3D name print

3d Printed Name - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

3D Printing Business Name Generator + (Instant Availability Check)

How to name your 3D printing businessHey, I’m Ashley (Branding Expert) and I’m going to guide you through our four steps to name your 3D printing business. Below you’ll find twenty example names I created in this process and next, I’ll show you how you can create your own. To get started try our 3D printing business name generator above and then scroll below to find the first step in the naming process.

- A New Dimension

- 3D Print It

- Power Prototype

- Innovate 3D

- Dream It, Build It

- 3D Objects

- Envision Creations

- 3D Lab

- Multi-Dimension Print

- New Reality

- Print the Future

- Shape Shifters

- 3Design

- We Print

- 3D Revolution

- Imagine Lab

- The 3D Workshop

- Mega 3D

- Powerful Printing

- Beyond Print

This four-step process will help you name your 3D printing business. In this example, I’m creating a name for a 3D printing business that conveys the innovative, powerful and conceptual nature of service provision. Here’s each step I took in crafting these business names.

#1) Brainstorm your name ideas

Start by brainstorming what words could fit into your business name. In my name ideas, I used words like dimension, dream, envision, innovative, powerful and prototype. These words carry a futuristic feel and indicate the innovative nature of 3D printing services. Your goal here is to create a list of words or names that come to mind when thinking about your business.

If you’re stuck on words to use, try our business name generator.

Here are my name ideas after brainstorming:

- A New Dimension

- 3D Print It

- Power Prototype

- Innovate 3D

- Dream It, Build It

- 3D Objects

- Envision Creations

- 3D Lab

- Multi-Dimension Print

- New Reality

- Print the Future

- Shape Shifters

- 3Design

- We Print

- 3D Revolution

- Imagine Lab

- The 3D Workshop

- Mega 3D

- Powerful Printing

- Beyond Print

#2) Shortlist your ideas

Once you’ve developed a list of possible names, do an analysis of your ideas. Remove any names that could be hard to remember, spell or speak aloud. Keep names that are brandable, sound great, are memorable and communicate your brand values, product or service to your target audience.

Remove any names that could be hard to remember, spell or speak aloud. Keep names that are brandable, sound great, are memorable and communicate your brand values, product or service to your target audience.

Here’s a quick checklist you can run your ideas through to help shorten your list of name:

- Is the name simple and easy to remember?

- Is the name easy to read and say aloud?

- Is the name different from competitors?

- Does the name convey a relevant meaning?

- Does the name avoid overused words or cliches?

My Shortlist:

- 3Design

- Power Prototype

- 3D Revolution

- Print the Future

Removed Ideas:

- A New Dimension

- 3D Print It

- Innovate 3D

- Dream It, Build It

- 3D Objects

- Envision Creations

- 3D Lab

- Multi-Dimension Print

- New Reality

- Shape Shifters

- We Print

- Imagine Lab

- The 3D Workshop

- Mega 3D

- Powerful Printing

- Beyond Print

#3) Get some feedback

You’ll now have a list of 3-6 great 3D printing business names and you can start to ask potential customers or people working in the industry for feedback (your target audience). Avoid feedback from family and friends, are more likely to praise all your ideas and they aren’t your customer.

Avoid feedback from family and friends, are more likely to praise all your ideas and they aren’t your customer.

Be sure to ask questions like:

- What first comes to mind when you first hear the name?

- How would you spell it?

With you’re customer feedback you can now ask yourself is the name still relevant? and did it represent your business how you intended?

My customer feedback:

3Design

This name conveys innovation, it has a cool and fun vibe.

Power Prototype

This name conveys confidence in design capabilities that goes beyond 3D printing itself.

3D Revolution

This name conveys a company that focuses on brand new developments, that wants to change the way things are done.

Print the Future

This name conveys a product that is futuristic and innovative, that goes beyond the scope of what others have to offer.

#4) Check It’s available

At this point, it’s good to have at least three great 3D printing business names on your list, in case your any of your names are already taken. You can do a quick Business Name Search online to find out if you’re name is available within your country/state, also be sure to search if the name is also available for Trademark and Domain name Registration.

You can do a quick Business Name Search online to find out if you’re name is available within your country/state, also be sure to search if the name is also available for Trademark and Domain name Registration.

To help you brainstorm potential business names, let’s take a look at three successful 3D printing businesses and break down why and how they’ve chosen to name their business and why it works for them.

Sculpteo is a 3D printing company name that carries a lot of meaning. It brings together the technological nature of 3D printing with the creative process of conceptualizing a design. This name also sounds quite different from other titles in the field, allowing the business to stand out.

iMakr relies on creative spelling and a futuristic feel. The way in which maker is spelled shows that the company is different and unafraid to break the rules. The addition of “i” to the title suggests something hi-tech, digital and innovative.

3Diligent is another fun name that helps for the establishment of the right brand image. It combines 3D and “diligent.” The first word tells potential clients what services the company has to offer. The second one is a positive characteristic that customers would be looking for when choosing a service provider.

5 Tips for naming your 3D printing businessThe ideal business name should be simple, memorable and convey a meaning all at the same time. Here are my 5 tips to keep in mind when developing your business names.

1. Do a Competitor Analysis

Doing a competitor analysis as your first step will save you a lot of time in the future, knowing what names to avoid and understanding why and how your competitors business name words for them will help you in forming your own business names. When analyzing competitors think about:

- What business or product values are they conveying in their business name? How does that work for them?

- Is there a trend in how these businesses are naming themselves? It’s best to avoid sounding like “just another one of those businesses”.

- Who does it best? Why does it work and how can I produce a better name?

2. Focus on Naming your Business not Describing it.

A typical pitfall most businesses run into is describing their business name too literally, relying on overused words like print, printer, dimensional, project and architecture. A more effective business name should convey to customers your businesses and product values at a deeper level. Try name your business in a way that has a story behind it.

Let’s take for example a real 3D Printing business named Shapeways.

This name needs to be analyzed to start making sense because it’s not literal. Shapeways could be a business in any kind of industry but when examined in the context of 3D printing, it starts making sense. It speaks of creativity, confidence and design capabilities that exceed expectations.

3. How to make a more memorable name

Creating a memorable business name is the first step in getting into a customers mind and is also a task that’s easier said than done. Your business name should aim to stop a customer in their tracks and give an extra thought on your product among your wave of competitors. Some tips to create a memorable name would be:

Your business name should aim to stop a customer in their tracks and give an extra thought on your product among your wave of competitors. Some tips to create a memorable name would be:

- Use rhythmic pronunciation or alliteration (Shape Shift, Fun Formations, Power Print)

- Try using a word that wouldn’t be relevant when out of context (MeltWerk is a name that refers to the material that is utilized in the 3D printing process)

- Keep it short and simple.

4. Try purchasing a Brandable business name

Brandable business names are names that are non-sensical but read and are pronounced well. They often use letter patterns of Vowel/Consonant/Vowel as these word structures are typically short, catchy and easy to say and remember. For example, some brandable business names could be:

- Printerio

- Fixtify

- Panderia 3D

You can find a full list of Brandable business names at Domainify.com

5. Avoid combining words just to create a unique name.

Another mistake business owners typically make is creating bad word combinations when they find out that their business name idea is already taken. For example, John names his business Power Dimension and finds out it’s already taken. Because he’s already decided this is what he’ll name his business he tries to opt for similar sounding names like PoDim, DimPower, WerDimension.

You can see how these ideas are a step backward as they are not catchy, easily pronounceable or memorable. In these situations, we suggest starting from scratch and trying the tips we mentioned previously.

Our Business Name GuidesRelated: Manufacturing Company Names

Related: Printing Company Names

Related: How To Name A Business

Related: How to Get a Business Name

Related: How to Trademark a Business Name

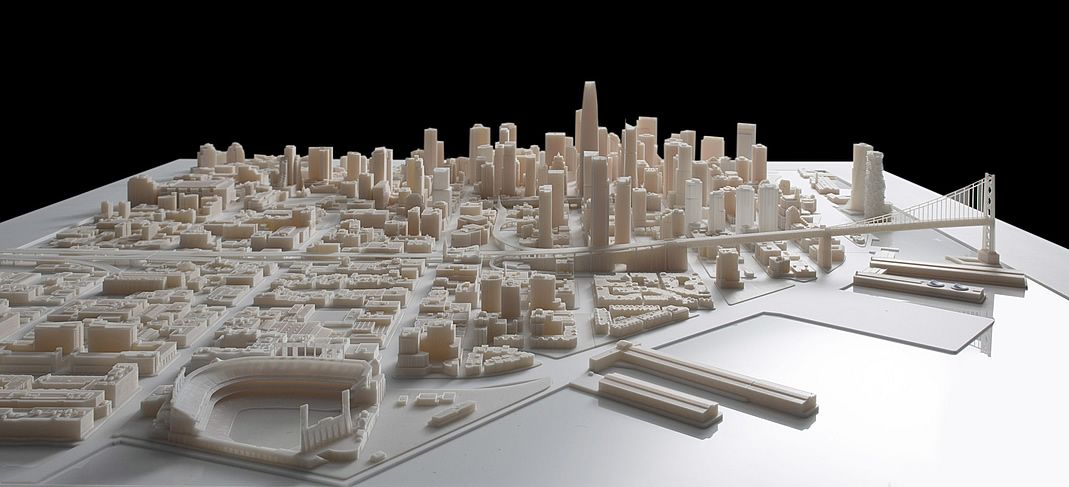

3d printing of the layout of the school named after Kaptsov

The company MG3D, whose main specialization is 3D printing, was approached by a customer who wanted to create a model of the Moscow school No. 1520 named after the Kaptsovs. This is an old educational institution, built at the end of the century before last. The masters of the company took upon themselves the execution of the order for the manufacture of a detailed model of the school.

1520 named after the Kaptsovs. This is an old educational institution, built at the end of the century before last. The masters of the company took upon themselves the execution of the order for the manufacture of a detailed model of the school.

A separate difficulty of this order was that it was required to complete it in just three days. However, the MG3D masters did an excellent job with the task.

A school with an amazing history that deserves professional attention

It was originally a boys' school in the city. Its construction was undertaken in 1892 by the city philanthropist Alexander Kaptsov. He donated the school to Moscow and named it after his father Sergei Kaptsov. Initially, the school was intended for the children of low-income Muscovites: peasants, soldiers, townspeople.

In 1892 a room was rented for the school on Malaya Bronnaya Street. Well, by 1893, the construction of the very building was completed, which in the future the client of the MG3D company wanted to reproduce in the form of a detailed layout.

Thus, since 1893 there has been its own building for the men's school. And three years later, Alexander Kaptsov presented Moscow with another building, in which a women's school was opened, named after Ksenia Kaptsova, the mother of the city philanthropist. Such an amazing history of the school, which later received the number 1520, deserves professional attention in any field, including the 3D printing of the layout of this educational institution.

The unique architecture of the Kaptsov School - details that needed attention

The first building in chronology, which was originally assigned to a school for boys, was erected by Moscow architect Chichagov. He created the appearance of the building, inspired by the characteristic features of the Swedish-Norwegian farmstead, which was located on the site of the school before. This is easy to see by several characteristic features, among them:

- recognizable combinations of white and red;

- architectural style characteristic of Christian IV;

- decor in the style of the Copenhagen Stock Exchange, Rosenborg and other similar buildings.

Looking at the craftsman-made MG3D, you can see that the building in which the boys were originally trained really resembles a Scandinavian castle with towers and a gabled roof. It was this building that delighted the eyes of Muscovites since 1893.

The building added three years later, where the school for girls was originally located, was erected by the Moscow architect Geppener, the creator of many fashionable buildings for his time. He left the general color scheme red and white, but used recognizable white ornaments characteristic of most of his works. Despite the stylistic differences, the new building perfectly complemented the old one and created a single architectural ensemble.

Unfortunately, in the middle and in the second half of the last century, when the school building was reconstructed and completed, far from all the unique architectural details were preserved. The early building in the Scandinavian style greatly changed the appearance, the characteristic elements remained mainly in the courtyard. The new building has also been changed. The whole school was supplemented with the third and fourth floors, extensions were added, so that the modern look of the educational institution is very different from the original.

The new building has also been changed. The whole school was supplemented with the third and fourth floors, extensions were added, so that the modern look of the educational institution is very different from the original.

How to print a detailed layout in just three days

The time limit has become one of the factors complicating the task. For many 3D printing companies, working on such a project in just three days would be an impossible task. But not for MG3D. The masters drew up a project and implemented it in the shortest possible time.

Polylactide, aka PLA, was chosen as the main material for manufacturing. This material has several features, thanks to which, when fulfilling an order, it is 3D printing with PLA plastic came up as a working option:

- the model does not require long processing;

- you can use a wide range of colors;

- material is non-toxic and environmentally friendly;

- does not require much energy to soften and print;

- plastic does not shrink or expand with temperature.

Thus, at no extra cost and at the same time in the shortest possible time, it was possible to print a reduced copy of the school - with all its architectural details and features, without losing sight of anything.

Painting a building model: how to reproduce the Scandinavian style in a single layout

As already mentioned, the architect Chichagov used the Scandinavian style recognizable at the end of the nineteenth century. Geppener also adhered to it, building the second building. Despite the fact that in the future the appearance of the school has changed a lot, the initial elements have been preserved even now. Therefore, MG3D set itself the task of reproducing the style with all the details.

Hand painted for this purpose. The model of the building was painted by professional artists, using resistant, environmentally friendly and durable paints. It is enough to look at the photos of the finished model to see how impressive the result of the work will be. The red and white color scheme is reproduced in all details. Saturation and colorful layout is not inferior to the source.

The red and white color scheme is reproduced in all details. Saturation and colorful layout is not inferior to the source.

Anyone who wants to admire the Kaptsov School No. 1520, but does not have the opportunity to go to the famous Moscow building in person, will just have to look - live, in a photo or video - at a model made by MG3D. It's safe to say that every detail that matters has been reproduced. The model turned out to be photorealistic and impressed the customer.

Bottom line: recreating a famous historic building in miniature is not a problem for true professionals

MG3D takes on many orders. This ranges from the printing of functional, utilitarian items, equipment and accessories to the production of aesthetically pleasing items that are primarily designed to make an aesthetic impression.

The layout of the Kaptsov School No. 1520 is an excellent example of such work. In addition to aesthetic pleasure, the observer also gets the opportunity to follow the architectural appearance of the original building and appreciate it in all its details.

The conclusions about the work done by the MG3D team are as follows:

- It is really possible to implement such a complex project with only three days at your disposal. But this requires professionalism.

- 3D printing combined with hand painting reproduces the appearance of the building in every detail.

- Modern technologies make it possible to create not only photorealistic, but also durable, inexpensive layout.

Recreating the model of Kaptsov School No. 1520 is one of the many examples of excellent work that MG3D does for its customers. Representatives of state organizations and commercial firms, individuals apply to this company in order to order 3D printing based on the latest technology.

Checkout.

Contacts

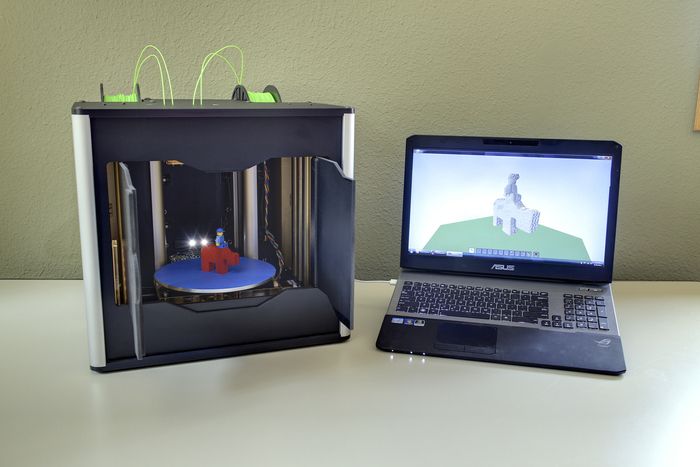

Introduction to 3D printing / Blog them.

qwertpoi / iXBT Live

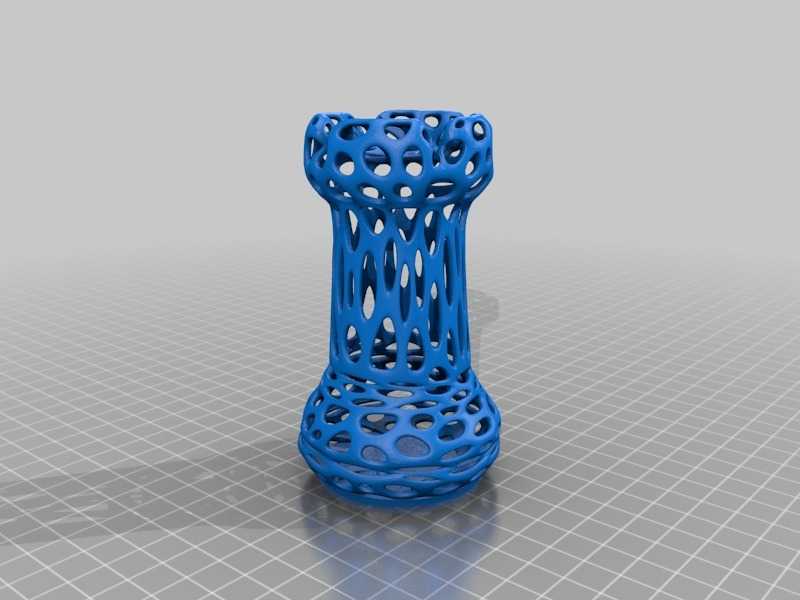

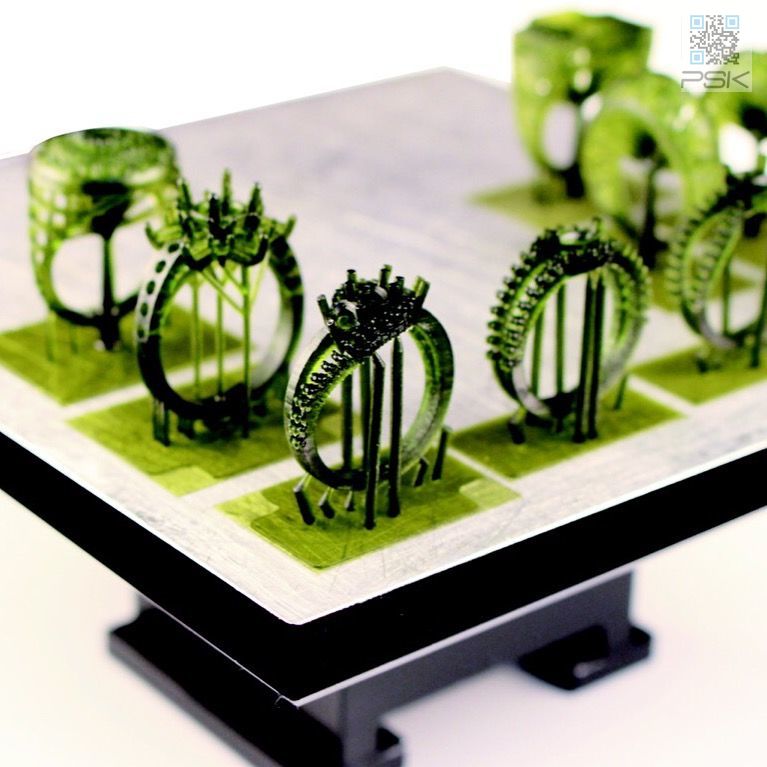

qwertpoi / iXBT Live Additive manufacturing or 3D printing is the process of combining material to create an object from 3D model data, usually layer by layer, unlike subtractive technologies. Subtractive technologies mean machining - the removal of excess material from an array of workpieces.

History of 3D printers

The very first 3D prototyping machine was the American SLA machine, developed and patented by Charles Hull in 1986, using stereolithography. Hull immediately set up 3D Systems, which produced the first 3D printing device called the Stereolithography Apparatus.

In 1990, a new method for obtaining three-dimensional "print impressions" was used - the fusing method. It was developed by Scott Crump, founder of Stratasys, and his wife, who continued the development of 3D printing.

The modern historical stage in the development of 3D printing started in 1993 with the creation of Solidscape. It produced inkjet printers that preceded 3D printers. In 1995, an inkjet printer was modified by two MIT students.

It produced inkjet printers that preceded 3D printers. In 1995, an inkjet printer was modified by two MIT students.

RepRap - The project was founded by Adrian Bowyer. First introduced in March 2005 on the RepRap project blog, the idea involved building a machine (with blueprints and freely available software) capable of replicating itself. This is where the name of the project came from. Of course, a Reprap printer cannot print electronics or an extruder, but the basic details of the kinematics can.

The most popular and widespread technology all over the world is FDM (aka FFF) - layer-by-layer filament fusing, implemented by most companies in numerous printers of "amateur" and "professional" classes. The filament in the form of a polymer thread is fed into the extruder, where the polymer thread is melted and with its help a physical model is formed in accordance with the configuration of the section of the virtual CAD model.

Feeders

1. Direct

Direct

Extruders are usually divided into two parts: hot-end (hot-end) and cold-end (cold-end). First, the printer must feed the filament into the heating zone in order to melt it. The plastic coils themselves are located outside the extruder, namely in the cold end. Typically, a cold end consists of a stepper motor and a pressure roller that allows the filament to pass further into the heating zone. In this case, it will be called direct (direct). Now let's move on to the second part of the extruder: the so-called hot end, where the filament is melted and extruded onto the platform. The most important parts in its construction are the heating element, the temperature control sensor (thermistor), the barrel of the extruder, the thermal barrier and the nozzle.

2. Bowden

The design difference from Direct is that the parts of the extruder are separated and connected by a long hollow Teflon tube. The plastic is pushed cold-ended with a long tube into the hot-end, where it is melted and deposited onto the platform

use delta printers. Cartesian coordinates are the construction of three-dimensional objects using three axes: X and Y (responsible for the length and width of the object) and Z (responsible for the height). The video shows the Wanhao Duplicator i3 - this design gained its popularity primarily due to the successful design of the RepRap Mendel printer, Prusa Mendel and its subsequent modification Prusa I3.

Cartesian coordinates are the construction of three-dimensional objects using three axes: X and Y (responsible for the length and width of the object) and Z (responsible for the height). The video shows the Wanhao Duplicator i3 - this design gained its popularity primarily due to the successful design of the RepRap Mendel printer, Prusa Mendel and its subsequent modification Prusa I3.

FDM Printer Materials

ABS - Acrylonitrile Butadiene Styrene. Number one in prevalence, which owes its low price. The suitable printing temperature depends on the viscosity of the polymer and is usually in the range of 210-240°C. The shrinkage of this thermoplastic is 0.4-2.5%, due to which the product at the edges may come off the table, and cracks may appear on its surface. Soluble in acetone. Well glued, processed and painted. Recommended for closed case 3D printers.

PLA - polylactide. One of the most versatile 3D printing plastics made from corn. It has low shrinkage of 0. 2-0.5% and excellent interlayer adhesion. The printing temperature is 175-210°C. Soluble with dichloroethane and dichloromethane. Due to the rather high hardness, it is more difficult to process than ABS. It has a very low softening point (about 60°C) and can be decomposed over time by exposure to the environment. Slightly more expensive than ABS.

2-0.5% and excellent interlayer adhesion. The printing temperature is 175-210°C. Soluble with dichloroethane and dichloromethane. Due to the rather high hardness, it is more difficult to process than ABS. It has a very low softening point (about 60°C) and can be decomposed over time by exposure to the environment. Slightly more expensive than ABS.

Nylon - polyamide. It has good strength characteristics. The temperature of use of finished products is from -60°C to +120°C. High wear resistance. Good resistance to deformation. Excellent intercoat adhesion. For successful printing with nylon, a heated bed is required, since its shrinkage rate is 1.2-2%. The printing temperature, depending on the grade of polyamide, can range from 225 to 265 °C. It is also better to print in a closed case.

FLEX — Classic flexible material. Very sensitive to the surface. Delamination is extremely low due to the high flexibility of the material. Good interlaminar adhesion. It absorbs water very quickly and a lot, so you need to store it in closed bags with hydrogel. The printing temperature is 220-240°C. HIPS PVA

The printing temperature is 220-240°C. HIPS PVA

HIPS is high impact polystyrene. HIPS, unlike ABS, is only soluble in limonene (an organic acid). This allows them to be combined using polystyrene as a support material. After printing, it can be removed by simply immersing the product in limonene, without resorting to mechanical cleaning. Printing temperature - 230-240 ° C, shrinkage - 0.8%, good impact resistance and plasticity.

PVA is another support material. PVA is soluble in water, which makes it completely unsuitable for creating durable products, but allows it to be used as a support material when printing models of complex geometric shapes. The recommended extrusion temperature is 160-175°C. Being water-soluble, the material is hygroscopic (easily absorbs moisture), which should be taken into account during storage.

Slicers

Before printing any model on a 3D printer, it must first be converted from a polygon model format (.stl) into a program for the printer, which it will print layer by layer. Most often, FDM printers use G-code, a programming language that was used for CNC machines (which, by the way, is a 3D printer). The software that does this conversion is called a slicer and is often built into the 3D model renderer. It allows you to see how the model is placed on the table before printing, build supports and select print options: layer, speed, filling, blowing, etc.

Most often, FDM printers use G-code, a programming language that was used for CNC machines (which, by the way, is a 3D printer). The software that does this conversion is called a slicer and is often built into the 3D model renderer. It allows you to see how the model is placed on the table before printing, build supports and select print options: layer, speed, filling, blowing, etc.

5.1. Kisslicer

There are two versions - paid and free. Well thought out support generation. Unfortunately, it does not work with all 3D printers.

5.2. Slic3r

A handy tool suitable for almost all printers and easy to understand for beginners in 3D printing. It's free and it's constantly being improved.

5.3. Makerbot desktop

Shell from the well-known printer manufacturer Makerbot. It contains Skeinforge and Slic3r slicers, which gives some choice for 3D printing. User-friendly interface, direct access from the program to the online library of Thingiverse models. It differs not in the most flexible settings, because it was originally conceived for "native" printers.