3D laser scanner data

WSDOT - 3D Terrestrial Laser Scanning

|

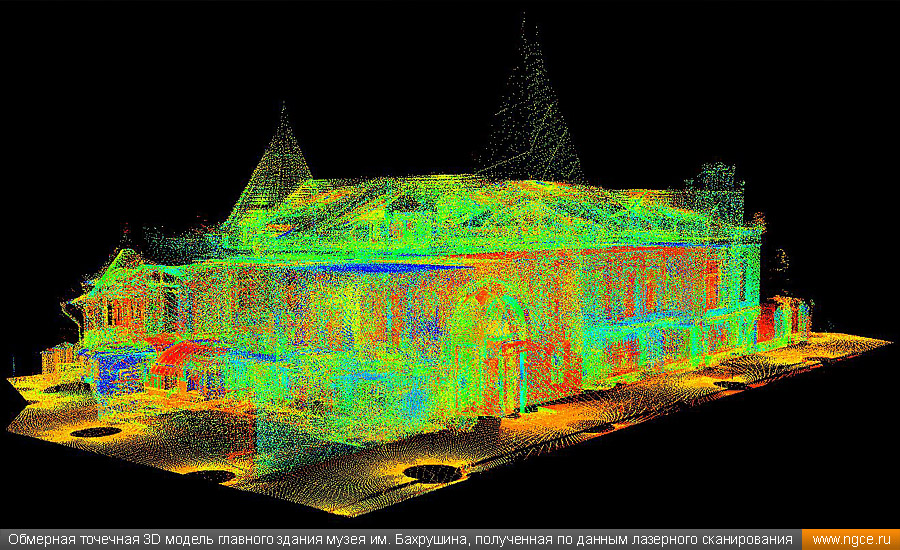

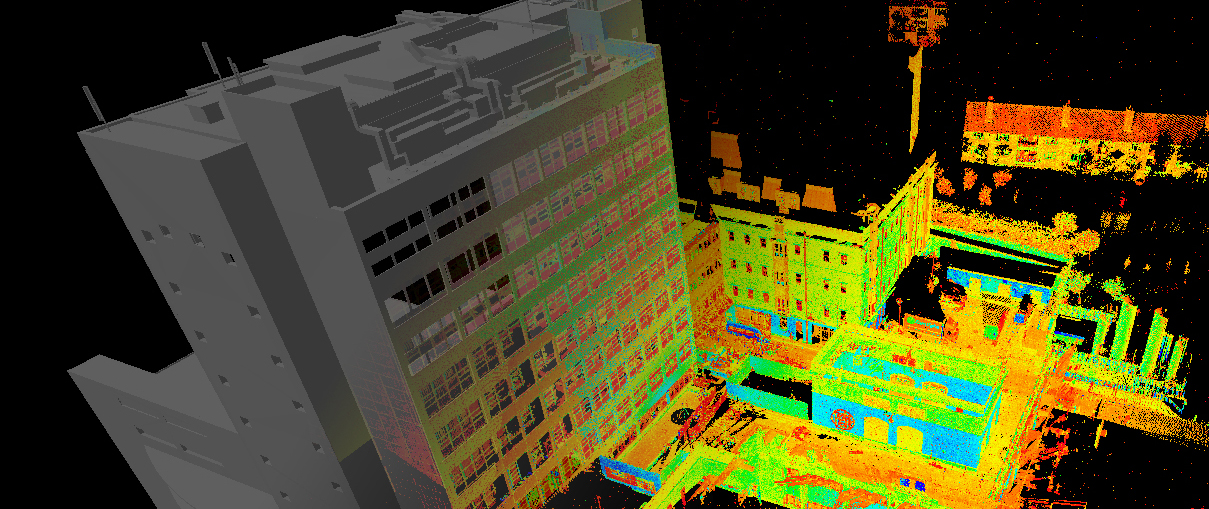

Data (Point Clouds) From The Terrestrial Laser ScannerClick images for larger view |

||

Downtown Seattle Point Cloud |

Manette Bridge Point Cloud |

|

3DTL Video 2min 11 sec |

||

|

||

Express Lane Tunnel under Interstate 5 Point Cloud |

Nile Valley Slide, State Route 410 Airborne LiDAR |

|

Map Products Created From Point Cloud Data |

||

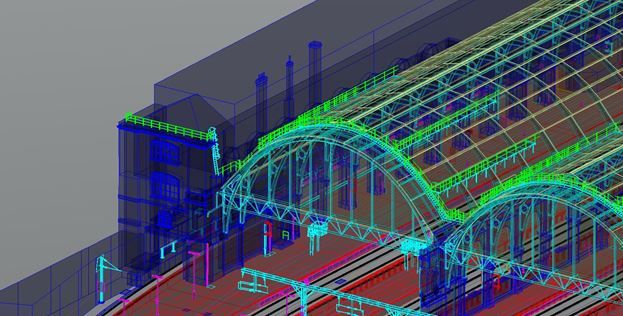

CAD Design File |

Orthophoto With CAD design file overlay (the I-5 express lane tunnel mapping can be seen in this view) |

|

Click images for larger view |

|

|

Vital Roadway Measurements |

||

SR 99 Tunnel low Clearance Measurements |

SR 99 AWV low clearance measurements |

|

Measurement on SR 90 Latah Bridge |

New way of mapping by reducing "noise" in pointclouds increases accuracy (Side View of Latah Bridge) |

|

Click images for larger view |

||

Substructure of lower deck on the Ship Canal Bridge Express Lane. |

Individual scans represented by colors are part of the 3DTL technology that allow accurate data scans on moving structures. |

|

Structure Monitoring |

||

Alaskan Way Viaduct (AWV) Bent 93 |

Western Building Downtown Seattle |

|

SR520 Pontoon Prototype Wall Deformation |

SR520 Pontoon Prototype - Measurements |

|

|

||

Click images for larger view |

||

Pavement Monitoring |

||

Interstate 90 Latah Bridge - roadway wear & ruts shown in variegated colors. |

|

Interstate 405 Thunder Creek - deformation of roadway surface shown in variegated colors. |

Click images for larger view |

||

Archeological Sites Near Highways |

||

Top view of artifacts in a "dig" site |

Side view of artifacts in the "dig" site |

|

Click images for larger view |

||

Volumetric Calculations and Angle Measurements |

||

Arlington PIT contour file over orthophoto |

Cross section view of volumetric calculation for cut and fill. |

|

Wrap around mesh of a rock face - new software technology allows all surface meshes to be on its own plane. |

Dip and Dip direction calculation |

|

Data ManagementClick images for larger view |

||

Point Cloud with grid data (2.6 miles long) |

|

Point Cloud data with grid close up view |

Point cloud grid from above overlayed onto orthophoto |

WSDOT scan locations for all 3DTL projects are maintained in Transmapper with a GIS compatible layer. |

|

Scanned data sets can be enormous, reaching a billion points or more. WSDOT Photogrammetry uses enhanced computers and software systems to manage these massive data sets.

Photogrammetry produces standard WSDOT CAD files that can be used on regular computers used by project designers and planners.

Keith Anderson

|

||

3D Laser Scanning

"In a typical building, without the laser scanning capabilities that TruePoint/GPRS provide, we would have to hire an architect that would have to go through and do manual assessments and measurements in order to provide us with a set of drawings that we can actually build off of."

Aaron Seymour,

Rudolph Libbe Group

Substantial structural deterioration as per CS-SB5-D does not necessarily include the following surface imperfections, unless the licensed engineer or architect determines that they indicate a structural problem:

- Cracks

- Distortion

- Sagging

- Deflections

- Misalignments

- Signs of Leakage

- Peeling Finishes

NDT tests like UPV and Tomography can help determine the severity of any underlying issue.

REDUCE OR ELIMINATE COST OVERRUNS WITH 3D LASER SCANNING SERVICES

GPRS Intelligently Visualizes The Built World™ above and below ground as the leading provider of accurate and creative 3D laser scanning solutions for the construction, architecture, and engineering industries.

engineering

Design Build

Architecture

Oil & Gas

Facilities

Multimedia & entertainment

Historical

Preservation

Stadiums & Theaters

Education

Healthcare & Pharmaceutical

Water & Wastewater

Energy & Utilities

Whether you are a general contractor who knows time is money and cannot afford to lose either one to costly change orders and delays, or an engineer who relies on absolute data precision for your design and modeling needs, GPRS meets the challenge.

GPRS provides accurate as-builts, point clouds, maps, CAD drawings, and 3D models for the engineering, design, construction, architectural, oil & gas, facility management, multimedia & entertainment, historical preservation, stadium & theater, education, healthcare, water & wastewater, and energy & utility industries.

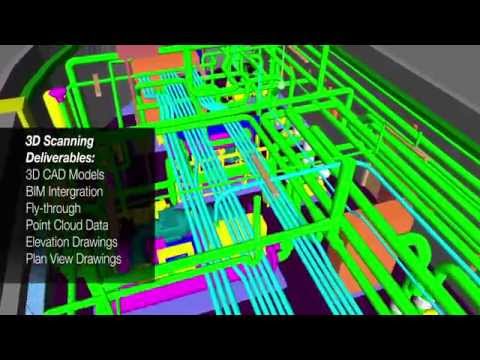

Our customized 3D Laser Scanning solutions include:

- Point cloud creation

- As-builts

- 3D BIM MODELING

- CLASH DETECTION & PREFABRICATION

- Mixed reality development models

- Above and below ground data capture

Our elite design team will package your maps & models to suit your needs – from raw point cloud data to a fully rendered 3D BIM model – to ensure you have all the information you need to get the job done right, delivered in formats that make them instantly understandable and easy to communicate.

According to a 2022 report in Digital Builder, 69% of projects in the last three years were 10% or more over budget.

Which means only 31% of projects came in almost on budget – within 10% of their original estimates.

The 2021 GPRS Market Study by Finch found that 78% of facility managers reported damage due to a locating issue, with an average cost of $56,000 and two-to-three months of project delay per event.

And global consulting firm, McKinsey & Company, reports that across all industry areas, 80% of construction projects finish over budget and suggests the #1 way to disrupt this troubling trend is to execute rapid digital mapping for greater accuracy and more immediate results.

The industry is so used to poor locates, as-builts, and communications that most have built these huge cost overruns into their budgets as routine.

Costly and potentially dangerous mistakes do not need to be routine.

It is impossible to execute a great plan on time and on budget if it is built on incomplete or incorrect data.

It is possible to greatly reduce or even eliminate cost overruns when you have accurate data delivered in easy-to-understand formats before you execute your project.

"Thank you for the 3D Model. You found all of the parts we were looking for with great accuracy. We were very pleased to see you found the “X” brace and the gas pipe under the feeder in your scan images."

We were very pleased to see you found the “X” brace and the gas pipe under the feeder in your scan images."

- Brian B. - Technical Lead - R&D

3D laser scanning allows you to capture complete as-builts in a fraction of the time of hand measuring, with 2-4 mm accuracy. In most cases our Project Managers can scan a project in a day or two and our design team can quickly interpret that data into the maps, models, and drawings you need. This allows you to assess any location with precision and confidently execute your vision in days instead of weeks or months, while further reducing costs by cutting down on inaccuracies and mistakes.

GPRS DELIVERS SINGULAR SOLUTIONS IN 3D TECHNOLOGY

- Every client is unique, so we work with you to understand the scope and purpose of your project to provide singular visualization solutions that meet your specific needs

- Our Project Managers complete hyper-accurate work in the span of a few hours or days by deploying state-of-the-art 3D laser scanners to capture the exact dimensions and locations of the structural, architectural, and MEP features of your site

- The captured point cloud and photographic data is registered and processed by our design team to set the coordinate system, remove any data fragments to rectify your scans and provide precise measurements of even the most complex spaces

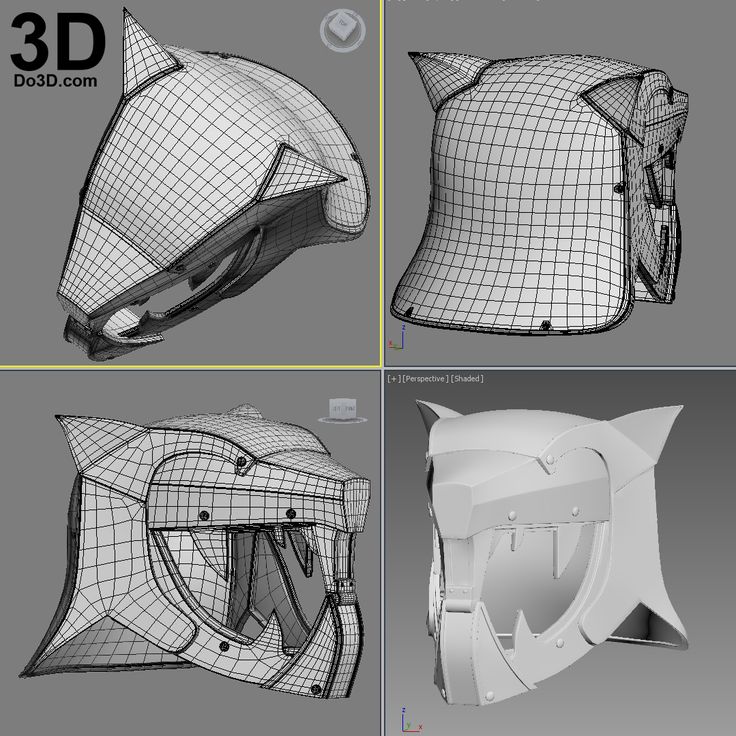

- We execute drawings, maps, and/or models that are customized to your project’s needs so that you can visualize every facet of your existing site: Point clouds, 2D CAD drawings, 3D BIM models and 3D mesh models.

We can also provide customized 3D walkthrough or flythrough BIMs to fully realize your space

We can also provide customized 3D walkthrough or flythrough BIMs to fully realize your space

- For those who wish to edit their own data, we provide raw point clouds in a wide range of file types to be used in many different software packages including Autodesk or Bentley products

- Because we design the project at the outset with your specific needs in mind, we eliminate unnecessary communications and delays to deliver the highest quality data on time and on budget

At GPRS, our goal is your goal: To provide you with the highest quality as-builts, point clouds, maps, and models available to reduce change orders, delays, and cost overruns. Our 2-4 mm scan accuracy provides tighter dimensions for superior clash detection and clean, clear visualizations.

And we’ve been providing outstanding 3D laser scan results for clients since 2011.

View Case Study

View Case Study

View specific case studies and information on how we help clients Visualize The Built World™.

View More Case Studies

Thank you so much for how quickly you pulled this together for us. Our end goal was to have a full-scale clean 3D surface body of a model that we can import into Solid Works, pull measurements from, and build models around. The file looks great and will work perfectly

- John M. – Mechanical Engineer

GPRS TruePoint Laser Scanning was a great partner to The Virginia Air and Space Science Center. The team at TruePoint was open and honest about the pricing and process. I was even happier when I heard they were able to meet an already tight deadline and budget. TruePoint had a quick turnaround on deliverables that saved time within the project. We look forward to working with them on future projects.

- Michael T. – Director Of Facilities, The Virginia Air And Space Science Center

You did a great job! The Revit model was very useful, it gave us a great starting point to build our design model. The fly-through was just as helpful. Doing a normal field investigation you never seem to get the picture you need. With the fly-through, I can get any angle needed -- not to mention -- having it during a meeting when something comes up clients want to see. We have used other scanning firms for smaller scale projects and haven’t had the same results. You guys were very professional and met every deliverable that was promised, even on the tight schedule. If and when we are doing a project of this scale we will keep you mind.

The fly-through was just as helpful. Doing a normal field investigation you never seem to get the picture you need. With the fly-through, I can get any angle needed -- not to mention -- having it during a meeting when something comes up clients want to see. We have used other scanning firms for smaller scale projects and haven’t had the same results. You guys were very professional and met every deliverable that was promised, even on the tight schedule. If and when we are doing a project of this scale we will keep you mind.

- Bradford S. – Mechanical Designer

Thanks for jumping into this assignment so quickly. What a great and productive trip. You guys work tirelessly, non-stop with all aspects of the setup and execution. Your ability to master the technology is a game changer for us.

- Don A. – Executive Vice President, Director Of Architecture, Engineering & Technology

3D LASER SCANS HAVE UNLIMITED APPLICATIONS

- As-builts, reality capture, and existing conditions data

- Construction verification, sequencing, scheduling, and simulations

- Design engineering for facility upgrades or expansions

- 2D and 3D laser map of a building

- Prefabrication

- Clash detection

- Architectural documentation or historical preservation

- Calculating volumes, deformation analysis, and overhead clearances

- Virtual design and construction

- Laser scanning for facility coordination

- Collecting geospatial data

- Creating a digital twin

- Performing advanced analysis to easily aggregate, query, visualize and analyze data in a single 3D model

- Augmented & Mixed Reality (AR & MR) for video games, television, film, and sports enhanced fan experiences

Knowing which application you need determines what kind of scan, the necessary resolution of the point cloud and photography, and what kind of maps, models, drawings, or other deliverables your project requires.

One of the exciting applications of 3D laser scanning is the work GPRS does for Mixed and Augmented Reality (MR & AR) companies for professional sports and entertainment. Our Project Managers have scanned dozens of NFL venues, and numerous NHL rinks, PGA courses, MLS and MLB fields, NASCAR tracks, and NBA courts to provide the digital canvas for enhanced fan experiences.

"We are still in awe that we made this thing work with such a crazy turnaround, and are so very grateful for your part in making the first project a success! Here’s hoping to many more. Thank you and your team for being the true rock stars of this project."

- Callie H. – Producer

Schedule ServiceRequest a Quote

HOW THE TECHNOLOGY WORKS

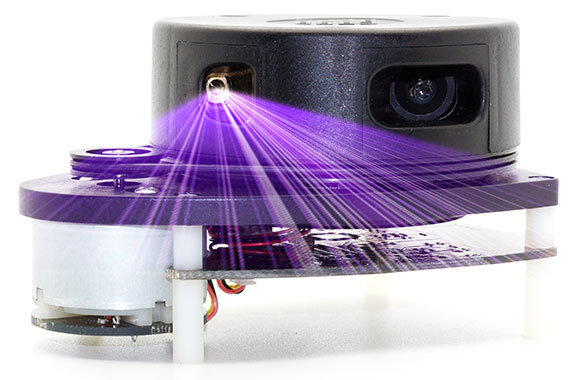

3D laser scanners use LiDAR (light detection and ranging) to measure and record precise locations and distances, ultimately producing a point cloud file.

The primary way a laser scanner works is to send light pulses at high speed which reflect off objects and return to the scanner’s sensor (LiDAR). For each pulse, the distance between the scanner and object is measured by determining the elapsed time between the sent and received pulses. Each data point is converted to a pixel with a known x, y, and z coordinate.

For each pulse, the distance between the scanner and object is measured by determining the elapsed time between the sent and received pulses. Each data point is converted to a pixel with a known x, y, and z coordinate.

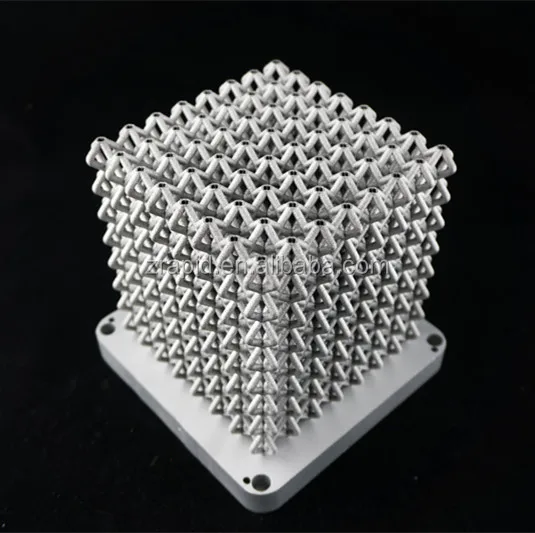

Millions of data points from multiple positions and viewpoints are captured and processed into a point cloud, creating an accurate 3D as-built data set of the site. This all happens very quickly, with some scanners, like our Leica RTC360, capturing and calculating 2 million points per second with 2-4 mm accuracy.

While the applications of LiDAR and laser scanning are almost limitless, there are specific formats that allow our design team to deliver customized solutions for your needs.

POINT CLOUD CREATIONOur 3D scanning service delivers unmatched site documentation with a variety of professional 3D laser scanners, including the Leica P-Series and RTC360 scanners. Each time we execute a 3D scan, we capture a point cloud. Our point clouds capture millions of data points from multiple on-site locations using LiDAR technology, giving you unrivaled image fidelity of up to 2-4 mm accuracy and up to 2 million 3D data points captured per second. You can learn more about how to laser scan a building, here. (How To 3D Laser Scan A Building (truepointscanning.com)

You can learn more about how to laser scan a building, here. (How To 3D Laser Scan A Building (truepointscanning.com)

As-builts have never been more accurate than with 3D laser scan technology. GPRS captures the exact building dimensions, locations, and layout – information that is crucial to the success of your project. Items are often moved, added, or removed from the original plan, making as-builts invaluable for design, construction, renovation, and facility modifications.

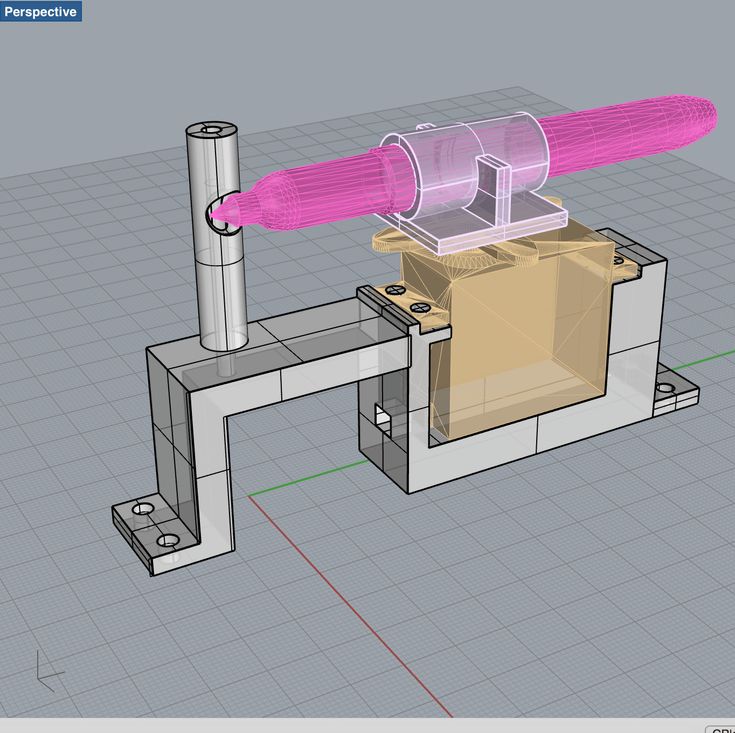

3D BIM MODELING3D BIM models are accurate digital representations of a building or site to facilitate design, construction and operational processes. 3D BIM models provide clients with the ability to break down architectural, structural and MEP building features and see how they fit into a single finalized structure. Users can isolate and alter walls, columns, windows, doors, etc. to support the planning and design needs of any project.

CLASH DETECTION / prefabrication3D laser scanning captures as-built site conditions with a high level of precision, helping to identify potential clashes, fabricate components and plan a flawless installation. Information can be shared with other teams to ensure everyone is on the same page and can coordinate their work effectively. This saves time, money and headaches by preventing costly modifications in the field.

Information can be shared with other teams to ensure everyone is on the same page and can coordinate their work effectively. This saves time, money and headaches by preventing costly modifications in the field.

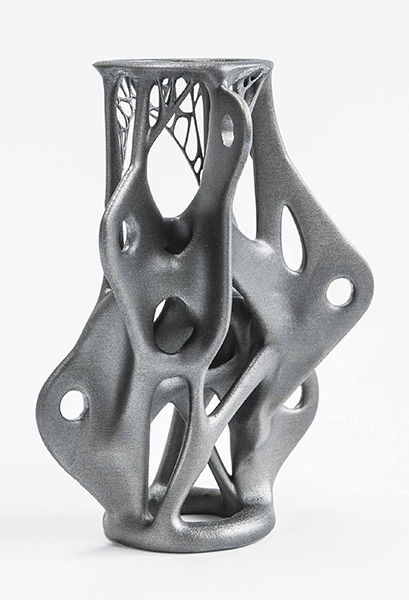

3D laser scanning can be used to create 3D models and 3D mesh files for use in mixed reality, projection mapping and 3D gaming. 3D laser scan technology documents real-world environments with millimeter precision and reconstructs them into a dimensionally accurate, 3D digital representation. Assets are delivered in high detail with texture, making them the perfect element for stunning visualization applications.

AERIAL DRONE VIDEO AND PHOTOGRAMMETRYOur FAA-licensed pilots provide aerial video, property imaging, building imaging, and photogrammetry services. We use HD video and HD photo cameras to capture aerial video and photos. We offer safe, accurate, and cost-effective data collection for vast, dangerous, or hard-to-reach areas.

The combination of laser scanning and ground penetrating radar captures precise documentation to visualize your facility effectively and accurately, above and below ground. With this fully integrated service, you receive clear and understandable findings of structural, MEP, and field markings in point cloud data format, 2D site plans and 3D models. This accurate data allows clients to expedite design planning, extract 3D coordinates and measure distances, along with the ability to mark-up and share this with project teams. Receiving critical site information will lower project risks and increase project efficiency.

3D laser scan technology provides a clear, cost-effective solution to your as-built and facility visualization needs. It can reduce and even eliminate costly errors to speed up your design, engineering, and construction process.

Learn how GPRS 3D Laser Scanning Services can help you streamline your next project to Intelligently Visualize Your Built World™.

Schedule ServiceRequest a Quote

scopes and overview of models / Sudo Null IT News

3D laser scanning - creating a digital model of a physical body using a laser beam. The technology is non-contact, works at close and long distances, eliminates damage to objects during scanning. The principle of operation of 3D laser scanners: a directed laser beam is reflected from the surface of an object, forming a cloud of points. Each point has its own coordinates in space. The software identifies them and creates a finished 3D digital model based on this data.

From the overview you will find out where laser scanning is used and what equipment is used to solve related problems.

Purpose of laser scanners

Source: newequipment.com

Compared to traditional measurement methods, laser scanners have an important advantage - they can digitize objects with complex surfaces and work in hard-to-reach places for humans. The main areas of application of devices are input and output quality control in production, inspection of working devices in order to prevent and eliminate defects, reverse engineering and other areas.

The main areas of application of devices are input and output quality control in production, inspection of working devices in order to prevent and eliminate defects, reverse engineering and other areas.

Construction, renovation and renovation of objects

Source: ellisdon.com

During the preparation of the building design, it is necessary to evaluate the features of the site and the cost of the forthcoming works. With the help of 3D laser scanners, a landscape model is created, on the basis of which further work is carried out. During the construction process, intermediate control of the geometry of future buildings is required: walls, corners, openings, etc. Laser scanning copes with this task more accurately and faster than conventional measuring technologies.

The basis for an exterior or interior renovation is often an accurate digital model, on the basis of which changes and additions to the current interior or exterior are planned. Laser scanners are also indispensable in this area.

Laser scanners are also indispensable in this area.

Road networks and transport

Source: autodesk.com

Laser scanning is becoming an integral part of the planning and creation of urban and suburban road networks, tunnels, pedestrian sections, railways, ports. The technology is used to assess the current state of coatings, plan and estimate the cost of repairs, to obtain models of perennial structures, such as bridges. The equipment is involved in the design, manufacture, repair and tuning of cars, air transport and ships.

Public utilities

Source: 3dscanner.es

With the help of 3D laser scanners, it became possible to quickly digitize and document engineering communications. Scanning significantly saves time during maintenance and reconstruction. The devices work remotely, minimizing the risks of people when working in adverse conditions and in hard-to-reach areas.

Oilfield installations

Source: ramboll.com

Oil production complexes located in the water require constant monitoring of work processes. Objects are regularly exposed to adverse and changeable environmental influences: winds of different strengths and directions, currents, temperature changes, etc. 3D laser scanning is becoming an integral part of the inspection of oil production installations. The equipment allows you to quickly identify and fix deformations and other damage, control wear, calculate the timing of scheduled maintenance, and prevent accidents.

Forensic examination

Source: faro.com

Photographs and manual measurements in investigative processes and forensic examinations are being replaced by 3D laser scanning. The devices create three-dimensional models of scenes of incidents with accurate fixation of the location of objects and the distances between them. The data is used in the process of pre-trial and litigation.

The data is used in the process of pre-trial and litigation.

Other applications

Source: news.microsoft.com

3D laser scanners facilitate and optimize workflows in the following areas:

- In cartography and geodesy - when creating terrain plans, maps, geographic information systems (GIS).

- In archeology - in the restoration and preservation of ancient artifacts.

- In paleontology, to create missing parts of excavated skeletons.

- In medicine, including plastic surgery and dentistry.

Overview of models and manufacturers

FARO Focus

Source: ifworlddesignguide.com

FARO is one of the popular manufacturers of laser scanning devices. The new Focus3D S-series instruments stand out from other scanners in lightness and compact size, as well as the ability to work in bright sunlight and keep in touch with the location using GPS.

The FOCUS 3D S 150 scanner works at a distance of up to one hundred and fifty meters, with an accuracy of up to ±2000 microns at a maximum distance. The device is used in design, architecture and construction, for digitizing equipment and other objects.

You can learn more about this model on the website.

Source: youtube.com

Focus3D S 350 scans with the same accuracy as the previous device, but the distance to the measurement object is increased to 0.35 km. The device is designed for outdoor use.

Source: kkgeosystem.blogspot.com

SHINING 3D

Source: shining3d.com

FreeScan is a line of well-known Chinese manufacturer of digital equipment SHINING 3D. These are universal laser handheld 3D scanners FreeScan X5 (X5+), FreeScan X7 (X7+) weighing up to 1 kg, with an excellent set of professional features.

Basic parameters:

Specifications

Creaform

Source: foundry-planet.com

Creaform's SCAN 3D range is characterized by high scanning quality combined with ease of use. Portable laser scanners HandySCAN 3D, MetraSCAN 3D have a clear interface, do not require special skills and complex user training.

Instrument features:

ScanTech

Handheld range

Source: cmmxyz.com

The HandHeld Prince series uses blue and red laser beams to scan large and small objects with high accuracy. Scanners can operate in bright sunlight and low light conditions. Due to its compact size, high speed and detail, the equipment is widely used in reverse engineering, quality inspection, digitization of museum, archaeological and other objects.

Key features:

Composite series

Source: twitter. com

com

In addition to the dual scan mode, the KSCAN20 is equipped with a photogrammetry system, thanks to which the working area of the device is 2.5 m * 3 m with an accuracy of 35 µm / m.

Blue and red lasers provide high-speed scanning of up to 650,000 measurements per second with a resolution of 0.01 mm.

Key Features:

3D Laser Scanner Applications

Reduce construction costs and time with FARO Focus

Source: autodesk.com

US construction company Gilbane invested $60,000 in a FARO Focus-S 350 laser scanner, software, and employee training. At first glance, the amount seems too large for a small-scale firm. But, after the calculations, the company's management came to the conclusion that the investment will pay off in the shortest possible time.

According to Gilbane's director of 3D design, John Tocci Jr., after introducing the expensive new technology, the company began to use the equipment even in areas where it was not originally planned. The specialists managed to save $30,000 for one hour of Focus-S 350 and Autodesk Revit software.

The specialists managed to save $30,000 for one hour of Focus-S 350 and Autodesk Revit software.

Source: autodesk.com

Building a digital model of air ducts and other systems made it possible to avoid errors during the installation of physical objects, which could take several weeks. The use of FARO Focus in the assembly of plumbing, electrical and mechanical installations helped to optimize costs at all stages of work

Case “Modernization of the building of the University of Miami”

Source: elevar.com

At the time of the start of work, the architects had drawings made 85 years ago, and a little more than 4.5 thousand square meters of the old building. Using a 3D laser scanner, Gilbane digitized the training areas in one day. Modernization of load-bearing structures, as well as the main utility systems: plumbing, electrical and ventilation, was based on data obtained from scanning.

Quality Inspection with ScanTech

Source: 3d-scantech.com

The advantage of metal stamping over forging and casting is the lower weight and thickness of the resulting parts. The use of molds gives high accuracy and maximum compliance of the obtained parts with the specified characteristics, but does not completely exclude deviations and deformations. Which, in turn, can lead to difficulties in assembling finished products and reducing product quality. Therefore, constant quality inspection is a necessary part of production.

Having understood the problems of the manufacturer, ScanTech experts proposed to check the quality of stamped parts using the PRINCE laser scanner. The ability to switch blue and red laser modes allowed the device to combine the functionality of traditional portable and metrological 3D scanners. The mode of operation with an active beam of a red laser provides fast digitization of objects. In the case of increased requirements for accuracy and detail, turn on the blue laser beam mode.

In the case of increased requirements for accuracy and detail, turn on the blue laser beam mode.

The photo shows the stages of work:

1. Installing markers - takes about two minutes.

Source: 3d-scantech.com

2. Digitizing a part takes about three minutes.

Source: 3d-scantech.com

Source: 3d-scantech.com

3. Deviation detection - lasts 3 minutes.

Source: 3d-scantech.com

The digital model shows the parameters and deviations, allows you to correct errors at the design stage. The case clearly shows that the process required a minimum of time and effort.

Using FARO 3D scanners on Justin Timberlake's world tour

Source: disguise.one

Timberlake's "Man of the Woods" program features scenery brought to life on stage. First, the ScanLAB team digitized a number of corners of the forest in the US state of Oregon. Laser projectors then directed images over the auditorium and stage, painting amazing pictures of the Portland landscape on translucent canvases suspended in the air.

First, the ScanLAB team digitized a number of corners of the forest in the US state of Oregon. Laser projectors then directed images over the auditorium and stage, painting amazing pictures of the Portland landscape on translucent canvases suspended in the air.

Source: faro.com

Two Faro Focus X 330 laser scanners, Faro Scene 6.2 software were used to prepare visual effects. In total it took 40 digital copies and 1 working day in the concert hall.

Source: www.esa.int

Considering the limited preparation time, the large surface areas for displaying the image and the corresponding need for high image resolution, creating visual effects in a short time without using the chosen technology was impossible.

Selection guide for 3D laser scanners

In the review, we introduced you to the equipment of market leaders with an excellent reputation. All the devices described have high performance, so we recommend that you pay attention to these devices for use in various fields:

All the devices described have high performance, so we recommend that you pay attention to these devices for use in various fields:

FARO Focus: Focus3D S350, Focus 3D S150.

Creaform: MetraSCAN 350 (350 Elite), MetraSCAN 750 (750 Elite), HandySCAN Black (Black Elite).

SHINING 3D: FreeScan X5 (X5+), FreeScan X7 (X7+).

ScanTech: KSCAN20, PRINCE 775, PRINCE 335.

Results

Source: 3d-scantech.com

The cases discussed clearly prove that the use of 3D laser scanning optimizes workflows in many areas. The range of tasks solved with the help of 3D laser scanners is constantly expanding.

Buy a professional 3D laser scanner in Top 3D Shop — experienced specialists will help you choose the most suitable equipment, software for your business, and offer a project to modernize production.

Leica RTC360 3D Laser Scanner | Leica Geosystems

- home

- Products/Solutions

- Laser scanners

- Scanners

- Leica RTC360 3D laser scanner

Use automatic on-site pre-registration of point cloud data for real-time quality control, increased productivity and better decision making on site

Document and digitize your environment in 3D with the Leica RTC360 3D reality capture solution. Increase productivity on site and in the office with fast, accurate, portable and easy-to-use hardware and software. With the RTC360 3D Laser Scanner, a skilled technician can overcome any design challenge with accurate and reliable 3D models to unlock the full potential of any site.

- The compact, highly automated, intuitive and user-friendly RTC360 solution includes a high-performance 3D laser scanner, the Leica Cyclone FIELD 360 mobile app for edge computing, such as automatic registration of scanned data in real time, and the Leica Cyclone REGISTER 360 office software , with which you can easily implement the resulting 3D model into your workflow.

- Capture scans, including stunning HDR images, in less than two minutes.

- Automatic recording of movements between survey points to pre-register scan data in the field without manual intervention.

- Augment the collected data with informative tags with hints for optimal planning and information about the real conditions on the site, which will help your colleagues to better understand the situation.

- Upload collected data from Cyclone FIELD 360 directly to Leica TruView Cloud to quickly share design data before import and registration.

Quick

The new Leica RTC360 laser scanner captures reality in 3D at a speed never seen before. Capturing up to 2 million points per second and using advanced HDR image capture, the scanner generates colorful 3D point clouds in less than two minutes.

Automated, labelless data logging in the field based on VIS technology and convenient automatic data transfer from site to office further speed up field work and increase productivity.

Automated, labelless data logging in the field based on VIS technology and convenient automatic data transfer from site to office further speed up field work and increase productivity.

Adaptive

Thanks to its portable design and foldable tripod, the compact and lightweight Leica RTC360 fits into a regular backpack. On the object, one click of a button is enough to scan the environment without any additional settings.

Fine

Low noise in the acquired data means better image quality – you get crisp, detailed scans that are ready for a variety of industries. Combined with the Cyclone FIELD 360 automated data logging software in the field, the Leica RTC360 delivers amazing accuracy that can be verified on site.

Pre-registration in the field

The Cyclone FIELD 360 app, part of the RTC360 solution, bridges the gap between on-site 3D data collection and on-site registration of laser scan data in the office with Cyclone REGISTER 360.

User can automatically capture, register, and control scan and image data on site . The easy-to-learn and user-friendly graphical interface offers visual aids for complex calculations, making it easy for even beginners to master.

User can automatically capture, register, and control scan and image data on site . The easy-to-learn and user-friendly graphical interface offers visual aids for complex calculations, making it easy for even beginners to master. Previous Next

Scanning options

The RTC360 3D Laser Scanner automatically captures movement between survey points to pre-register scanned data on the spot. Juergen Mayer spoke about the latest developments in an interview with The Reporter.

Introduction to the RTC360

The latest Leica RTC360 3D reality capture solution, unveiled at HxGN LIVE 2018, combines a high-performance laser scanner with a mobile application for capturing and pre-logging real-time scan data.

From hardware to software

Geosystems specialists optimize every link of the workflow in both software and hardware solutions to increase the efficiency and productivity of field work and data processing in the office.

Leica RTC360: 3D reality capture solution

Leica Cyclone FIELD 360 mobile-device app

Downloads

Videos

EXPERT ADVICE

Examples of using

Podcasts

Introducing the Leica RTC360 3D Laser Scanner

3D environments in a matter of minutes - an outlook on recent reality capture technology

3D reality capture - new opportunities, greater understanding

Transforming Ayacucho into a digital city

Services

myWorld Customer Portal

Active Customer Care

Customer Support Packages

Related products

Laser scanners

Leica BLK360 laser scanner

Leica ScanStation P40 / P30

Leica ScanStation P50

Software

Leica Cyclone

Leica Cyclone REGISTER

Leica Cyclone REGISTER 360

Leica CloudWorx

Leica TruView

Leica JetStream

Accessories

Accessories for 3D laser scanners 9003

contact-for-laser-scanning

As of v7. 0.1, Safari exhibits a bug in which resizing your browser horizontally causes rendering errors in the justified nav that are cleared upon refreshing.

0.1, Safari exhibits a bug in which resizing your browser horizontally causes rendering errors in the justified nav that are cleared upon refreshing.

As of v7.0.1, Safari exhibits a bug in which resizing your browser horizontally causes rendering errors in the justified nav that are cleared upon refreshing.

CONTACT US

The High-Definition Surveyor - Blog

Learn how Leica Geosystems laser scanning solutions are helping professional to shape the future of our world.

Learn how Leica Geosystems laser scanning solutions are helping professional to shape the future of our world.

Read More

The power of scanning

Quality is a tradition, built deep within our DNA. We have a commitment to excellence and exceptional attention to detail.

The power of scanning

Quality is a tradition, built deep within our DNA. We have a commitment to excellence and exceptional attention to detail.

WATCH NOW

Educational articles and analytics

What is 3D Reality Capture and how is it applied in your industry?

What is 3D Reality Capture and how is it applied in your industry?

learn more

Comparison table of laser scanners

Which laser scanner is right for you?

Which laser scanner is right for you?

download now

Reality Capture Newsletter

Click here to subscribe to our regular newsletter and stay up-to-date on all the latest reality capture news.