3D handheld scanner reviews

Best 3D Scanner - The Top 10 3D Scanners for 2022 [Reviews]

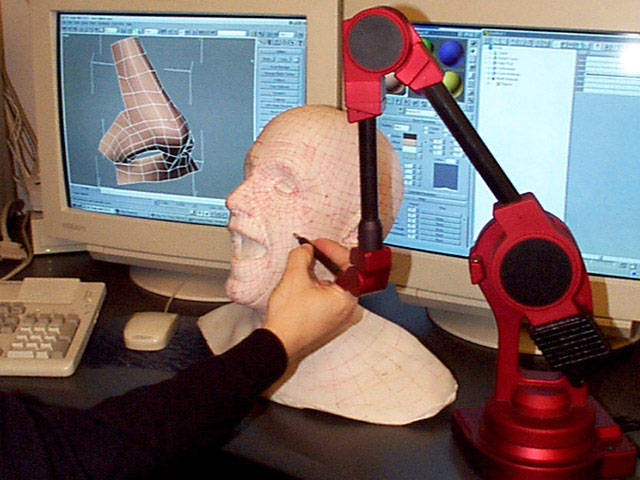

Much like a regular scanner, laser scanning 3D uses various methods to analyze a physical object and then relay that data to a computer to create digital 3D models. The 3D digitizer process might be automatic or users might need to complete the model to their requirements by using software. The aim is usually to get an accurate model to the right standard and format, ready for 3D printing, for virtual reality applications or other purposes.

Such scanners are used in many professional industries, but with advances in home 3D printing, there are now also a good variety of home options. They are sometimes called portable 3D scanners or handheld scanners if they’re designed as such. These allow you to easily scan small to medium-sized objects for 3D printing.

Some come completely assembled while others, like 3D printers themselves, you’ll have to put them together by yourself. The benefit for those that are good with that type of thing is it reduces the price and allows for easier upgrades and modifications.

Scanning is typically done using laser triangulation or various forms of structured light to surround the object and measure its 3D dimensions or ‘geometry’. High-quality 3D scanner camera lenses also capture the color and surface texture of the object. Using accompanying or third-party software, the model can then be scaled up or down, or completely modified.

It’s never been easier to scan 3D objects!

How Do 3D Scanners Work?So, how do you scan 3D objects into a computer? Whether it’s on an industrial scale, at a small business, or on a desk at home, 3D scanners all share similar characteristics in the way they work.

The majority use laser and/or white light technology and cameras. The physical object is placed in a bed, tray, or suitable location. Electromagnetic light bounces off the object, measuring its circumference, full dimensions, and all its finer details.

Depending on the scanner it may use multiple light sources, cameras, and other tech to aid this process. The collected data is called a point cloud, which refers to the number of points captured by the laser.

The more points collected the more accurate the scan. A high-resolution scanner can capture hundreds of thousands of points in seconds and reach millions overall. The whole process only takes a few minutes.

While the light tends to be a measure of the object’s geometry, HD cameras tend to capture the surface detail and color.

The data recorded can then be fed into a computer-aided design program or similar software for inspection and manipulation. E.g. if you’re planning to use it for 3D printing, the model might need scaling up or down, hollowing, have added support structures, be re-colored or have brightness/contrast changes, etc.

There are, of course, different types of 3D scanner and scanning technology. So, let’s take a closer look at each one:

So, let’s take a closer look at each one:

There are several 3D scanner types. Before making your decision check out the section below:

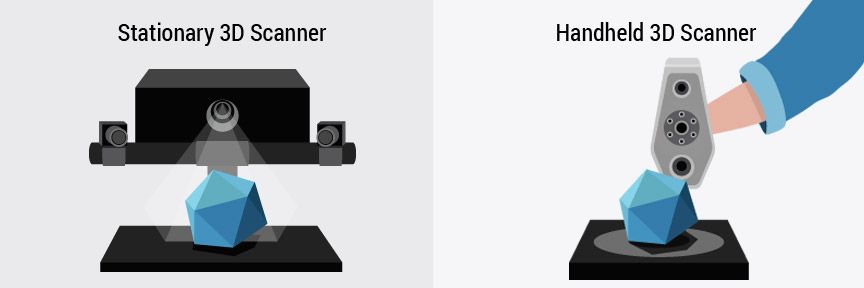

Handheld vs StationaryHandheld and stationary 3D scanners often use the same technology and can overlap in their functions. The difference lies mainly in the design.

A handheld scanner has a grip and lets the user move around the object themselves to capture it at every angle.

A stationary scanner has to be positioned in front of the object, which is typically placed on a rotating plate and captures it as it spins 360 degrees. The user may have to reposition the object several times to capture every angle.

Newer designs are becoming smaller and more easily portable.

Laser TriangulationThe most common technology used in 3D scanning is laser trigonometric triangulation. It records millions of different points on the surface of the object to build an accurate overall polygon mesh. These are common in handheld options and industrial-grade scanner machines. They can also work long-range and for laser-tracking objects.

It records millions of different points on the surface of the object to build an accurate overall polygon mesh. These are common in handheld options and industrial-grade scanner machines. They can also work long-range and for laser-tracking objects.

Similar and often used interchangeably with laser triangulation, structured light or ‘white light’ projects itself in a grid-like pattern over an object. It can then measure the structure of that grid as it applies to the object by using sensors/3D scanner cameras and triangulation.

Long RangeLonger range scanners use phase shift or pulse technology that can capture millions of points while rotating 360 degrees with the aid of mirrors. This is more commonly used to scan large objects like cars or buildings.

They might also use ‘time of flight’ technology that measures the distance of an object in relation to the speed of light and the time it takes for it to return to a sensor.

This is less relevant for everyday 3D scanning and printing.

3D Scanning ApplicationsThere are many different applications for 3D laser scanning - from those for 3D printing at home, to prototyping, industrial scale medical supply production and even architecture.

Hobbyist 3D printingCheaper 3D scanners are typically used by home users for scanning simple objects and 3D printing them for fun.

MedicalThe medical field and dentistry commonly use 3D scanning to create implants and aids to serve their patients’ needs. For example, scanning people’s feet with a high-quality 3D scanner allows for the creation of orthotics (shoe inserts). It is also used in the creation of prosthetics.

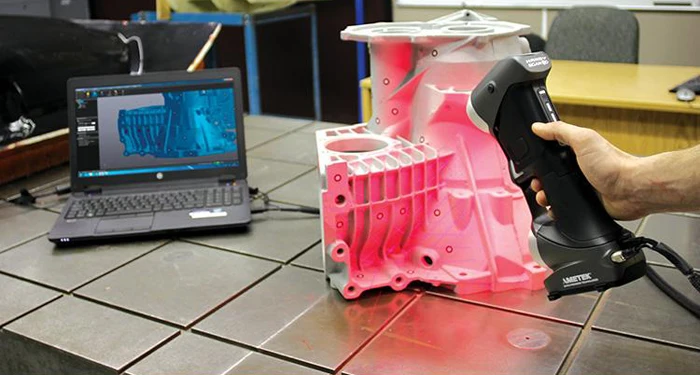

Virtual EngineeringIndustrial 3D scanners are used both in the creation and quality control of cars, planes, and even aerospace. It ensures existing parts are as accurate as their original models and that new viable parts are made.

From the home computer desk to the manufacturing floor, 3D scanning allows users to reverse engineer or copy existing objects. Saved models also allow for the reconstruction of damaged objects.

Virtual RealityFrom creating realistic 3D worlds to the people that occupy them, 3D scanning devices are integral to the growing virtual reality industry. This ranges from AAA video games, virtual cinematography, and computer-generated imagery (CGI), to virtual tours and office meetings. It is also a side industry to motion capture.

ForensicsCSI has come a long way. Forensic experts nowadays don’t just have to rely on memory, photos, and evidence of a crime scene. They can capture the entire location in a full 3D model for closer inspection and for running through different scenarios.

Archeology and ArchivingFrom museums to libraries, 3D scanning is being used to log and preserve everything from artifacts to digitizing books. This also gives experts and the public remote access.

This also gives experts and the public remote access.

3D scanning can also help architects map the areas they will be designing their buildings in, take inspiration from existing architecture, and aid in building miniatures/prototypes.

What Should I Know Before Buying a 3D Scanner?Before you buy a 3D scanner, there are several things to consider:

- your budget

- what you’ll actually be using it for

- it’s speed and accuracy

- the device’s other features.

3D laser scanner price ranges vary greatly. On the cheaper end, you may be able to pick one up for home for just shy of $300, like the XYZprinting 3D Scanner 1.0 A. However, if you want the highest overall quality and the ability to scan small and large objects. Or, if you’re a professional and need a 3D part scanner in a field like medical implants or automotive parts, you’re looking at anywhere between $3,000 and $35,000.

Typically, it’s best to look for 3D scanners for sale online where you can find the best selection and prices.

3D PrintingWhile a dual 3D printer scanner combo is rare, if you want to scan models for 3D printing, you will need to make sure it has good accuracy and resolution. The software also must be able to export to a usable format. You will need to check your 3D printer and its own software to see what file types it accepts and then choose your scanner accordingly.

Fortunately, almost all of our 3D scanner reviews include devices that can export in common file types like OBJ and STL.

It’s typically only the more expensive scanners that are good for other applications, like VR, full-body scanning, architecture, and engineering.

Handheld vs StationaryWe already explained the difference, but basically, a handheld scanner is mobile, while the stationary one will require you to move and adjust the object. Neither is necessarily better than the other, it’s all down to your needs.

Neither is necessarily better than the other, it’s all down to your needs.

How fast is the scanner? Do you have a lot of spare time or require the job to be done as fast as possible? All 3D scanners will take a few minutes to complete, while many scanning complex objects in high resolution can talk half an hour or longer.

Accuracy and ResolutionAccuracy refers to how close to the object being scanned your digitized model will be, measured in millimeters. Therefore, the smaller the better. The term resolution may be used interchangeably with accuracy or refer to the resolution of any cameras being used as part of the scanning process.

Generally, the lower the millimeter, the better. Other factors also play a role in overall quality, such as lighting conditions, color, and depth.

Object Size and SpaceSome types of 3D scanners excel at scanning small objects while others are better at medium to large. Others are all-rounders. Before buying a scanner, you should decide the general size of the items you will be scanning.

Others are all-rounders. Before buying a scanner, you should decide the general size of the items you will be scanning.

You will also need to make room for the scanner. Although all the products on our list are small and relatively portable, stationary scanners at least need a table to work from. Likewise, there will be a minimum and maximum distance the scanner must be in relation to the object being scanned.

You’ll need more room when scanning larger objects in full.

Connected DevicesAll 3D scanners need to be connected to a computer or device to help monitor the process and for saving the digital model. This is usually done via a USB or HDMI cable. You will need to check that your computer or laptop meets the minimum requirements for the scanning and modeling software. Also, make sure that you have a tablet to make real-time monitoring easier.

SoftwareYour device will either come with its own software or a popular third-party program to aid the process and to help touch-up the model once it’s scanned. Different 3D printing software is better suited to different skill levels. Some programs have a lot of features for experienced users and others do most of the basic tasks automatically. Check our 3D scanner reviews to see the software each device comes with and how advanced and easy to use it is.

Different 3D printing software is better suited to different skill levels. Some programs have a lot of features for experienced users and others do most of the basic tasks automatically. Check our 3D scanner reviews to see the software each device comes with and how advanced and easy to use it is.

Whether you’re looking for a tool for your home or something more on an industrial scale for your business, our 3D scanner reviews have something for everyone. From handheld devices to structured lightboxes with turntables, you’ll be creating 3D models or reverse engineering parts in no time. Perhaps you’ll even do a 3D selfie or two!

If you’re still unsure about 3D printing after reading our reviews and guides, check out our answers to your most commonly asked questions below.

Best handheld 3D scanners under $30K

Looking for the best handheld 3D scanner? This selection features what we believe are the 6 best handheld 3D scanners under $30,000, based on our own experience as well as feedback from our trusted network.

Last update April 27, 2022

In our last major update, we swapped out the Scantech KSCAN-Magic for the SIMSCAN that we tested weeks earlier. We also added the FreeScan UE Pro, Shining 3D's recent follow-up to the metrology-grade FreeScan X series. We swapped out the Go!SCAN SPARK for the HandySCAN 307 to narrow this selection's price range down to $30K. Minor updates were also made to the buying guide section.

Table of contents

What is the best handheld 3D scanner on the market?

Our handheld 3D scanner selection this year (under $30K)

peel 2

EinScan HX

HandySCAN 307 (SILVER series)

FreeScan UE Pro

SIMSCAN

Leo

Purpose: What do you need your 3D scanner for?

Handheld 3D scanner specifications

Budget

FAQ

What is the best handheld 3D scanner on the market?

There are hundreds of 3D scanners available on the market, from desktop 3D scanners to advanced 3D metrology systems. However, handheld 3D scanners have been gaining a lot of popularity over the past few years.

However, handheld 3D scanners have been gaining a lot of popularity over the past few years.

There are several key tendencies that may be behind this segment’s growth. Over the years, we’ve noticed that handheld 3D scanners and their software (which is often the most complex part of the process) are becoming much easier to use, with smoother workflows and improved design and ergonomics. New entrants – mostly from Asia– have driven prices down to overcome some of the market’s entry barriers, all while providing quality hardware and performance.

More generally speaking, handheld 3D scanners offer various benefits over other types of 3D scanners:

- Ability to access hard-to-reach places

- Relative ease of use

- Portability

Their versatility makes them suitable for a wide range of industries, including automobile, aerospace, engineering, and design, and some can even be used for 3D body scanning.

From affordable handheld 3D scanners to advanced, industrial-grade portable 3D scanners, the market caters to almost every need. Our goal is to showcase the best handheld 3D scanners currently available for professionals for under $30,000.

This buyer’s guide is based on a combination of our own experience, in-house 3D scanner reviews, and feedback from our partners.

Note: Not sure if handheld 3D scanning is the right fit for your use case? Take a step back and learn about other types of 3D capture solutions (metrology-grade solutions, jewelry 3D scanners, dental …) in our all-round 3D scanner buyer’s guide.

Our handheld 3D scanner selection this year (under $30K)

The table below recaps our selection of some of the best handheld 3D scanning options. The goal is to provide a quick, visual overview of the market; there are of course numerous other factors to take into account (certifications, software, customer service, …) to get the full picture for each solution and eventually make the right choice.

| Brand | Product | Accuracy | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| peel 3D This brand is a certified partner from our network. | peel 2 | 0.1 mm0.003937 in | Canada | $ 8,0908 090 €7,176 £1,205,863 ¥ | Quote |

| Shining 3D This brand is a certified partner from our network. | EinScan HX This product has been reviewed by our team. | 0.04 mm0.001575 in | China | $ 12,00012 000 €10,644 £1,788,672 ¥ | Quote |

| Creaform This brand is a certified partner from our network. | HandySCAN 307 (SILVER series) | 0. 04 mm0.001575 in 04 mm0.001575 in | Canada | $ 21,90019 900 €19,426 £3,264,326 ¥ | Quote |

| Shining 3D This brand is a certified partner from our network. | FreeScan UE Pro This product has been reviewed by our team. | 0.02 mm0.000787 in | China | $ 24,00022 000 €21,289 £3,577,344 ¥ | Quote |

| Artec 3D | Leo | 0.1 mm0.003937 in | Luxembourg | $ 29,80029 800 €26,434 £4,441,869 ¥ | Quote |

| SCANTECH (HANGZHOU) CO., LTD This brand is a certified partner from our network. | SIMSCAN This product has been reviewed by our team. | 0.02 mm0.000787 in | China | upon request | Quote |

Expand to see more specs

*Accuracy: Results measured in ideal conditions. Note that 3D scanner OEMs do not always follow the same protocols to measure their products’ accuracy.

** Max. resolution: Refers to point-to-point distance. Learn more about 3D scanning resolution and accuracy here.

The products in the table are ranked by price (low to high).

| Brand | Product | Technology | Os compatibility | Accuracy | Max resolution | Wireless | Weight | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|---|---|---|---|

| peel 3D This brand is a certified partner from our network. | peel 2 | Structured light | Microsoft Windows | 0.1 mm0.003937 in | 0.5 mm0.02 in | 0.95 kg2.09 lb | Canada | $ 8,0908 090 €7,176 £1,205,863 ¥ | Get a quote | |

| Shining 3D This brand is a certified partner from our network. | EinScan HX This product has been reviewed by our team. | Structured light | – | 0.04 mm0.001575 in | 0.05 mm0.001969 in | 0.71 kg1.57 lb | China | $ 12,00012 000 €10,644 £1,788,672 ¥ | Get a quote | |

| Creaform This brand is a certified partner from our network. | HandySCAN 307 (SILVER series) | Laser triangulation | – | 0.04 mm0.001575 in | 0.1 mm0.003937 in | 0.85 kg1.87 lb | Canada | $ 21,90019 900 €19,426 £3,264,326 ¥ | Get a quote | |

| Shining 3D This brand is a certified partner from our network. | FreeScan UE Pro This product has been reviewed by our team. | Laser triangulation | – | 0.02 mm0.000787 in | – | 0.84 kg1.85 lb | China | $ 24,00022 000 €21,289 £3,577,344 ¥ | Get a quote | |

| Artec 3D | Leo | Structured light | Microsoft Windows | 0. 1 mm0.003937 in 1 mm0.003937 in | 0.2 mm0.007874 in | 2.6 kg5.73 lb | Luxembourg | $ 29,80029 800 €26,434 £4,441,869 ¥ | Get a quote | |

| SCANTECH (HANGZHOU) CO., LTD This brand is a certified partner from our network. | SIMSCAN This product has been reviewed by our team. | Laser triangulation | – | 0.02 mm0.000787 in | 0.02 mm0.000787 in | 0.57 kg1.26 lb | China | upon request | Get a quote |

Overview of the best handheld 3D scanners under $30,000

In this section, we give some more context and information about each 3D scanner from our selection.

Peel 3d is a subsidiary of Creaform, a leading 3D scanner manufacturer. They first created the original peel 3d (which we reviewed a while back) in order to tap into the entry-level 3D scanner market.

This second-generation peel 3D scanner offers a higher resolution than its predecessor, and is capable of capturing textures and colors. It is available with a smaller scan volume as the peel 2-S version was designed for parts measuring between 5 and 50 cm.

It is available with a smaller scan volume as the peel 2-S version was designed for parts measuring between 5 and 50 cm.

Peel 3D scanners are easy to use, even for beginners with little 3D scanning knowledge. The software that comes with the peel 2 is also intuitive and user-friendly, offering multiple editing functionalities.

Contact manufacturer Get a quote Add to comparison

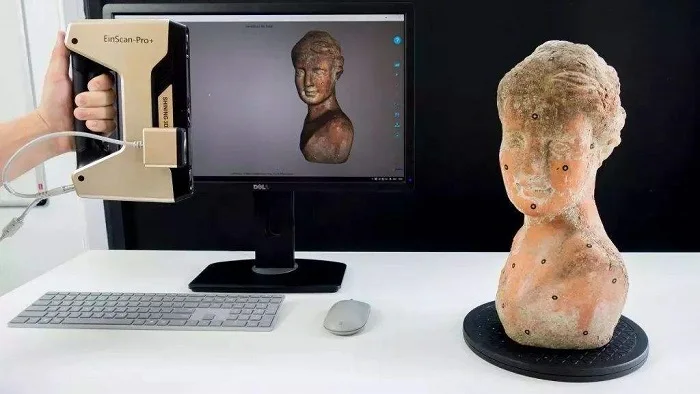

The EinScan HX is a follow-up to the first-generation EinScan-Pro, EinScan Pro HD, and later EinScan Pro 2X and 2X Plus. In this price range and at this level of performance, the flagship EinScan HX is unrivaled.

This portable 3D scanner features hybrid 3D scanning technology: its rapid mode is based on structured light, while the fine mode uses laser triangulation. The HX is capable of color and texture acquisition, too.

It is a powerful and versatile product that is capable of acquiring difficult surfaces (reflective, dark, or both) and adapting to parts of all sizes. Shining 3D also made great efforts in terms of weight and design; the HX is well-balanced and comfortable to use.

Read the full review: Shining 3D EinScan HX review

Contact manufacturer Get a quote Add to comparison

The SILVER series is a mashup of old and new recipes, combining the HandySCAN 307/700’s excellent reputation with ongoing updates to an already highly capable software.

We reviewed the HandySCAN 700 (HS700) twice; it is identical to the HandySCAN 307 aside that it features a single laser line mode and offers a slightly higher accuracy (0.03mm versus 0.04mm).

In short, we believe that the HandySCAN SILVER Series is an excellent option with a well-rounded and professional software suite. We highly appreciate the fact that the software saves every bit of information from each scan before letting you decide (reversibly) what you keep and which mesh resolution you want.

Read the full review (HS700 version): Creaform HandySCAN 700 review

Contact manufacturer Get a quote Add to comparison

The FreeScan series is a step above the EinScan series, namely in terms of accuracy and repeatability. It is a recent upgrade to the FreeScan X, boasting a faster acquisition rate, larger scanning range, lighter weight, and more competitive pricing.

It is a recent upgrade to the FreeScan X, boasting a faster acquisition rate, larger scanning range, lighter weight, and more competitive pricing.

This blue laser 3D scanner offers metrology-grade precision and repeatability, all while being able to scan difficult surfaces in a wide range of environments and industries. Common industries and applications for this type of 3D scanner include the automotive industry, transportation, mould inspection, energy manufacturing, aerospace, and machine manufacturing, among others.

The FreeScan UE Pro offers three scanning modes: 13 laser crosses for quick scans or large objects, 5 parallel laser lines to scan fine details, and a single laser line for deep holes and pockets.

Contact manufacturer Get a quote Add to comparison

The SIMSCAN is extremely lightweight for a handheld 3D scanner, weighing only 570 grams. It’s also very compact– the absolute smallest in its class– with dimensions of 203 x 80 x 44 millimeters. Scantech earned a Red Dot Design Award in 2021 for the SIMSCAN’s disruptive design.

After using the SIMSCAN to 3D scan various types of parts, we can confirm it’s an excellent product that feels, looks, and works great. With a price of around €25,000, the SIMSCAN’s price-to-performance is outstanding. The only blemish lies in the software, but it receives updates regularly and you can export your scans to your preferred suite.

Read the full review: Scantech SIMSCAN review

Contact manufacturer Get a quote Add to comparison

The Artec Leo has been one of the only wireless 3D scanners on the market since its original launch in 2017. It features an onboard processor to capture all data locally, and a large screen that offers real-time 3D visualization.

For its five-year anniversary in March 2022, Artec3D revamped the AI-based Leo with a new processor, the NVIDIA Jetson TX2. It is said to double the Leo’s speed and overall performance. Artec3D now also sells the Leo with a calibration certificate to guarantee its accuracy.

The Leo 3D scanner is a great option, namely in hard-to-reach areas or wherever it can be complex to plug in the Leo and a laptop. However, for more standard use cases, keep in mind that the Leo weighs 2.6kg; that’s around x5 times heavier than the most lightweight portable 3D scanners.

However, for more standard use cases, keep in mind that the Leo weighs 2.6kg; that’s around x5 times heavier than the most lightweight portable 3D scanners.

Contact manufacturer Get a quote Add to comparison

Portable 3D scanner buying guide

Before choosing a portable 3D scanner, it’s important to take certain elements into account.

Purpose: What do you need your 3D scanner for?

Today’s handheld 3D scanners are very versatile and can be used for multiple use cases in various industries. Nevertheless, there are a few questions you can ask yourself to help make the right choice.

- How big or small are the parts you’re going to scan? This will determine your field of view. Some 3D scanners have multiple modes or fields of view to handle small, medium, and large parts, while some are specially designed for small pieces.

- Are you already familiar with 3D scanning? If you’re new to 3D scanning, you may want to look out for streamlined workflows.

Some brands have several product generations of experience and provide more intuitive software.

Some brands have several product generations of experience and provide more intuitive software.

- Do you need to acquire colors? Many recent handheld 3D scanners boast texture/color capture, but this feature isn’t standard. It is quite rare on 3D scanners that focus on metrology applications, as having color maps could be superfluous when you just want to inspect a part’s shape.

- Will you be 3D scanning every day? Perhaps you’d prefer a 3D scanner that’s easy and quick to set up and put away.

3D scanning can serve an amazing amount of purposes– determine yours before you choose a handheld 3D scanner.

Handheld 3D scanner specifications

Accuracy

A 3D scanner’s accuracy is its ability to obtain exact measurements. In certain industries, like quality inspection, high accuracy is of utmost importance. Entry-level handheld 3D scanners generally boast accuracies around 200 microns, while more premium products can go down to 20 microns.

Resolution

Just like with photos or screens, the level of resolution will count more or less depending on the amount of detail you need. In 3D scanning, resolution is generally measured in point-to-point distance.

Speed

The speed factor is especially important when 3D scanning large objects and landscapes (where SLAM/iMMS scanners shine), or for 3D body scanning.

Large objects take a while to scan, and some 3D scanners require you to stand still for a few seconds before moving on to the next perspective. Keep in mind that you’ll be “pointing and shooting” with your handheld 3D scanner in your hand; the longer you carry it, the heavier it feels.

Nonetheless, some 3D scanners like the Go!SCAN SPARK or the EinScan HX allow you to easily pause and resume from anywhere thanks to efficient automatic scan alignment.

Budget

Last but not least, and as is the case for so many other products, budget is definitely something to take into account. There are cheap handheld 3D scanner options for under $1,000 if you’re willing to sacrifice accuracy and performance (see our “Affordable 3D scanner” selection here).

There are cheap handheld 3D scanner options for under $1,000 if you’re willing to sacrifice accuracy and performance (see our “Affordable 3D scanner” selection here).

Industrial 3D scanners are the most expensive, with advanced 3D scanning technologies and prices around $100K. Unless you need a 3D scanner for 24/7 automated quality inspection or other very specific use cases, an entry or mid-level 3D scanner will suit you.

FAQ

How much does a handheld 3D scanner cost?

Mid-range handheld 3D scanners tend to cost between $10,000 and $30,000. There are affordable handheld 3D scanner options under $1,000, and high-end, metrology-grade handheld scanners priced at over $50,000.

How accurate are handheld 3D scanners?

High-end handheld 3D scanners can reach an accuracy up to 0.020mm. Entry-level, affordable scanners offer a scan accuracy of around 0. 10mm.

10mm.

Top Ten 3D Scanners from $100 to $100,000 / Sudo Null IT News There are several ways for you: you can of course create your 3D model from scratch in a 3D modeling program or find a suitable one on the Internet, but you can also scan an existing object! The purpose of this review is to help you understand the variety of 3D scanners available and offer the best in every price segment from a photogrammetric smartphone app to professional 3D scanners. nine0003

Scanners are listed in ascending price order so you can choose the one that suits your budget and use the resulting 3D models for both 3D printing and animation.

If you are not satisfied with the proposed solutions, there is an extended overview at this link.

3D scanner in hand:

1. Best smartphone app: Autodesk 123D Catch (free)

Autodesk 123D Catch is a free photogrammetric application. It allows you to create a 3D model from photographs of an object taken from different angles. You can use it to scan objects, people, and even the landscape. For some applications, if you don't need perfect accuracy, you don't need special equipment. This application actually provides quite good detail and is easy to use. However, it will take you at least 30 minutes for the app to process your photos as the processing takes place on the server and it takes time to send them. nine0003

You can use it to scan objects, people, and even the landscape. For some applications, if you don't need perfect accuracy, you don't need special equipment. This application actually provides quite good detail and is easy to use. However, it will take you at least 30 minutes for the app to process your photos as the processing takes place on the server and it takes time to send them. nine0003

2. Best DIY 3D Scanner: Kinect ($99.99)

The Xbox Kinect is designed to expand your gaming experience. It is not designed for 3D scanning, but you can easily find manuals and third party software (like ReconstructMe) to turn it into a 3D scanner. If your arms are growing out of your shoulders, this is an interesting and inexpensive solution for 3D scanning.

Price: $99.99

Resolution: 0.051mm

)

This scanner can be attached to your tablet or phone (generally designed for iPad, but can be adapted to other devices). Lightweight and easy to use, with a very good resolution. Suitable for large items (can scan a full-length person) and outdoor scanning. You will be able to use it with software running on Occipital's SDK. This will increase the resolution and give you access to special features like room scanning. It probably won't be something you'll use for 3D printing, but it's interesting for game development, for example. nine0003

Lightweight and easy to use, with a very good resolution. Suitable for large items (can scan a full-length person) and outdoor scanning. You will be able to use it with software running on Occipital's SDK. This will increase the resolution and give you access to special features like room scanning. It probably won't be something you'll use for 3D printing, but it's interesting for game development, for example. nine0003

Price: $ 379

Resolution up to: 0.5 mm

accuracy to: 4 mm

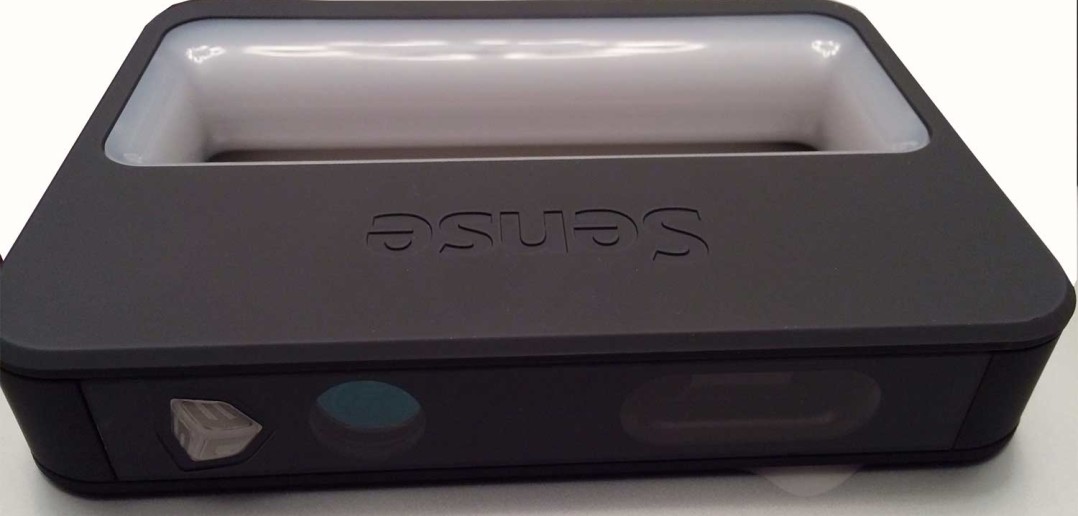

4. The best of cheap manual 3D scanners: Cubife ($ 399)

3D 3D scanners can be quite affordable and easy to use if you choose from inexpensive portable models. Cubify fits these criteria very well and has a relatively good resolution. But still, its capabilities are not enough for texture scanning and it is better to use it for subsequent 3D printing of one-color models. nine0003

Price: $ 399

Resolution: 0. 9 mm

9 mm

Resolution at a distance of 0.5 m: 1 mm

3D scanner on the table:

5. Best and cheapest table 3D 3D 3D 3D 3D 3D 3D 3D 3D 3D 3D 3D 3D 3D 3D 3D 3D 3D- Scanner: Matter and Form ($519)

If you're looking to take your quality to the next level, you can purchase a desktop 3D scanner. This model is compact, easy to use, and delivers good resolution, especially considering the price (not your go-to option if you're looking for perfection, but great for educational and demo purposes). The scanning process takes place with the help of a laser and a rotating platform. The scan takes about five minutes and simultaneously reads the texture of the object. nine0003

Price: $ 519

Resolution: 0.43 mm

accuracy: ± 0.25 mm

6. The best device "two in one": XYZPRINTING DA VINCI 1.0 ($ 600)

is inexpensive combines a 3D scanner and a 3D printer. The quality of the models is not too high, but the price is very low for such a combined device. This makes the XYZprinting Da Vinci the easiest solution for beginners who want to get into the world of 3D scanning-printing. nine0003

The quality of the models is not too high, but the price is very low for such a combined device. This makes the XYZprinting Da Vinci the easiest solution for beginners who want to get into the world of 3D scanning-printing. nine0003

Professional 3D scanners:

7. Best value for money portable 3D scanner: Fuel3D Scanify ($1490)

Very easy to use, intuitive, and feels good in the hand, this scanner delivers good accuracy and texture quality. The only limitation is that the size of the scanned area is limited, which is great for small objects, but for scanning a full-length person, for example, it will not work. nine0003

Price: $ 1490

Resolution: 0.35 mm

accuracy: to 0.3 mm

8. Best price The scanner uses a different scanning technology than others. Instead of a dual laser scanning system, it uses a structured light source and cameras for fast scanning with very fine detail down to 0. Price: $ 3995 9. The best table professional 3D-scanner: SolutionIX REXAN 4 ($ 79 900)  06mm! The scanner comes with DAVID Pro Edition 3 software that works with OBJ, STL and PLY 3D file formats that can be exported to other programs for further editing. nine0003

06mm! The scanner comes with DAVID Pro Edition 3 software that works with OBJ, STL and PLY 3D file formats that can be exported to other programs for further editing. nine0003

Resolution: 0.06 mm

accuracy: 0.5% of the size of the object

Price: $ 79 900

accuracy: from 0. 03 to 0.71 mm

03 to 0.71 mm

10. Best professional manual 3D scanner: Metrascan 750 ($ 50,000 - $ 100,000)

Creaform Metrascan 750 is a complete professional, production solution for accurate 3D scanning. It is light, accurate, fast, and scans objects of any surface quality, with any texture with excellent accuracy.

Price: $79900

Resolution: 0.050 mm

Accuracy: Up to 0.03 mm

We hope this was a useful read and you found a 3D scanning solution suitable for your needs and your budget! If you want to learn more about photogrammetry, you can read this article.

Good luck with your 3D scanning!

review of the peel 2 CAD-S handheld 3D scanner / Sudo Null IT News Compared to its predecessor, the peel 2, the device boasts higher detail when scanning small objects. nine0003

Peel 3d is a trademark of Ametek/Creaform. All of the parent company's knowledge and know-how in 3D scanning and reverse engineering has been invested in making peel 3d products more accessible to reach a different target audience.

The peer 2 scanner proved to be very functional and useful in many applications, but it lacked the ability to capture the finer details of objects. Consider the new peel 2 CAD-S model to evaluate the changes that have taken place. nine0003

peel 2 CAD-S uses the same structured white backlight technology as the previous model, but with higher resolution and therefore better suited for working with smaller elements. The recommended part size is less than 0.5 m (for comparison, for peel 2 - from 0.3 to 3 m).

In practice, this means that when using the same sensors and cameras, the scan area is reduced from 380 x 380 mm to 142 x 108 mm. Essentially, you get the same number of pixels in a much smaller space, so peel 2 CAD-S can capture 3D shapes at 0.1mm grid resolution—in other words, five times more accurate than peel 2.

Setting up and using the 3D scanner for the first time

The setup process is almost the same as for all other 3D scanners. The whole set comes in a regular case with a foam insert: a scanning device, software and a license key on a USB stick, as well as a switch. The cables are designed for power (from a standard power supply) and data transfer (via Hi-Speed USB 2.0). The installation process is simple: insert the flash drive into your computer, run the installation and follow the suggested steps. nine0003

The cables are designed for power (from a standard power supply) and data transfer (via Hi-Speed USB 2.0). The installation process is simple: insert the flash drive into your computer, run the installation and follow the suggested steps. nine0003

For hardware requirements, you'll need a modern workstation or laptop with an Nvidia GPU and at least 2 GB of VRAM. Processor - the faster the better, but because the system is geared towards small parts, the chances of overloading a modern processor are minimal.

Calibration must be performed after installation. Calibration of this type of device is not difficult, and the general recommendation is that it should be done fairly regularly, especially as the conditions in which the scanner is used change. This may be due to light (for example, moving to another office, to another area of \u200b\u200bthe shop or workshop) or temperature. After the calibration is completed, the device is ready for use. nine0003

The first time the peel 3d software is launched, the user is presented with two main options. You can follow the help guide that will guide you through the entire 3D scanning process, determining how to capture the object, what resolution and positioning methods to use (geometry, texture, or position labels), and help you with your work. Another option is to do the setup yourself.

You can follow the help guide that will guide you through the entire 3D scanning process, determining how to capture the object, what resolution and positioning methods to use (geometry, texture, or position labels), and help you with your work. Another option is to do the setup yourself.

First you need to define the scan resolution. The default is 1.0 mm, but values from 0.1 mm to 2.0 mm are possible. The lower the value and the sharper the resolution, the better the scan and the larger the dataset. Given that peel 2 CAD-S is designed for small objects with fine detail, a good GPU can easily handle even 0.1mm resolution.

The next step is to set how the system will track the movement of the 3D scanner around the object. As with other similar devices, there are three options: texture, geometry, and labels. Structured light scanners equipped with texture capture can use the surface texture to track the movement of the scanner/object. peel 2 CAD-S can also use object geometry. Both of these methods work well for organic shapes and textured objects. nine0003

peel 2 CAD-S can also use object geometry. Both of these methods work well for organic shapes and textured objects. nine0003

Regularly shaped products with uniform surfaces (most often mechanical parts) may require the use of position marks.

These are small, custom-sized reflective markers that can be stuck on or around an object. They are used to determine the position of the scanner in relation to the object using triangulation methods. As long as there are three marks in the field of view of the 3D scanner at the same time, this method usually gives a good result and ensures correct tracking of the scanner. nine0003

The peel 2 CAD-S kit includes a set of small plastic jigs with three marks that can be placed around the object for quick adjustment. These devices are very useful considering that the device is focused on digitizing small details with high detail, and sticking several 4mm marks on them is not a very practical solution. The

peel 2 CAD-S is designed to scan physical objects at high resolution and many of its features are based on the proven design of CreaformScanning process

3D scanning typically involves collecting as much data as possible in one position. The device is quite light and well balanced, which many competitors' products cannot boast of. The function of determining the distance to the object (ideally 300 mm) with color indication on the screen and on the device itself allows you to scan very quickly.

The device is quite light and well balanced, which many competitors' products cannot boast of. The function of determining the distance to the object (ideally 300 mm) with color indication on the screen and on the device itself allows you to scan very quickly.

It is worth noting that the peel 3d software provides a very rough preview. Since the scanner usually collects a huge amount of data, it makes sense to gradually filter it out as you work. nine0003

As you get used to the operation of the device and develop the skill of quickly moving the scanner around an object (or quickly rotating a part on a turntable), you will understand how to maintain continuous tracking. At any time, you can take your finger off the shutter, pause the scan and review the data, and then return to digitizing the missing areas.

There are two options after the initial scan. If there is enough data, then you can start the cleaning process and remove excess data. There are a number of tools available for this and the procedure is quite simple - this is one area where all the investment in Creaform know-how is worth it. Then the meshing and further cleaning is performed. nine0003

Then the meshing and further cleaning is performed. nine0003

Otherwise, especially for complex parts, a more thorough rescan may be required. This repeats the same process, resulting in two or more data sets that need to be matched. Once again, Creaform's knowledge and technology comes into play, allowing you to use common dots (you must select three common dots between two or more images) to combine multiple scans.

After the scan (or set of scans) is ready, the next step is to prepare for data post-processing. You may just need to create a mesh, fill holes, and export the data to OBJ or STL format. In this case, the available tools will help smooth surfaces, remove noise and fill in all holes to ensure reliable export. nine0003

In addition, you may want to build analytical surfaces from the point/mesh data, either to get a point of reference to reuse the mesh in CAD (surfaces allow you to align and reassemble the model) or to create reference geometry to build a more complete model.

The peel 3d software is not really designed to build a fully sealed solid model. Its purpose is to help build a set of reference surfaces that are consistent with point and grid data. This view of the scanned data can be imported into a full-featured 3D design system and the 3D model can be completed. nine0003 Once you've mastered the best techniques for capturing a physical object with peel 2 CAD-S, the results will speak for themselves

Although it may sound a little complicated, in fact, in most cases other surfaces (such as cylinders, spheres, planes) can be added to the prismatic model almost instantly etc.).

These surfaces and points can then be loaded into CAD. This usually requires two exports: first a mesh data file in STL or OBJ format, then a surface data file in STEP or IGES format (for example). The result should be a set of two types of geometry that can be used to build the required model. nine0003

Conclusions

At first glance, the peel 2 3D scanner makes a strong impression.