slot_layerslayer_thickness),0.00,0.00]...

thingiverse.com/apps/customizer/run?thing_id=56795 Instructions Using the following options: keybladelength = [29.00,18.50,13.00] 5cylbackslotlayers = [2,3,3,3,3,3] frontslotzoffset = [(5cyl_front_slot_layerslayer_thickness),0.00,0.00]...

Impression and bump key Handle

thingiverse

this tool can help to tighten a key for key-impressioning. tighten the key into the handle and heat it up with a lighter for a nice imprint. after that remove the key and let it cool down. now you have a very strong support for this key shape. ...

5 Pin Bump Key

thingiverse

Customized version of http://www. thingiverse.com/thing:52761 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=52761

thingiverse.com/thing:52761 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=52761

Schlage SC1 bump key

thingiverse

Customized version of https://www.thingiverse.com/thing:2058244 Created with Customizer! ...https://www.thingiverse.com/apps/customizer/run?thing_id=2058244

Bump Key Hammer

thingiverse

Bumpkey Hammer

Pad Lock Bump Key

thingiverse

Customized version of https://www. thingiverse.com/thing:52761 Created with Customizer! ...https://www.thingiverse.com/apps/customizer/run?thing_id=52761

thingiverse.com/thing:52761 Created with Customizer! ...https://www.thingiverse.com/apps/customizer/run?thing_id=52761

House Bump Key

thingiverse

Customized version of https://www.thingiverse.com/thing:52761 Created with Customizer! ...https://www.thingiverse.com/apps/customizer/run?thing_id=52761

5 Cylinder House Key Bump Key

thingiverse

Customized version of http://www.thingiverse.com/thing:52761 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=52761

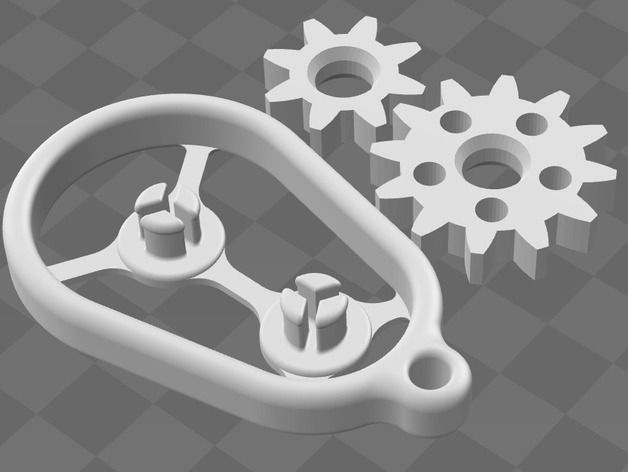

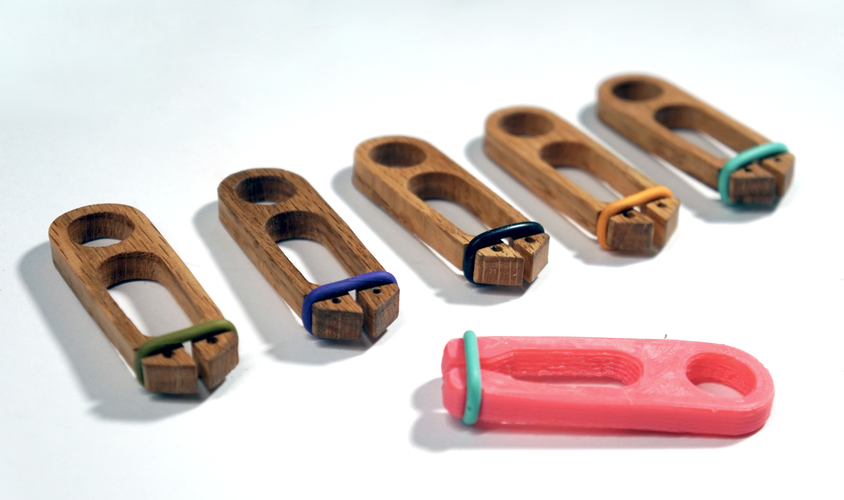

Pirate 3. 0 (Bump Key Lock Pick)

0 (Bump Key Lock Pick)

thingiverse

Moved knocker over so the rubberband fits better. Countersunk Nut Holes. Modified front hole to be much stronger. Included in the files is a video of me creating this thing from scratch. ... Based on an old concept whose patent had run out in the...

Pirate v3.0 (bump key lock pick)

thingiverse

Moved knocker over so the rubberband fits better. Countersunk Nut Holes. Modified front hole to be much stronger. Included in the files is a video of me creating this thing from scratch. ... Based on an old concept whose patent ran out in the 1970s

Pirate v. 2.0 Bump Key Lock Pick

2.0 Bump Key Lock Pick

thingiverse

Based on the design by peterthinks on YouTube.. https://www.youtube.com/watch?v=o_lXz6A6MSQ&t=21s Use metal strip from windshield wiper blade for knocker rod and tension wrench. There is a video in the files, of my design process for this...

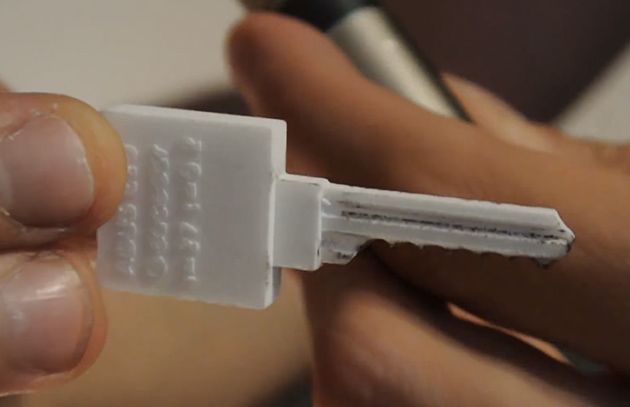

Turning the Common Lock Key Inside Out - UrbanAlps Launches Additively Manufactured Stealth Key - 3DPrint.com

For every lock and key, there are people who feel the need to crack them.

And 3D printing has already been used, by Jos Weyers and Christian Holler to 3D print “bump” keys which can be inserted into nearly any lock and given a “bump” to engage the tumblers and open the lock.

3D printed bump key

Fortunately, Weyers and Holler are engineers and security consultants, but their demonstration shows the technology of breaking and entering, via software called Photobump, has taken a great leap forward.

But fear not. For every person working on ways to defeat locks, there are teams working to toughen them up against intrusion. Alejandro Ojeda is the co-founder of UrbanAlps and he and his company have recently unveiled The Stealth Key. It’s an additively manufactured security key they say solves the problem of 3D scanned and printed lockpicking.

Ojeda and Dr. Felix Reinert say they’ve developed a range of cylinder locks and keys based on their Stealth Key concept. They say the keys are un-scannable and cannot be copied. They also call their solution “the simplest and most affordable key copy protection available.”

It works like this: the key hides most of its mechanical security features internally, thus rendering the key unscannable.

The company the pair formed, UrbanAlps, is a high-tech startup based in Switzerland, and they say they’re confident they’ve done no less than develop a new standard of high security cylinder-locks and keys.

Alejandro Ojeda

Dr Felix Reinert

Ojeda, a native of the Canary Islands in Spain, says he lives by the motto “control your destiny or someone else will. ” He’s a mechanical engineer with a pair of Masters degrees with more than 5 years of industrial experience at R&D departments as project manager for advanced laser processes and 3D scanning.

” He’s a mechanical engineer with a pair of Masters degrees with more than 5 years of industrial experience at R&D departments as project manager for advanced laser processes and 3D scanning.

Reinert, the co-founder and CTO of UrbanAlps, is a Swiss citizen with a PhD in laser physics with 7 years experience in novel manufacturing technologies.

The pair say it was the moment they saw a simple key scanned and used to open a standard lock that inspired them to create their Stealth Key system. They add that they personally used an Ultimaker 3D printer – among others – to print existing keys.

So they sought to create a mechanical key which cannot be copied using existing 3D scanners and printers.

“For centuries mechanical keys have relied on external features,” Ojeda says. “Today, thanks to additive manufacturing, we place those features inside. Unlike electronic combinations, the Stealth key is the affordable solution to the lost sense of security of key duplication.

In addition, the possibilities are beyond the key itself: it opens the door to mass-customization, near-zero waste material, bringing manufacturing back to Europe, reduced factory layoffs.”

While their current products are based on the Swiss cylinder profile and the European profile, they plan to adapt the Stealth Key to additional markets and profiles in the near term. They add that their solution is “in a similar price range” to current systems and that they plan to do a product launch – via a Kickstarter campaign – sometime this year. Their hope is to have the system in place in some European countries by 2016.

Can you see an idea like the Stealth Key from UrbanAlps changing the way lock-based security systems function? Think you could crack their “unscannable” system? Let us know in the UrbanAlps Stealth Key forum thread on 3DPB.com. Check out the video below highlighting the Stealth Key’s advantages in the face of what UrbanAlps calls the “3D printing threat” of scan-and-print keys.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printed keys • 3d printed lock security systems • 3d printed unscannable key • 3d printing security • bump keys • keys • security • UrbanAlps

Please enable JavaScript to view the comments powered by Disqus.

Arc Welding 3D Printing, Homemade Holographic Projector and More News of the Week!

Better to have a pet tiger

Have you just put a third lock on the steel front door of your precious home? Do you think that now no one will definitely enter your living space with dirty intentions? But in vain. Still won't help.

If there is a lock, it can be picked. In general, the main difficulty in creating master keys is not the selection of cloves, because in many cases this problem is solved by the so-called bump keys, but variable profiles designed to deal with the same bump keys. It is worth changing the cross-section pattern at least a little, and it will become difficult, if not impossible, to find a suitable blank for making a bump key if the profile of the window and key were selected to order.

In general, the main difficulty in creating master keys is not the selection of cloves, because in many cases this problem is solved by the so-called bump keys, but variable profiles designed to deal with the same bump keys. It is worth changing the cross-section pattern at least a little, and it will become difficult, if not impossible, to find a suitable blank for making a bump key if the profile of the window and key were selected to order.

With 3D printing, this problem is easily solved: a photograph of the window can be processed with the KeysForge program, which generates the corresponding CAD models of blanks. Then it remains only to indicate the teeth for the bump key or use a photo of the original key to repeat the pattern, and then print the master key from a sufficiently durable material. With the introduction of elastic nylon rods and increasingly strong composites, this will not be impossible either, although there is no guarantee of success, unless sintering plants are used to produce high-strength picks.

Note that KeysForge didn't include anything criminal from the very beginning. This program, developed by students at the University of Michigan, was conceived as a demonstrator of technology and the existing security threat. Most importantly, don't tell the bear cubs. Learn more about KeysForge here.

Metal Arc Welding 3D Printing

New details about Plus-Mfg's +1000K printer have been revealed. Recall that this device uses a metal arc welding method - today it is possible to use 6000 series aluminum alloys (with magnesium and silicon), 300 series low-carbon stainless steel and titanium, and soon 7000 series aluminum alloys (with zinc), copper and other materials.

The machine has one print head in its basic configuration, but the total number can be increased to four, allowing printing with different materials. The build-up speed reaches 2.5 kg per hour. The device provides constant temperature control and a cuvette with water to cool the printed layers.

So, the models in the illustration took 50 minutes each. The energy consumption did not exceed 2 kW, and the cost of the consumed steel bar was $20 for each model. The device itself is relatively compact, having a roughly cubic shape with a side of two and a half meters, and the build area reaches 1200x900x600mm.

Overall, this project focuses less on the quality of finished metal products and more on reducing production costs and increasing productivity compared to competing metal and alloy 3D printing technologies and traditional fabrication methods. According to the company itself, "the goal is to reduce energy consumption by at least half compared to sand casting and more economical material consumption without compromising the strength of the finished products."

More information can be found on the manufacturer's website.

Where there is demand, there is supply

While we are talking about metal 3D printing, it is worth mentioning laser sintering (SLS), which is currently the most popular method of metal additive manufacturing. This method (and variations on the theme - DMLS and EBM) achieves exceptionally high quality, but suffers from high installation costs and, importantly, high cost of consumables. Moreover, the cost of powder metals of the required quality is determined to a large extent by a banal shortage.

But there is good news. Following the growing popularity of sintering plants, raw material producers are also catching up. This week it became known that the American company Praxair Surface Technologies will launch a production line designed specifically for the manufacture of titanium powder for 3D printing. Reportedly, this decision was made after the conclusion of a partnership agreement with the developers of aviation technologies.

Praxair's small, custom-made batches of materials have previously been ordered by all three of the world's leading competing aircraft engine manufacturers: General Electric, Pratt & Whitney and Rolls Royce. Let's hope that the increase in production capacity will lead to lower prices and, perhaps, the development of a market for the large-scale production of metal powders for 3D printing.

Holography made easy and simple

What to do on the weekends? We offer a simple and entertaining project on applied holography. As the experiments of an Italian designer named Gianluco Pugliese have shown, there is nothing difficult in turning a smartphone into a holographic projector in the presence of a transparent plastic pyramid.

This idea can be realized without 3D printing by cutting out the sides of the pyramid from transparent plastic, but isn't it interesting? Of course, for the implementation of the venture you will need a transparent bar. The main problem will be getting a flat surface, because the quality of the three-dimensional image will depend on its smoothness.

The main problem will be getting a flat surface, because the quality of the three-dimensional image will depend on its smoothness.

This is where it's time to think about different materials and smoothing methods. Transparent PET suggests itself, but Gianluco chose to opt for ABS plastic. True, the treatment in an acetone bath did not give the desired results. Although this point is not disclosed, we dare to assume that the problem was the appearance of washouts, which happens quite often. But the optimal result was obtained after processing the model with a smoothing varnish - thus XTC-3D. Pyramid Printables can be found here.

3D printing technology can be used to break doors / +1

Society

Intruders make duplicate keys from a photo

Photo: iStock The British company Protecting. co.uk, which develops security software, told about one of the ways to enter the premises. Attackers get a photo of the keys and create a model for printing on a 3D printer. Experts recommend not publishing snapshots of keys on the network and being more careful about your own security.

co.uk, which develops security software, told about one of the ways to enter the premises. Attackers get a photo of the keys and create a model for printing on a 3D printer. Experts recommend not publishing snapshots of keys on the network and being more careful about your own security.

To create a 3D model, criminals can use telephoto cameras that capture high-resolution images from long distances. But for experienced crackers, a photo of the key posted on a social network will be enough. Images are processed in rendering programs (rendering, or drawing, is obtaining an image based on a two- or three-dimensional model. - Approx. Plus-one.ru). Metals and polycarbonates (hard plastic) are used for printing - high-strength materials, thanks to which the key will not break in the keyhole.

According to Protecting.co.uk employee Mark Hall, you can protect yourself from risks with the help of simple rules. He advises to hide the keys from prying eyes and use locks with complex locking mechanisms that cannot be broken by picking keys. It is also recommended to install several locks of different types and equip the apartment with an alarm system. At the entrances to commercial premises, it is necessary to install video surveillance cameras and, if possible, hire security guards. “We know that many people will not be able to afford advanced systems, but even small changes in the approach to security can significantly reduce the risks,” says Mark Hall.

It is also recommended to install several locks of different types and equip the apartment with an alarm system. At the entrances to commercial premises, it is necessary to install video surveillance cameras and, if possible, hire security guards. “We know that many people will not be able to afford advanced systems, but even small changes in the approach to security can significantly reduce the risks,” says Mark Hall.

The possibilities of using 3D printing technology to make duplicate keys have been discussed for a long time. In 2011, American engineer Nirav Patel printed a plastic key on a simple and inexpensive RepRap open source printer. To do this, he measured the Schlage SC1 lock key model, which is popular in the USA, with a ruler and calipers, and then created a three-dimensional model of it in the OpenSCAD 3D modeling program. Today, anyone can download a .scad file and edit it depending on the parameters of their key, Nirav Patel writes in his blog. After that, you need to create a three-dimensional model in . stl format, after which the key is ready for printing.

stl format, after which the key is ready for printing.

Tools for printing keys on a 3D printer

In 2013, MIT students David Lawrence and Eric Van Albert created a program that allows you to duplicate Schlage Primus "restricted keys". These are keys with a high degree of protection, the manufacturer of which monitors the release of blanks and limits their free distribution. After studying the manufacturer's information, the students learned how to match the code to the pins (internal parts that interact with the key) and accurately reproduce it in simulation programs. To print finished 3D models, students used Shapeways and i.Materialise, which work with various materials, including nylon and titanium.

Researchers from the University of Michigan also worked with duplication-protected keys. In 2015, they introduced the KeysForge tool. Based on data about the key and a photograph of the lock, the program creates a CAD file (from Computer-Aided Design - "computer-aided design systems", used, among other things, when creating architectural plans. - Approx. Plus-one.ru), which can be printed on any custom 3D printer. “We have shown that anyone with a 3D printer can quickly and easily hack into restricted systems,” said one of the authors of the development, Ben Burgess. The program works with a large number of lock systems with classic latches and is in the public domain.

- Approx. Plus-one.ru), which can be printed on any custom 3D printer. “We have shown that anyone with a 3D printer can quickly and easily hack into restricted systems,” said one of the authors of the development, Ben Burgess. The program works with a large number of lock systems with classic latches and is in the public domain.

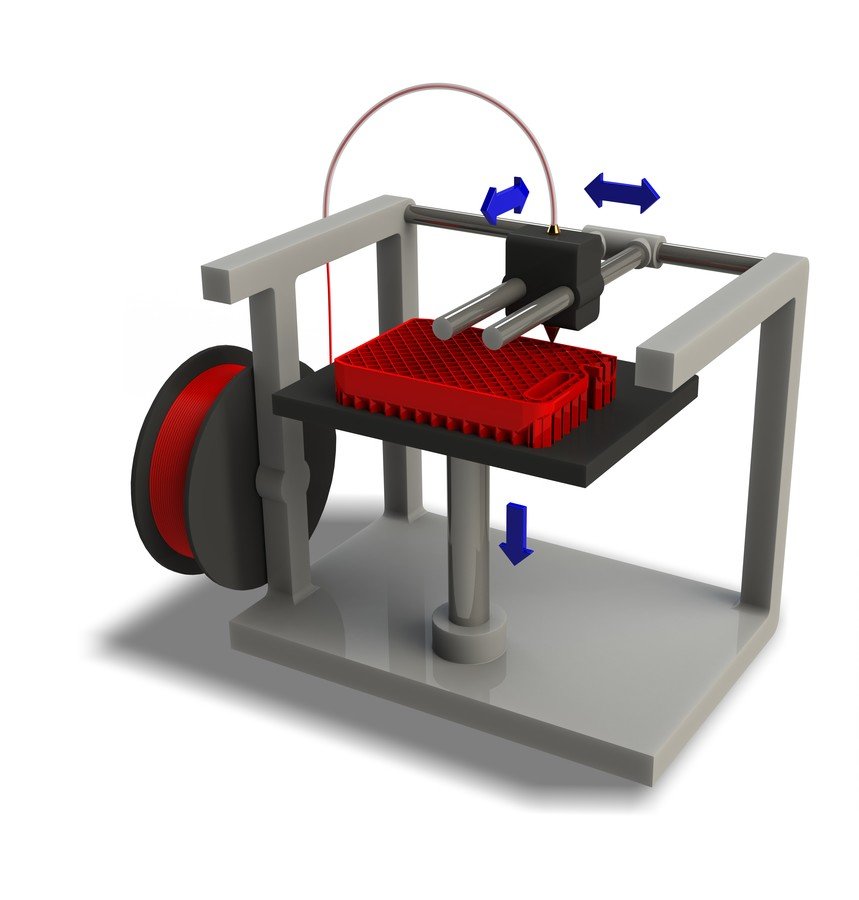

3D printing technology can also be used by attackers who break cylinder locks using bumping. When using this method, a specially machined key is inserted into the lock, which is struck with a small hammer. During the impact, the lock mechanism can take the desired position, and if the key is turned at this moment, the door will open.

In 2014, security experts Jos Weiers and Christian Holler created the Photobump bumping app. With the help of a photo of the lock mechanism and information about the position of its code pins - according to Jos Weyers, their depth can be measured with any thin tool or found in the descriptions of key cutting programs - Photobump creates a model of a lock pick suitable for printing on a 3D printer.