Most reliable 3d printer reddit

Purchase Advice Megathread - October 2022 : 3Dprinting

Welcome back to another purchase megathread!

This thread is meant to conglomerate purchase advice for both newcomers and people looking for additional machines. Keeping this discussion to one thread means less searching should anyone have questions that may already have been answered here, as well as more visibility to inquiries in general, as comments made here will be visible for the entire month stuck to the top of the sub, and then added to the Purchase Advice Collection (Reddit Collections are still broken on mobile view, enable "view in desktop mode").

If you are new to 3D printing, and are unsure of what to ask, try to include the following in your posts as a minimum:

Your budget, set at a numeric amount. Saying "cheap," or "money is not a problem" is not an answer people can do much with. 3D printers can cost $100, they can cost $10,000,000, and anywhere in between. A rough idea of what you're looking for is essential to figuring out anything else.

Your country of residence.

If you are willing to build the printer from a kit, and what your level of experience is with electronic maintenance and construction if so.

What you wish to do with the printer.

Any extenuating circumstances that would restrict you from using machines that would otherwise fit your needs (limited space for the printer, enclosure requirement, must be purchased through educational intermediary, etc).

While this is by no means an exhaustive list of what can be included in your posts, these questions should help paint enough of a picture to get started. Don't be afraid to ask more questions, and never worry about asking too many. The people posting in this thread are here because they want to give advice, and any questions you have answered may be useful to others later on, when they read through this thread looking for answers of their own. Everyone here was new once, so chances are whoever is replying to you has a good idea of how you feel currently.

Reddit User and Regular u/richie225 is also constantly maintaining his extensive personal recommendations list which is worth a read: Generic FDM Printer recommendations.

Additionally, a quick word on print quality: Most FDM/FFF (that is, filament based) printers are capable of approximately the same tolerances and print appearance, as the biggest limiting factor is in the nature of extruded plastic. Asking if a machine has "good prints," or saying "I don't expect the best quality for $xxx" isn't actually relevant for the most part with regards to these machines. Should you need additional detail and higher tolerances, you may want to explore SLA, DLP, and other photoresin options, as those do offer an increase in overall quality. If you are interested in resin machines, make sure you are aware of how to use them safely. For these safety reasons we don't usually recommend a resin printer as someone's first printer.

As always, if you're a newcomer to this community, welcome. If you're a regular, welcome back.

If you're a regular, welcome back.

Best 3D Printer Under 1000 Reddit : 3dPrintersMania

Best 3d printer under $1000 reddit on 2020-21.

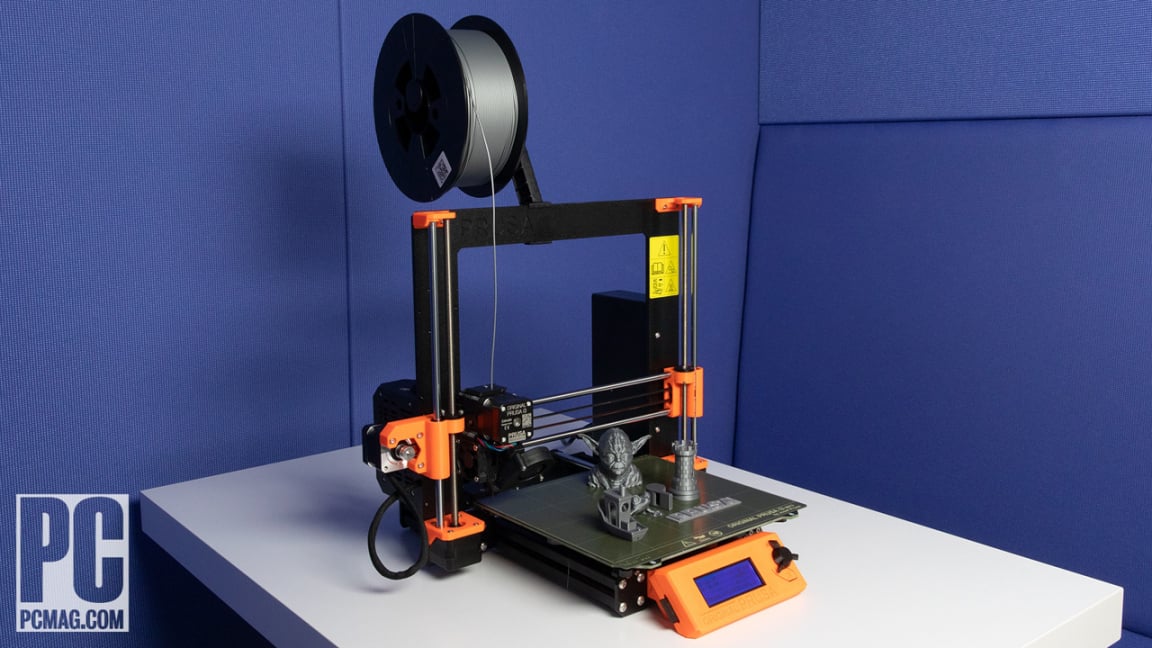

Best Overall: Prusa i3 MK3. reddit best 3d printer

Best Value: Creality Ender 3.

Best For Your Desk: Monoprice Maker Mini Pro.

Best Value Delta: Monoprice Mini Delta.

Best Value Resin: AnyCubic Photon. Best 3d printer under 1000 reddit

For Moe Details: https://3dprintersmania.com/

For the last five years we've invested in the 3D printing world, using as many printers as we can to see what is good and what is bad. We all know that printing can be expensive — there are machines out there that start at $3,000 and go up from there — so we want you to have some idea of what you can get for cheaper. When it comes to value and quality you can't beat the Prusa i3 MK3. While it isn't the cheapest of the machines on this list, it is easily the best quality in terms of build and print.

Best Overall:

Prusa i3 MK3

Best Value:

Creality Ender 3

Best For Your Desk:

Monoprice Maker Mini Pro

Best Value Delta:

Monoprice Mini Delta

Best Value Resin:

AnyCubic Photon

Best Overall: Prusa i3 Mk3

In the world of hobbyist 3D printing, there are few names as well known as Josef Prusa. His work in open source 3D printing has revolutionized what can be done at home and on a budget for those who want to create amazing prints. The Prusa i3 MK3 is the latest machine based on his open source design and is easily the most advanced printer in this list.

The Prusa has automatic bed leveling, making each print start the best it can, but it also corrects the print on-the-fly if anything happens to shift the bed. With a sensor in the extruder, the Prusa can tell when you run out of filament, pause the print, and alert you to add more, saving countless mistakes in the process. From the removable bed to easily being able to remove prints without breaking them to the excellent save function, which stops your prints being lost in a power cut, the Prusa goes out of its way to make every print work.

From the removable bed to easily being able to remove prints without breaking them to the excellent save function, which stops your prints being lost in a power cut, the Prusa goes out of its way to make every print work.

The listing is for the kit version of the i3 mk3 so you will be required to build it yourself. Prusa does supply a fully made one but it's $200 more when you add in the extra shipping. Which one you buy will depend on your preference, but we recommend getting the kit. Plus, it's actually a lot of fun learning to build one from scratch.

Pros:

Auto bed leveling

Excellent print quality

Open source

Active community

Save functionality

Cons:

Cheaper to buy the kit

Best Overall

Prusa i3 MK3

Fantastic quality

If you are just starting out in the 3D printing game and you want to start off with the best, then go for the Prusa MK3.

$750+ at Prusa Research

Best Value: Creality Ender 3

The Creality Ender 3 is a shining example of how a community can get together, take something cheap and flawed, and turn it into something special. The Ender 3 is not a printer for someone who wants quality prints straight of the box — you have to earn them. Sure, it's easy to get set up and it doesn't take much other to put together — just a few screws —but to get a print that you can be proud of takes effort.

The Ender 3 is not a printer for someone who wants quality prints straight of the box — you have to earn them. Sure, it's easy to get set up and it doesn't take much other to put together — just a few screws —but to get a print that you can be proud of takes effort.

The Ender 3, while being cheap, it is not configured well by Creality. The extruder setup is poor, as are a lot of the acceleration settings and because of that, it can take endless fine-tuning. Don't be dismayed though, there are people out there who are willing to help put you on track.

I never would have gotten the Ender 3 to the point of usability without the help of the Facebook and Twitter 3D printing communities, and I strongly urge you to look into those places if you intend to buy an Ender 3. Especially check out Filament Frenzy on Twitter. He can make the Ender 3 sing and dance like magic.

Of course, if you have the time to spend on it, $220 for a full-size printer that can make some fantastic prints is a bargain. If you have time to love it, it can be a great investment.

If you have time to love it, it can be a great investment.

Pros:

Extremely cheap

Simple setup

Can create amazing prints

Cons:

Can take a lot of work to get right

Best Value

Creality Ender 3

Community favorite

The Ender 3 can be a real pain to get right, but when you do it can some amazing prints. Make sure you join some communities for help.

$230 at Amazon

Best For Your Desk: Monoprice Maker Mini Pro

If you are completely new to 3D printing and want something simple, reliable, and cheap, you can't do much better than Maker Mini Pro by Monoprice. The printer itself is small enough and quiet enough to sit on the desk in your office and allow you to make small, fun little projects fairly quickly. The Mini has several high-end features like Wi-Fi connectivity, along with the SD Card and direct PC connection that you normally get with larger printers.

It even comes with auto bed-leveling, which can be picky but is a great addition. There's also a heated bed for printing with multiple types of filament, something you'd expect on a more expensive printer, all wrapped in a sturdy metal body that reduces the "noise" often associated with cheaper printers. With a 4.75-inch print bed, the Mini is the smallest of the printers on this list, but if you are just starting out in 3D printing and only want to experiment, the small bed is more than enough.

With the Bowden extruder setup already a part of the Mini the results of printing are significantly better than I ever thought a $200 printer would produce. I helped my local youth room purchase three of these so the young people there can learn how to design and print in 3D and so far the only issue I have had is a blocked nozzle and an uneven print bed, both of which are the basic foibles of 3D printing and easily fixed by anybody.

Pros:

Auto bed leveling

Fits on your desk

Wi-Fi printing

Heated bed

Cons:

The print bed is really small

Best For Your Desk

Monoprice Maker Mini Pro

Teeny desk printing

Sometimes you just want a little fun at your desk. The Mini Pro is perfect for a desktop 3D printing setup.

The Mini Pro is perfect for a desktop 3D printing setup.

$200 at Amazon

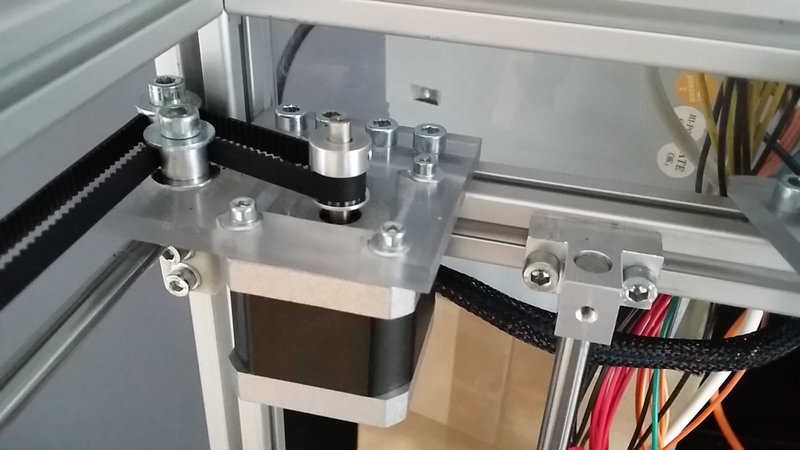

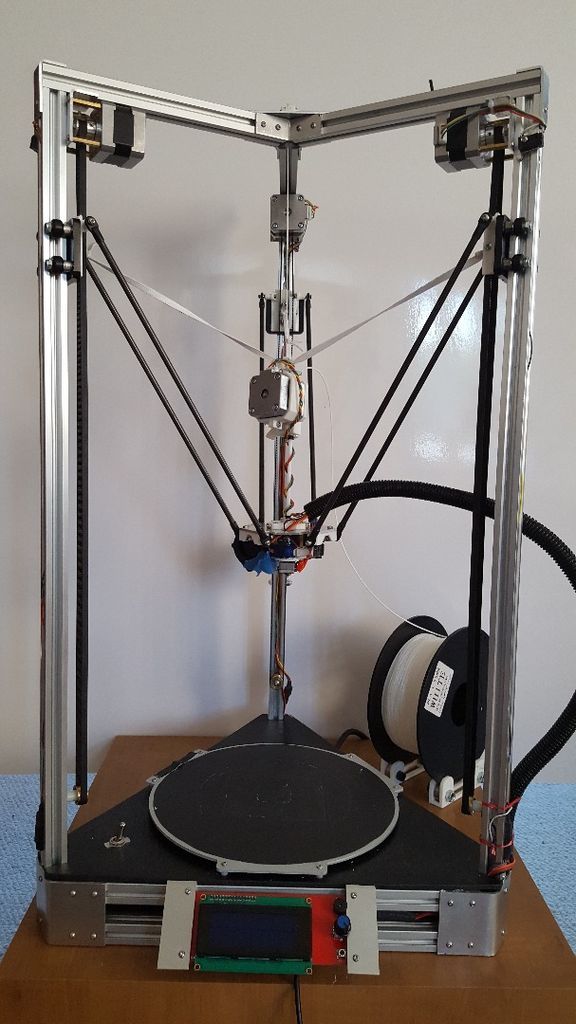

Best Value Delta: Monoprice Mini Delta

When I first used the Mini Delta I was ready to write it off from the start — $160 for a delta printer? It was obviously going to suck. Turns out, I was wrong. I like the Delta for a lot of reasons including its portability, it's build quality, as well as its great print quality. None of those things are as awesome as the price though. For just $160 you can have a 3D printer of your own that works as soon as you turn it on.

The interface on the Mini Delta is incredibly simple, making it perfect for youngsters and first-timers who aren't interested in taking things apart to make them work. The printer has three buttons and each one is self-explanatory, helping you get printing straight away. The nature of delta printers — delta printers use three constantly moving servo arms instead of rods and screws — means this mini model is dependable, even when being jostled. A delta, once dialed in, will give you great prints even under the worst of circumstances.

A delta, once dialed in, will give you great prints even under the worst of circumstances.

I was blown away by the print quality of this little machine and, even though it can only make really small models, it remains one of my favorites to have close by for small, quick jobs. The only issue I sometimes have is the auto-leveling is sometimes a little off and you will need to manually adjust or use a product like Magigoo to help keep it all stuck down.

Pros:

Solid as a rock

Great print quality

Simple interface

Portable

Cons:

Small

Bed leveling is janky

Best Value Delta

Monoprice Mini Delta

Mini dependability

The Mini Delta is an amazing little machine with some advanced features. The print quality is excellent and the portability is superb.

$160 at Amazon

Best Value Resin: AnyCubic Photon

Resin printing can be expensive. The machines themselves are normally high-priced and the resins can be even pricier. Resin printing differs from the other printers on this list because it uses a liquid plastic that is cured over a UV light or shot with a laser. It can be messy, difficult, and a little dangerous so it's best to know what you want before you buy.

Resin printing differs from the other printers on this list because it uses a liquid plastic that is cured over a UV light or shot with a laser. It can be messy, difficult, and a little dangerous so it's best to know what you want before you buy.

Somehow Anycubic made an affordable resin printer that produces some of the best quality prints I've seen from a printer under $2,000. The prints from a resin printer are gorgeous and are often impossible to tell that they are 3D printed. They often look like injected molded models.

Using Chitubox — a slicer now used by a large number of 3D printer manufacturers — to slice the models is simple and effective and makes the entire process of printing models on the Photon a breeze. One word of warning though: make sure your supports are thick in Chitubox since they can be a little wimpy if you aren't careful.

Of all the resin printers that I have owned and used the Photon is the one I recommend to friends, and therefore to you, dear readers. It's dependable and accurate every time.

It's dependable and accurate every time.

Pros:

Entry level price

Almost invisible layer lines

Simple to use

Excellent slicing

Cons:

Small build plate

Chitubox can be tricky

Best Budget - Infinite-Z 3D Printer

Known for its quality desktop 3D printers and high market share in the 3D printing industry, Creality 3D launched the revolutionary Infinite-Z 3D printer, 3DPrintMill, on Kickstarter on November 19, 2020.

More information about the campaign: https://www.kickstarter.com/projects/3dprintmill/creality-infinite-z-axis-build-volume-printer-3dprintmill?ref=1dse7g

Simply put, 3DPrintMill is something between a traditional 3D printer and a conveyor belt. This means two things:

Continuous, maintenance-free printing of parts. The parts are 3D printed, the heated ribbon moves forward, the parts come off and fall into the tray. There is no need to constantly remove parts from a heated bed and start the printing process again. 3DPrintMill can turn a whole roll of plastic filament weighing 1, 5 or 10 kilograms into precisely sized plastic parts without any human control.

3DPrintMill can turn a whole roll of plastic filament weighing 1, 5 or 10 kilograms into precisely sized plastic parts without any human control.

Very long 3D prints (theoretically "infinite" along the Z axis). By tilting the hot end 45 degrees, the back of the printed object slides out of the 3D printer while the front remains printed inside the printer. The longest 3DPrintMill print to date is a 20ft, 6m long bar all in one piece, machine-made at just 66cm long.

-

The 45° angle allows for longer passes than ever before. The maximum length of a structure is no longer an obstacle. The hot end is also adjustable to 15°, 25° and 35° with accessories.

-

Conveyor belt combined with 45° hot section for endless prints. The printed design will eventually come out of the belt.

Users can leave the printer unattended until it finishes printing. All prints can be collected at the collection area at the end. nine0003

Users can leave the printer unattended until it finishes printing. All prints can be collected at the collection area at the end. nine0003 -

Silent 32-bit motherboard for the desired printing environment. Users no longer have to look for another way to eliminate engine noise.

-

Filament sensor. It is a necessary component for endless or repeated identical prints. It will pause printing if the filament runs out or breaks to prevent possible printing failure.

-

Proprietary 350 W power supply. It is able to provide sufficient power of the thermal layer. The heating layer is located at the back of the tape, next to the hot spot. The model cools by slowly moving away from the heated area and then detaches from the belt into the collection area. nine0003

3DPrintMill's unique triangular structure gives it perfectly balanced strength and superior rigidity. The moving belt allows the mass production of an identical object or purlins, which are usually located outside the building slab.

The 3DPrintMill triangular frame is built using a Core-XY structure that provides precision, speed and stability.

Creality will provide the special slicer version required to match the unique structure of this printer. It allows users to select the number of copies for a single part, or use the infinite Z-axis to create a long print. nine0003

This campaign was launched on Kickstarter at 12 noon on November 19 (GMT +8), 3DPrintMill is available for order from November 19 to December 19 on Kickstarter, shipping in March 2021. The regular retail price of 3DPrintMill is $999. You can save up to $461 with the flash sale. Super Early Birds also save up to $411. The sooner you join the program, the more benefits you will receive.

Special price per piece:

Urgent sale price - $538

Early Booking Price - $588

Early Booking Price - $688

Kickstarter Special Price - 738

Multipack Special Price:

2 pieces for $1363

3 pieces for 1998

3DPrintMill is the most affordable 3D printer -Z ever created. Similar strip printers currently on the market are for industrial use and cost about 10,000 euros.

Similar strip printers currently on the market are for industrial use and cost about 10,000 euros.

3DPrintMill will be available at about 1/10 of our competitor's price. In addition, when buying on the Kickstarter platform, you can save up to 50%. It will not be available elsewhere until the Creality Kickstarter campaign completes all backer orders. nine0003

Creality was inspired by the open source design and collaborated with those who developed it. By combining these ideas with our hardware design team over the past few months, we have been able to create a configuration that is both high performance and low cost.

Creality releases this product at such an affordable price for the following reasons: Creality is a manufacturer and distributor, there are no intermediaries. Our products are distributed by word of mouth, which saves on advertising. We are grateful to all Creality users. We want to thank our users with this innovative and revolutionary product at the most affordable price on the occasion of Creality's 6th Anniversary. nine0003

nine0003

Since its founding in 2014, Creality 3D has grown rapidly to become a well-known and trusted name in the 3D printing community. Creality 3D is headquartered in Shenzhen, with branch offices in Beijing, Shanghai, and Wuhan that include R&D, manufacturing, and after-sales divisions. With a total area of 30,000㎡ factory and research space, a team of more than 1,000 employees, and a sales volume of more than half a million 3D printers per year, our ability to meet production deadlines is guaranteed. Creality 3D is proud of its major R&D facility, the Creality 3D Printing Labs and Research Institute. It is this drive to innovate - to develop and improve open source designs - that led to the creation of 3DPrintMill. nine0003

The mission of Creality to enable thousands of families to enjoy the convenience that technology brings. 3DPrintMill is a powerful continuous printing and mass production 3D printer for your micro factory that really offers simple and very affordable 3D printing solutions.

For more information, please visit:.

- Official CREALITY website: https://www.creality.com

- Kickstarter campaign page: https://www.kickstarter.com/projects/3dprintmill/creality-infinite-z-axis-build- volume-printer-3dprintmill?ref=1dse7g

Source : CREALITY

This page has been translated using machine translation. Suggest the best translation

Previous

ShareNext

Examples of positive and negative applications of the 3D printer

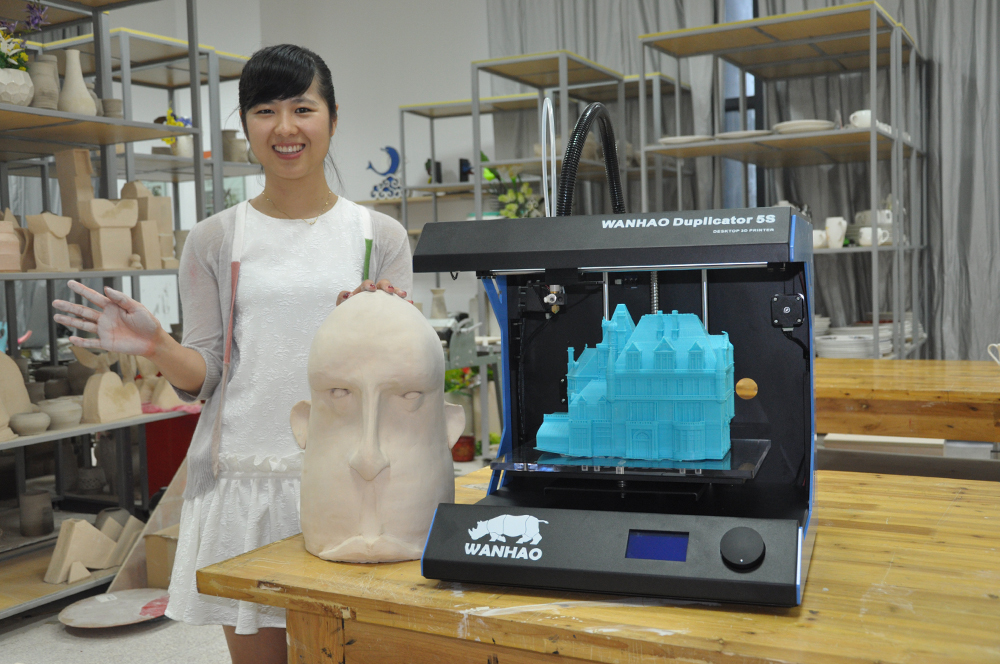

Every year 3D printing becomes more and more popular. The 3D printer, as a tool for turning a digital model into a physical object, is gaining popularity, outperforming other production methods in many ways due to its affordability. nine0003

But do not forget that a 3D printer is just a tool. A lot depends on how this tool will be used.

Available 3D printing technologies

All 3D technologies can be conditionally divided into 4 types.

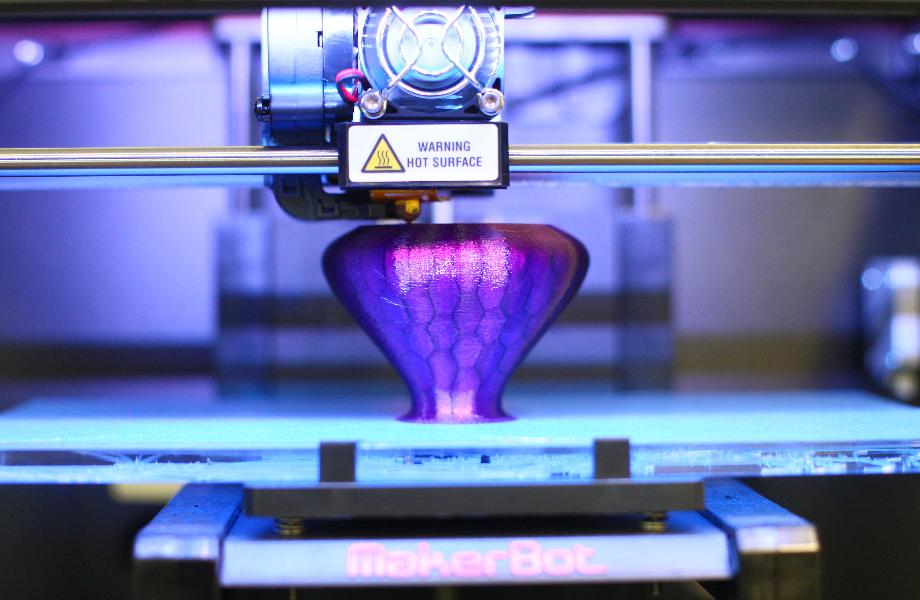

Layer by layer welding with molten material.

The principle of operation is similar to the familiar glue gun. The print media is melted to a semi-liquid state in the print head and applied with a nozzle to the print surface where it solidifies. This is how the finished 3D model “grows” layer by layer on the printing table. Not only thermoplastics can be used as consumables, but, for example, chocolate, icing, concrete, etc. nine0003

This is the most common type of printer. Inexpensive FDM printers are often used as home assistants. This is facilitated by an inexpensive price and a variety of consumables.

Selective curing of resin (photopolymer printers).

The material used is a photopolymer resin that hardens under the influence of UV radiation. As a source of UV radiation, a thin laser beam, a DLP projector or an LCD screen with a UV matrix, or any other design can be used. For example, some industrial 3D printers apply a photopolymer using thin nozzles and immediately illuminate it with a UV lamp. nine0003

nine0003

Previously, these printers were quite expensive. Today, with advances in technology, photopolymer 3D printing has become affordable and photoresin printers have become popular as home hobby printers.

Selective bonding of powdered material.

On the print head of the printer there are several nozzles through which a binder is supplied, which is selectively applied to the powdered material. Various materials can be used as a material: for example, gypsum or metal powders. But gypsum is most often used. nine0003

Since dye can be added to the "glue" during printing, such printers are usually used for the production of color demonstration models or souvenirs.

Laser sintering of powdered materials.

The youngest technology, but with great potential for use in large-scale production. With the help of a laser or a heated print head, selective sintering of the metal powder occurs in an environment filled with an inert gas. nine0003

nine0003

These are already serious industrial printers that are used for the production of functional metal assemblies and parts. Currently, such 3D printers are actively used in the aerospace industry.

Unethical use

3D piracy

Where there is duplication of objects, there are always disputes about copyright and piracy.

The production of any product is a long and painstaking work, and often more than one person. Before you get a finished decorative product, for example, a figurine, you need to think through everything to the smallest detail. Usually, before modeling, the artist draws a lot of sketches, the details of clothing and accessories are thought out. Only after that the 3D modeler gets to work and begins painstakingly recreating the 3D model. nine0003

Functional models are often redesigned by engineers after a prototype has been made. There can be a very long way between the initial idea and a stable working mechanism. And it’s very disappointing when such work is simply copied and posted in the public domain.

LEGO

It was one of the first mass manifestations of "3D piracy". At that time, 3D printing was only gaining popularity, and many users, having printed a dozen figurines, were looking for a useful application for a 3D printer. Given the low plastic consumption, the printed LEGO blocks were very inexpensive. nine0003

3D printed LEGO bricks

Despite the far from ideal surface, many were satisfied with such a copy. Some have argued that the accuracy of a home FDM printer is not enough for the bricks to fit well with the original LEGO, but for most users everything fit perfectly.

At the moment, LEGO is actively removing models that copy the original sizes of the famous bricks and men from the network. On popular sites, only custom elements of LEGO-men and LECO are left that are not the original size. nine0047

Custom heads for LEGO men

Games Workshop

Games Workshop, which produce the most expensive table soldiers in the world, sued Thomas Valenti (USA) back in 2012. Thomas has modeled, printed and made publicly available several miniatures based on the Warhammer universe. The court sided with Games Workshop and the models had to be removed. nine0003

Thomas has modeled, printed and made publicly available several miniatures based on the Warhammer universe. The court sided with Games Workshop and the models had to be removed. nine0003

3D Printed Chaplain

Warhammer 40k 3D Chaplain

Games Workshop went one step further by banning fans from creating art and other work based on the original settings and characters. As a boycott, users of the Warhammer 40,000 section on Reddit are proposing to abandon the company's products as much as possible - print game figures on 3D printers, use paints from other companies, or switch to other universes. nine0003

Hollywood

The production of modern films is not a cheap pleasure, and film companies try to recoup their costs not only by showing them in cinemas, but, for example, by producing souvenirs.

DreamWorks has an entire consumer goods division that helps recoup the cost of a movie if it fails at the box office. Film companies recognize that fan-made productions often surpass the official "souvenir" in accuracy and detail. nine0003

Film companies recognize that fan-made productions often surpass the official "souvenir" in accuracy and detail. nine0003

DC Batman fan model

Many film companies are closely following the development of 3D printed merchandise, but do not yet know how to respond. For example, Paramount Pictures, Marvel Studios and Warner Bros. They themselves began to upload models for 3D printing to the network, before the release of new films.

Weapon Seal

Weapon Seal

24-year-old law student Cody Wilson was the first to make a gun on a 3D printer. Cody designed and 3D printed a combat pistol on his own. After 8 years, the idea of making firearms using 3D printing has not only not died out, but flared up with a bright fire. nine0003

It started in Texas in 2012. It was there that the company Defense Distributed was registered, the ideology of which was the development of models of firearms that anyone could make on a home 3D printer.

Guns

Liberator

The first “swallow” was the Liberator - a compact plastic pistol printed on a 3D printer from ABS plastic. The only thing that could not be made on a 3D printer was the striker, which was successfully replaced by an ordinary nail. The first printed pistol was made on a Stratasys Dimension SST 3D printer. nine0003

Liberator - the name is borrowed from a cheap pistol that was developed in 1942 in the USA.

The Liberator fired a fairly weak .380 ACP round and could only last a dozen rounds at most.

Failed Liberator

Zig Zag

In the spring of 2014, a video appeared on the Internet with a man shooting from a plastic revolver with a huge drum. The video greatly stirred up all of Japan. nine0003

Zig Zag

Unknown was Yoshitomo Imura (Yoshitomo Imura) - 28-year-old employee of the Shonan Institute of Technology. Despite Imuru's claim that he fired blanks on the tape, he was arrested and sentenced to 2 years in prison.

Despite Imuru's claim that he fired blanks on the tape, he was arrested and sentenced to 2 years in prison.

The Zig Zag design was a reimagining of revolvers popular in the 19th century, which used a rotating .38 caliber barrel block mounted on a pistol grip. nine0003

Washbear

In 2015, mechanical engineering student James Patrick posted a video online showing a 3D printed PM522 Washbear in operation.

PM522 Washbear

The PM522 visually resembled a children's pistol from a science fiction movie, but at the same time the pistol had a strong and rigid frame. Washbear is also safer than its predecessors. At rest, the firing mechanism was not in line with the primer, so the PM522 was protected from accidental firing, for example, when dropped. The only metal part was the nail that replaced the striker. nine0003

Rifle

Grizzly

Canadian with the nickname CanadianGunNut, ThreeD Ukulele or simply Matthew, inspired by the Liberator project, designed and posted his project - Grizzly. Grizzly is an ABS+ plastic rifle. It took the Canadian 3 days to design the rifle and another 27 hours to manufacture it using a Stratasys Dimension 1200es industrial 3D printer.

Grizzly is an ABS+ plastic rifle. It took the Canadian 3 days to design the rifle and another 27 hours to manufacture it using a Stratasys Dimension 1200es industrial 3D printer.

Grizzly 9 Rifle0150

The first version of the Grizzly had a smooth and straight .22 barrel. But this turned out to be not a very good decision, and the barrel cracked after the first shot. Subsequently, Matthew replaced the barrel with a tapered barrel with rifling inside.

Plastic “cutting” could not affect the ballistics of the bullet in any way, but added strength to the barrel.

Shotgun

Liberator 12k

The Liberator 12k is a 12-round shotgun made by a well-known, in narrow circles, enthusiast in the world of 3D printing - Jeff Rodriguez. nine0003

Liberator 12k

Rodriguez managed to create a simple and at the same time reliable design, "mixing" a pistol and a pump-action shotgun in the design of the Liberator 12k. A huge plus for manufacturing and reliability was the absence of small parts in the shotgun mechanism.

A huge plus for manufacturing and reliability was the absence of small parts in the shotgun mechanism.

Since the plastic was not strong enough, Rodriguez reinforced the design of the Liberator 12k with metal pins and added metal tubes inside the barrel and drum. The metal parts were purchased from a regular hardware store, so anyone could easily make a Liberator 12k with their home 3D printer. nine0003

Semi-automatic weapons

Shuty-MP1

The first sign was the Shuty-MP1, a semi-automatic pistol made by an amateur gunsmith with the nickname Derwood, in April 2017.

Shuty-MP1

Shuty AP-9

The Shuty AP-9 still uses a pistol barrel, but the trigger and return spring are taken from the civilian version of the M16. This improved the reliability of the rifle. nine0003

Ethical use

Despite the negative examples of application, 3D printing is actively used in many areas, helping to save time and create products that cannot be produced by other methods.

Medicine

Implants

Metal-printing 3D printers are actively used in medicine for the manufacture of titanium implants. For example, a patient needs to have a hip joint implant made. According to the results of CT, the necessary area of bone tissue replacement is agreed with the doctors and a prosthesis model is created that is ideal for this patient. After all approvals, the finished model is sent for printing. nine0003

3D model of implant

The main areas of 3D printing of implants in medicine are maxillofacial surgery, traumatology, orthopedics, oncology and veterinary medicine. A big advantage over classical methods of manufacturing implants is the ability to create a cellular or porous structure. This allows for better integration of the prosthesis into the bone tissue.

nine0149 Samples of printed implants and pins

Dentures

The manufacture of even a relatively simple traction prosthesis is a rather laborious and lengthy process. 3D printing has reduced costs and accelerated the production of prostheses. In addition, it became possible to customize the prosthesis.

3D printing has reduced costs and accelerated the production of prostheses. In addition, it became possible to customize the prosthesis.

Customized child prostheses

Some enthusiasts are modeling and posting models and detailed instructions for assembling traction prosthetic hands and fingers in the public domain so that any user can print and make a prosthesis at home. nine0003

Simple traction prosthetic hand model

Production

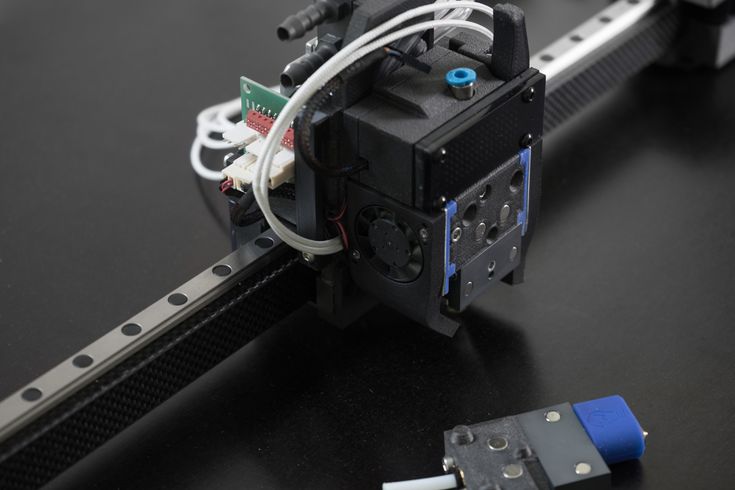

Building custom drones

Aerialtronics is a small Dutch company that specializes in building unique, customized drones. Aerialtronics manufactures and develops unique drones, the characteristics of which can vary depending on the needs of the customer. nine0003

Initially, a basic concept model was designed, which consists of a platform and a set of elements that can be changed at the request of the customer. Changes can affect almost any part of the drone. The customer can choose the number of motors and their power, payload, flight time, supported software and much more.

The customer can choose the number of motors and their power, payload, flight time, supported software and much more.

Aerialtronics base model

But any, even minor changes in the characteristics and design of the drone required the manufacture of new elements and design changes. Classical manufacturing methods turned out to be quite laborious and long. To save time and money, a Stratasys uPrint SE Plus 3D printer was purchased. nine0003

Drone Assembly

Thanks to 3D printing, it was possible not only to speed up production, but also to devote more time to improving individual components, because the finished model is ready the next morning. Rapid manufacturing allows you to print a part, test it, make the necessary changes to the 3D model and make a new sample. Aerialtronics engineers manage to manufacture and test 8-10 variants of a part in a few days in order to achieve maximum quality. nine0003

Prototyping

Prototyping of gas turbines.

Prototyping by traditional methods is often time consuming and expensive. Because of this, the price of an error in calculations and 3D modeling can be very expensive.

For example, the production of turbine engine parts is usually based on careful preparatory calculations, but even this does not always prevent errors in the production of a test prototype. After all, even the most modern software methods cannot replace physical tests. But due to the high cost (over $20,000), it becomes impossible to produce multiple prototypes for testing. nine0003

Turbine Technologies (Wisconsin, USA) and its subsidiary Kutrieb Research have found a way out - 3D printing. Thanks to the 3D Systems ProJet 3D printer, it was possible to reduce the cost of prototyping by about 10 times to $2,000.

3D model and printed part of turbine

A turbine model is printed on a wax 3D printer, tested and then cast from metal. In addition to the cost, it was possible to significantly speed up production.